Preparation method of porous tantalum and device applied to same

A technology of porous tantalum and powder, which is applied in the field of medical materials and can solve problems such as residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

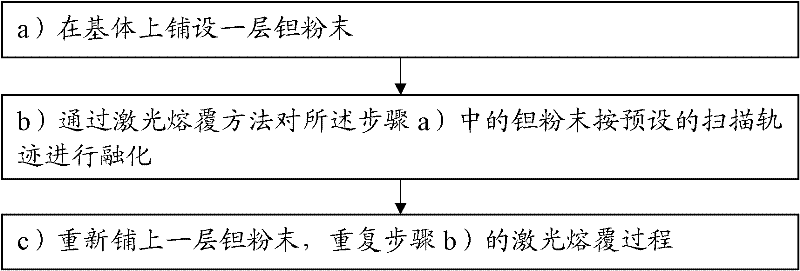

[0042] ginseng figure 1 As shown, the invention discloses a method for preparing porous tantalum, comprising the following steps:

[0043] a) laying a layer of tantalum powder on the substrate;

[0044] b) Melting the tantalum powder in step a) according to the preset scanning trajectory by laser cladding method;

[0045] c) Respread a layer of tantalum powder, repeat the laser cladding process of step b);

[0046] The step c) is performed at least once to produce multilayer porous tantalum.

[0047] The method of direct manufacturing of laser cladding to manufacture porous materials has unique advantages, and can quickly and conveniently manufacture the required porous tantalum. Moreover, no toxic organic substances are introduced during the manufacturing process, and the material is of high purity. The required porous material can be manufactured directly by layer-by-layer stacking under the control of computer programming and CNC. Although tantalum has a high melting p...

Embodiment 1

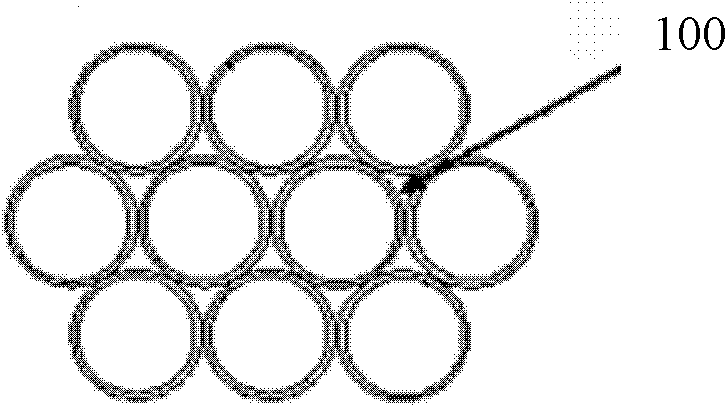

[0068] a) be programmed in a computer according to figure 2 Design the corresponding laser spot scanning track (the edge of the laser spot is just tangent) for the aperture arrangement diagram of the main hole 100;

[0069] b) Pretreat the tantalum powder with a purity greater than 99% and a powder particle size of less than 300 mesh. The pretreatment temperature is 200°C and the time is 2 hours;

[0070] c) Laying a layer of the above-mentioned pretreated tantalum powder on the biological titanium alloy substrate

[0071] d) Melt the tantalum powder in step c) according to the preset scanning trajectory by laser cladding method, wherein the laser power is 60W, the spot diameter is 0.5mm, the energy of each action is 3-5J, pulse The width is 0.6ms, the pulse frequency is 4Hz, and the scanning speed is 3mm / s;

[0072] e) respreading a layer of powder, repeating the laser cladding process of step b);

[0073] The step c) is performed at least several times to produce multila...

Embodiment 2

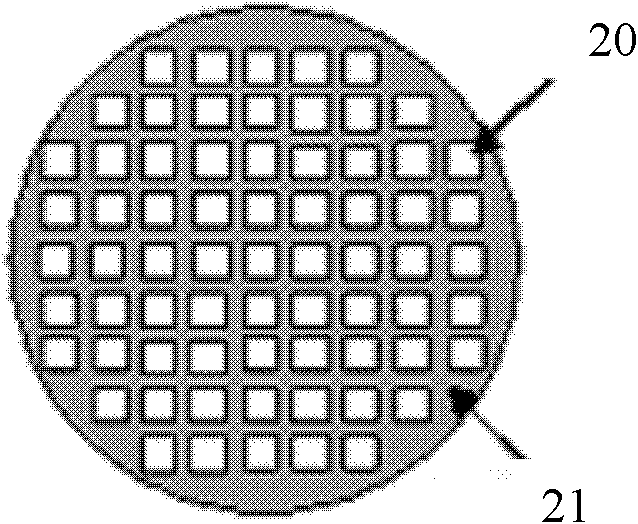

[0077] a) be programmed in a computer according to Figure 3-a Design the corresponding laser spot scanning trajectory for the aperture layout of the central main hole 20, and preset the wall thickness between adjacent main holes 20 to be 0.12mm;

[0078] b) Pretreat the tantalum powder with a purity greater than 99% and a powder particle size of less than 300 mesh. The pretreatment temperature is 200°C and the time is 2 hours;

[0079] c) Laying a layer of the above-mentioned pretreated tantalum powder on the biological titanium alloy substrate

[0080] d) Melt the tantalum powder in step c) according to the preset scanning trajectory by laser cladding method, wherein the laser power is 130W, the spot diameter is 0.8mm, the energy of each action is 5-10J, and the pulse The width is 1.0ms, the pulse frequency is 8Hz, and the scanning speed is 5mm / s;

[0081] e) respreading a layer of powder, repeating the laser cladding process of step b);

[0082] The step c) is performed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com