Resin-filled back drilling hole processing method of PCB (Printed Circuit Board)

A technology of PCB board and processing method, which is applied in the field of PCB board processing with resin plug back drilling, can solve the problems of weak signal loss, leakage of resin, incomplete exposure, etc., so as to ensure the quality of the circuit and improve the authenticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

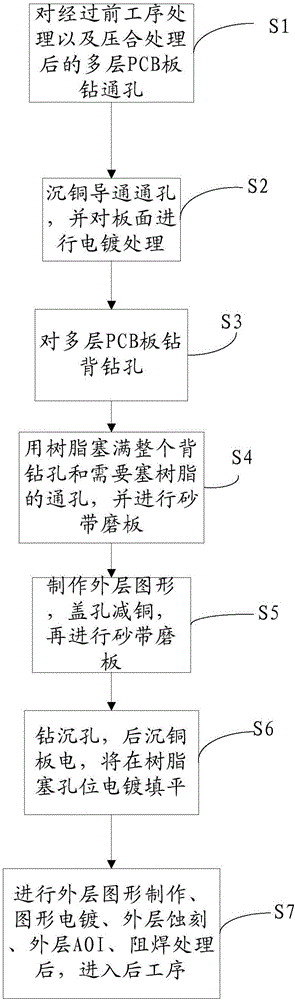

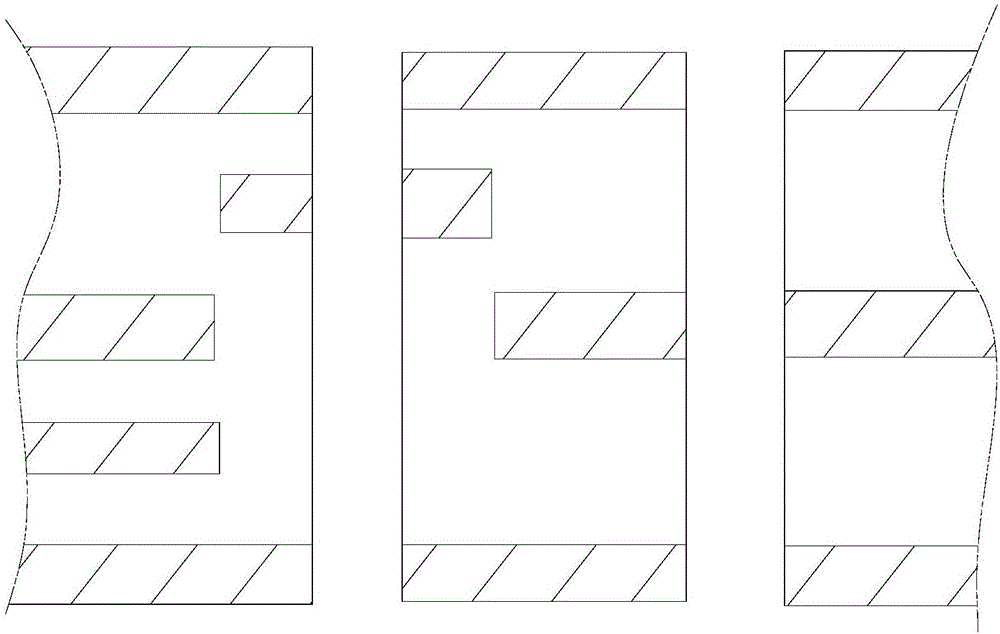

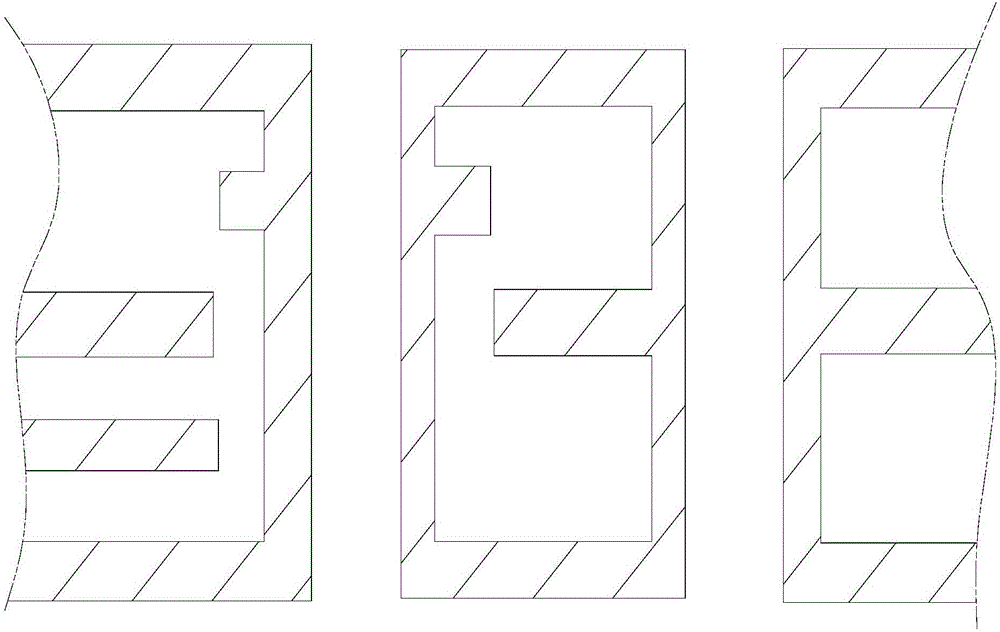

[0032] Such as Figure 1 to Figure 7 In the specific embodiment shown, the method for processing PCB boards with resin plug back drilling provided in this embodiment can be used in the process of manufacturing PCB boards to realize that the back drilling hole is NPTH and plugged with resin, and the It can ensure the quality of the line, and at the same time realize the effect that both the PTH through-hole and the NPTH back-drilled hole can be filled with resin, and can also improve the authenticity of the signal to a higher degree.

[0033] A PCB board processing method for resin plug back drilling, the method comprising:

[0034] S1. Drill through holes on the multi-layer PCB board after the previous process treatment and pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com