Patents

Literature

31results about How to "Easy Processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bamboo leaf bean curd and processing method thereof

The invention discloses bamboo leaf bean curd and a processing method thereof, and relates to a bean curd product and the processing method thereof, in particular to a bamboo leaf-containing bean curd product and the processing method thereof. In the bamboo leaf bean curd, bamboo leaf juice (or bamboo leaf powder) serves as a bean curd coagulator. The processing process of the bamboo leaf juice (or the bamboo leaf powder) comprises the following steps of: selecting and using fresh bamboo leaves; washing; adding water; grinding into thick liquid; keeping a temperature for enzymolysis; squeezing and taking the juice; preparing the bamboo leaf juice by filtering and concentrating; and preparing the bamboo leaf powder by spray drying. The invention provides a novel bean curd food with bamboo nutrient components, has a simple and convenient process, and does not use conventional chemical raw materials such as halogen, plaster and the like as a coagulator; and the product has the characteristics of virescent to green color and luster, fresh and clean mouthfeel, rich nutrient, safety and health.

Owner:深圳超跃食品有限公司

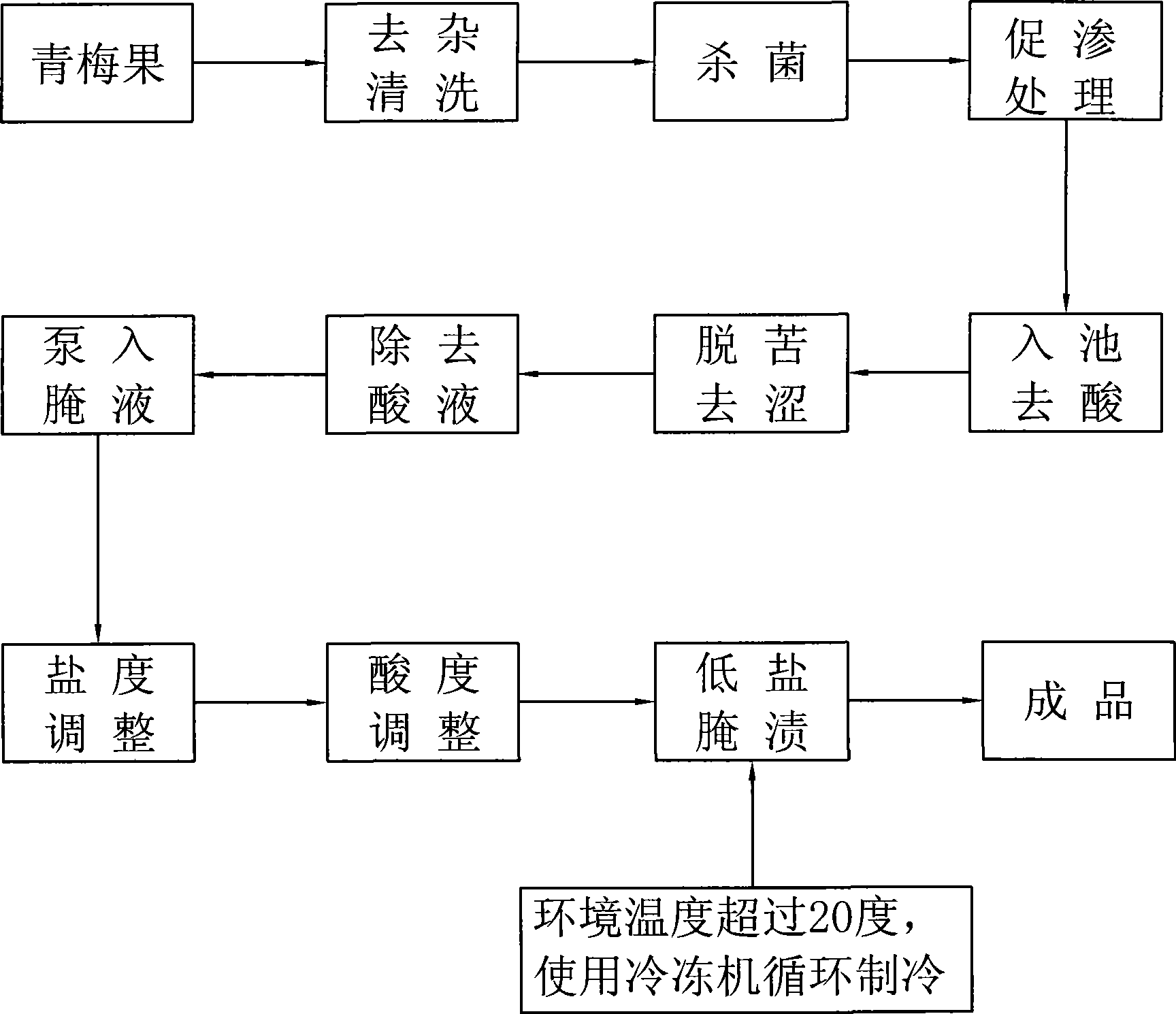

Method for pickling green plum fruits

InactiveCN101411357AEasy processingGood product qualityFruits/vegetable preservation using acidsOrganic acidSalt content

The invention provides a method for pickling green plum fruits, which comprises the following steps: a. picking up green plum fruits; b. removing impurities and cleaning; c. desulfurization; d. deacidification; e. preparing low-salt pickling liquid; f. controlling the temperature of the pickling liquid; and g. pickling the green plum fruits in a pickling pond for 25 to 30 days. The method has the advantages that: the green plum fruits are pickled under a condition of less than 6 percent salt concentration; and the high acidity and the high osmotic pressure are utilized to restrain the growth and breeding of microbes, so that the pickled green plum fruit keeps the original light-scent taste, and the shelf life reaches nearly 30 months; and, the following processing steps are simple, the desalting step is unnecessary, the processed product has good quality, the organic acid and nutritive materials are insusceptible to loss, the green plum fruit can also be processed into various products, thereby facilitating the mass production of all varieties. Once the pickled liquid is prepared, common salt does not need to be added, the pickled liquid can be repeatedly used, so that the method can reduce sewage discharge, salt content in the sewage, thereby facilitating the sewage treatment and environmental protection, saving cost and improving economic benefits.

