Customized porous tantalum implant and preparation method thereof

The technology of porous tantalum and implant is applied in the field of personalized customized porous tantalum implant and its preparation, which can solve the problems that new bone and scaffold cannot be well fused, spherical holes are not easy, and holes are easily blocked, etc. Achieving favorable nutrient delivery, promoting good fusion, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] like Figure 1 to Figure 6 As shown, a method for preparing a personalized porous tantalum implant of the present invention comprises the following steps:

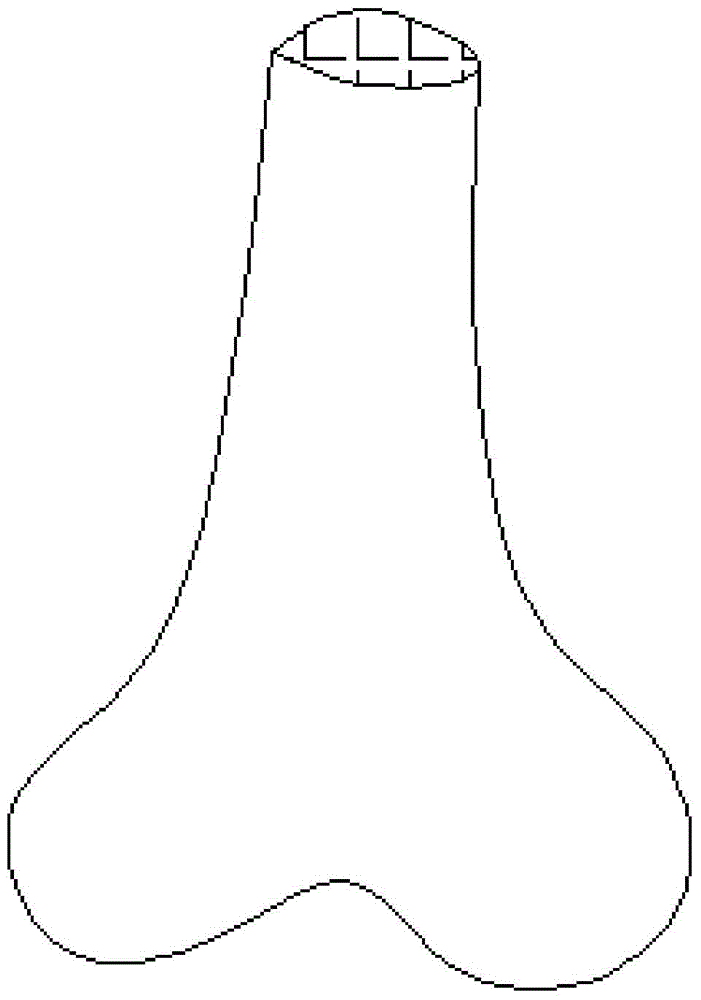

[0039] 1) Use the CT multi-planar reconstruction image of bone tissue to reconstruct the three-dimensional model of bone tissue in three-dimensional modeling software (such as figure 1 shown), and then import the three-dimensional model of bone tissue into the reverse software to design a three-dimensional model of a personalized bone implant;

