A cutter for substrate using microwaves laser beam and method thereof

An ultra-short pulse, cutting device technology, applied in glass cutting devices, laser welding equipment, optics, etc., can solve the problems of focus distance and irradiation direction, and achieve the effect of avoiding thermal damage, improving accuracy, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

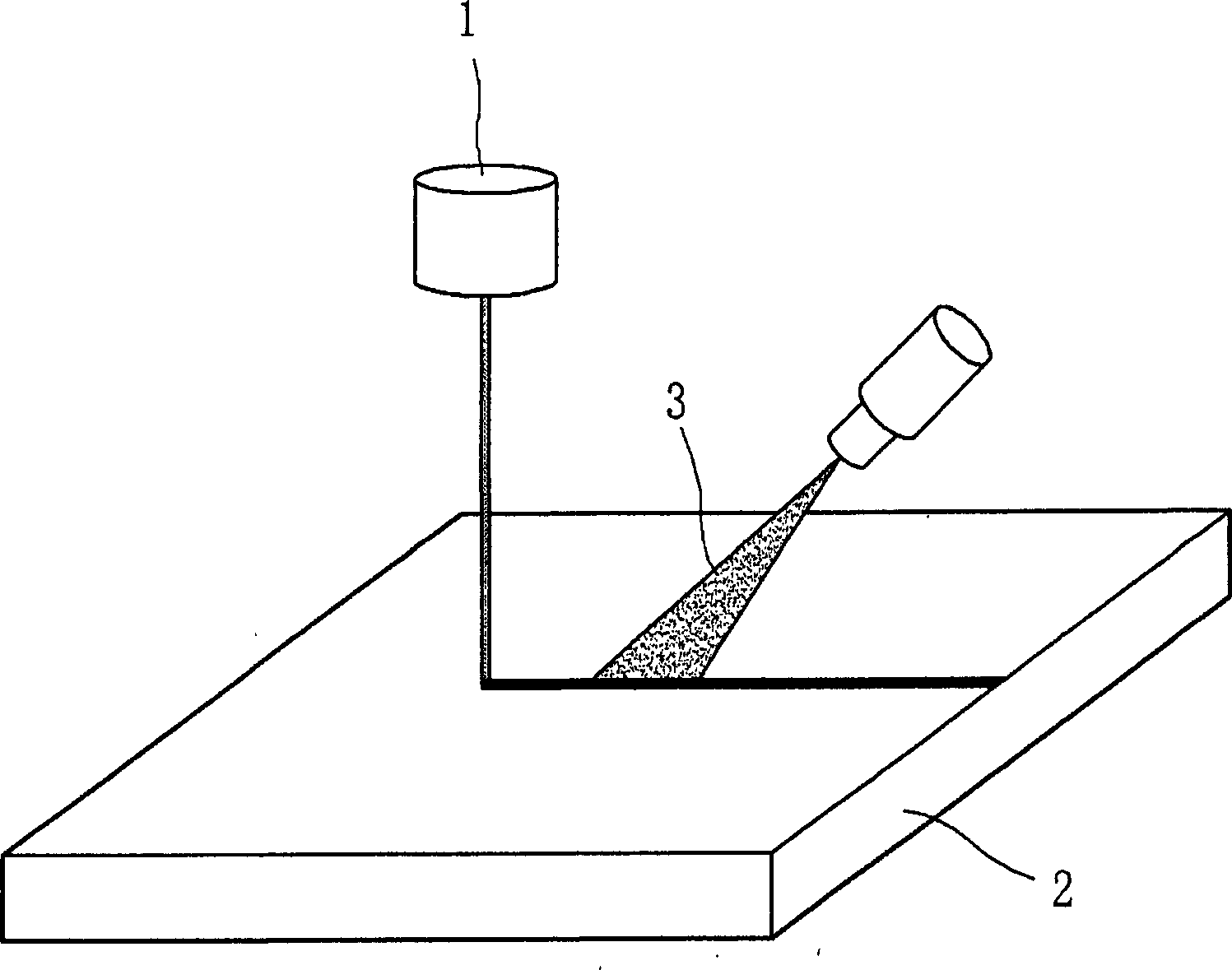

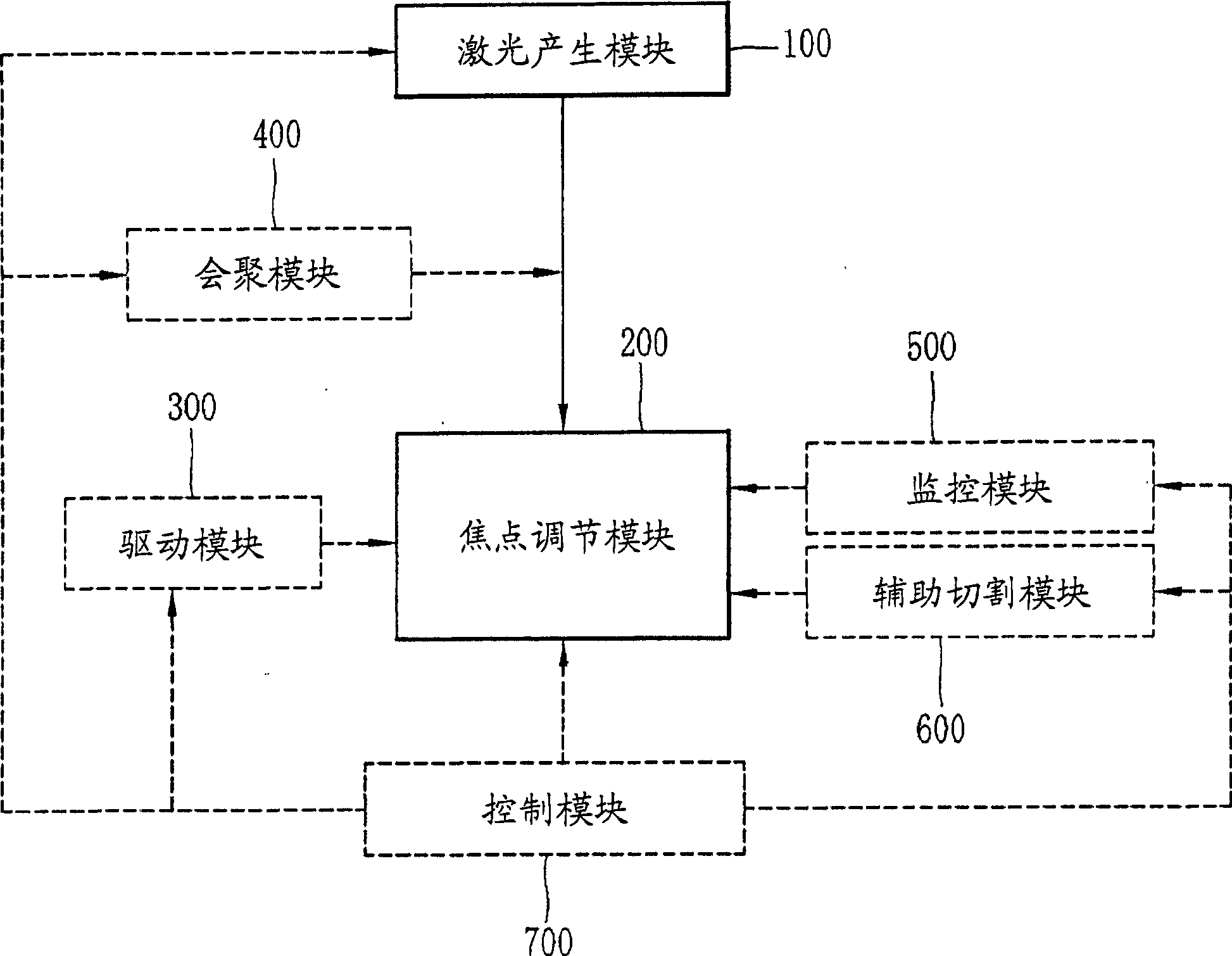

[0060] figure 2 It is an overall block configuration diagram schematically showing a substrate cutting device using an ultrashort pulse laser beam according to a first embodiment of the present invention.

[0061] refer to figure 2 , the substrate cutting device utilizing the ultrashort pulse laser beam according to the first embodiment of the present invention roughly comprises: a laser generating module 100 generating an ultrashort pulse laser beam; and a fixed substrate S (refer to Figure 3 to Figure 5 ) and the focus adjusting module 200 etc. which freely adjust the focus of the ultrashort pulse laser beam generated by the laser generating module 100.

