Sheet-processing lathe

A sheet metal processing and lathe technology, applied in the field of sheet metal cutting and processing devices, can solve the problems of sheet waste, double-knife saw cutting without incision waste, etc., and achieve the effects of reducing labor intensity, saving cutting time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

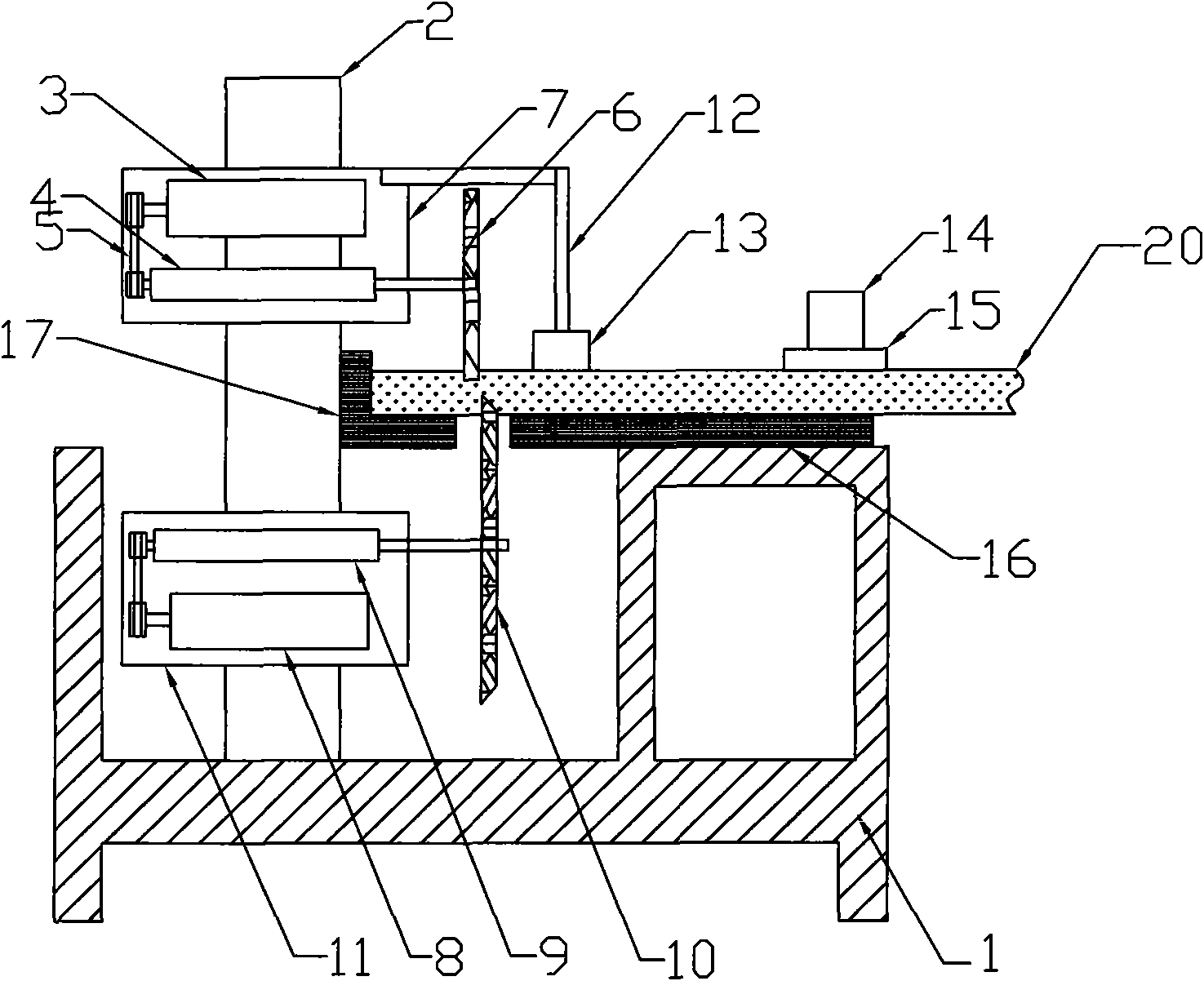

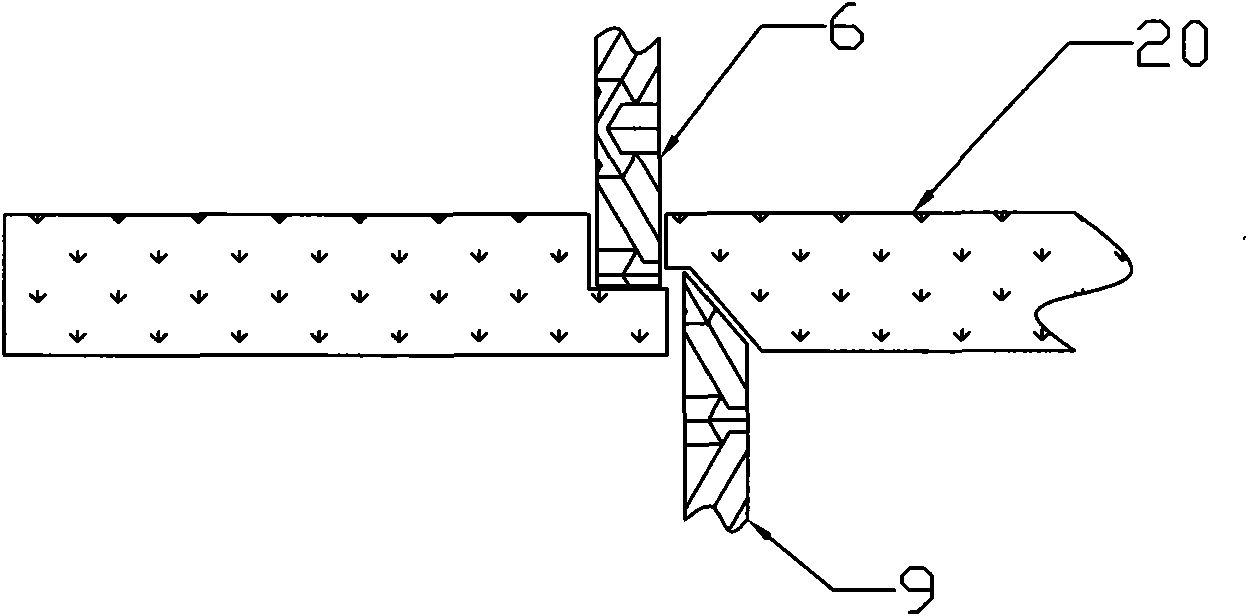

[0017] Such as figure 1 As shown, the woodworking lathe workbench of the present invention is installed in the middle of the vehicle frame 1, and a vertical column is installed on the left side of the vehicle frame 1. The column adopts a steel material in the shape of a dovetail groove, and a motor plate is respectively installed on the upper and lower ends of the column. The first motor 3, the upper transmission shaft 4, the upper knife saw 6 are installed, the second motor 8, the lower transmission shaft 9, the lower knife saw 10 are installed on the lower motor plate 11, each motor drives the respective transmission shaft by the belt 5, and the transmission shaft drives the other The knife and saw installed at one end rotates. For the convenience of adjustment, there is a chute corresponding to the dovetail groove on the back of each motor plate, and the adjusted position of the motor plate is fixed by adjusting bolts. The upper knife saw 6 and the lower knife saw 10 are pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com