Owner:俞关权

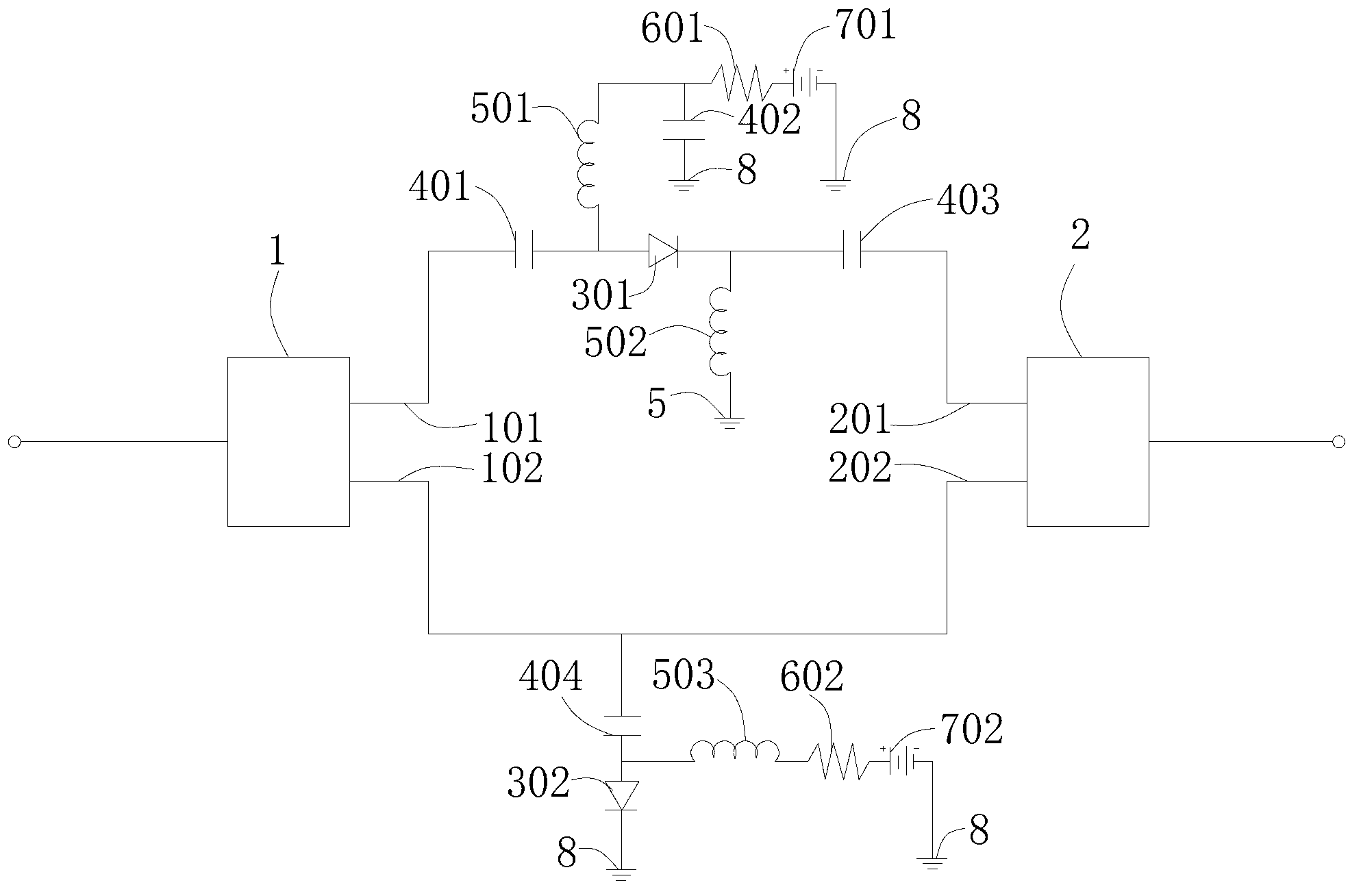

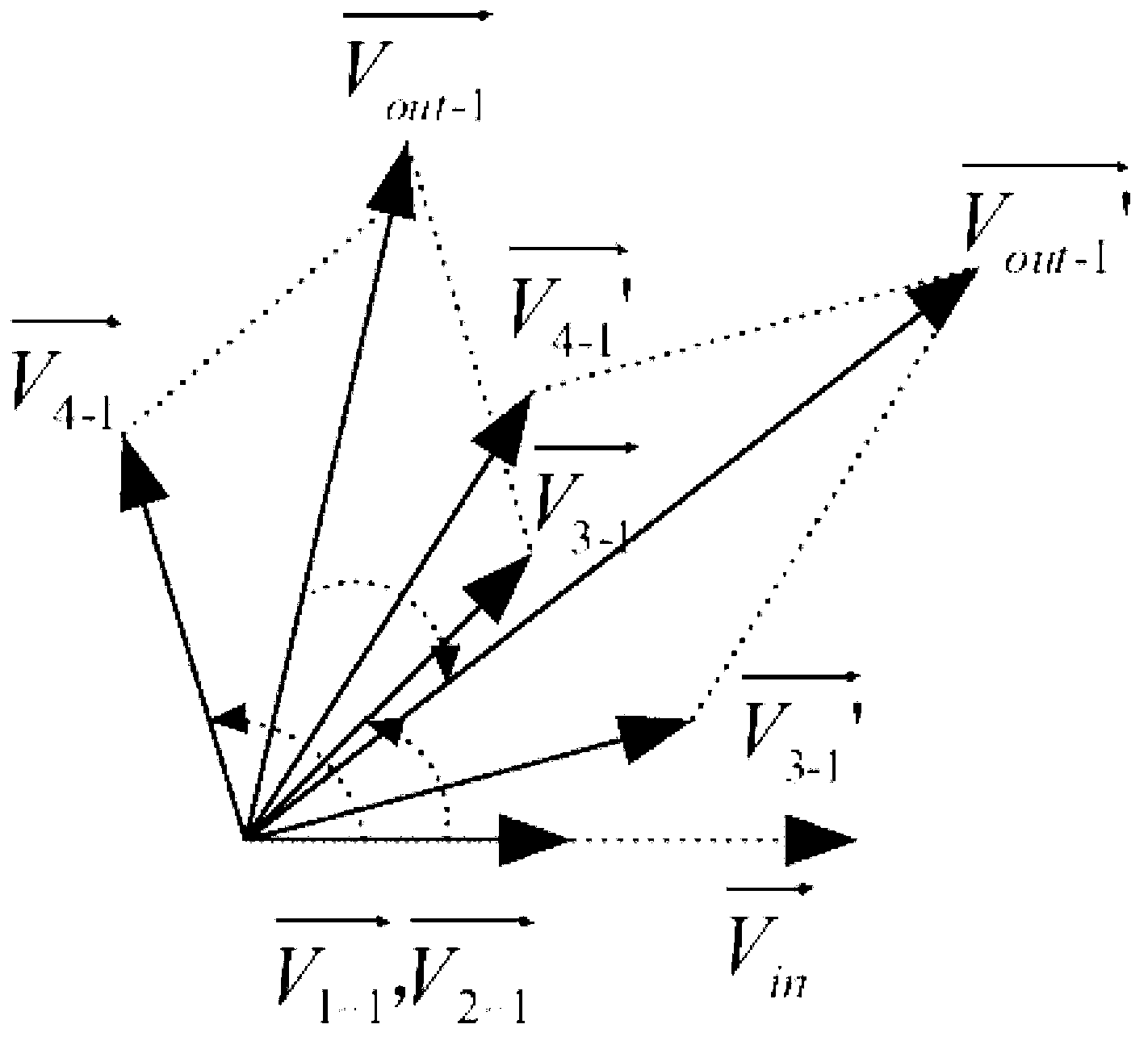

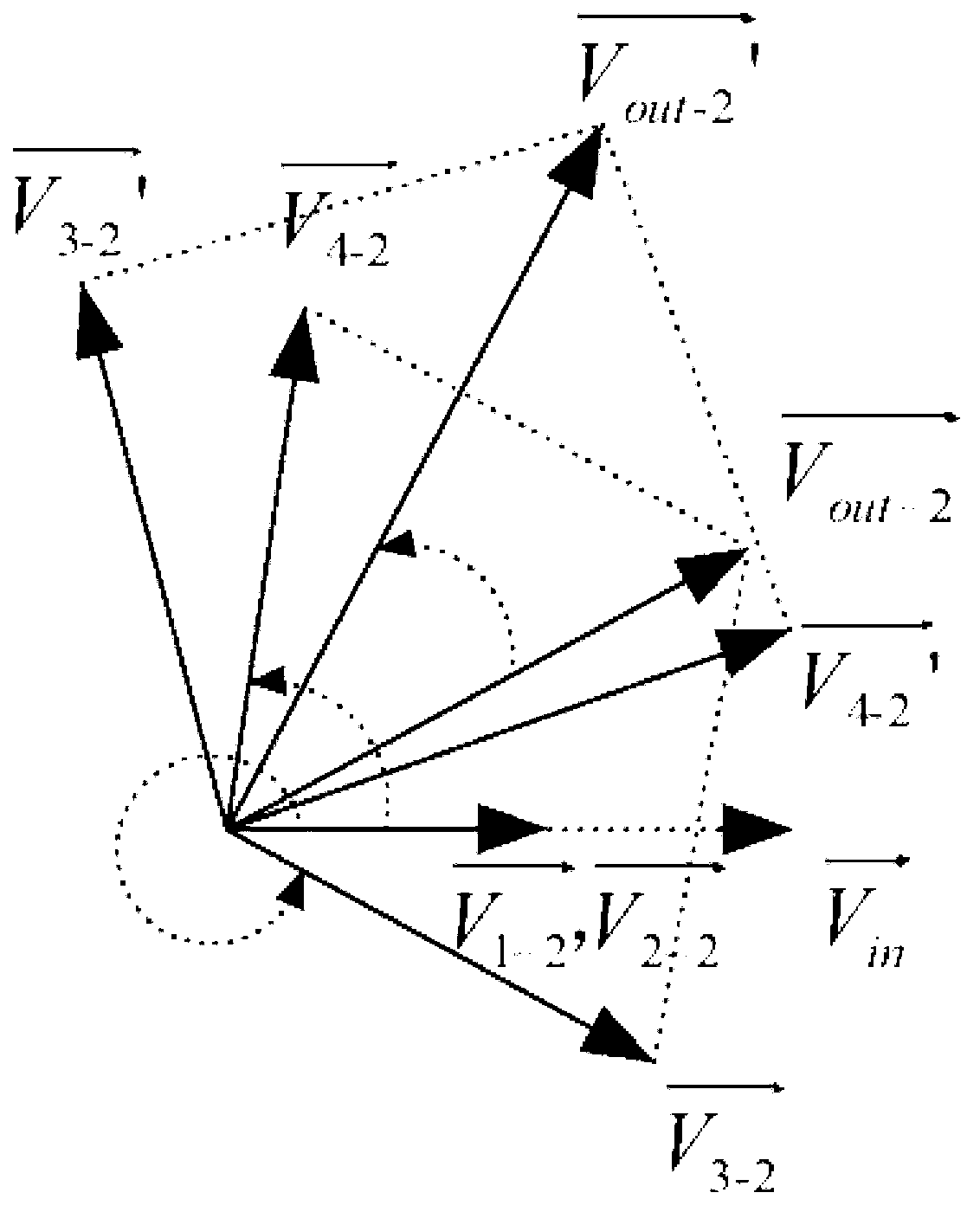

Hybrid pre-distortion linearizer

InactiveCN103312275AAchieving nonlinear predistortion linearizationImprove controllabilityAmplifier modifications to reduce non-linear distortionEngineeringSolid state power amplifier

The invention discloses a hybrid pre-distortion linearizer with wide application range. The hybrid pre-distortion linearizer comprises a power divider and a synthesizer, wherein output ports of the power divider are in one-to-one connection with input ports of the synthesizer through a series transmission type analog pre-distortion circuit or a parallel transmission type analog pre-distortion circuit. The linearizer synthesizes multiple nonlinear signals with different characteristics to obtain the required spectrum and phase pre-distortion signals, overcomes the shortcomings that independent series and parallel transmission type analog pre-distortion circuits can only produce pre-distortion signals suitable for solid-state power amplifiers and most reflection-type pre-distortion circuits can only produce pre-distortion signals suitable for millimeter wave traveling-wave tube power amplifiers, can realize the nonlinear pre-distortion linearization for the millimeter wave traveling-wave tube power amplifiers and the solid-state power amplifiers, has wide application range, and is suitable for being popularized in the technical field of millimeter wave linearization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

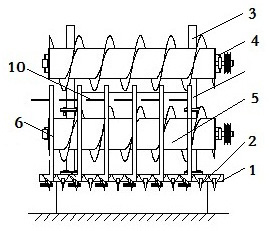

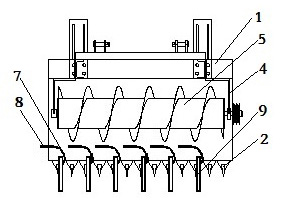

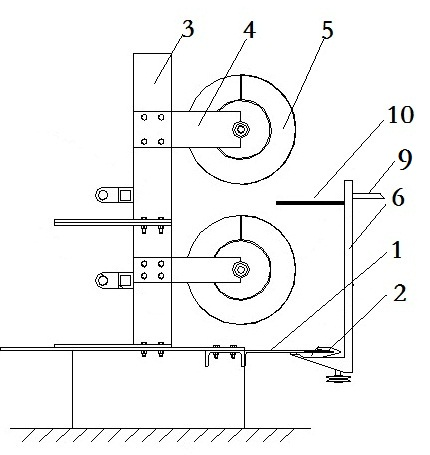

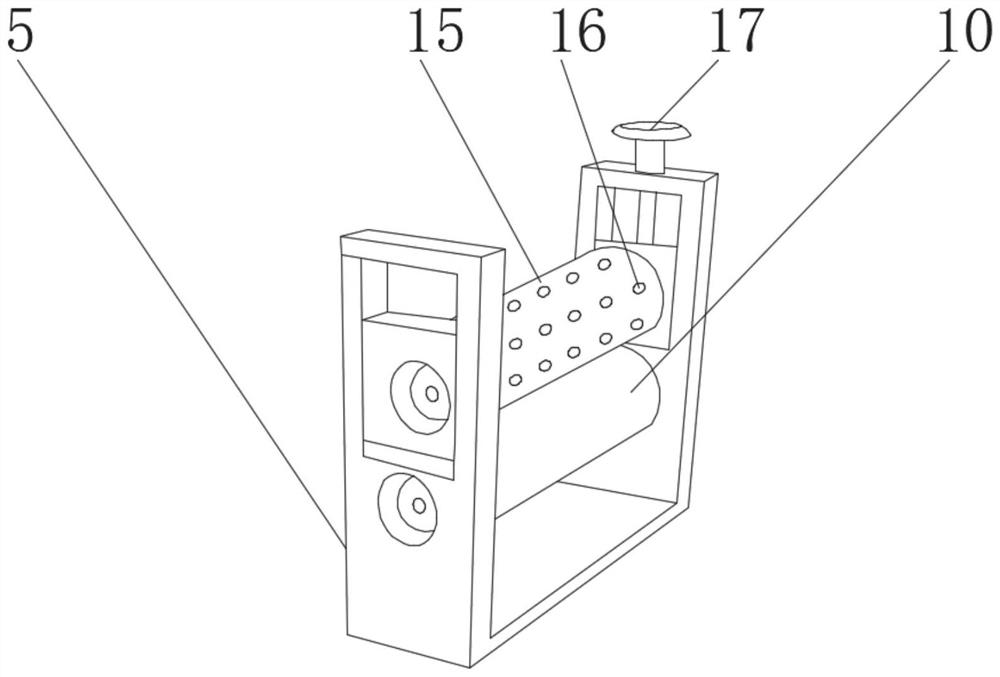

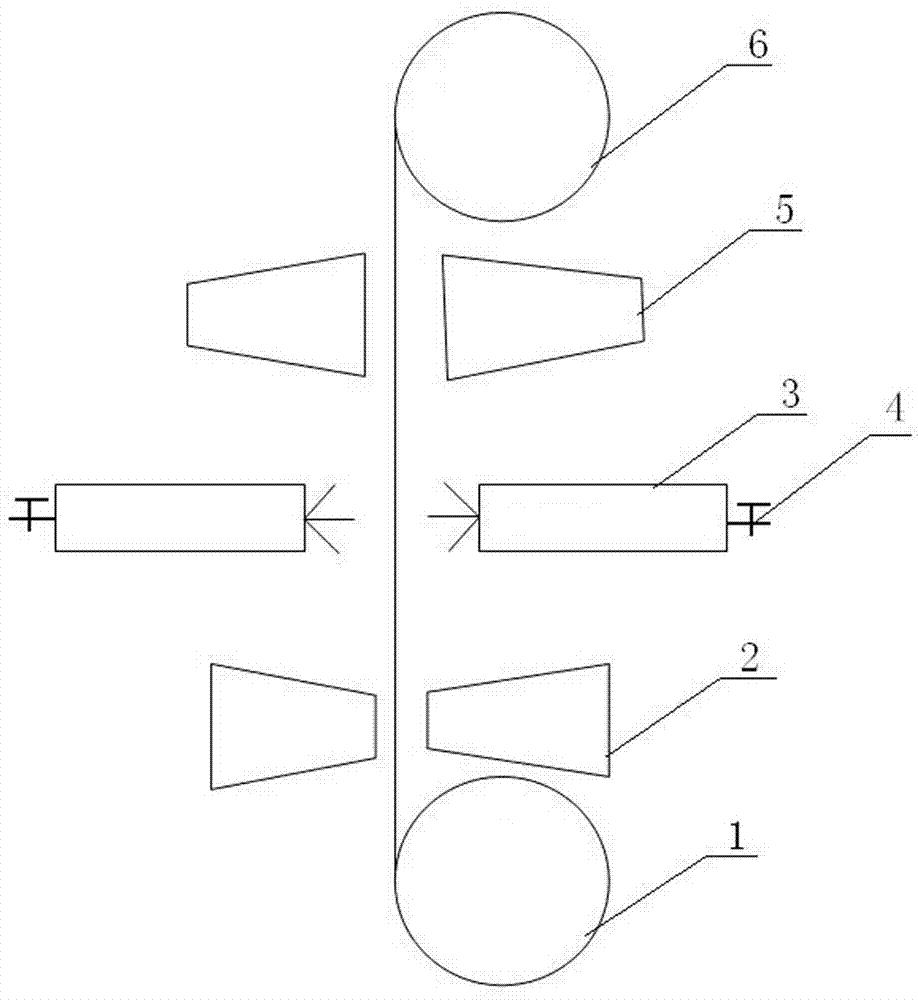

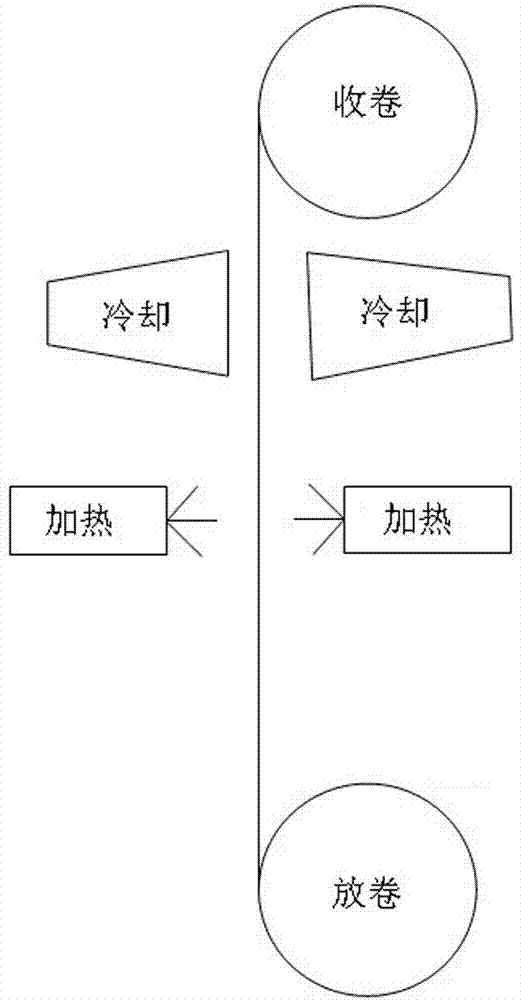

Long-stalk crop vertical conveying header and conveying device thereof

The invention relates to a long-stalk crop vertical conveying header and a conveying device thereof. The long-stalk crop vertical conveying header comprises a header body used for long-stalk crop, wherein the front end of the header body is provided with a cutter device, a conveying device is arranged above the header body and provided with a bracket and two screw conveyers used for vertically conveying stalks to the left side or right side of the header to be cut by the cutter device, and the two screw conveyers which synchronously rotate in the same direction are arranged on the upper part and the lower part of the bracket respectively. Because the header body of the conveying header of the invention is provided with the conveying device with the screw conveyers, when the conveying header runs, the stalks can keep upright after being cut by the cutter device of the header and then can be directionally conveyed by the screw conveyers; and when the corresponding stalks are conveyed tothe corresponding end heads of the screw conveyers, the stalks orderly fall down on the same side under the action of the screw conveyers, which contributes to the following processing procedures of the stalks of the long-stalk crop and realizes the orderly upright conveying of the stalks of the long-stalk crop.

