High-definition OLED line post-procedure automatic distribution system

An automatic distribution and distribution system technology, applied in the field of OLED display, can solve the problem of not being able to meet the requirements of high-generation OLED panel manufacturing, and achieve the effect of improving manufacturing speed and production efficiency and reducing product loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

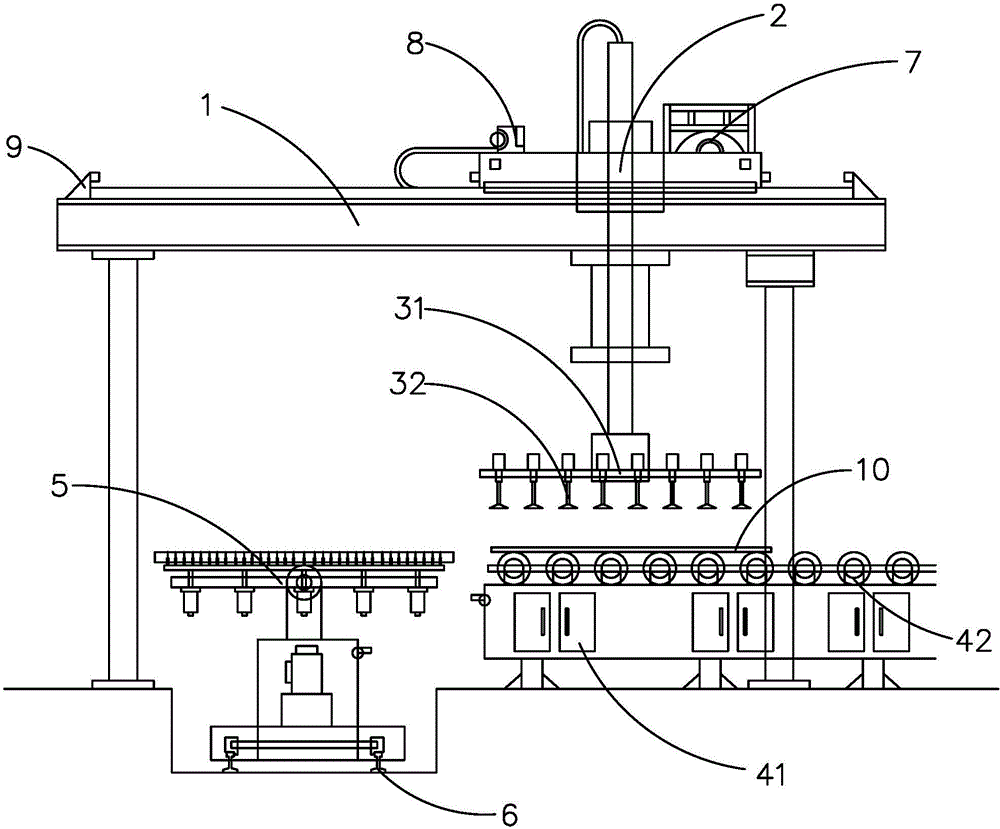

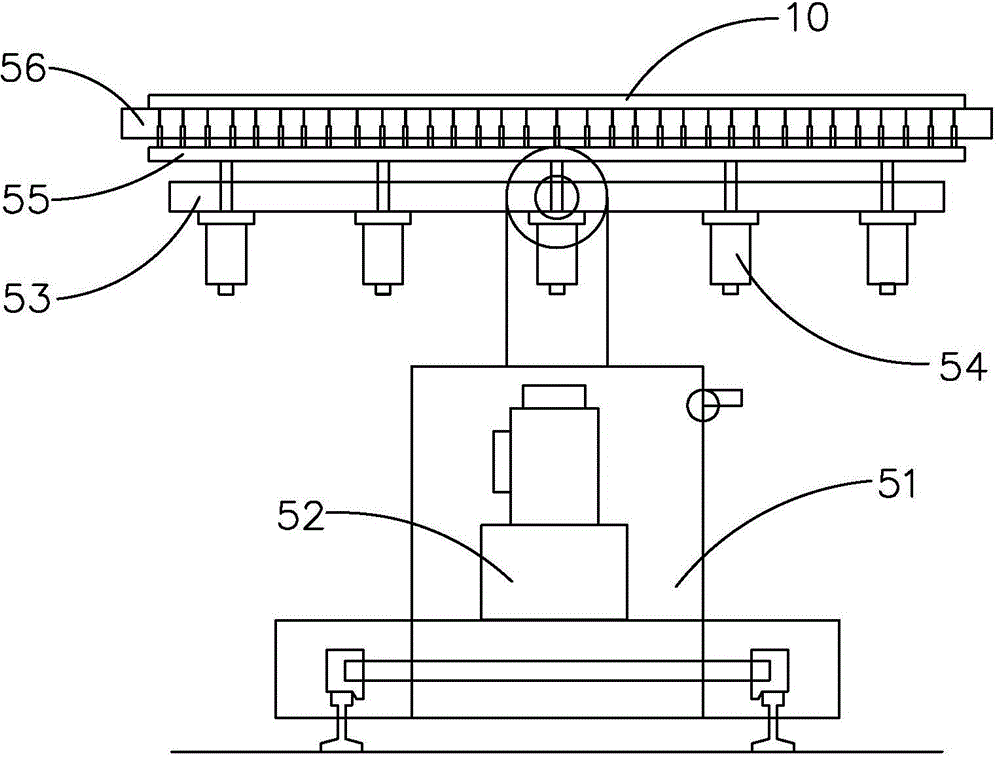

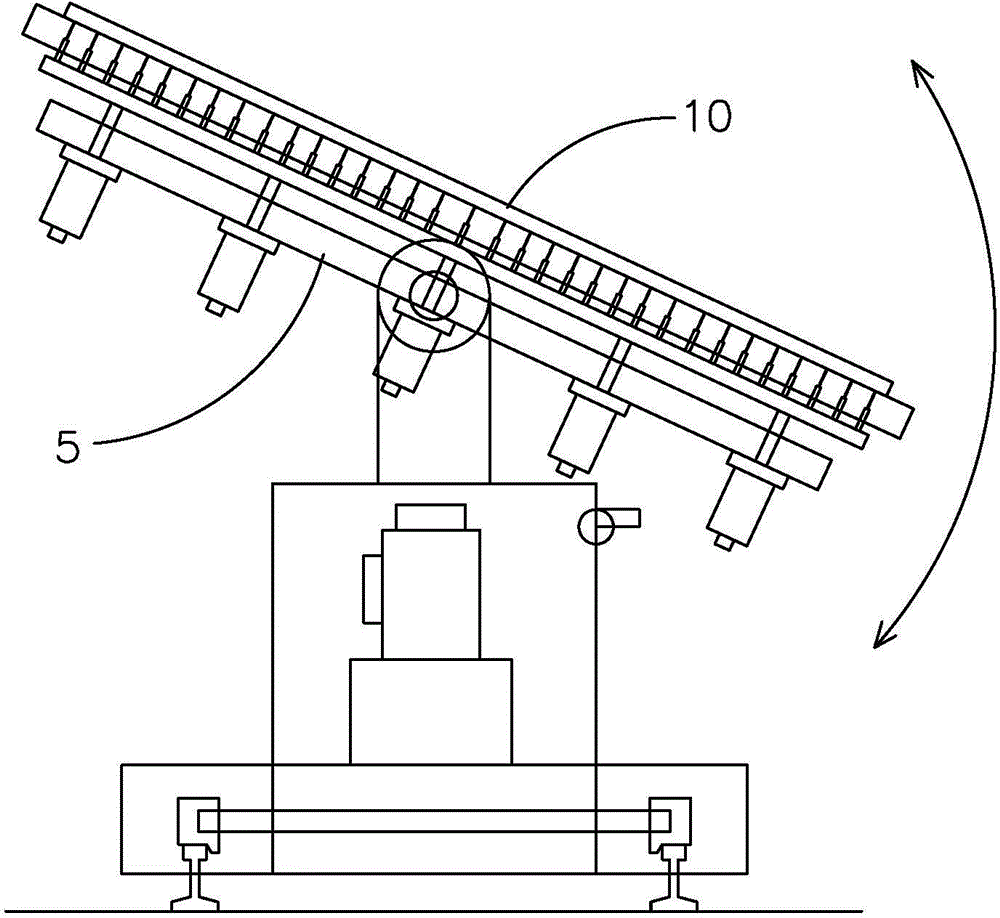

[0021] Such as Figure 1 to Figure 3 As shown, the high-generation OLED line post-process automatic distribution system provided by the present invention includes a manipulator truss 1, a manipulator 2 that can move in the XYZ axis direction is installed on the beam of the manipulator truss 1, and the lower end of the manipulator 2 is provided with an adsorption OLED substrate 10, the adsorption device is provided with a transmission device for transmitting the OLED substrate 10 under the adsorption device, and a loading drive device 5 that can move according to the process route is also provided under the beam of the manipulator truss 1. In specific implementation, the loading drive device 5 can pass through the It can be realized by installing rollers at the bottom, or by placing the loading drive device 5 on a movable conveyor belt or cart; the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com