Method and special bacteria-adding equipment for adding bacteria after preparing bio-organic fertilizer

A bio-organic fertilizer and organic manure technology, applied in the field of bio-organic fertilizer preparation technology, can solve the problems of low content of beneficial microorganisms, loss of beneficial activity, loss of beneficial bacteria, etc., to promote the development of green agricultural economy and green agricultural ecological data, Improving the soil and improving the fertility of organic fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

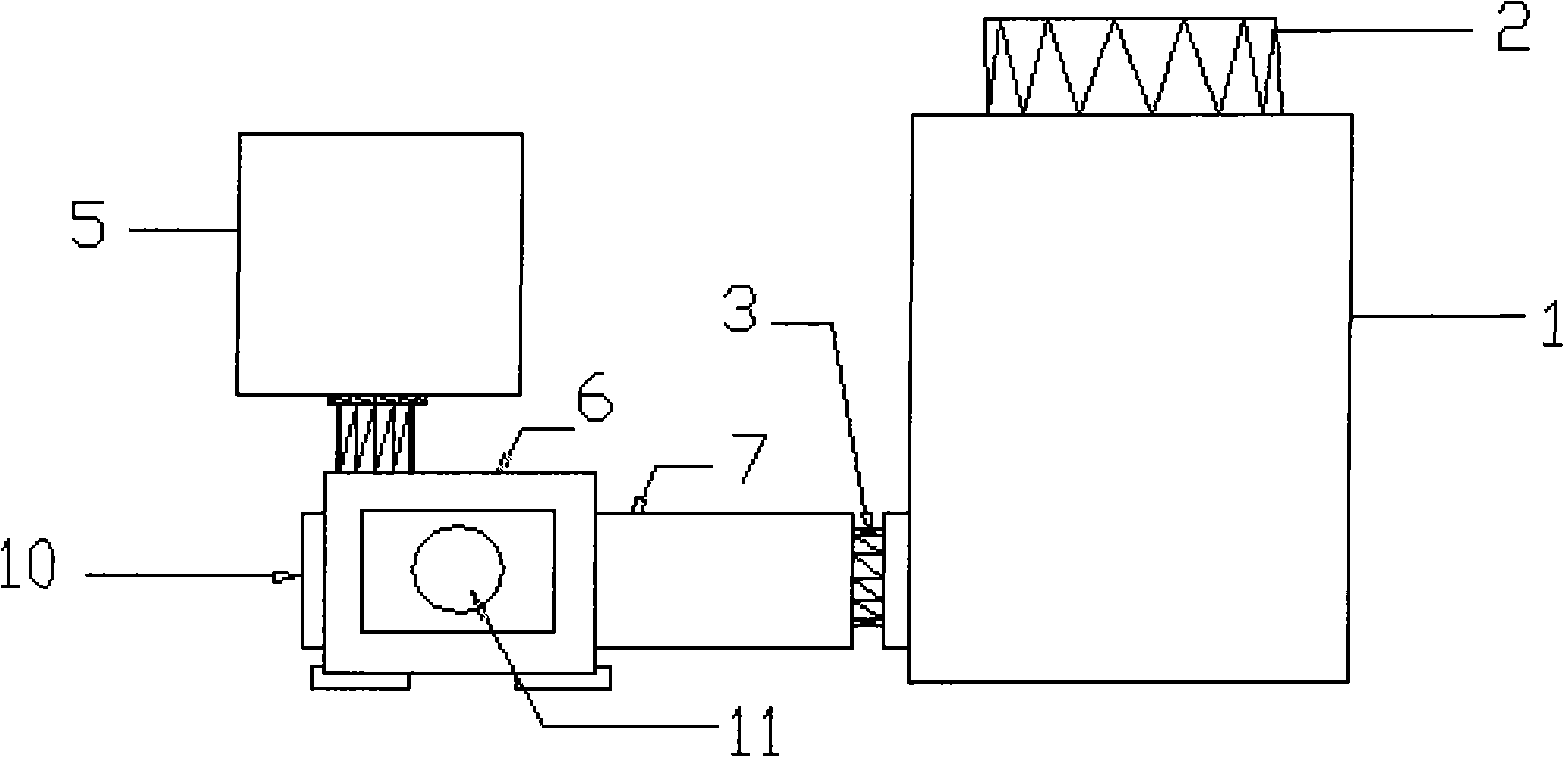

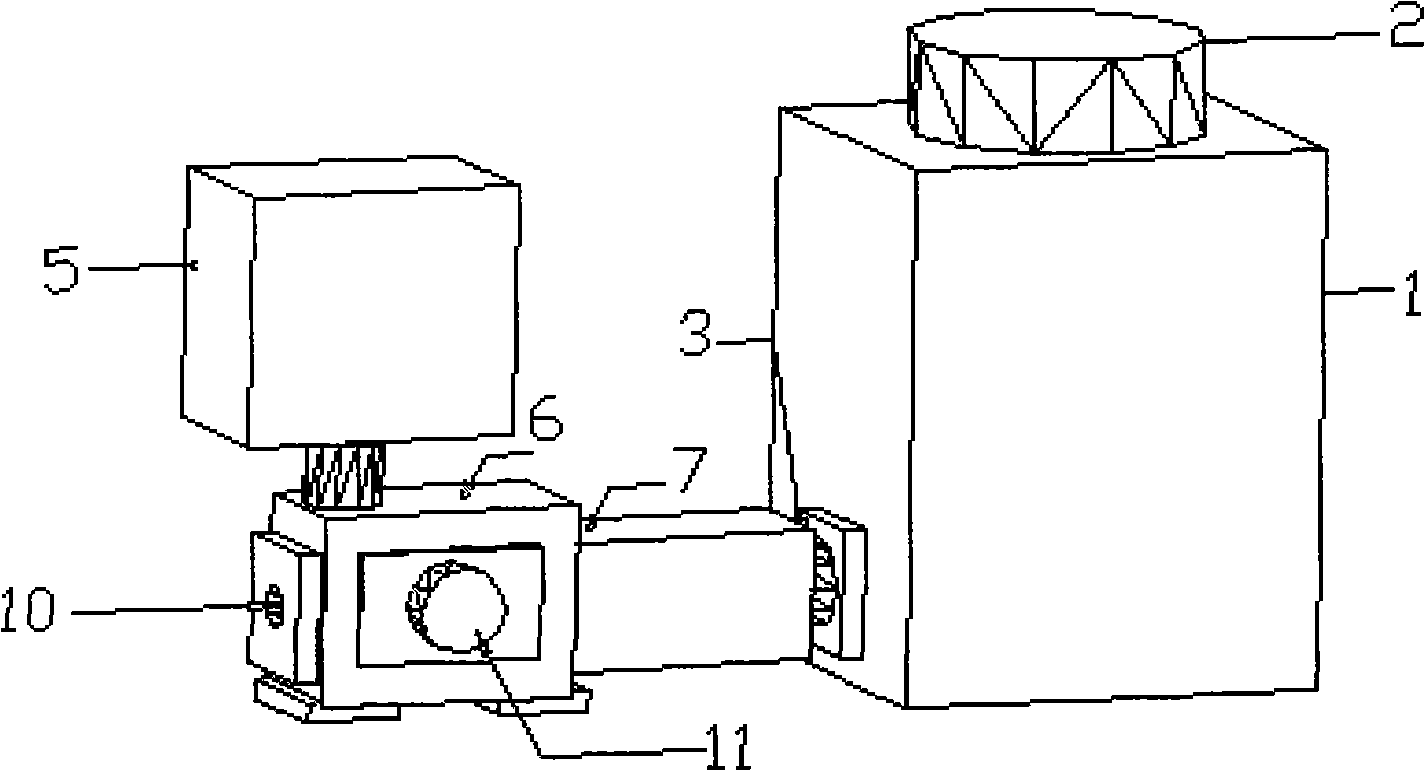

[0020] Embodiment one: post-adding bacterium process production prepares bio-organic fertilizer

[0021] In the production of bio-organic fertilizers, after granulation, drying, and cooling in the cooling cylinder, the bacterial agent is added before packaging, and a special bacteriostasis device is used for high-pressure mist spraying for metered addition. After the post-bacteria addition process and Use special bacteria-adding equipment to keep the selected bio-organic fertilizer particles uniform, keep the water in the environment required for adding microbial strains, and maintain the number of viable microorganisms that bio-organic fertilizers should have.

[0022] Specifically, the present invention is based on the existing conventional production process for preparing bio-organic fertilizers, by changing some control procedures in the process, the specific steps are as follows:

[0023] 1. Carry out aerobic fermentation of organic manure for 10 days;

[0024] 2. When g...

Embodiment 2

[0027] Embodiment two: post-adding bacterium process production prepares bio-organic fertilizer