Owner:HENAN UNIV OF SCI & TECH

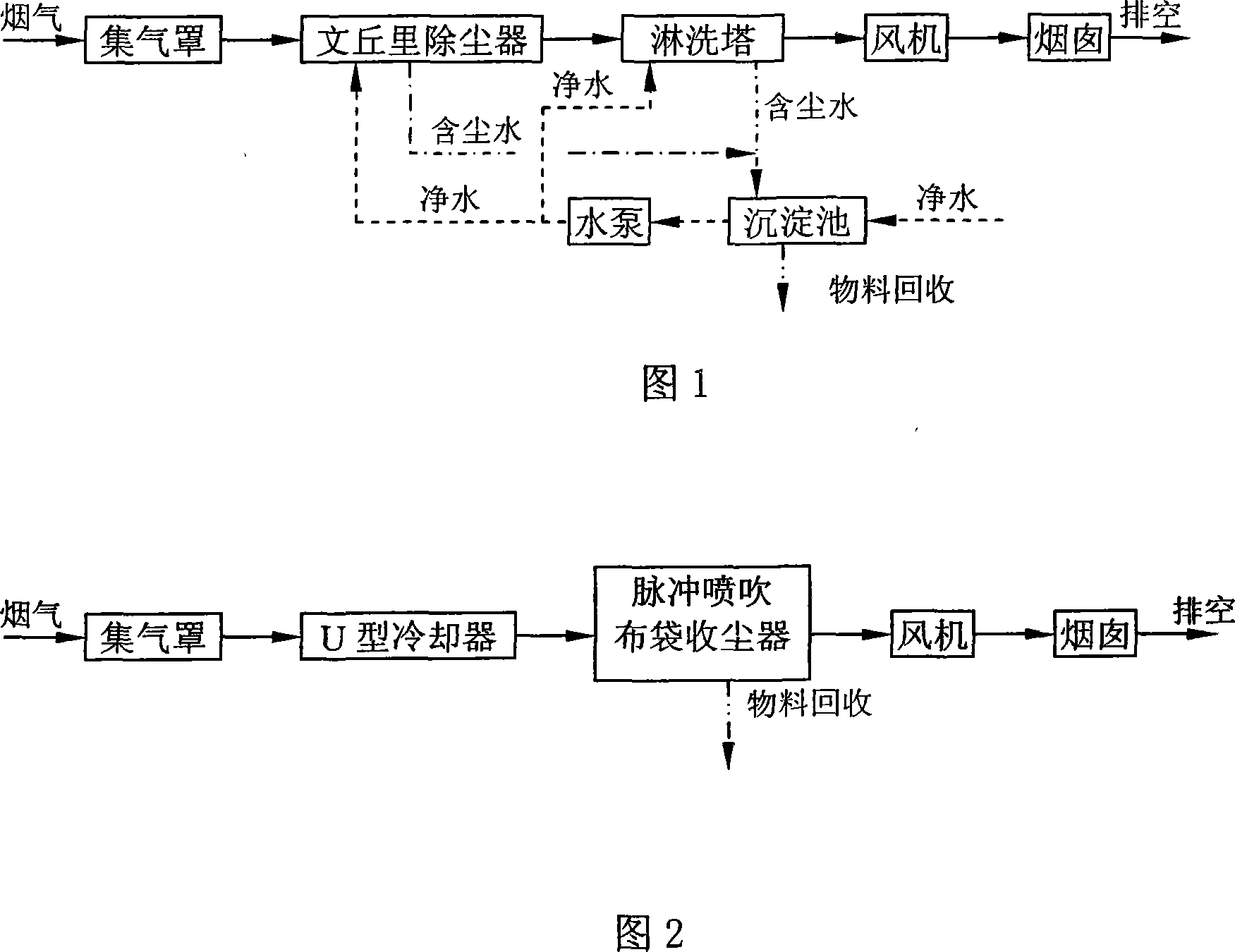

Dry method dust collecting technique for ferromolybdenum smelting flue gas

InactiveCN101108389ASmall scaleSmall catchDispersed particle filtrationDirt cleaningBaghouseEngineering

A ferromolybdenum smelting smoke and gas dry method dust collection technics, which solves the problems that the existing wet method dust collection has low dust collection efficiency, the smoke and gas can't meet the environment protection requirements, the system runs unstably, take serious erosion to the fan and the pipeline equipment and the recycled material is not easy to store. The method is that: the smoke and gas produced by ferromolybdenum smelting furnace enters into a U-shaped cooling machine to lower temperature naturally by a gas skirt, and proceed dust collection by a bag dedusting machine and is discharged reaching the standard; the dust material collected by the bag falls into the dust hopper of the bag dust collection machine by pulse spraying and blowing, which is used for smelting to produce ferromolybdenum, the smoke and gas after dust collection is transferred into a chimney to discharge out. The advantages of the invention are that: the invention has low investment and small running expense, which is economic with obvious environment benefit, and has quick capital payoff, the material recycle efficiency can reach above 99.9 per cent; the discharged smoke and gas can meet the requirement of protecting environment; the management is convenient, the operation is simple and the running is stable; the erosion to the fan and the pipeline equipment is small, which prolongs the service life of the equipment; the dry power material can be recycled directly, and is easy to lay; the process mating is easy, the engineer occupies small space and is easy to arrange.

Owner:LIAONING CHENGUANG ENVIRONMENT ENG TECH

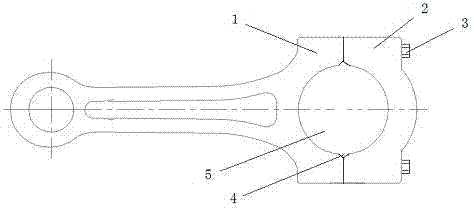

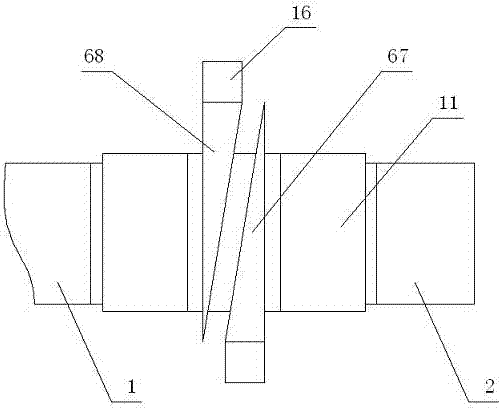

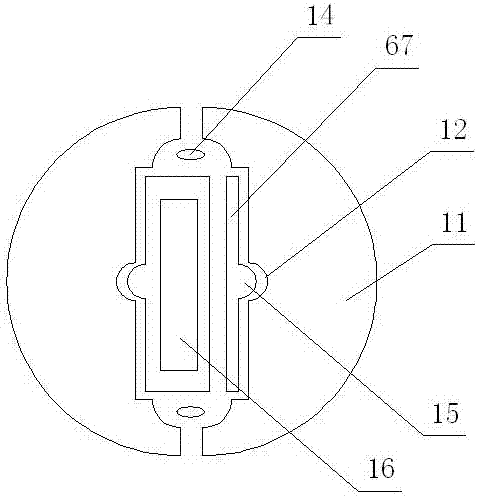

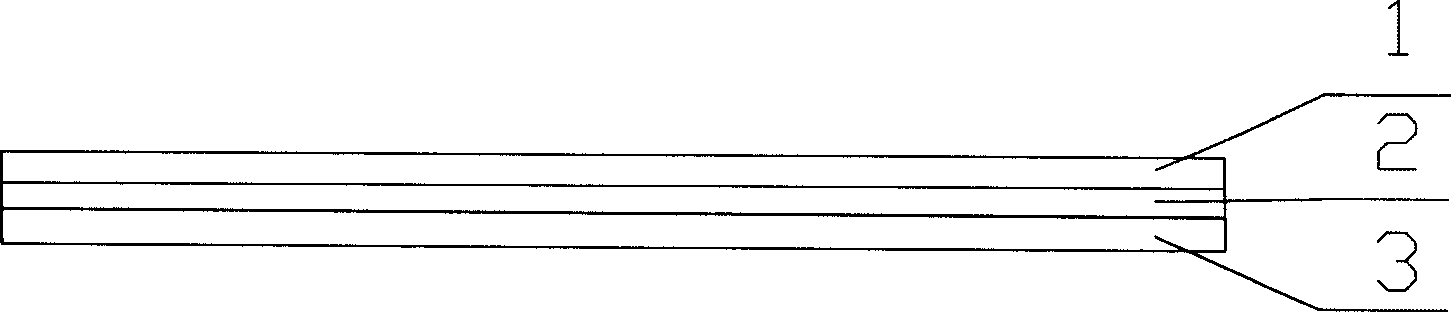

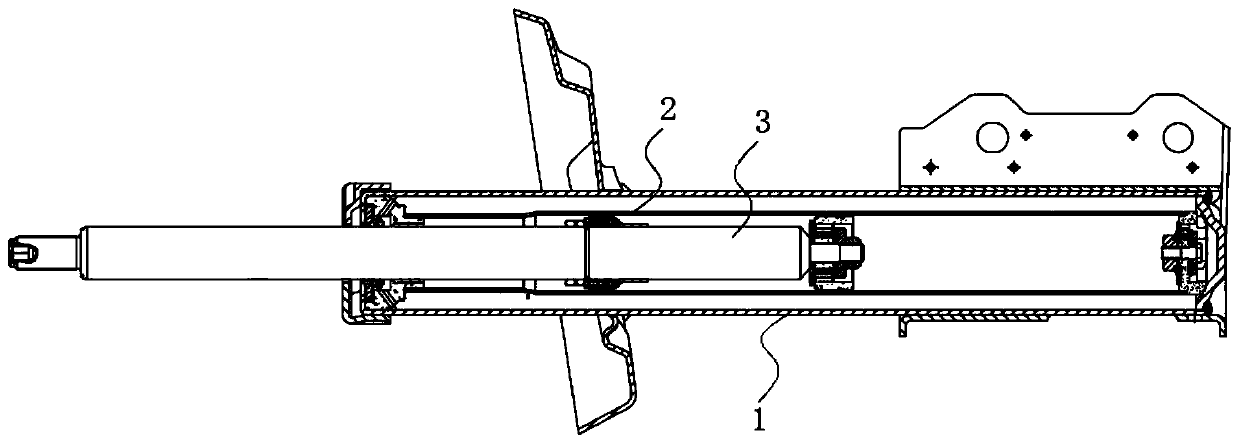

Cracking method machining technology of engine connecting rod

The invention relates to a cracking method machining technology of an engine connecting rod. A large-end hole machined in a connecting rod blank is a round hole; the connecting rod blank where the large-end hole is machined is separated into a connecting rod body and a connecting rod cover in a cracking manner; the joint faces of the connecting rod body and the connecting rod cover are cracking faces which are not subjected to cutting machining; and connecting and locating between the connecting rod body and the connecting rod cover are achieved through engagement of the joint faces of the connecting rod body and the connecting rod cover. A connecting rod cracking device for connecting rod cracking comprises a vertical rack and a workbench mounted on the vertical rack, and further comprises an upper machine head and a lower machine head. The upper machine head is provided with an upper wedge part and an upper cracking pushing force mechanism used for driving the corresponding wedge part to move up and down, and the lower machine head is provided with a lower wedge part and a lower cracking pushing force mechanism used for driving the corresponding wedge part to move up and down. Extrusion force formed by opposite movement of the upper edge part and the lower wedge part is used for achieving connecting rod cracking. By means of the method of the technology, the cracking difficulty is reduced, the quality of the connecting rod obtained after cracking is guaranteed, production procedures and manufacturing cost are reduced, and good economical benefits are achieved.

Owner:BEIJING BEINEI DIESEL ENGINE

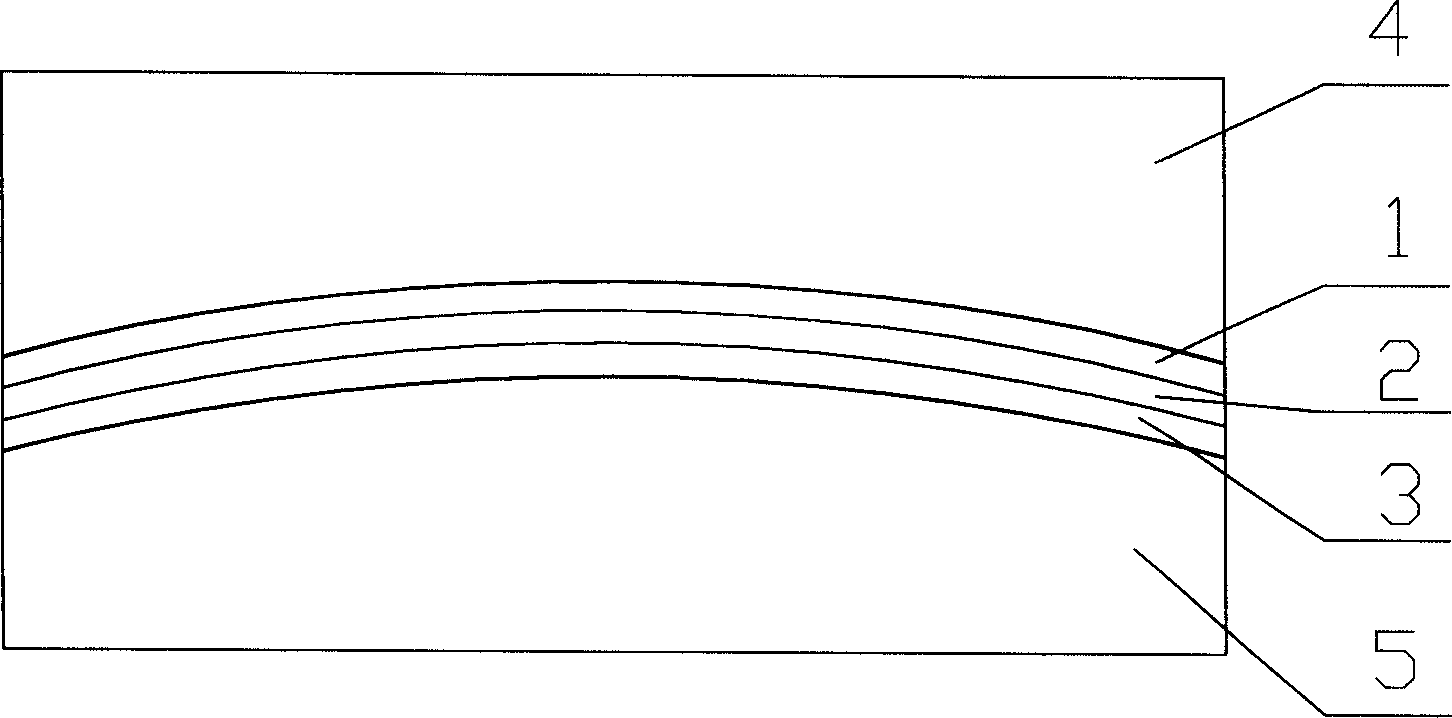

Manufacturing method of double-layer bamboo surface window shutter

InactiveCN1911616AEasy processingAdd novelty and generosityWood working apparatusFilling materialsEngineering

The present invention relates to curtain lip forming technology and is especially bamboo coated venetian blind lip making process. The bamboo coated venetian blind lip making process includes the following steps: sorting bamboo material and base material, cutting the bamboo material and the base material into sheets in required sizes, adhering the bamboo sheets to two sides of the base material sheets, pressurizing in curved mold to form the multilayer integral, polishing, chamfering and painting. Thus made bamboo coated venetian blind lip may have different shapes, and may be used in producing beautiful venetian blind. In addition, the present invention can make full utilization of bamboo and wood material.