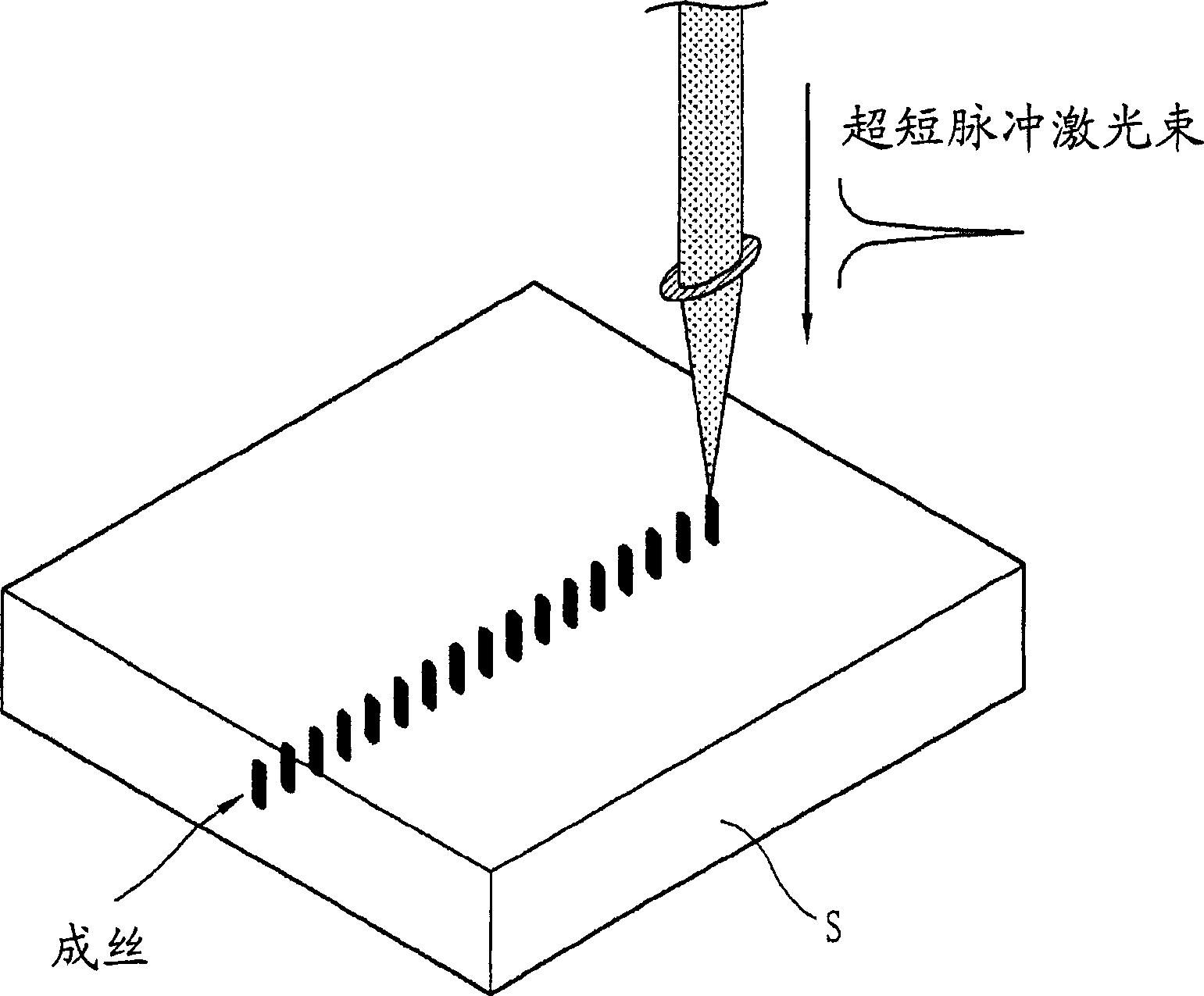

[0062] Here, the above-mentioned ultrashort pulse laser beam has, for example, a femtosecond FS (10 -15 seconds) ~ picosecond PS (10 -12 second) (preferably about 50 FS to 3 PS) pulse.

[0063] The above-mentioned substrate S can be used in various display devices (for example, LCD, PDP, OLED, FED, etc.), and prefera...

no. 2 Embodiment

[0088] The substrate cutting device utilizing the ultrashort pulse laser beam of the second embodiment of the present invention is the same as the aforementioned first embodiment of the present invention, and all apply the laser generation module 100, the focus adjustment module 200 and the auxiliary device in the same way, and the auxiliary device For example, there are the driving module 300 , the convergence module 400 , the monitoring module 500 , the auxiliary cutting module 600 , and the control module 700 , etc. For specific descriptions of these, refer to the first embodiment of the present invention.

[0089] In particular, the focus adjustment module 200 applicable to the second embodiment of the present invention has the following function, that is, when adjusting to make the ultrashort pulse laser beam generated by the laser generation module 100 focus on the substrate S along the desired cutting path Afterwards or at the same time, adjust so that the focus of the u...

no. 3 Embodiment

[0101] The substrate cutting device using the ultrashort pulse laser beam of the third embodiment of the present invention is the same as the aforementioned first embodiment of the present invention, and all apply the laser generating module 100, the focus adjustment module 200 and the auxiliary device in the same way, and the auxiliary device For example, there are the driving module 300 , the convergence module 400 , the monitoring module 500 , the auxiliary cutting module 600 , and the control module 700 , etc. For specific descriptions of these, refer to the first embodiment of the present invention.

[0102] On the other hand, the focus adjustment module 200 applicable to the third embodiment of the present invention is different from the above-mentioned first and second embodiments of the present invention in that it has the following functions, that is, to fix the substrate S and adjust it so that The ultrashort pulse laser beam generated by the module 100 is focused on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com