Transition metal sulfide/carbon nanotube composite material as well as preparation method and application thereof

A technology of carbon nanotubes and transition metals, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and electrolytic inorganic material coatings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: prepare highly hydrophilic porous iron sulfide / carbon nanotube composite material (FeS 2 / CNTs)

[0045] (1) Electrode pretreatment: take a glassy carbon electrode (PINE USA, rotating disk electrode, diameter 5mm), and perform polishing, washing, and 16KHz ultrasonic pretreatment for 10s in sequence;

[0046] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: Add arrayed carbon nanotubes (1mg) to a mixture (1mL) of ethanol and water with a volume ratio of 1:1, and form a suspension by ultrasonication at 16KHz for 1h. The suspension is added dropwise on the surface of the glassy carbon electrode pretreated in step (1), and dried naturally to form a uniform thin layer of carbon nanotubes (the thin layer is about 40 μg of carbon nanotubes), to obtain carbon nanotube-modified Glassy carbon electrode;

[0047] (3) Preparation of electroplating solution: Add precursor thiourea (9.1344g, 0.3mol / L) and ferric chloride (0.1590g, 2mmol / L) to dei...

Embodiment 2

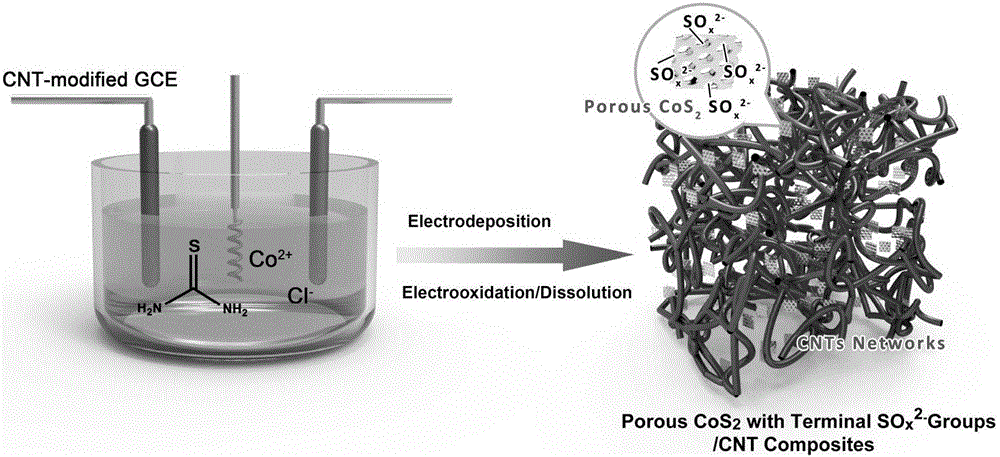

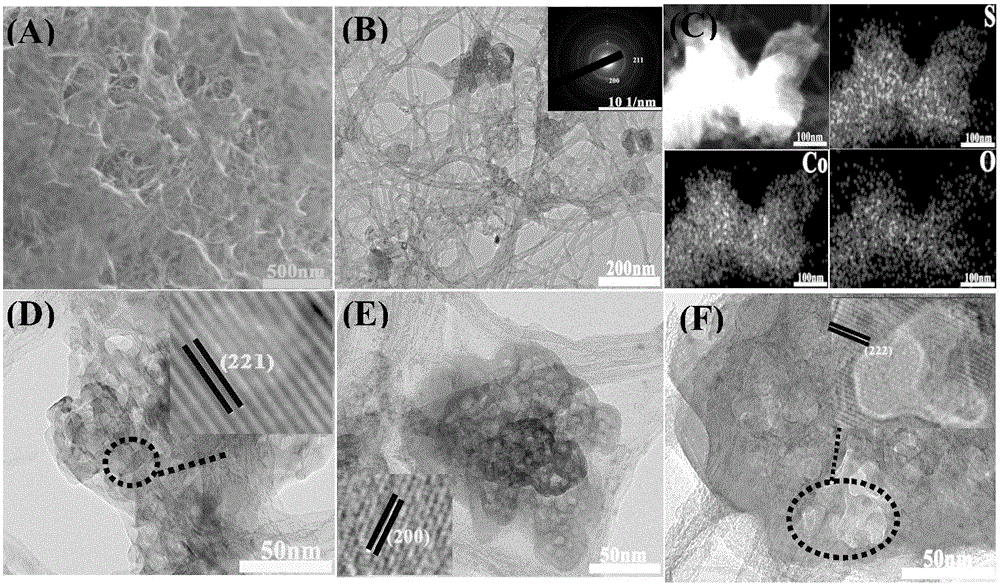

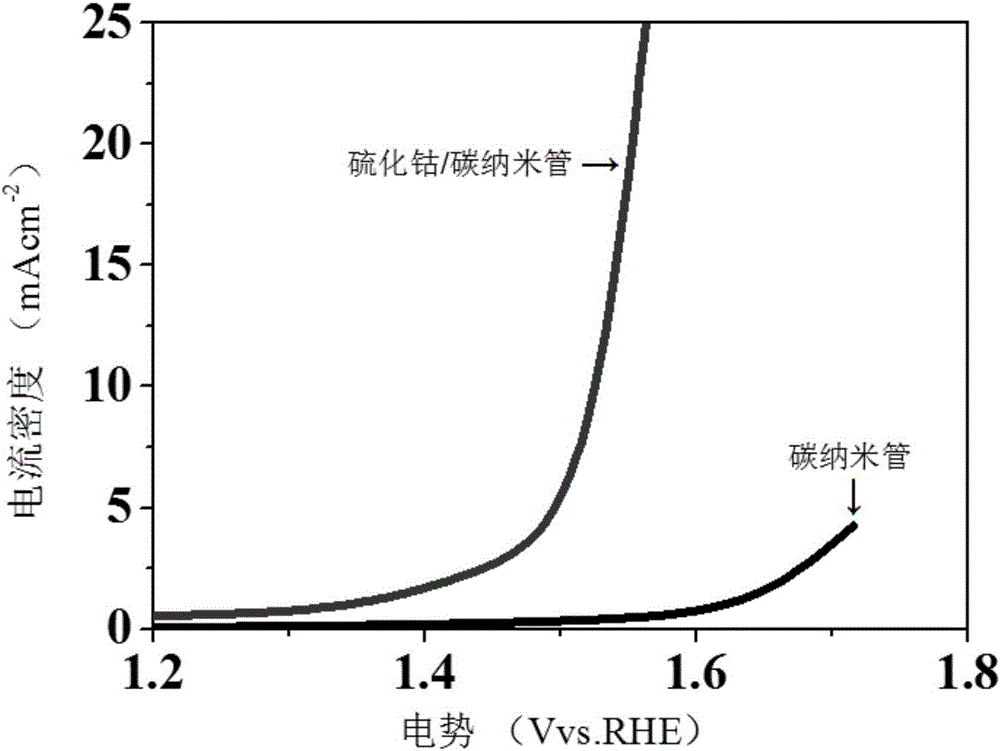

[0050] Embodiment 2: prepare highly hydrophilic porous cobalt sulfide / carbon nanotube composite material (CoS 2 / CNTs)

[0051] (1) Electrode pretreatment: Take a glassy carbon electrode (PINE USA, rotating disk electrode, diameter 5mm), and perform polishing, washing, and 20KHz ultrasonic pretreatment for 60s in sequence;