Owner:陈玉强

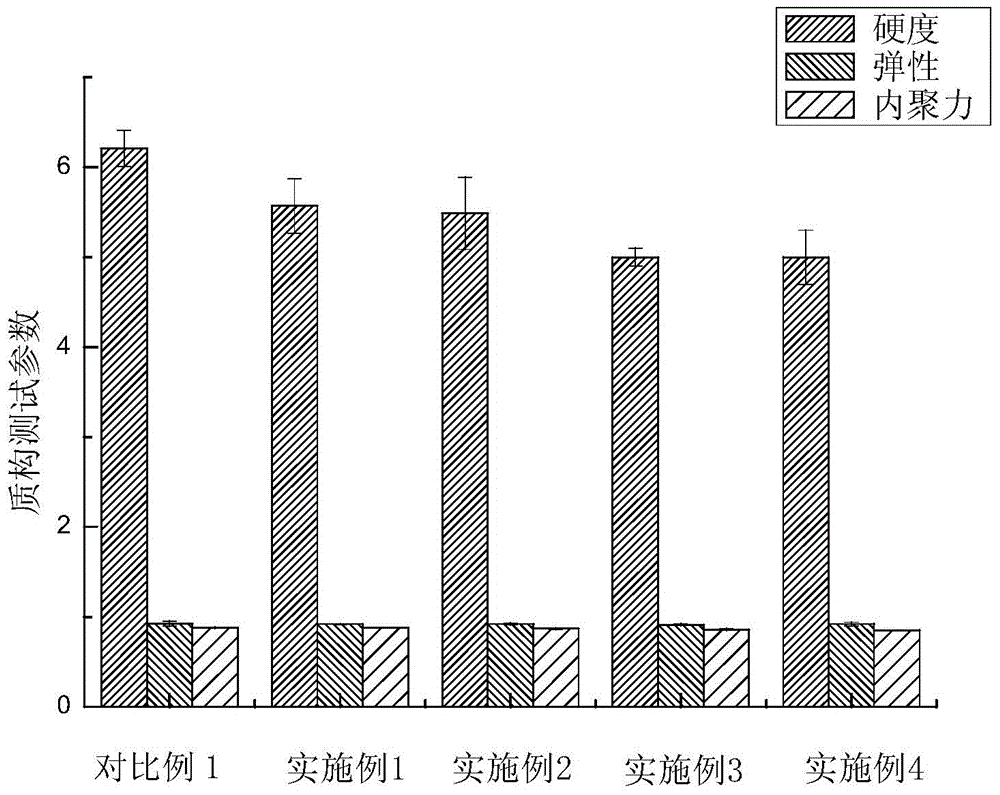

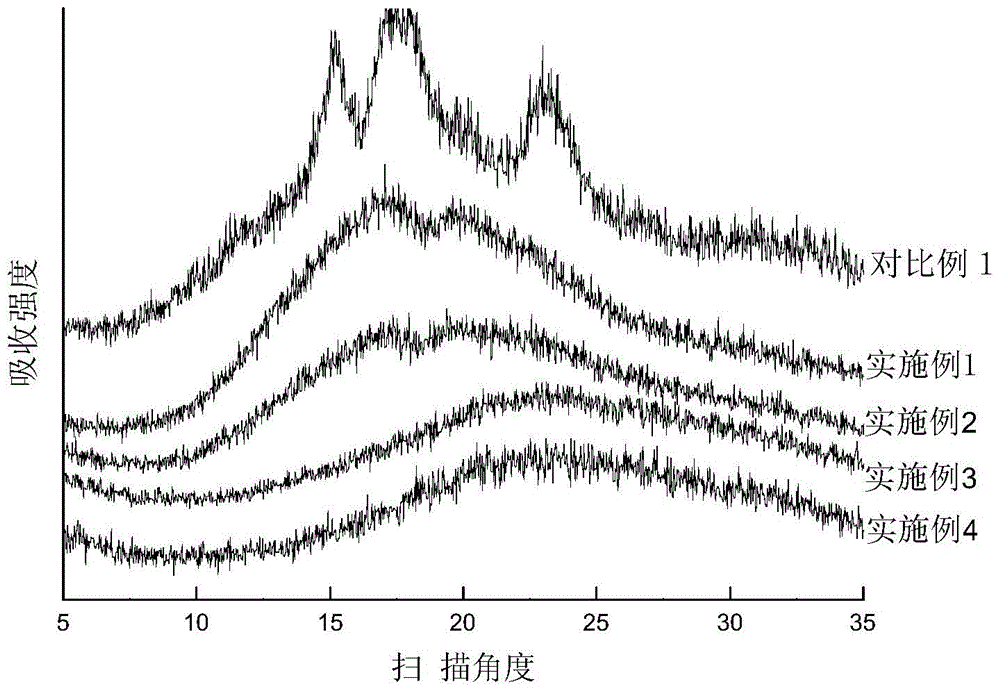

Corn viscose-starch gel and preparation method thereof

InactiveCN104472981AEasy processingImprove efficiencyFood preservationFood preparationProtein contentChemistry

The invention belongs to the technical field of the food processing and in particular relates to corn viscose-starch gel and a preparation method of the corn viscose-starch gel. Corn viscose is utilized to delay long-term ageing of starch gel, and the gel comprises the corn viscose and the starch, wherein the mass ratio of the starch to the corn viscose is 14:1-136:1, the content of protein in the corn viscose is 0.4-9%, the content of fat in the corn viscose is 0.24-0.5%, and the intrinsic viscosity of the corn viscose is 1.35-1.71dL / g; the gel is prepared by the following method, and the method comprises the steps of extracting corn viscose, preparing a corn viscose solution, preparing corn viscose-starch suspension, stirring, heating, gelatinizing, ageing corn viscose-starch gel, concentrating, carrying out freeze drying and testing. The method has simple processing procedures, the efficiency is high, the ageing phenomenon of the starch gel can be effectively delayed after the starch gel is stored for 14 days at low temperature, the quality of the starch gel after storage can be improved, and the corn viscose-starch gel has no obvious color change, and also has no unpleasant odor.

Owner:CHINA AGRI UNIV

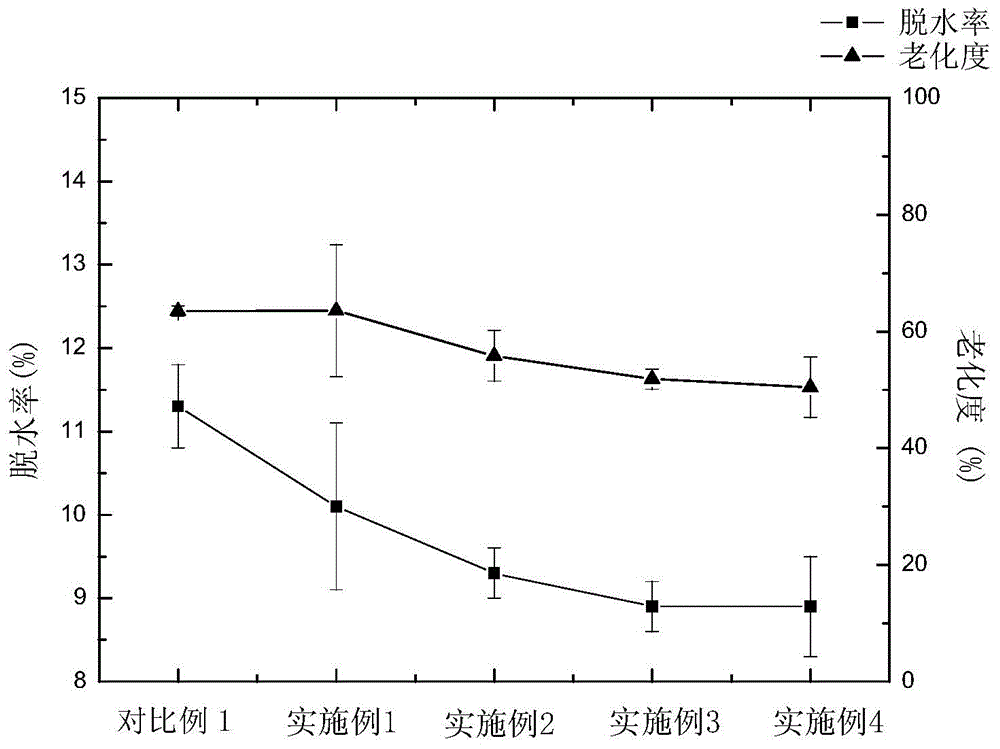

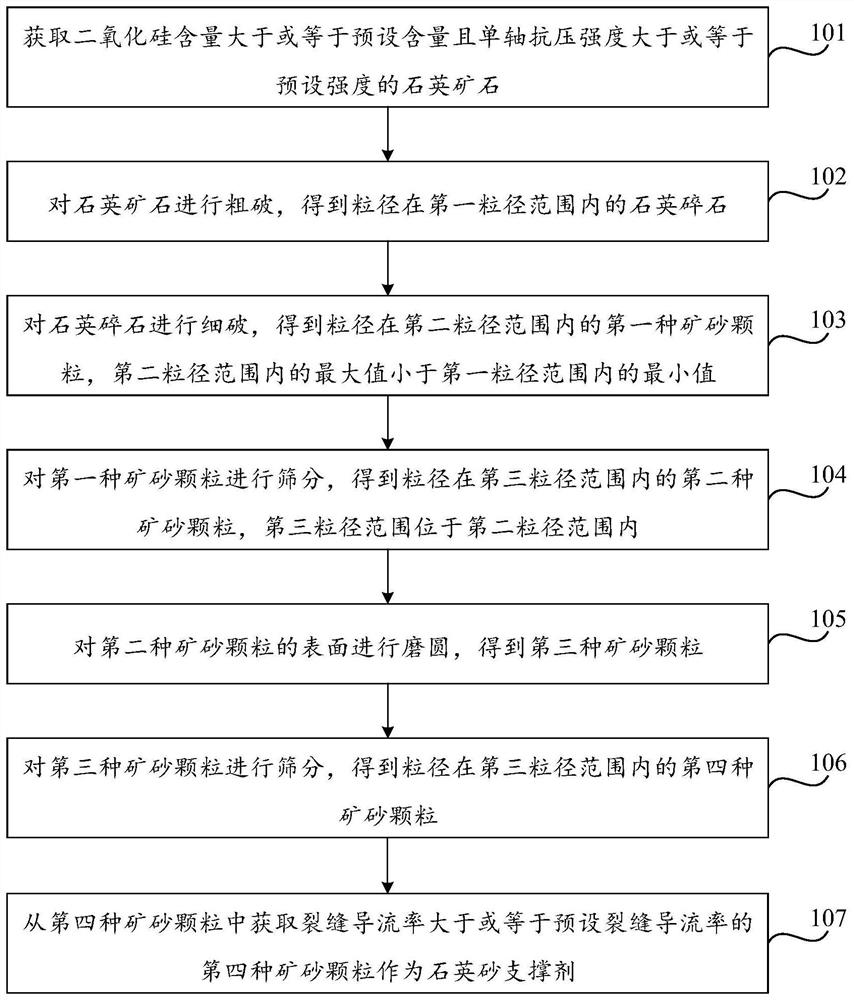

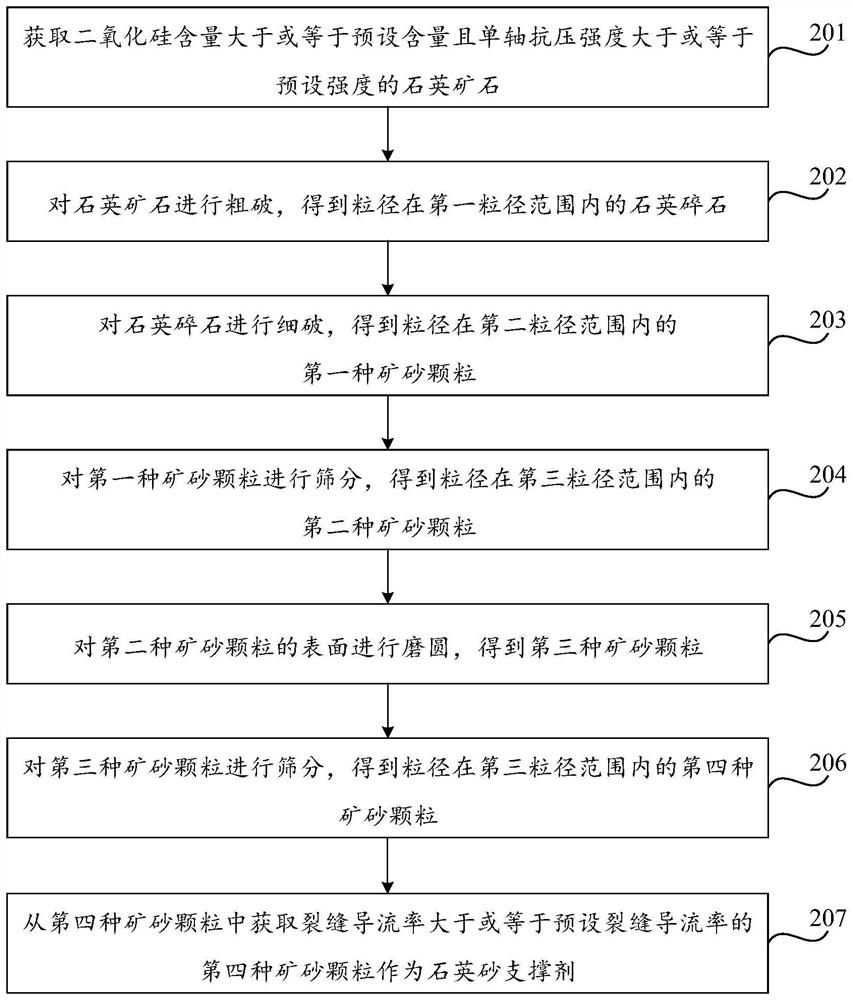

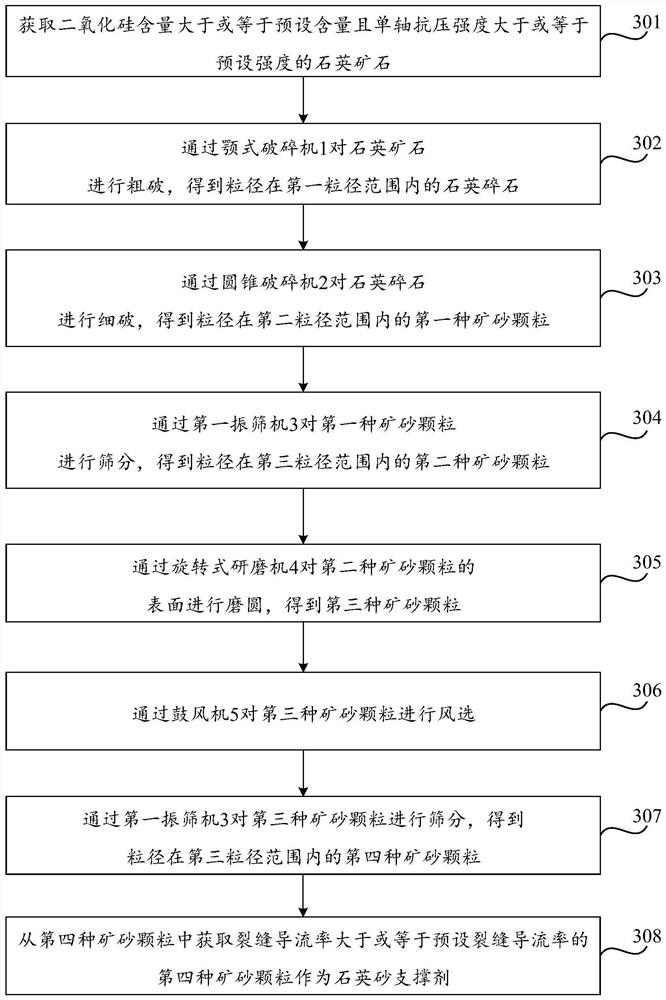

Processing method of quartz sand proppant

PendingCN111607384AEasy processingReduce processing costsFluid removalDrilling compositionPhysicsMineralogy

The invention discloses a processing method of a quartz sand proppant, and belongs to the technical field of shale fracturing. The method comprises the steps that: quartz ore with the silicon dioxidecontent being larger than or equal to preset content and the uniaxial compressive strength being larger than or equal to preset strength is obtained; the quartz ore is sequentially subjected to coarsecrushing, fine crushing and screening, so that second ore sand particles with the particle size being within a third particle size range are obtained; the surfaces of the second ore sand particles are rounded, third ore sand particles are obtained; the third ore sand particles are screened, fourth ore sand particles with the particle size within a third particle size range are obtained; and fourth ore sand particles with the crack flow conductivity greater than or equal to preset crack flow conductivity are obtained from the fourth ore sand particles as the quartz sand proppant . The quartz sand proppant can be obtained by processing the quartz ore which is wide in source and low in cost and serves as the raw material; a processing process is simple and convenient; and the processing costof the quartz sand proppant can be effectively reduced.

