Cache device for glass substrate production line and control method thereof

A glass substrate and control method technology, applied in glass production, glass manufacturing equipment, glass transportation equipment and other directions, can solve the problems affecting the production efficiency of the previous process, the large space occupied by the conveyor belt, the retention of the glass substrate, etc., to save production space, The effect of improving production efficiency and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

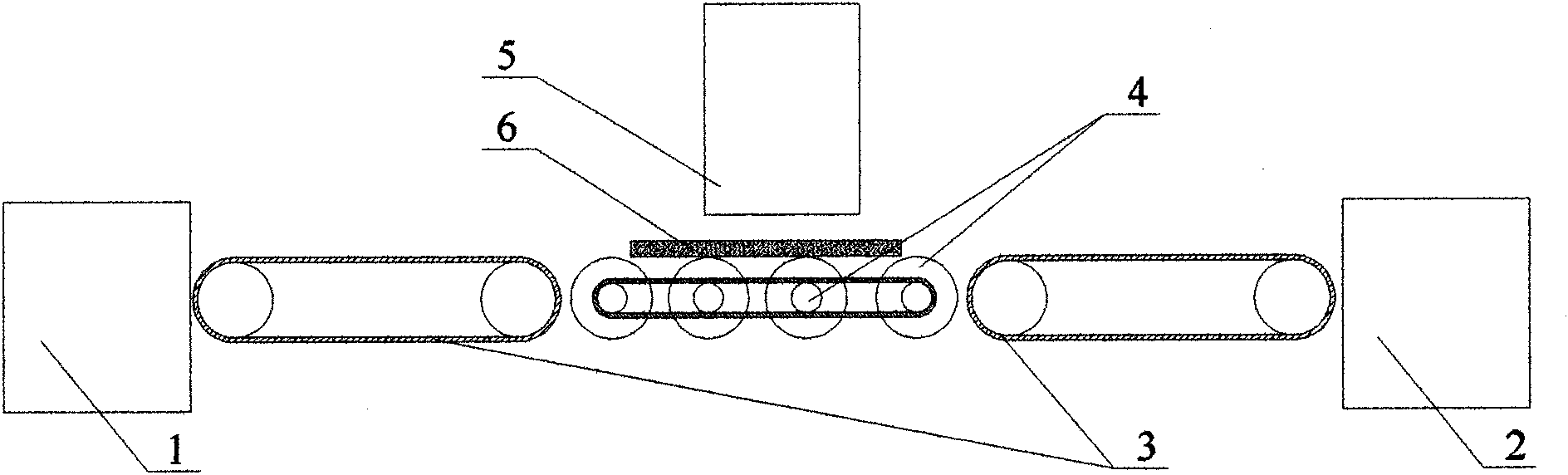

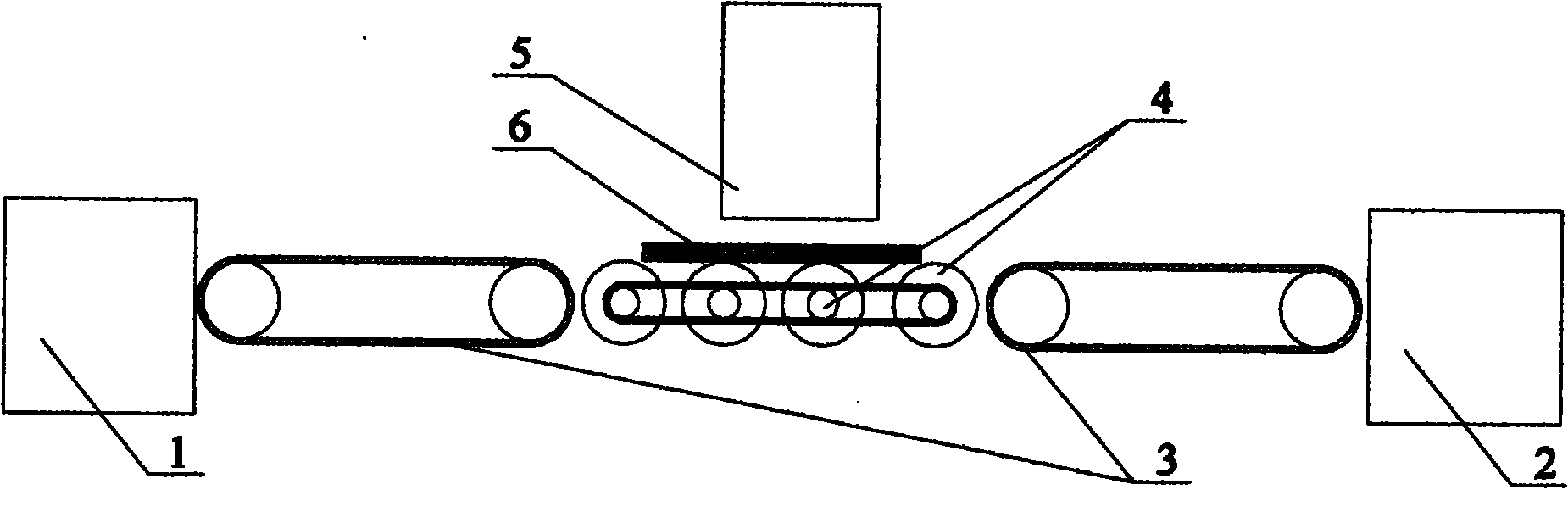

[0013] see figure 1 , a buffer device used in a glass substrate production line and a control method thereof, the above control method is to continuously transport the glass substrate by means of a horizontal conveyor belt arranged between the previous process 1 and the subsequent process 2, a control unit with a CPU and a supporting software program Realized in the process, a set of transfer roller-type intermediate conveyor belt 4 is added between the horizontal conveyor belt 3 of the previous process 1 and the latter process 2, and a buffer consisting of a servo motor, a transposition mechanism and a storage mechanism for temporarily storing glass substrates 6 Device 5, the previous process 1 transports the glass substrate 6 to the intermediate conveyor belt 4 through the horizontal conveyor belt 3, and according to the working status of the previous process 1 and the subsequent process 2, the management circuit controls the buffer device 5 to buffer the glass substrate 6. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com