Medical tantalum powder and preparation method thereof

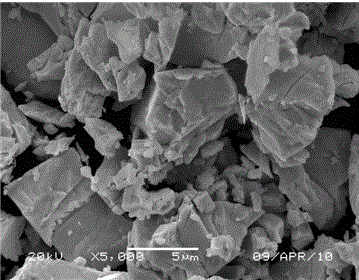

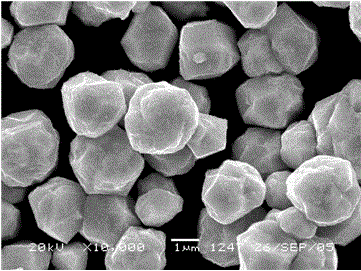

A technology of tantalum powder and particle size control, which is applied in the field of tantalum metal powder, can solve the problems of only degraded use, complex tantalum powder particle shape, high oxygen content, etc., and achieve the effect of low production cost, low oxygen content and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of medical tantalum powder, carry out according to the following steps:

[0025] Raw materials: The selected raw materials are hydrogenated tantalum ingots;

[0026] Crushing and grading: The above-mentioned tantalum ingots are crushed into particles of about 2mm by a jaw crusher, and then added to a cyclone crushing and classifying machine, and compressed air is introduced to impact for crushing and grading. The speed of the classifying wheel is controlled to 30KW / h. The gas flow rate is 0.5MPa;

[0027] Impurity removal treatment: the tantalum powder obtained after crushing and classifying by the above-mentioned cyclone crushing and classifying machine is pickled to remove metal and non-metal impurities on the surface; finally, 1wt% metal magnesium is added, and the temperature is kept at 800°C for 3 hours for dehydrogenation, Deoxidation and impurity removal treatment to obtain tantalum metal powder.

[0028] The obtained tantalum metal...

Embodiment 2

[0030] A kind of preparation method of medical tantalum powder, carry out according to the following steps:

[0031] Raw materials: The selected raw materials are hydrogenated tantalum ingots;

[0032] Crushing and grading: The above tantalum ingots are crushed into 3mm particles by a jaw crusher, and then added to a cyclone crushing and classifying machine, and compressed air is introduced to impact for crushing and grading. The flow rate is 0.5MPa;

[0033] Impurity removal treatment: the tantalum powder obtained after crushing and classifying by the above-mentioned cyclone crushing and classifying machine is pickled to remove metal and non-metal impurities on the surface; finally, 1wt% metal magnesium is added, and the temperature is kept at 800°C for 3 hours for dehydrogenation, Deoxidation and impurity removal treatment to obtain tantalum metal powder.

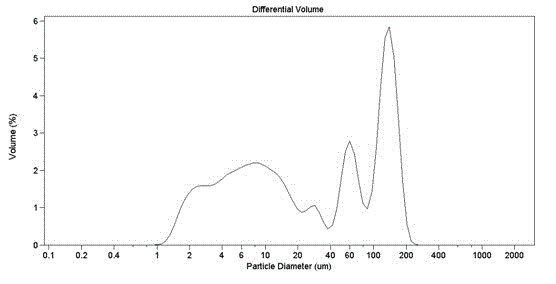

[0034] The obtained tantalum metal powder has an average Fischer particle size of 12.15 μm, a nearly spherical or sph...

Embodiment 3

[0036] Raw materials: The selected raw materials are hydrogenated tantalum ingots;

[0037] Crushing and grading: The above-mentioned tantalum ingots are crushed into particles of about 1.5mm by a jaw crusher, and then added to a cyclone crushing and classifying machine, and compressed air is introduced to impact for crushing and grading. The gas flow rate used is 0.55MPa;

[0038] Impurity removal treatment: the tantalum powder obtained after crushing and classifying by the above-mentioned cyclone crushing and classifying machine is pickled to remove metal and non-metal impurities on the surface; finally, 1wt% metal magnesium is added, and the temperature is kept at 800°C for 3 hours for dehydrogenation, Deoxidation and impurity removal treatment to obtain tantalum metal powder.

[0039] The obtained tantalum metal powder has an average Fischer particle size of 8.15 μm, a nearly spherical or spherical particle shape, an oxygen content of 670 ppm, and a particle size of 95%-9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Fisherman's average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com