Owner:PETROCHINA CO LTD

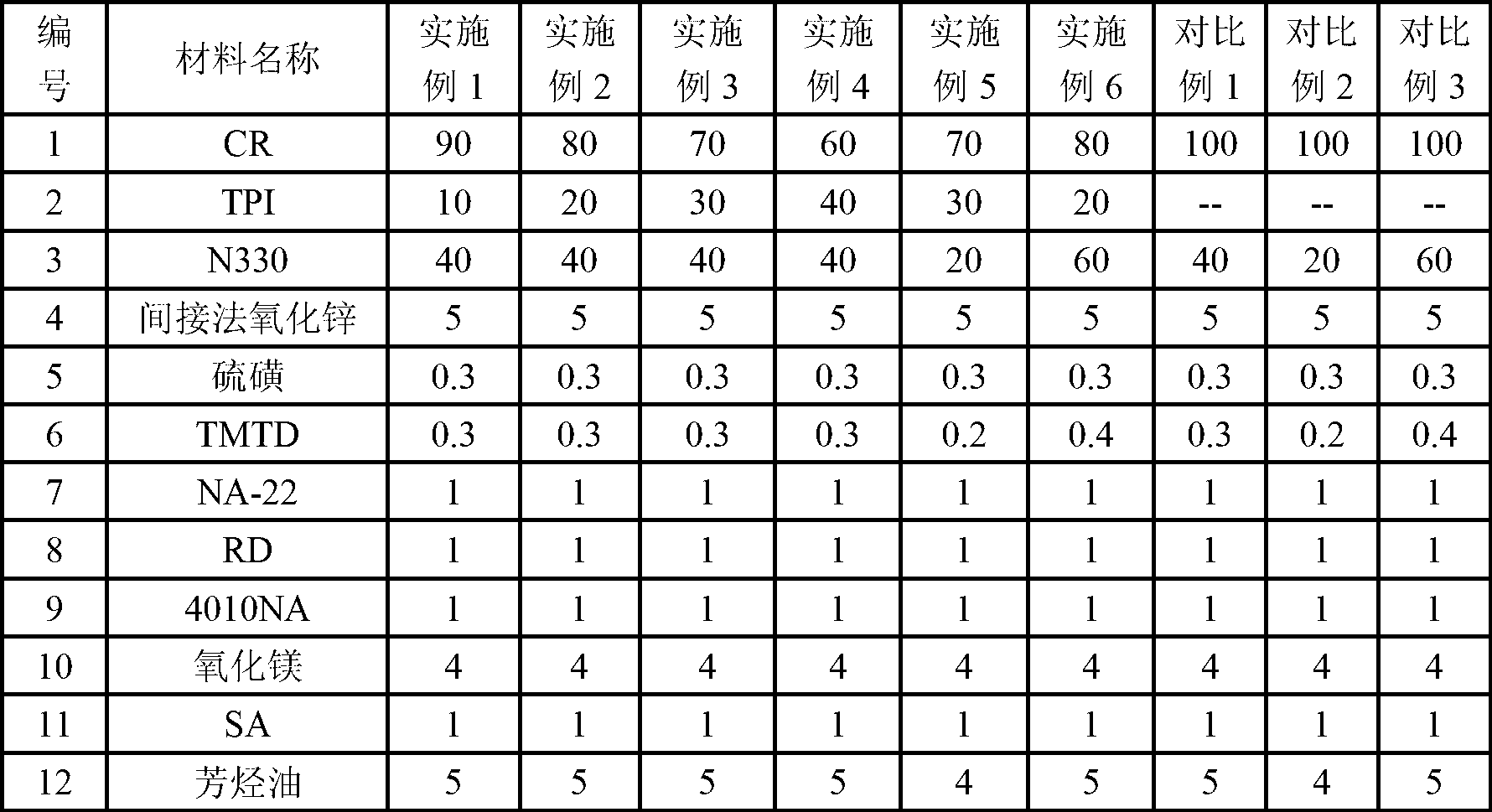

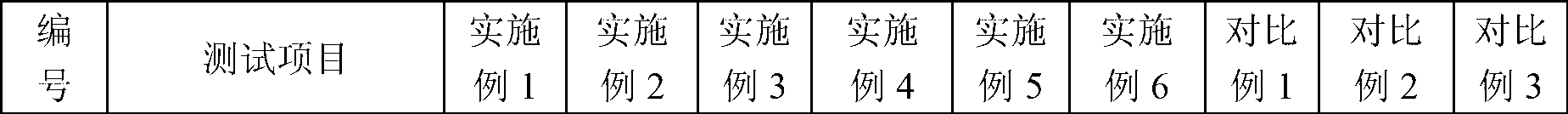

Low dynamic multiplying power antifatigue neoprene material and preparation method thereof

ActiveCN103059365AImprove fatigue resistanceLow dynamic magnificationRubber materialProcess equipment

The invention discloses low dynamic multiplying power antifatigue neoprene material and a preparation method thereof. The low dynamic multiplying power antifatigue neoprene material is composed of the following raw materials by weight, neoprene 60-90 portions, trans-1,4-polyisoprene 10-40 portions, carbon black 10-80 portions, accelerant 2-6 portions, vulcanizing agent 4-10 portions, antiager 2-5 portions, active agent 6-10 portions and operating auxiliaries 2-10 portions. The low dynamic multiplying power antifatigue neoprene material has the advantages that the trans-1,4-polyisoprene (TPI) is adopted to be functional auxiliaries of rubber, an ordinary rubber processing device is adopted to process, rubber materials achieved are capable of being improved in the antifatigue and lowered in the dynamic multiplying power, and convenient and simple to process.

Owner:SHANGHAI PRET COMPOSITES

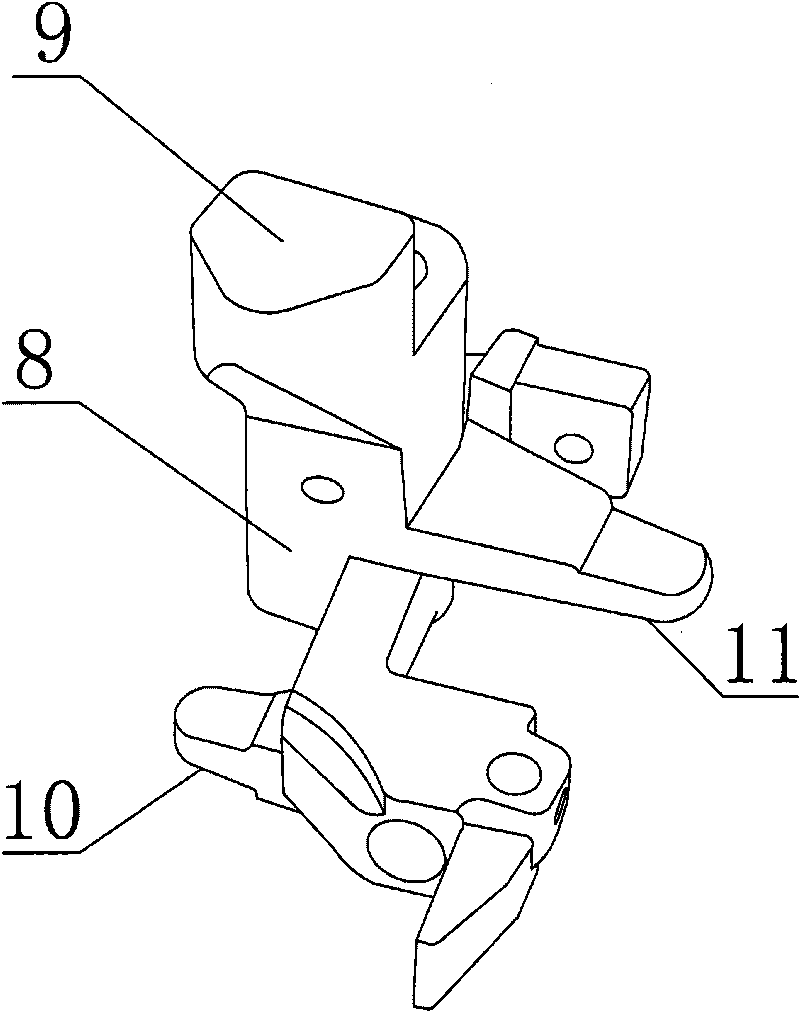

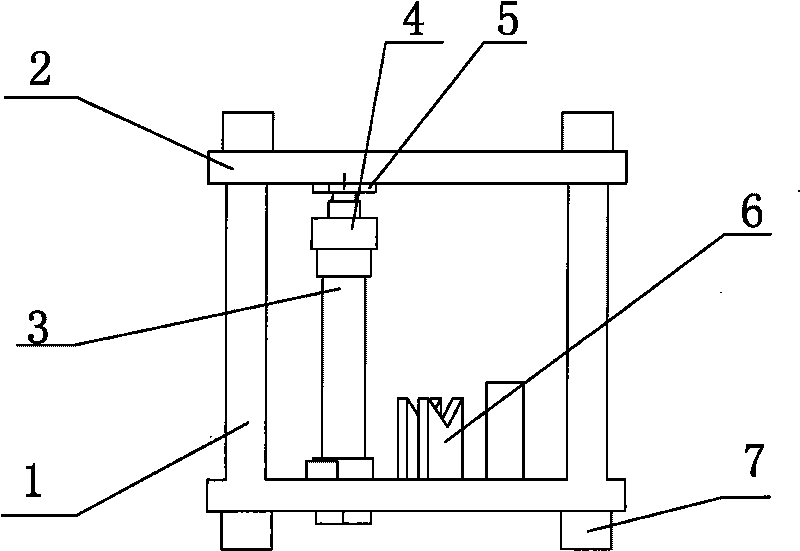

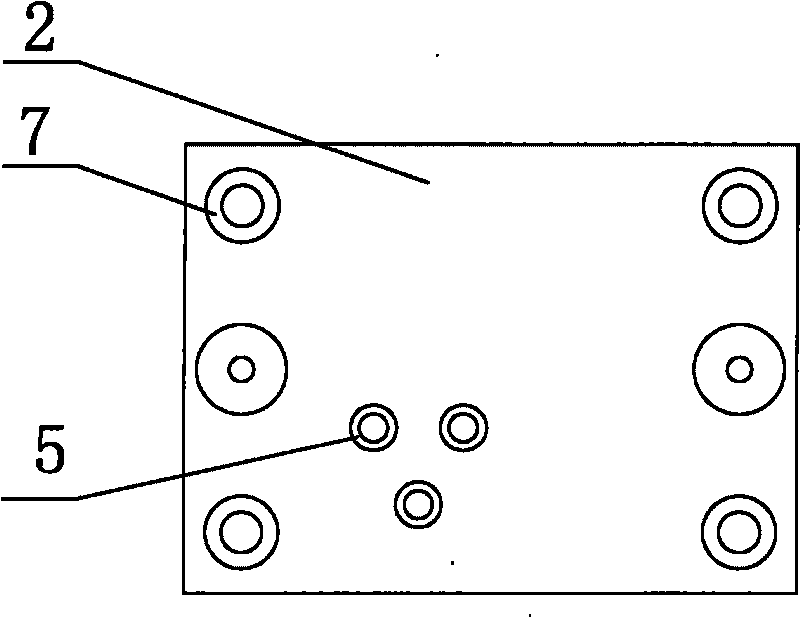

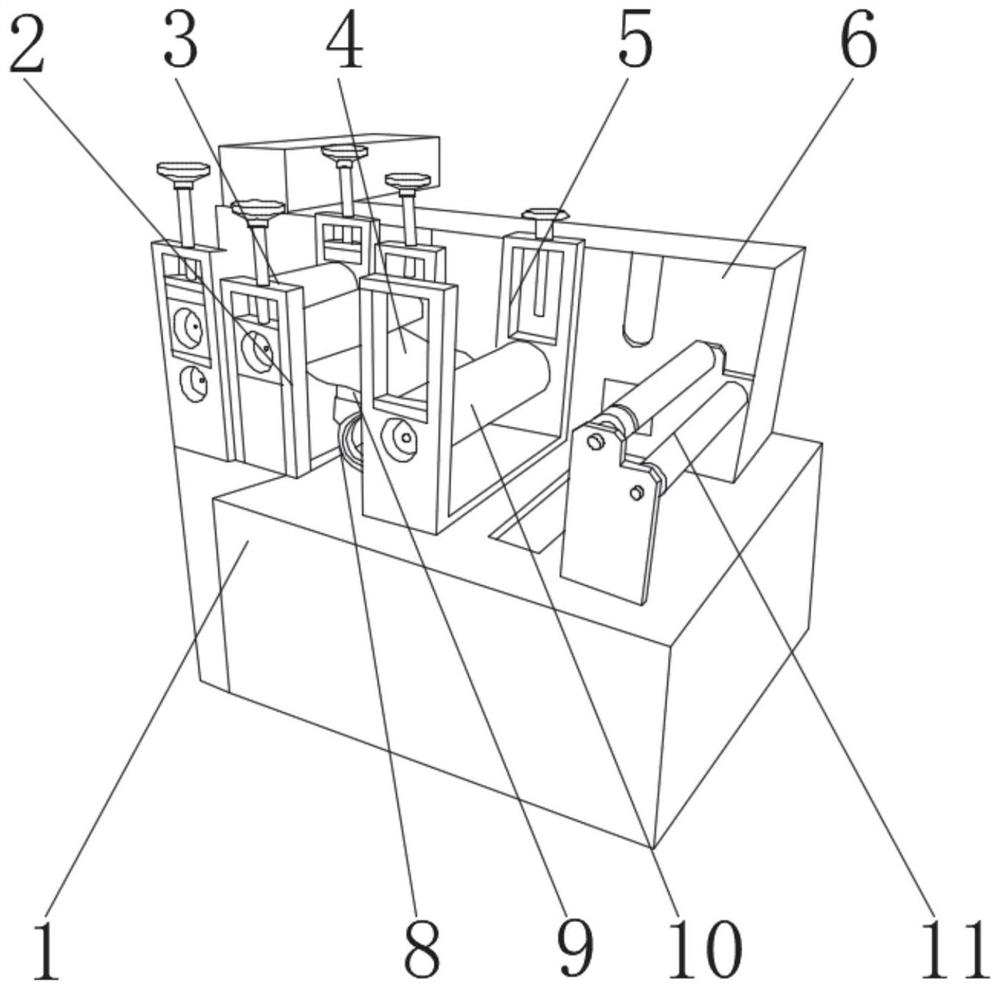

Double-face drilling jig

InactiveCN101722320AAvoid repeated positioning accuracy reductionEasy processingWork holdersBoring/drilling machinesDrill holeEngineering

