Method for preparing porous tantalum medical implant material through three-dimensional printing forming

An implant material and a three-dimensional printer technology, which are applied in the field of preparation of porous medical metal implant materials, can solve the problems of complex shapes of biological materials, high requirements for tiny details, and failure to meet the requirements, and achieve three-dimensional connected distribution, low cost, and no cost. The effect of poisonous dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a porous tantalum medical implant material, first fully mixing pure tantalum powder with a particle size of 15 μm and stearic acid at a volume ratio of 70:30, then grinding, passing through a 200-mesh sieve to agglomerate the powder into a larger Particles, but there is no agglomeration between the particles; the mixed tantalum particles prepared above are transported to the three-dimensional printing platform, rolled and laminated, and the sample size to be prepared is designed to be φ10×100mm, and its UG file is input In the three-dimensional printing equipment, according to the cross-section information of each layer of the sample, the print head sprays the α-ethyl cyanoacrylate binder with a mass concentration of 1% on the above-mentioned mixed tantalum powder particles to form a two-dimensional plane, and each layer sticks The binder is sprayed 3 times. After one layer is processed, the workbench is lowered by 80 μm, and the next layer is proc...

Embodiment 2

[0024] A method for preparing a porous tantalum medical implant material, first fully mixing pure tantalum powder with a particle size of 20 μm and zinc stearate at a volume ratio of 60:40, then grinding, and passing through a 200-mesh sieve to agglomerate the powder Large particles, but no agglomeration between particles; transport the above-mentioned mixed tantalum particles to the 3D printing platform, roll the layer, design the sample to be prepared, and input its UG file into the 3D printing device In the process, according to the cross-section information of each layer of the sample, the print head sprays the α-ethyl cyanoacrylate binder with a mass concentration of 0.8% on the mixed tantalum powder particles to form a two-dimensional plane, and each layer of binder sprays 3 times, after one layer is processed, the workbench is lowered by 100 μm, and the next layer is processed, and the layers are piled up and formed until the final sample is completed. After the sample i...

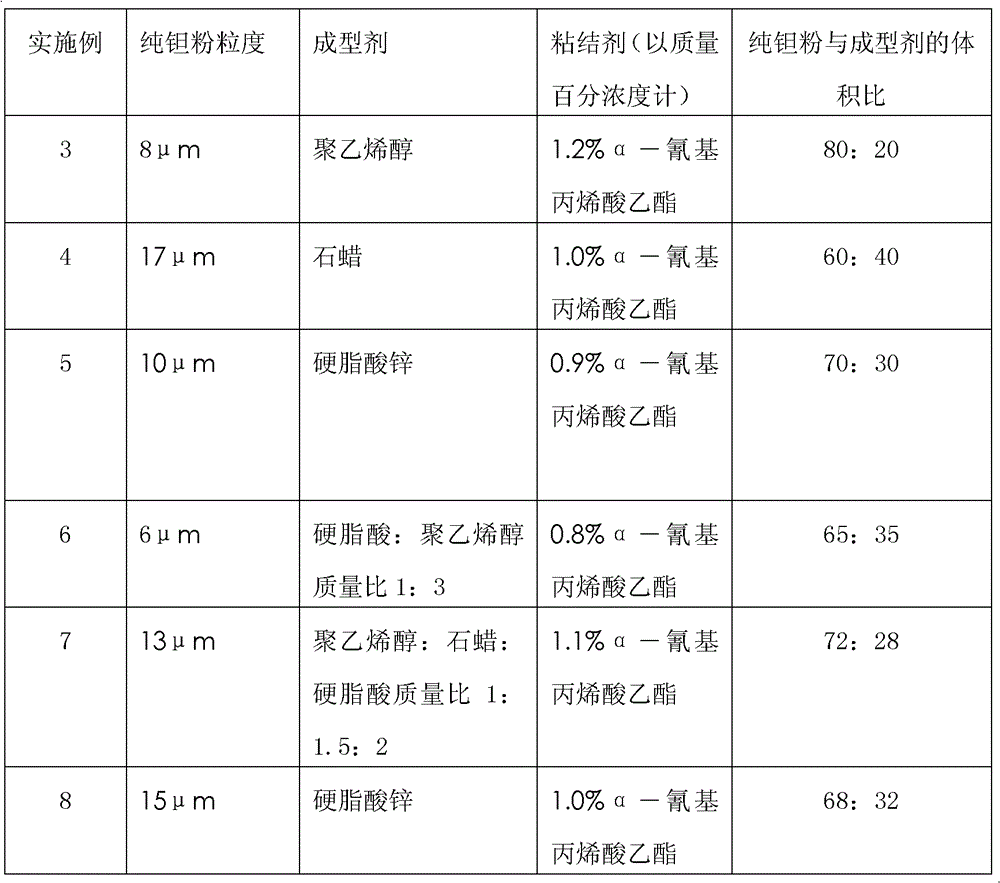

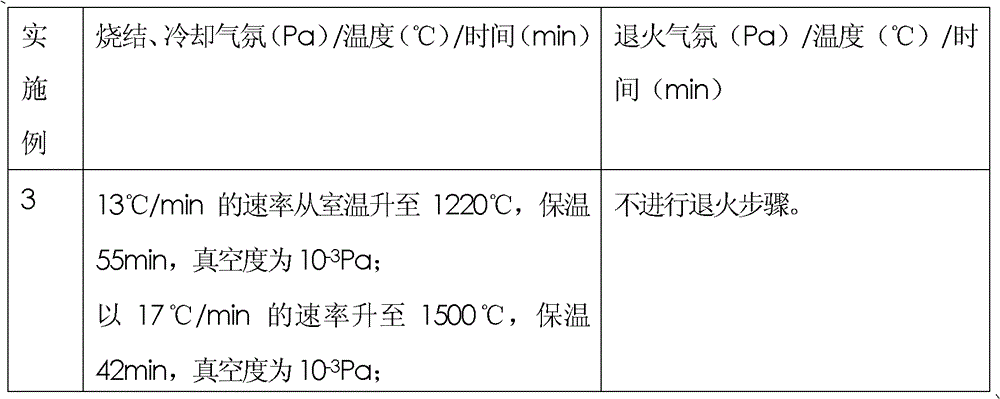

Embodiment 3~8

[0025] Embodiment 3~8: carry out according to following steps and process parameter, all the other are the same as embodiment 1.

[0026]

[0027]

[0028]

[0029]

[0030]

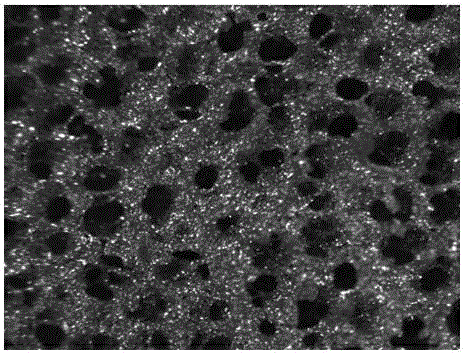

[0031] The obtained porous tantalum finished product is three-dimensionally completely connected, the pores are evenly distributed, and the biocompatibility is good. The test results according to the aforementioned method are as follows:

[0032] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com