[0052] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: Add arrayed carbon nanotubes (1mg) to a mixture (1mL) of ethanol and water with a volume ratio of 1:4, and form a suspension by ultrasonication at 40KHz for 2h. The suspension is added dropwise on the surface of the glassy carbon electrode pretreated in step (1), and dried naturally to form a uniform thin layer of carbon nanotubes (the thin layer is about 40 μg of carbon nanotubes), to obtain carbon nanotube-modified Glassy carbon electrode;

[0053] (3) Preparation of electroplating solution: add precursor thiourea (18.2688g, 0.6mol / L) and cobalt chloride (0.3807g, 4mmol / L) to ...

Embodiment 3

[0057] Embodiment 3: prepare highly hydrophilic porous nickel sulfide / carbon nanotube composite material (NiS 2 / CNTs)

[0058] (1) Electrode pretreatment: take a glassy carbon electrode (PINE USA, rotating disk electrode, diameter 5mm), and perform polishing, water washing, and 32KHz ultrasonic pretreatment for 30s in sequence;

[0059] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: Add arrayed carbon nanotubes (1mg) to a mixture (1mL) of ethanol and water with a volume ratio of 1:5, and form a suspension by ultrasonication at 28KHz for 5h. The suspension is added dropwise on the surface of the glassy carbon electrode pretreated in step (1), and dried naturally to form a uniform thin layer of carbon nanotubes (the thin layer is about 40 μg of carbon nanotubes), to obtain carbon nanotube-modified Glassy carbon electrode;

[0060] (3) Preparation of electroplating solution: add precursor thiourea (27.4032g, 0.9mol / L) and nickel chloride (0.5705g, 8mmol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com