Owner:WUJIANG WUGANG PUNCHING MACHINERY

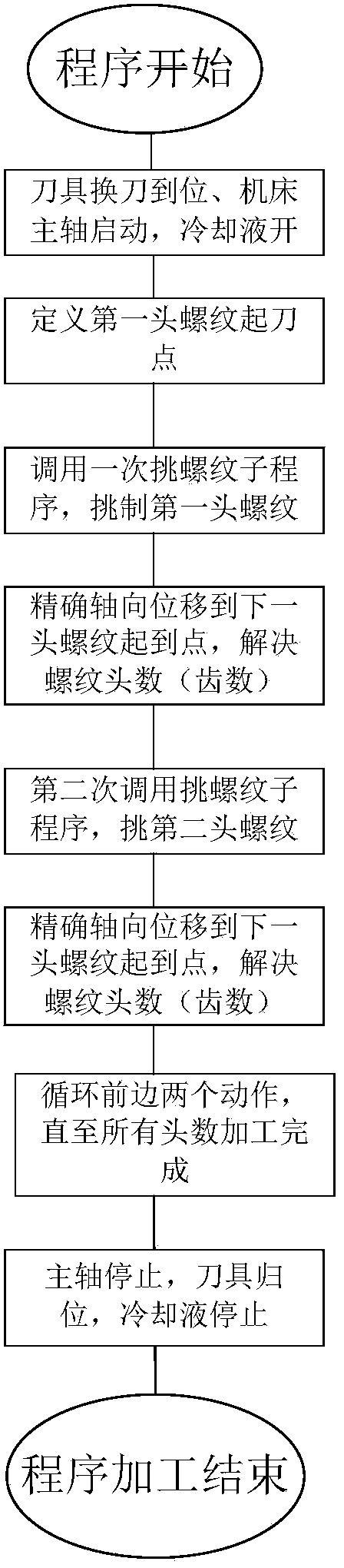

Spiral gear tooth form turning method

InactiveCN104384619AEasy processingStable and reliable processing technologyGear teethNumerical controlGear wheel

The invention provides a spiral gear tooth form turning method. Firstly, a cutter is designed and prepared; then, spiral parameters are determined; and finally, a numerical control lathe thread picking program is programmed according to the spiral parameters, and a numerical control lathe is controlled to use the prepared cutter for circularly picking threads to realize the spiral gear tooth form turning. The spiral gear tooth form turning method has the following beneficial effects: a numerical control turning method is adopted; such special complex forming cutters as tooth form slotting tool, milling cutter, hobbing cutter and broaching tool have no need to be customized; the spiral gear tooth form machining can be finished in a shorter period only by sharpening a single tooth form turning tool; and a convenient and reliable machining process is provided for the gear tooth form machining. The spiral gear tooth form turning method can be applied to a product development stage or a single small-batch production phase, is short in development stage, is much lower in tool cost, and is economic and practical.

Owner:SHAANXI AVIATION ELECTRICAL

Preparation process of conductive rubber

InactiveCN105061825AImprove product qualityImprove conductivityPlastic recyclingNon-conductive material with dispersed conductive materialRubber materialElectrically conductive adhesive

Relating to the technical field of rubber preparation, the invention discloses a preparation process of a conductive rubber. The process includes the following four processing steps: preparation of a rubber material, preparation of a conductive rubber material, desulfurization treatment and formation of a finished product. The preparation process of the conductive rubber provided by the invention has a simple and convenient processing procedure, and the produced conductive rubber product has good quality and good electrical conductivity, saves the production cost, employs low cost raw materials, has good performance, is clean and environment-friendly, thus meeting the needs of the vast majority of users. Also, the produced rubber has high leveling strength, small elongation, good shape preserving, light weight, good ageing resistance and water resistance, convenient installation and maintenance, provides a superexcellent solution for short supply of industrial conductive rubber, and is heavily favored by the majority of rubber users.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

Recycled butyl flame-retarding rubber preparing technology

The invention discloses a recycled butyl flame-retarding rubber preparing technology, and relates to the technical field of rubber material preparation. The recycled butyl flame-retarding rubber preparing technology comprises four processing steps of preparing banburying rubber, preparing rubber powder, preparing A rubber and forming a product. The recycled butyl flame-retarding rubber preparing technology has the advantages that a recycled butyl flame-retarding rubber processing process is easy and convenient to conduct, the produced product is good in quality and high in wear resistance, the production cost is saved, a made engine rubber pad is better in elasticity and toughness, the vibration reduction and noise reduction functions can be improved, the service life of the rubber pad is prolonged, bubbling is not likely to happen in the processing process, certain fragrant flavor is emitted, and the sealing performance is good.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

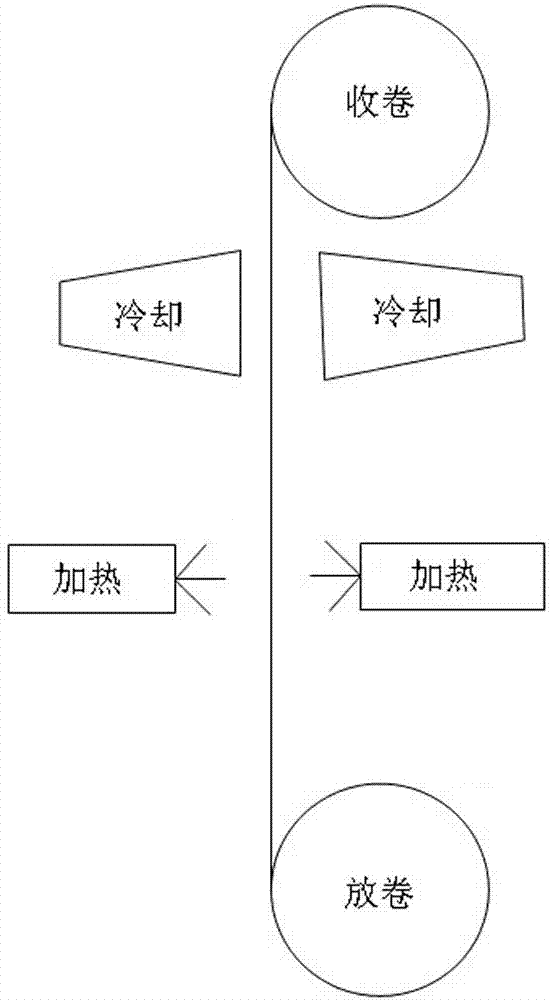

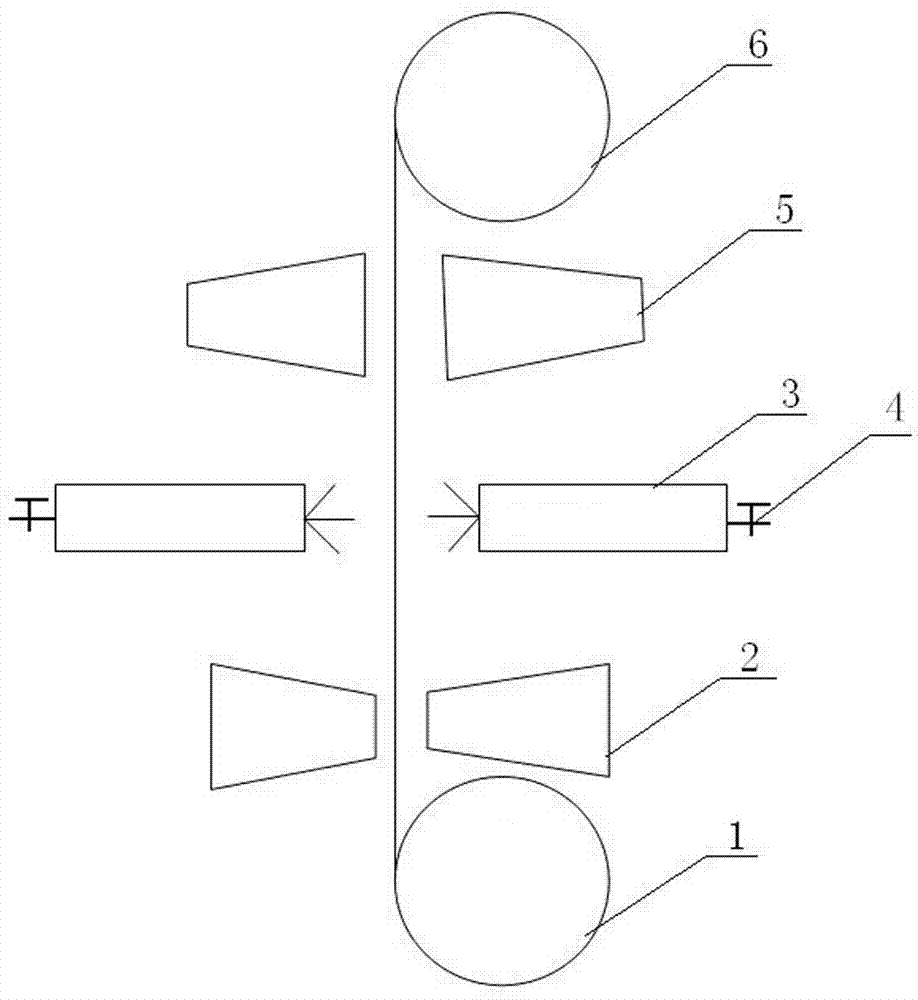

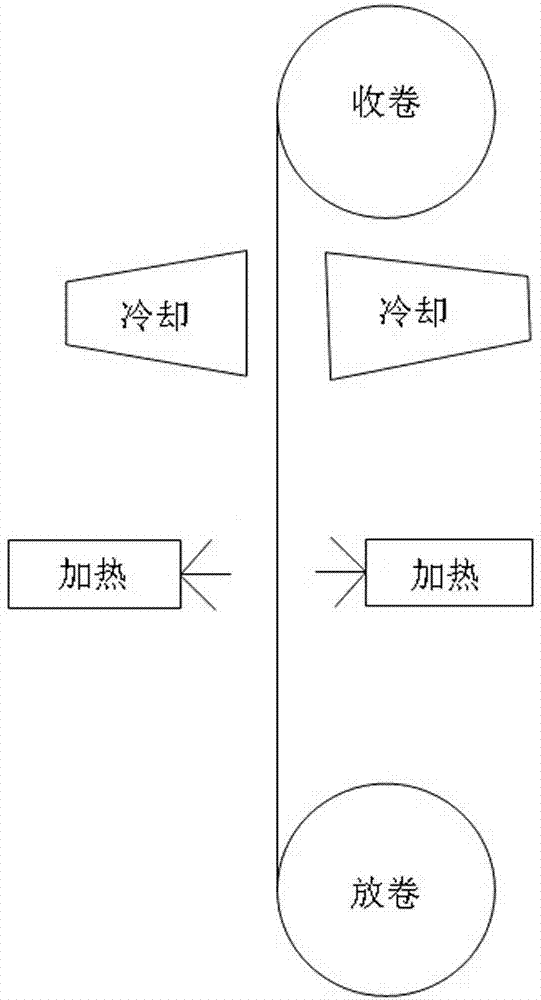

Method for preparing double-face flexible aluminum foil by spraying macromolecular composite PTC (phenylthiocarbamide) powder body through plasmas

InactiveCN103789712AEasy processingImprove production efficiency and high-quality product rateMolten spray coatingPhenylthiocarbamideFast speed

The invention discloses a method for preparing double-face flexible aluminum foil by spraying macromolecular composite PTC (phenylthiocarbamide) powder body through plasmas. The method comprises the following steps of (1) preparing the macromolecular composite PTC powder body; (2) heating an aluminum foil to 100-300 DEG C through a heating device, coating the macromolecular composite PTC powder body prepared in the step (1) on the aluminum foil through plasma spraying equipment, thus forming a macromolecular composite PTC powder body coating layer on the aluminum foil; (3) baking the aluminum foil which is coated with the macromolecular composite PTC powder body coating layer in the step (2), and performing recrystalization technology to obtain the double-face flexible aluminum foil. Compared with the prior art, the method has the advantages that the working process is simple; the production efficiency and the yield can be improved, and the thickness consistency of a product is high; the quality and the reliability of the prepared double-face flexible PTC aluminum foil are high; the thermosensitive reaction is quick and accurate, and the capacity adjustment is facilitated.