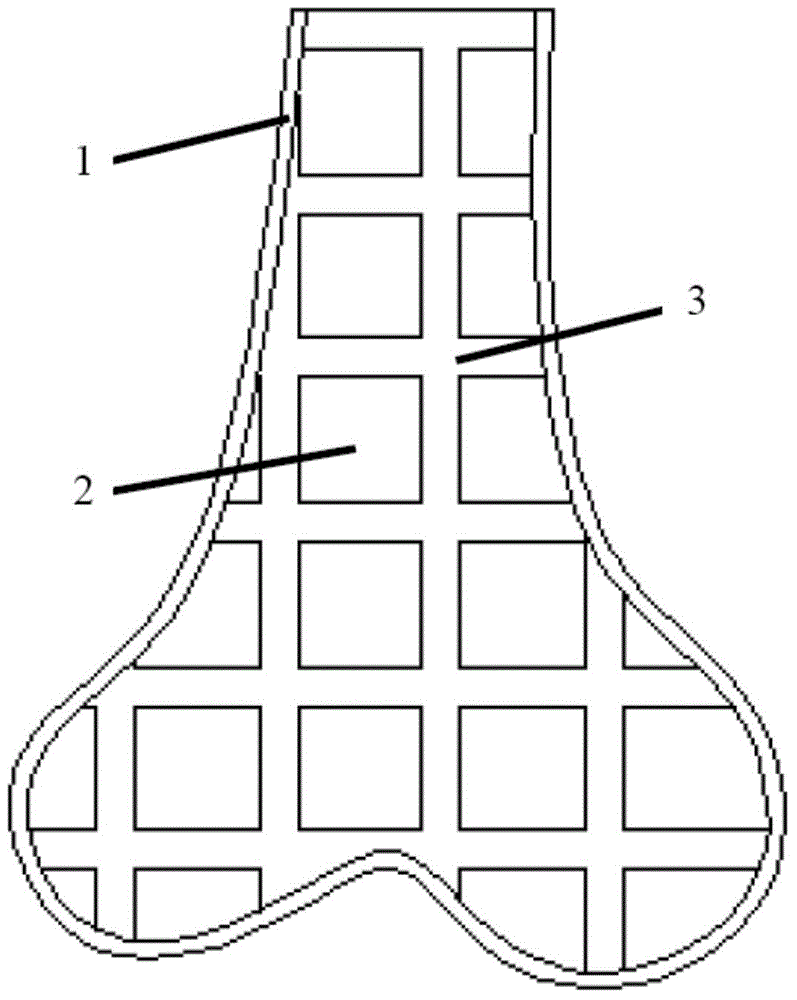

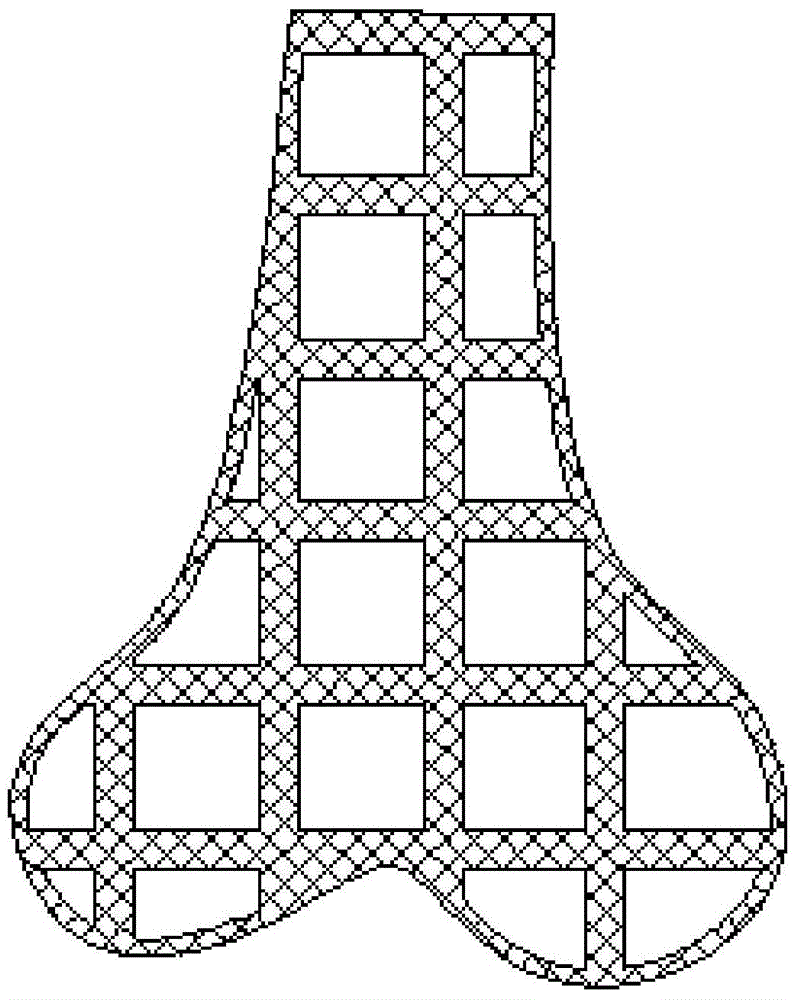

[0040] 2) Carry out shelling processing on the three-dimensional model of the personalized bone implant to obtain the shell 1 of the model after shelling, and then add criss-cross grids 3 inside the shell 1 of the shelled model to obtain a personalized model containing the grid 3 inside. The three-dimensional shell model of the bone implant, wherein the space 2 filled with the model slurry is between the criss-cross grids 3, the thickness h of the three-dimensional shell mo...

Embodiment 2

[0049] like Figure 1 to Figure 6 As shown, a method for preparing a personalized porous tantalum implant of the present invention comprises the following steps:

[0050] 1) Use the CT multi-planar reconstruction image of bone tissue to reconstruct the three-dimensional model of bone tissue in three-dimensional modeling software (such as figure 1 shown), and then import the three-dimensional model of bone tissue into the reverse software to design a three-dimensional model of a personalized bone implant;

[0051] 2) Carry out shelling processing on the three-dimensional model of the personalized bone implant to obtain the shell 1 of the model after shelling, and then add criss-cross grids 3 inside the shell 1 of the shelled model to obtain a personalized model containing the grid 3 inside. The three-dimensional shell model of the bone implant, wherein the space 2 filled with the model slurry is between the criss-cross grids 3, the thickness h of the three-dimensional shell mo...

Embodiment 3

[0060] like Figure 1 to Figure 6 As shown, a method for preparing a personalized porous tantalum implant of the present invention comprises the following steps:

[0061] 1) Use the CT multi-planar reconstruction image of bone tissue to reconstruct the three-dimensional model of bone tissue in three-dimensional modeling software (such as figure 1 shown), and then import the three-dimensional model of bone tissue into the reverse software to design a three-dimensional model of a personalized bone implant;

[0062] 2) Carry out shelling processing on the three-dimensional model of the personalized bone implant to obtain the shell 1 of the model after shelling, and then add criss-cross grids 3 inside the shell 1 of the shelled model to obtain a personalized model containing the grid 3 inside. The three-dimensional shell model of the bone implant, wherein the space 2 filled with the model slurry is between the criss-cross grids 3, the thickness h of the three-dimensional shell mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com