Acoustic material cutting device

A cutting device and acoustic material technology, applied in sampling devices, metal processing, etc., can solve the problems of uneven cutting, complex device structure, low cutting efficiency, etc., and achieve the effect of reducing cutting time, ensuring flexibility, and smooth edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

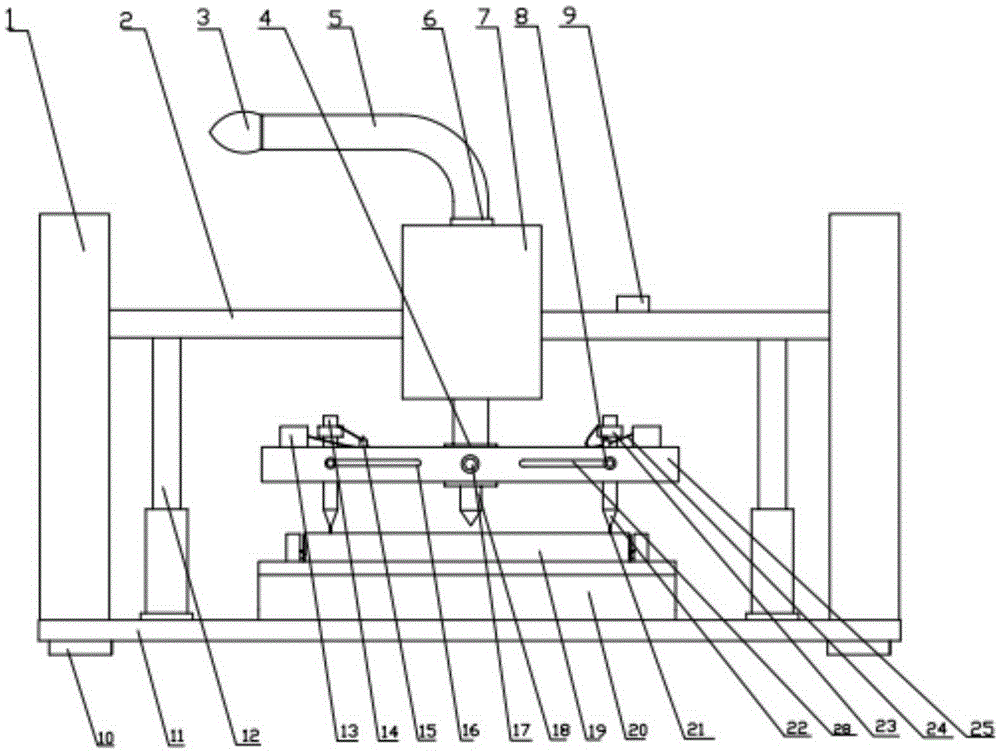

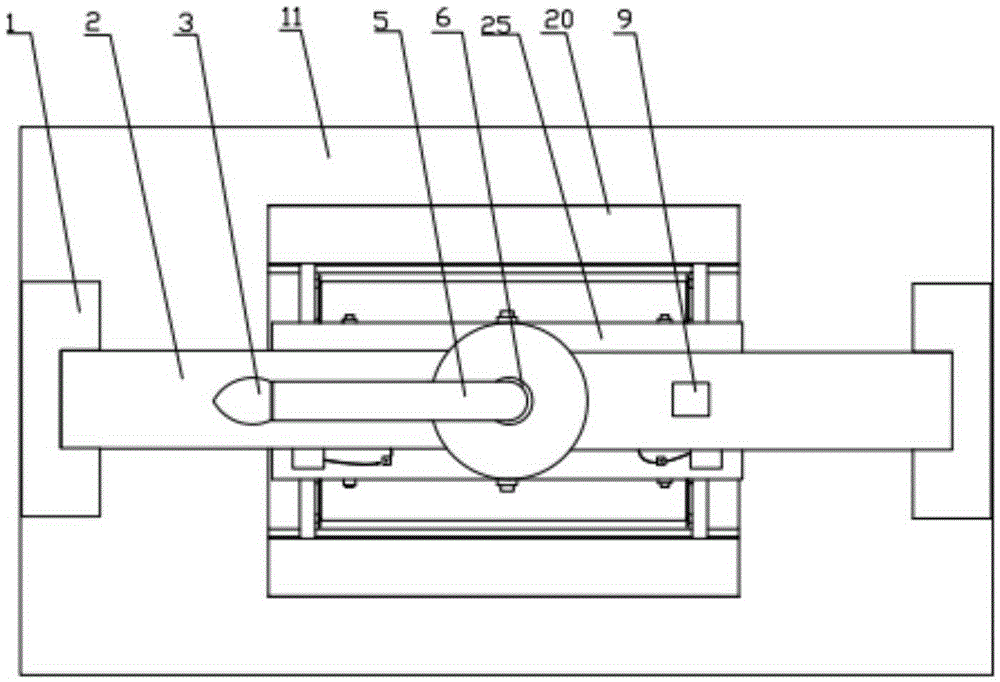

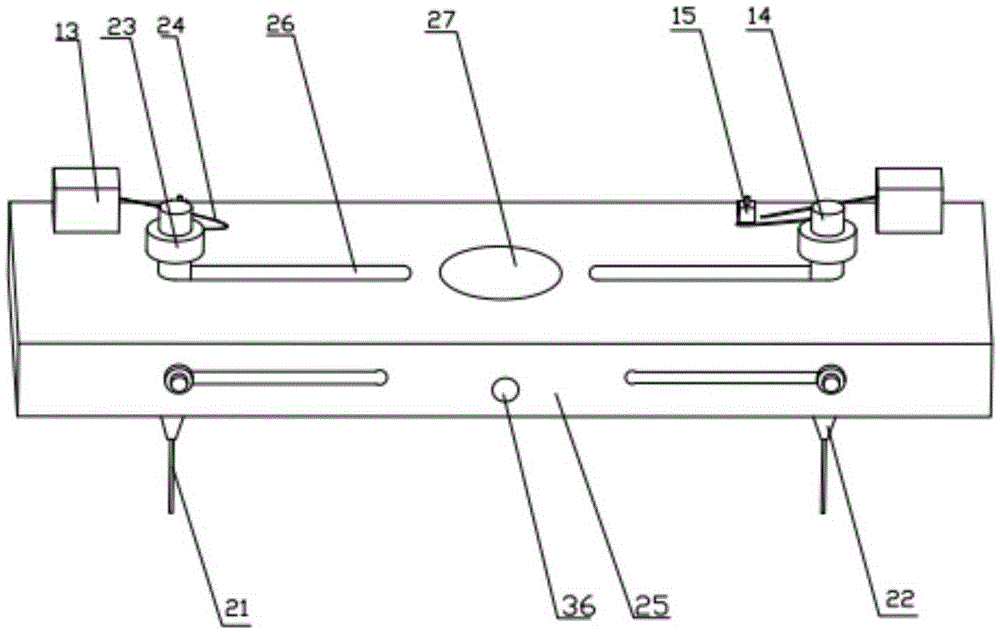

[0030] refer to figure 1 , figure 2, an acoustic material cutting device, the device includes a manual rotating device, a cutting device part, a material clamping device 20, a support device and a hydraulic jack device 12; wherein said manual rotating device is fixed on the cutting device part; said The material clamping device 20 is fixed at the middle position of the support device; the hydraulic jack device 12 is arranged at both ends of the material clamping device 20 and fixed on the support device; the cutting device part is arranged at the lower end of the manual rotation device, And the cutting head in the part of the cutting device before the test is in contact with the upper surface of the acoustic material clamped by the material clamping device, and will move up and down with the hydraulic jack during the test.

[0031] refer to figure 1 , figure 2 , the manual rotating device includes crank handle 3, drill rod 5, bearing 6, drill pipe 7 and laser light 18; wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com