Owner:ZHONGYUAN ENGINEERING COLLEGE

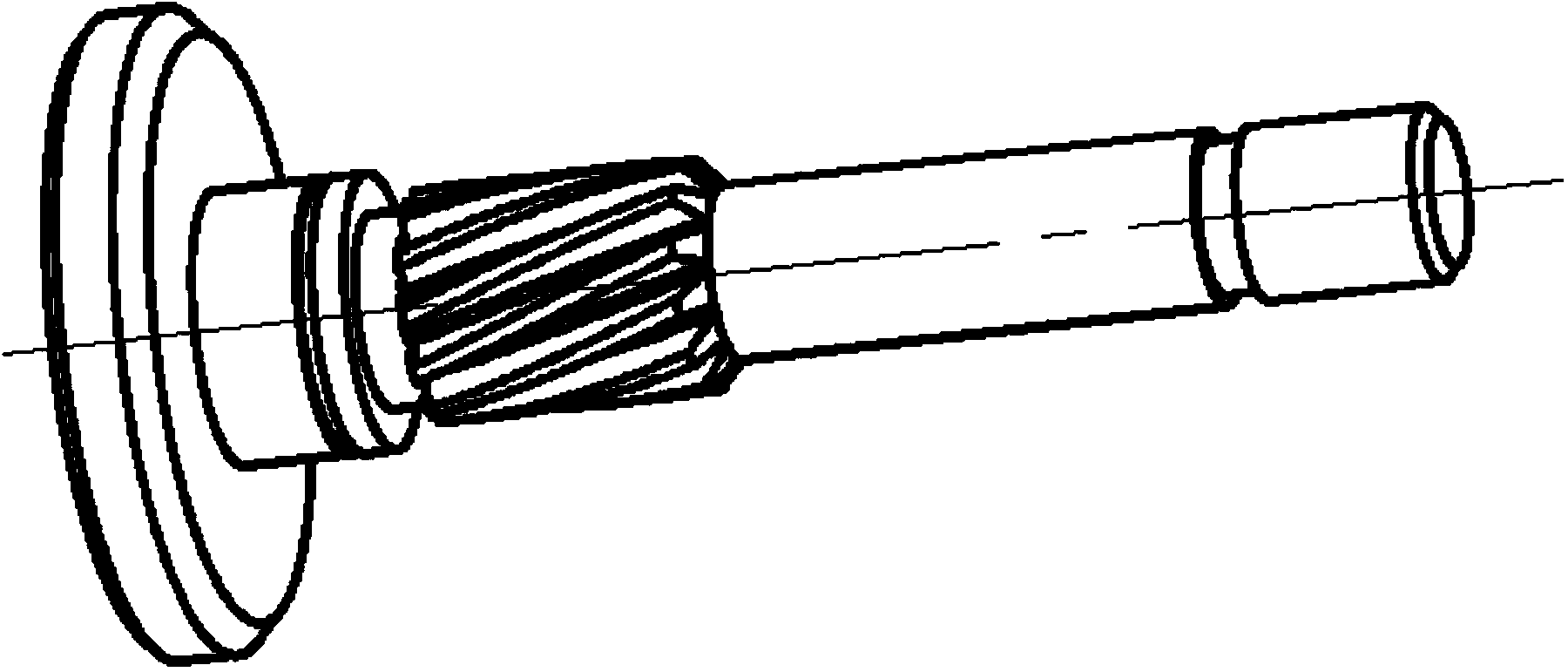

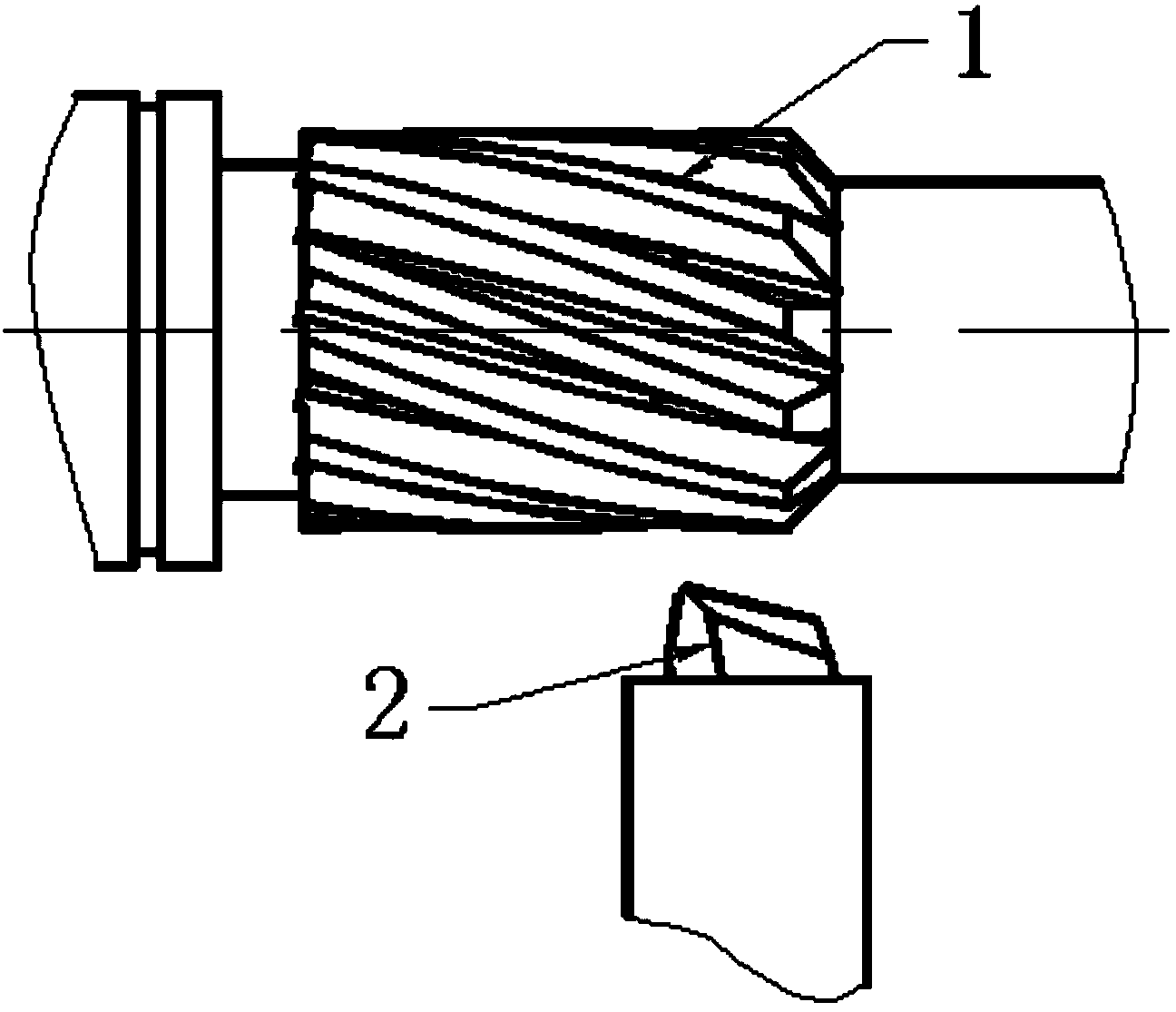

Spiral elastic coupler machining method

InactiveCN104259786AEasy processingImprove processing efficiencyYielding couplingEngineeringMachining process

The invention discloses a spiral elastic coupler machining method, and relates to the field of machining. The method includes the steps: turning an outer circle and the length of a spiral elastic coupler, and reserving a 20mm long mounting technology head; linearly cutting a feed groove and a relief groove; turning a spiral groove in a lathe; clamping the outer circumference of a workpiece by the aid of an elastic sleeve, turning an inner hole in one end of the workpiece, cutting the technology head after the workpiece is turned around, turning an end face and turning an inner hole in the other end of the workpiece; drilling a bottom hole and tapping a threaded hole by a bench worker. The length of the workpiece is a required size, and two inner holes are communicated. The method is simple and convenient in machining process and high in machining efficiency, and higher machining accuracy can be ensured.

Owner:SHAANXI QIYUAN TECH DEV

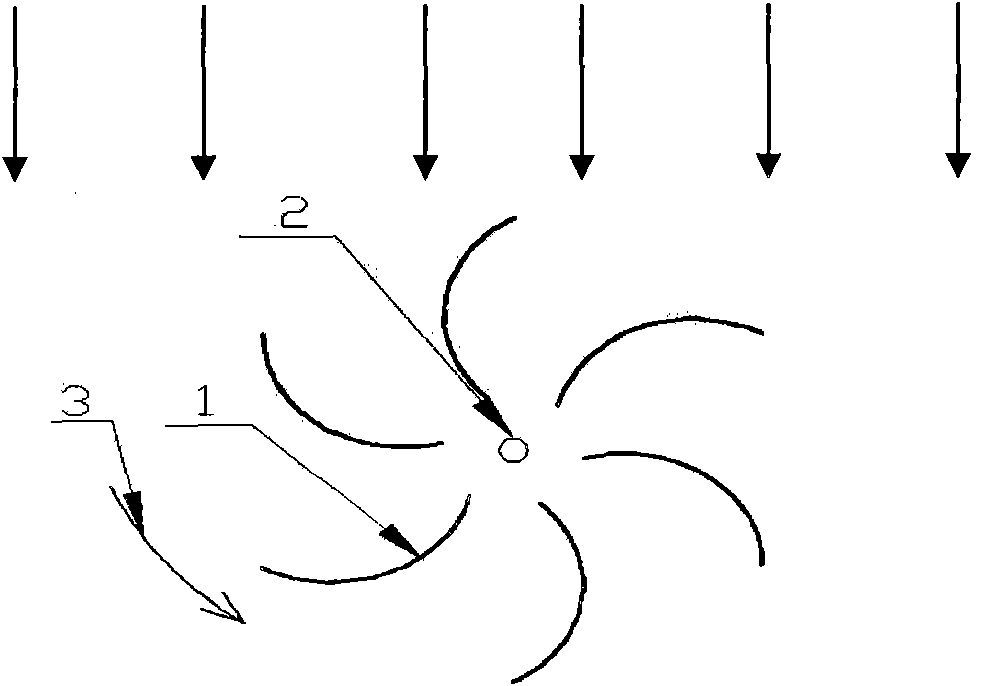

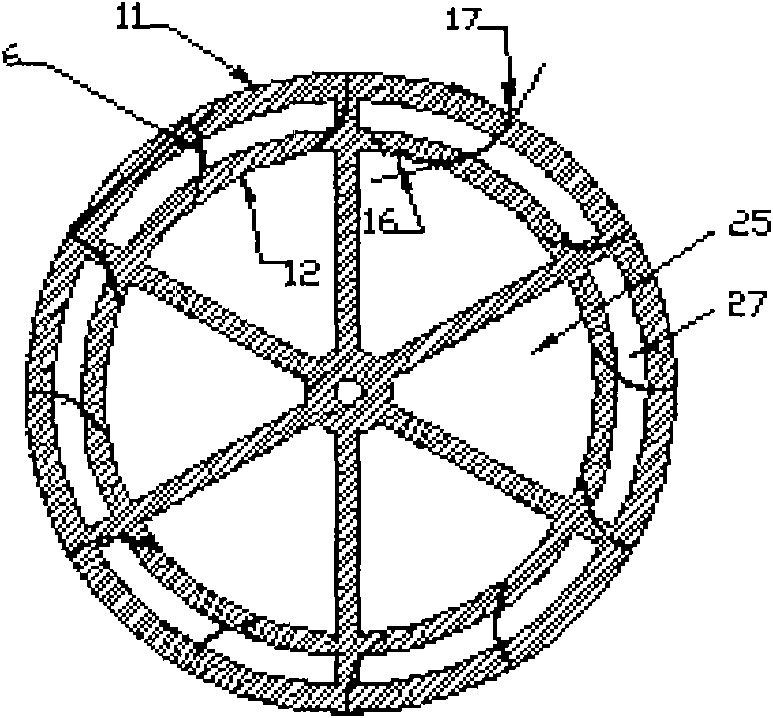

Guide-type vertical-axis wind turbine with multisection combined vanes

InactiveCN101793224AReduce wind resistanceReduced Viscous DissipationMachines/enginesRenewable energy generationEngineeringVertical axis wind turbine

The invention relates to a guide-type vertical-axis wind turbine with multisection combined vanes, which comprises an inducer and a wind wheel, wherein guide vanes in the inducer are composed of an inlet radial section, a middle transitional section and an outlet guide section, and form a smooth curve composed of two straight-line segments and a circular arc which is respectively tangent to the two straight-line segments; vanes in the wind wheel are composed of an inlet circular arc section and an outlet straight-line segment; and the upper cover plates and the lower cover plates of the inducer and the wind wheel are respectively provided with vent holes. The invention has the advantages of strong wind energy collection capability, low flow loss, high guide property, high aeroperformance, simple processing technique and the like, and has the characteristic of high utilization ratio of wind energy.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Robot sweeping rag ultrasonic bonding and cutting device

The invention discloses a robot sweeping rag ultrasonic bonding and cutting device. The device comprises a device main body and a feeding frame, wherein a cutting frame, a driving seat, a bonding frame and a feeding frame are arranged at the upper end of the device main body, the bonding frame is located on one side of the feeding frame, the cutting frame is located on one side of the bonding frame, a cutting roller way is arranged on the inner side of the cutting frame, a waste chip clearing machine and a heating plate are arranged between the cutting frame and the bonding frame, and the heating plate is located at the upper end of the waste chip clearing machine. According to the robot sweeping rag ultrasonic bonding and cutting device, the ultrasonic bonding roller way, the heating plate and the waste chip clearing machine are arranged, the rag can be conveniently and better processed and treated, the heating performance is achieved, the toughness of the rag is improved, the rag is not prone to damage, the device is more durable, waste chips can be conveniently collected and treated, confusion is prevented, better use is facilitated, and better use prospects are brought.

