Method for detecting failure dapth of deep channel

A deep groove and depth technology, applied in the field of analysis and detection, can solve problems such as failure depth measurement and analysis, affecting cross-sectional view analysis, and difficulty in controlling collimation, so as to reduce analysis time, control and adjust easily, and reduce effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

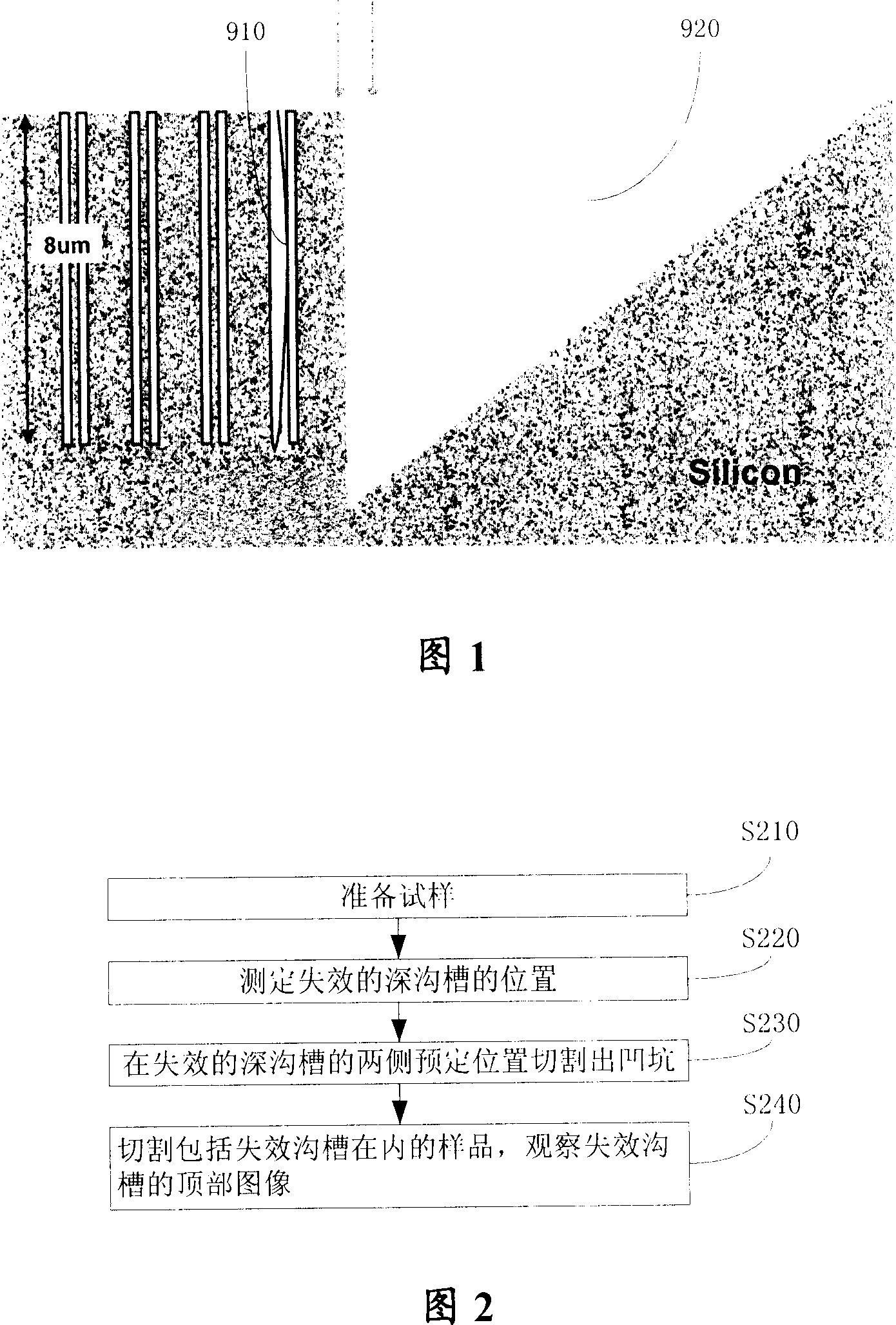

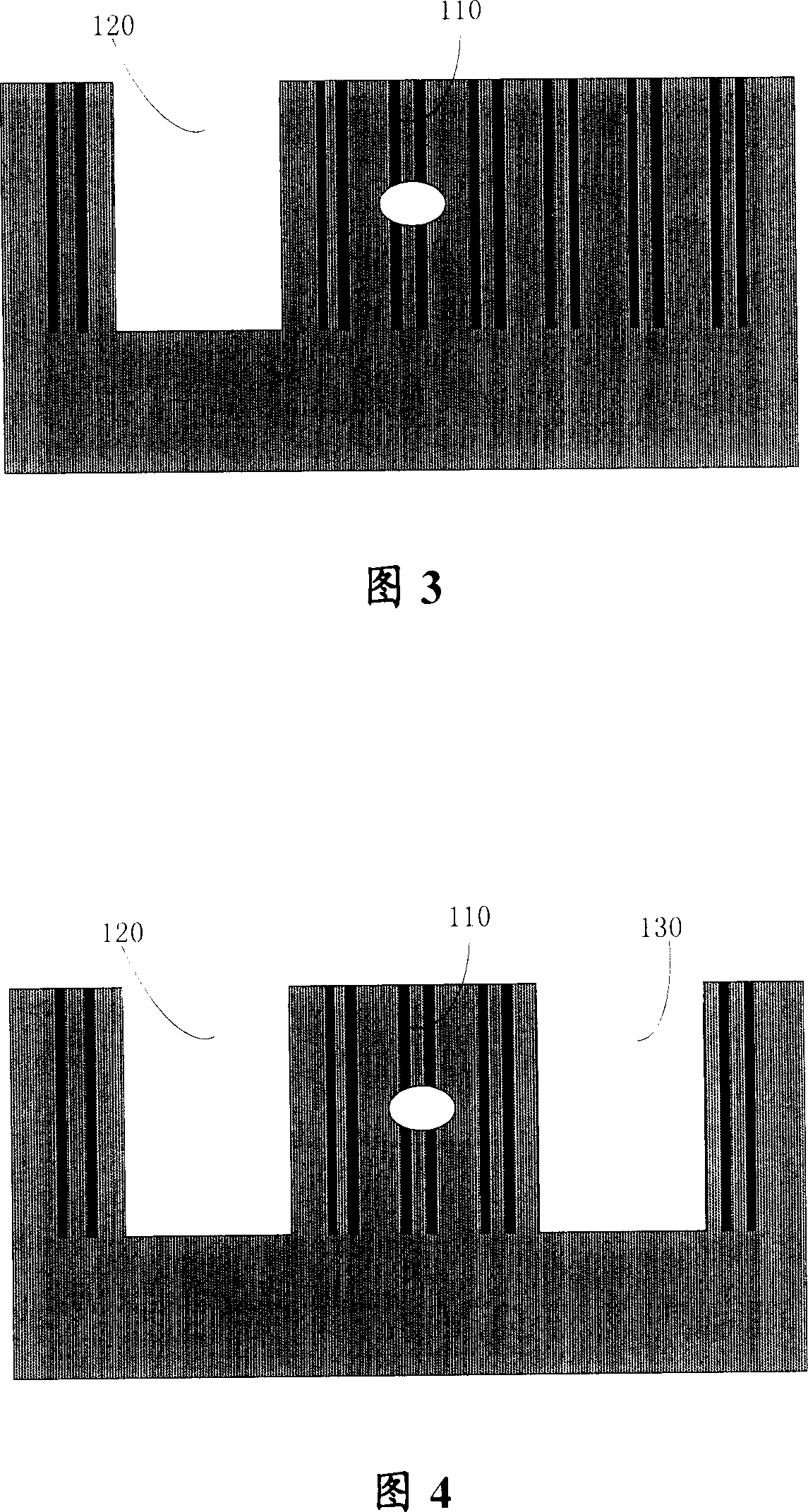

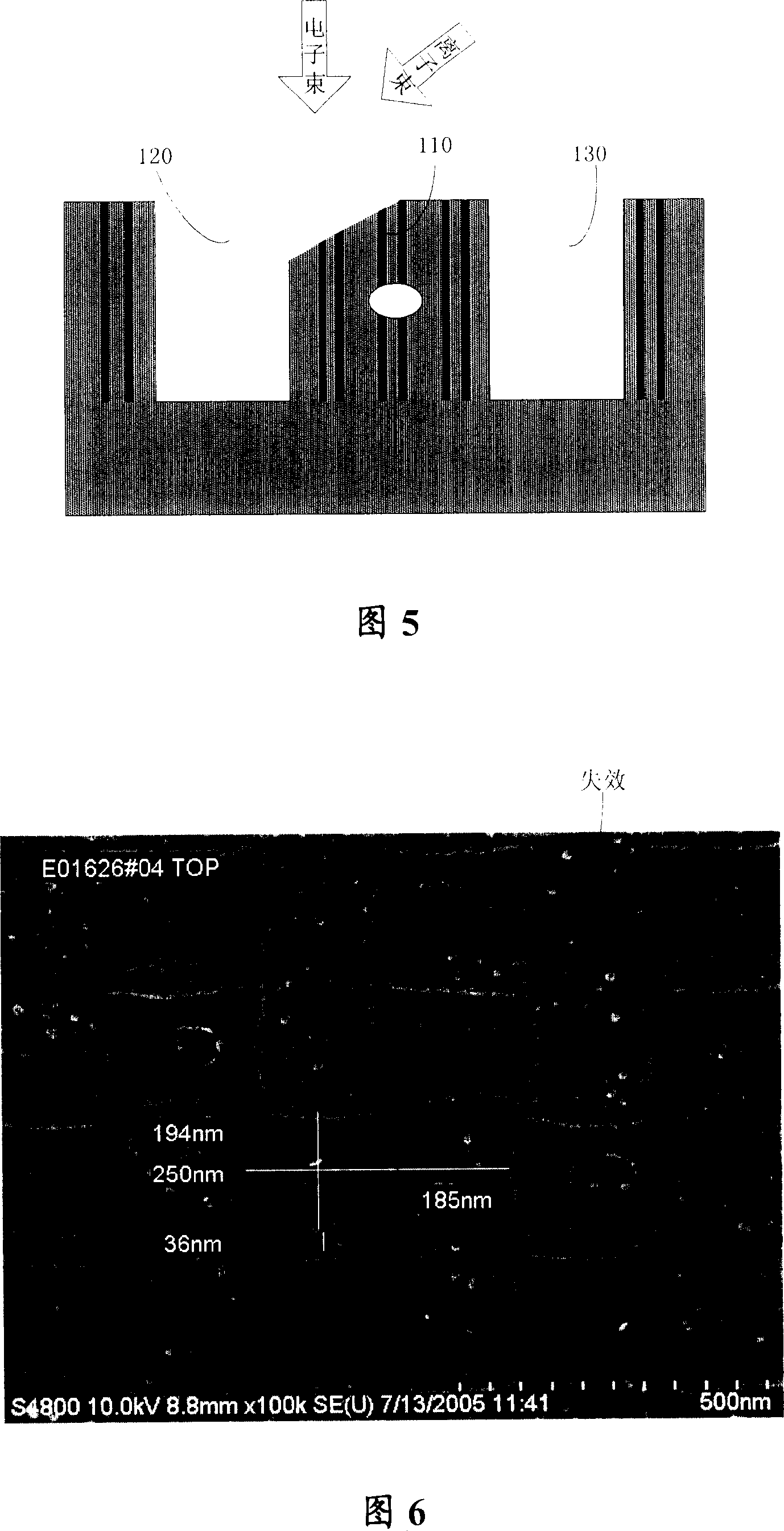

[0039] Please refer to FIG. 2 , which is a flow chart of the method for measuring the failure depth of a deep trench according to the present invention.

[0040] Step S210, sample preparation.

[0041] In the embodiment of the present invention, the size of the cut sample is about 10mm*10mm, and the surface treatment is performed on the sample test piece, so that the treatment described later can be performed on the deep trench layer.

[0042] Wherein, the surface treatment process can adopt chemical methods, such as soaking in 49% hydrofluoric acid HF for about 3 minutes, so that the surface of the test piece can be treated to the layer where the failure address can be located.

[0043] Step S220, put the sample into the FIB, rotate the FIB sample stage to a predetermined angle, so that the ion beam is perpendicular to the surface of the sample, and measure the position of the failed deep groove.

[0044] In an embodiment of the present invention, the predetermined angle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com