[0028] In the production of bio-organic fertilizers, after granulation, drying, and cooling in the cooling cylinder, the bacterial agent is added before packaging, and a special bacteriostasis device is used for high-pressure mist spraying for metered addition. After the post-bacteria addition process and Use special bacteria-adding equipment to keep the selected bio-organic fertilizer particles uniform, keep the water in the environment required for adding microbial strains, and maintain the number of viable microorganisms that bio-organic fertilizers should have.

[0029] Specifically, the present invention is based on the existing conventional production process for preparing bio-organic fertilizers, by changing some control procedures in the process, the specific steps are as follows:

[0030] 1. Carry out aerobic fermentation of organic manure for 10 days;

[0031] 2. When g...

Embodiment 3

[0034] Embodiment three: post-adding bacteria process production and preparation of bio-organic fertilizer

[0035] In the production of bio-organic fertilizers, after granulation, drying, and cooling in the cooling cylinder, the bacterial agent is added before packaging, and a special bacteriostasis device is used for high-pressure mist spraying for metered addition. After the post-bacteria addition process and Use special bacteria-adding equipment to keep the selected bio-organic fertilizer particles uniform, keep the water in the environment required for adding microbial strains, and maintain the number of viable microorganisms that bio-organic fertilizers should have.

[0036] Specifically, the present invention is based on the existing conventional production process for preparing bio-organic fertilizers, by changing some control procedures in the process, the specific steps are as follows:

[0037] 1. Carry out aerobic fermentation of organic manure for 10 days;

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com