Medical porous tantalum metal material and preparation method thereof

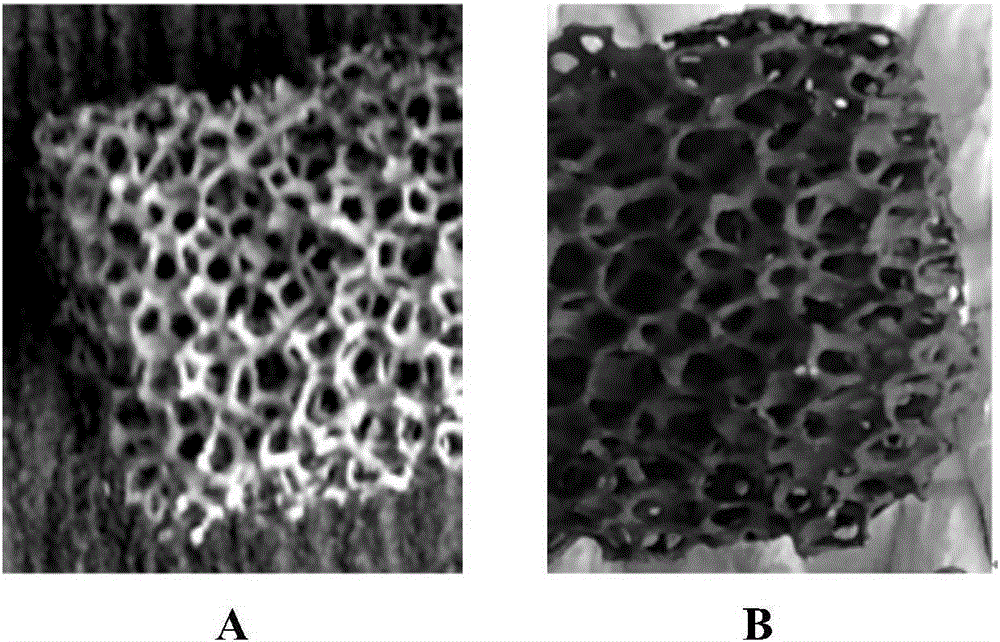

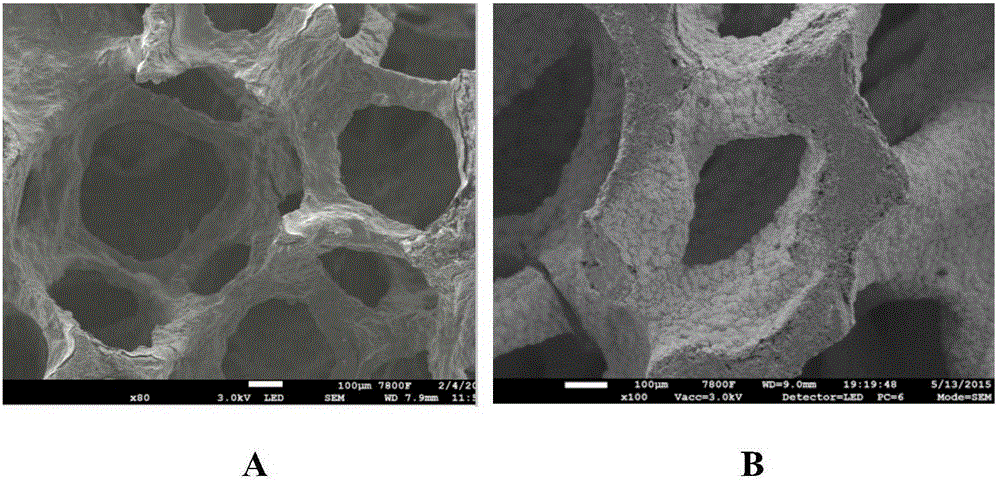

A metal material and porous tantalum technology, applied in metal material coating technology, medical science, gaseous chemical plating, etc., can solve problems such as limited thickness of tantalum plating coating, lower mechanical properties of products, uneven pore size, etc., to achieve The effect of uniform pores, low density and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation of a medical porous tantalum metal material, comprising the steps of:

[0033] (1) Use 40% HF: 68% HNO to the porous silicon carbide support with a porosity of 85% and a pore diameter of 500 μm 3 :H 2 O=1:5:6 mixed solution is cleaned by ultrasonic vibration, blown dry with dry nitrogen, and placed in a vapor deposition reaction chamber;

[0034] (2) Connect the inlet / exhaust pipeline device, check the sealing condition of the reaction chamber, evacuate, and then heat to 950°C under the protection of argon;

[0035] (3) Put the carbon pentachloride powder with a particle size of 400 mesh into the source tank, heat it to 200°C, and use high-temperature argon (300°C) as the carrier gas to pass into the reaction chamber, and the flow rate of the carrier gas is 120ml / min , the temperature of the reaction chamber is 950°C, and the vacuum degree of the reaction chamber is 10Pa; while the tantalum pentachloride powder is passed into the reaction chamber with ar...

Embodiment 2

[0039] A preparation of a medical porous tantalum metal material, comprising the steps of:

[0040] (1) Use 40% HF: 68% HNO to the porous silicon carbide scaffold with a porosity of 85% and a pore diameter of 400 μm 3 :H 2 O=1:5:6 mixed solution is cleaned by ultrasonic vibration, blown dry with dry nitrogen, and placed in a vapor deposition reaction chamber;

[0041] (2) Connect the inlet / exhaust pipeline device, check the seal of the reaction chamber, evacuate, and then heat to 1050°C under the protection of argon;

[0042] (3) Put the carbon pentachloride powder with a particle size of 400 mesh into the source tank, heat it to 250°C, and use high-temperature argon (300°C) as the carrier gas to pass into the reaction chamber, and the flow rate of the carrier gas is 120ml / min , the temperature of the reaction chamber is 1050°C, and the vacuum degree of the reaction chamber is 15Pa; while the tantalum pentachloride powder is passed into the reaction chamber with argon as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com