Manufacturing method of flexible printed circuit board post-procedures

A flexible circuit board and manufacturing method technology, applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of increased transportation costs, space occupied by trays, and high packaging costs, and achieve reduced product wrinkles, neatly arranged products, The effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

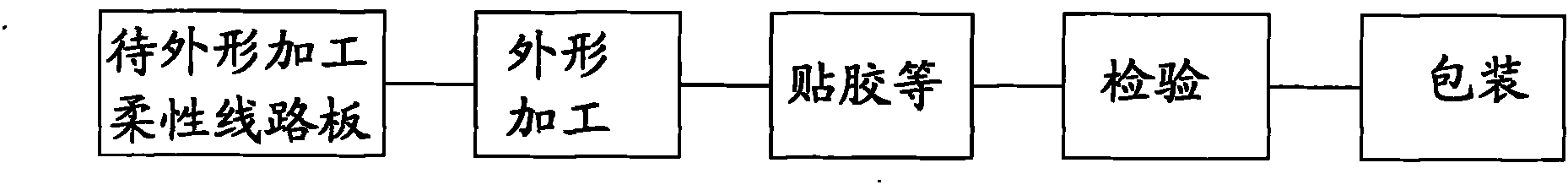

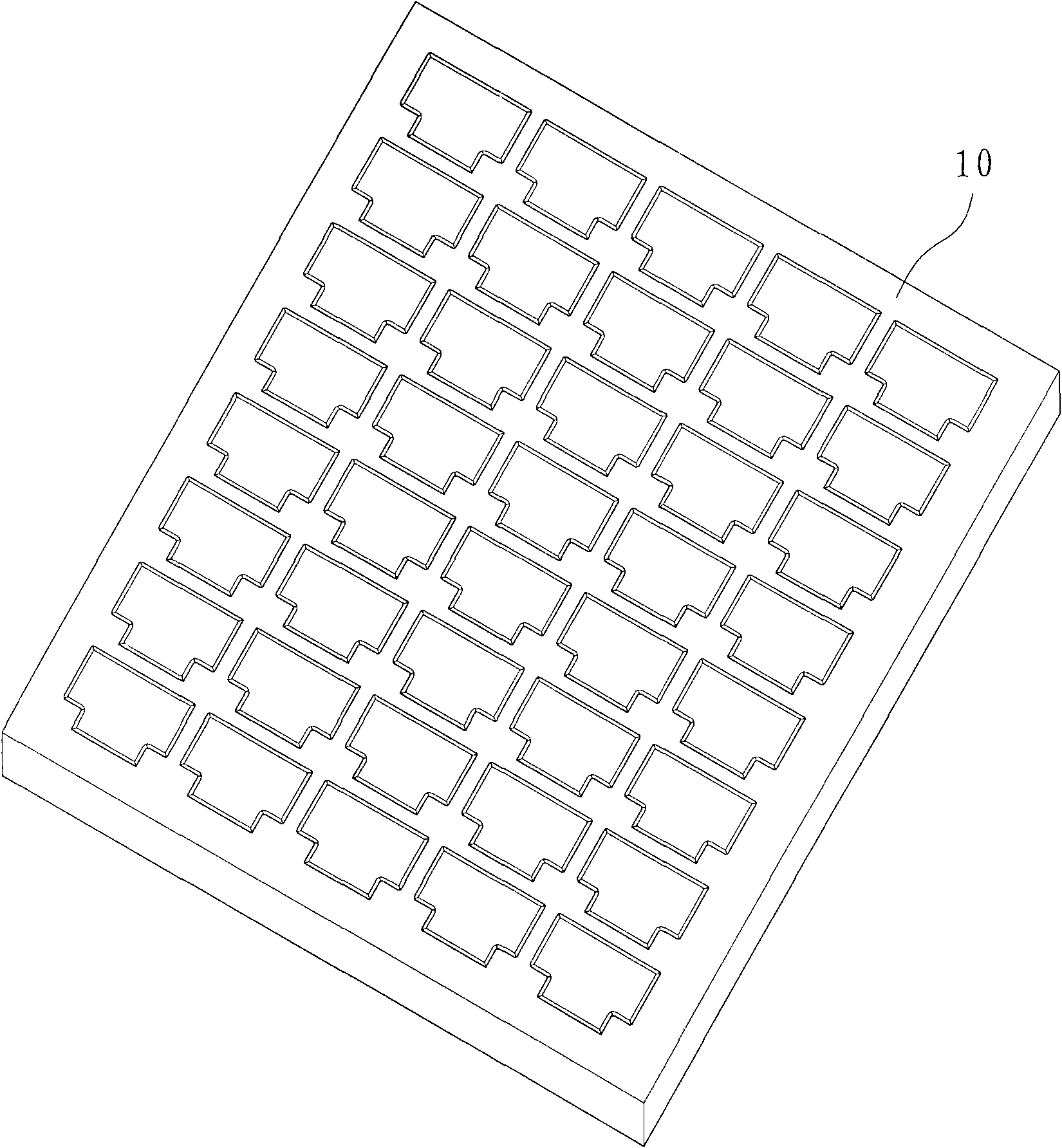

[0030] Cooperate Figure 3 to Figure 8 As shown, the manufacturing method of a single flexible circuit board post-process disclosed by the present invention specifically includes the following steps:

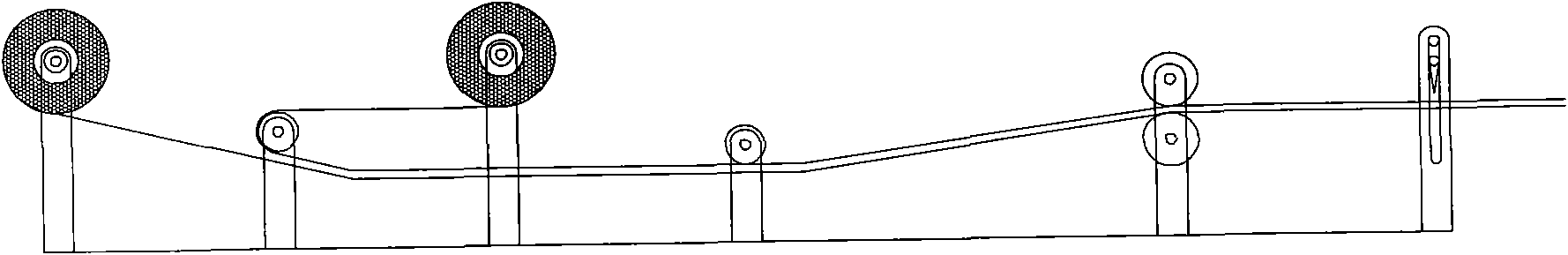

[0031] (1) Cutting material: such as image 3 As shown, first, the low-viscosity protective film is made by a cutting machine. The low-viscosity protective film is a non-transferable low-viscosity protective film. The protective film is bonded together to facilitate cutting and prevent dust pollution. A layer of release paper can also be pasted on the sticky side of a layer of low-viscosity protective film, which can also facilitate cutting and prevent dust. Cut the low-viscosity protective film according to the size required for production, which is consistent with the specifications of the flexible circuit board to be processed. The low-viscosity protective film here is PET low-viscosity protective film or OPP low-viscosity protective film.

[0032] (2) Drilling: Drill the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com