Owner:苏州恒富清洁科技有限公司

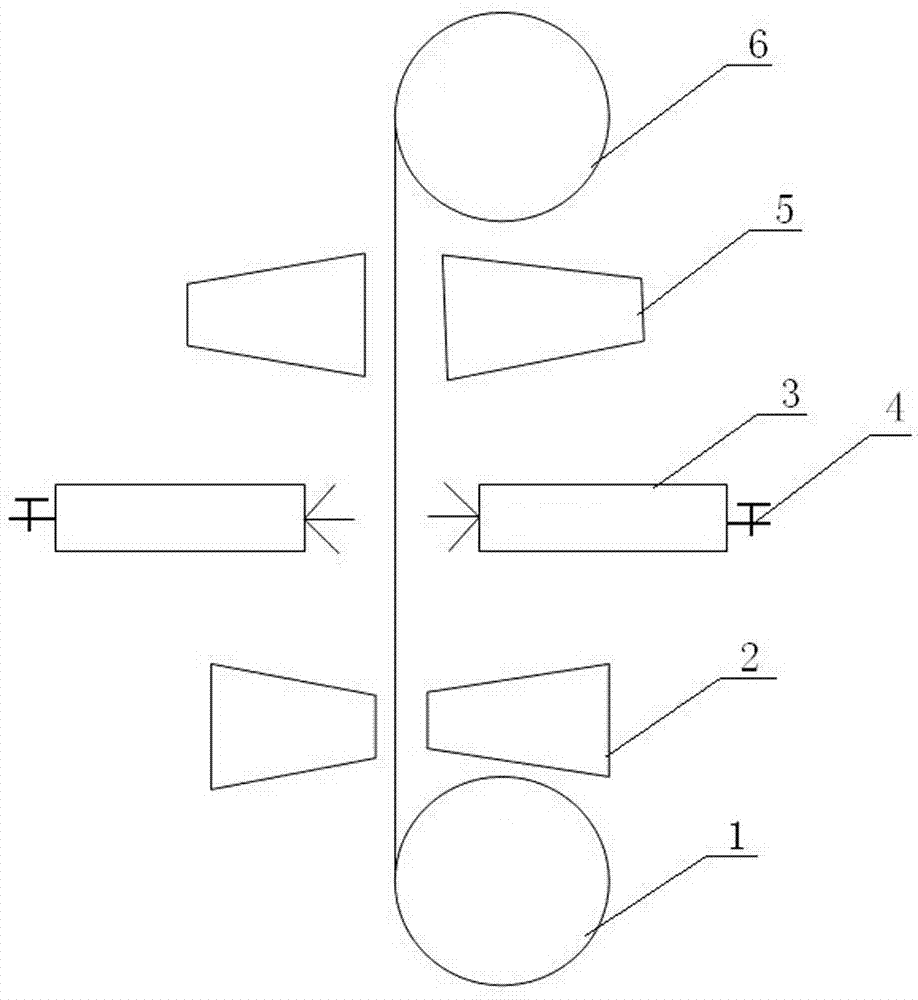

Method for preparing double-sided flexible copper foil by sprinkling polymer composite PTC powder through powder sprinkling device

InactiveCN103785593AEasy processingImprove production efficiency and high-quality product rateLiquid surface applicatorsCoatingsCopper foilPolymer composites

The invention discloses a method for preparing double-sided flexible copper foil by sprinkling polymer composite PTC powder through a powder sprinkling device. The method includes the following steps of firstly, preparing the polymer composite PTC powder; secondly, heating copper foil through a heating device till the temperature reaches 160 DEG C to 450 DEG C, sprinkling the polymer composite PTC powder prepared in the first step on the copper foil through the powder sprinkling device, and forming a polymer composite PTC powder coating on the copper foil; thirdly, baking the copper foil where the polymer composite PTC powder coating is sprinkled in the second step, and obtaining the double-sided flexible copper foil through the recrystallization process. Compared with the prior art, the method has the advantages that the machining process is easy and convenient, the production efficiency and the yield rate can be improved, the thickness consistency of products is high, the prepared double-sided flexible PTC copper foil is high in quality and reliability, high in sensitive reaction speed and accurate in thermal sensitive reaction, and capacity adjustment is convenient.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Pinellia ternate producing area processing and preparing technology

PendingCN114470082AGuaranteed freshGuaranteed qualityPlant ingredientsMedicinal herbsProcess engineering

Compared with the prior art, the pinellia ternate is processed in the production place, so that the freshness of the pinellia ternate is ensured, and compared with a traditional fermentation process, the qualitative change of the pinellia ternate medicinal material is avoided, so that the pinellia ternate can be fresh and treated in time; corrosion of the pinellia ternate is avoided, the quality of the pinellia ternate medicinal material is guaranteed, the processing technology is convenient and rapid, use is convenient, and application and popularization value is achieved.

Owner:甘肃工业职业技术学院

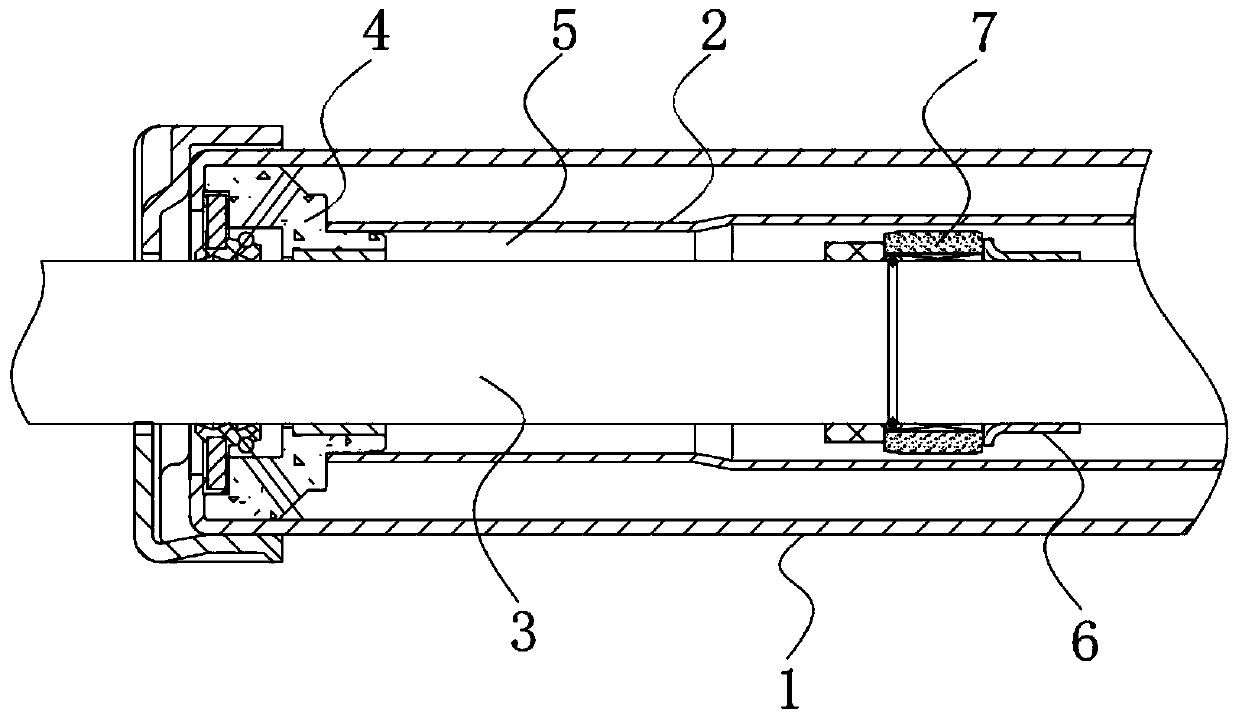

Diameter change type hydraulic buffer structure automobile shock absorber assembly

PendingCN110645303AStrong buffer effectEasy processingSpringsLiquid based dampersPhysicsReciprocating motion

The invention provides a diameter change type hydraulic buffer structure automobile shock absorber assembly, and relates to the technical field of automobile parts. The diameter change type hydraulicbuffer structure automobile shock absorber assembly comprises a body. A work cylinder is arranged in the body. A guide device is arranged on the end portion of the work cylinder. Necking diameter change processing is conducted on the end, close to the guide device, of the work cylinder. A piston rod is arranged in the work cylinder. The free end of the piston rod penetrates through the guide device and extends to the outer portion of the body. The portion, located on the area subjected to necking diameter change, in the work cylinder is arranged into a buffer zone. An inner limiting part is arranged on the outer surface of the piston rod. A buffer is fixedly installed on the outer surface of the inner limiting part. By conducting necking diameter change processing on the work cylinder, thedamping of the buffer zone can be larger than two or more times of the normal shock absorber recovery damping force, the buffering power value is increased in a doubled manner according to the reciprocation speed, and a strong buffering effect is achieved.

Owner:ZHEJIANG WENDA SHOCK ABSORBER

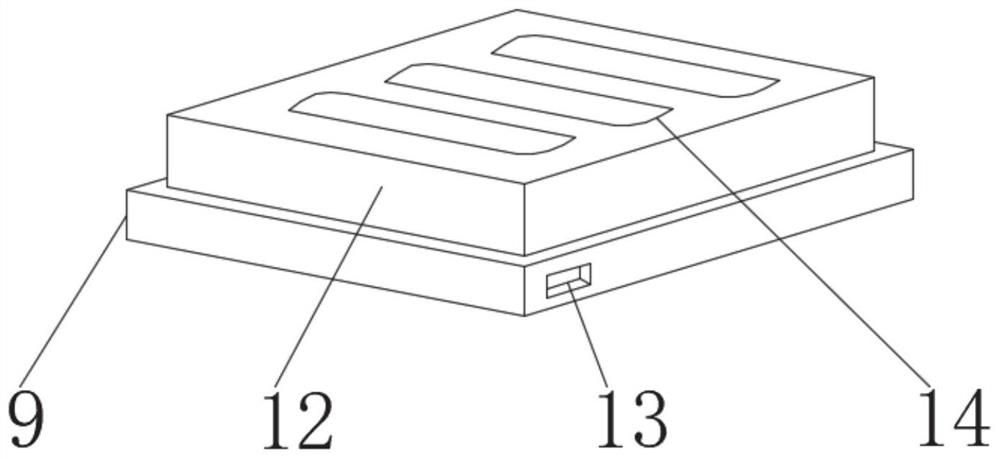

An electroless, environment-friendly magnetic core inductor and its processing technology

ActiveCN104934190BAvoid damageImprove the induction effectTransformers/inductances coils/windings/connectionsCoils manufactureEpoxyCopper wire

The invention relates to an electroless-plated and environment-friendly magnetic core inductor and a processing process thereof. The inductor comprises a base body, wherein the base body comprises an upper end surface and a lower end surface; a concave part between the upper end surface and the lower end surface is wound with enamelled copper wires; concave parts on two sides of the upper end surface are provided with copper foils; the copper foils are connected with the enamelled copper wires; an adhesive layer is arranged on the surfaces of the enamelled copper wires; an anti-rust layer is further arranged on the surface of the base body; the base body is a ferrite iron core; and the adhesive layer is formed by mixing epoxy resin with a magnetic material. The processing process sequentially comprises the following steps of: copper foil pasting, winding and tin soldering, gluing, external inspection, testing, code spraying, packaging and warehousing. The inductor provided by the invention has a very good effect of protecting the enamelled wires as well as very good induction effect in actual operation; the damage of electronic products caused by excessive instantaneous current can be prevented; the processing process optimizes the deficiencies in the prior art, so that the processing process is more convenient and rapider and can meet existing processing needs.

Owner:TAI TECH ADVANCED ELECTRONICS SI HONG

Ginkgo seed preparation method

The invention discloses a ginkgo seed tea preparation method. The ginkgo seed preparation method comprises the following steps: (1) selecting high-quality, mature and full ginkgo seed fruits, cleaning and hulling; (2) slicing the ginkgo seed fruits and removing cores; (3) immersing the ginkgo seed fruit slices in honey for 1-2 hours, and then steaming the ginkgo seed fruit slices with honeydew in boiled water for 15-20min to remove bitterness and toxin; (4) filtering the honeydew on the steamed ginkgo seed fruits, and airing for 4-6h at ventilating and shading places; (5) dehydrating the aired ginkgo fruit slices, drying and sterilizing; and (6) standing the dehydrated, dried and sterilized ginkgo fruit slices in vacuum, cooling to room temperature and storing, thus obtaining the ginkgo seed tea. According to The ginkgo seed preparation method, a processing process is simple and convenient, the nutritional ingredients of the ginkgo seeds are effectively retained, and the ginkgo seed tea tastes sweet, is suitable for batch production and meets the drinking demands of people.

Owner:徐州太阳泉生态农业科技有限公司

Method for preparing flexible double-sided aluminum foil by spraying polymer composite positive temperature coefficient (PTC) powder through powder spraying device

InactiveCN103789762AEasy processingImprove production efficiency and high-quality product rateHeat inorganic powder coatingPolymer compositesPositive temperature

The invention discloses a method for preparing flexible double-sided aluminum foil by spraying polymer composite positive temperature coefficient (PTC) powder through a powder spraying device. The method comprises the steps of (1) preparing the polymer composite PTC powder; (2) heating the aluminum foil to 160-450 DEG C by a heating device, and spraying the polymer composite PTC powder obtained in the step (1) onto the aluminum foil through the powder spraying device to form a polymer composite PTC powder coating on the aluminum foil; (3) baking the aluminum foil coated with the polymer composite PTC powder coating in the step (2), and carrying out a recrystallization technology to obtain the flexible double-sided aluminum foil. Compared with the prior art, the method is simple and convenient in processing process, improves the production efficiency and the yield, and is high in product thickness consistency; the prepared flexible double-sided PTC aluminum foil is high in quality reliability, rapid in speed of thermosensitive reaction, accurate and convenient in capacity adjustment.

Owner:ZHONGYUAN ENGINEERING COLLEGE

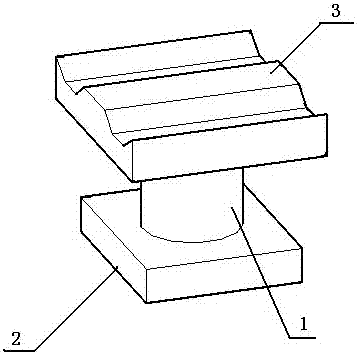

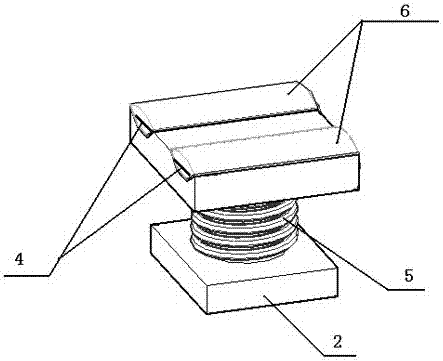

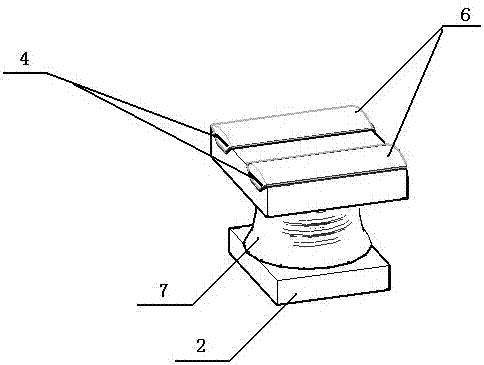

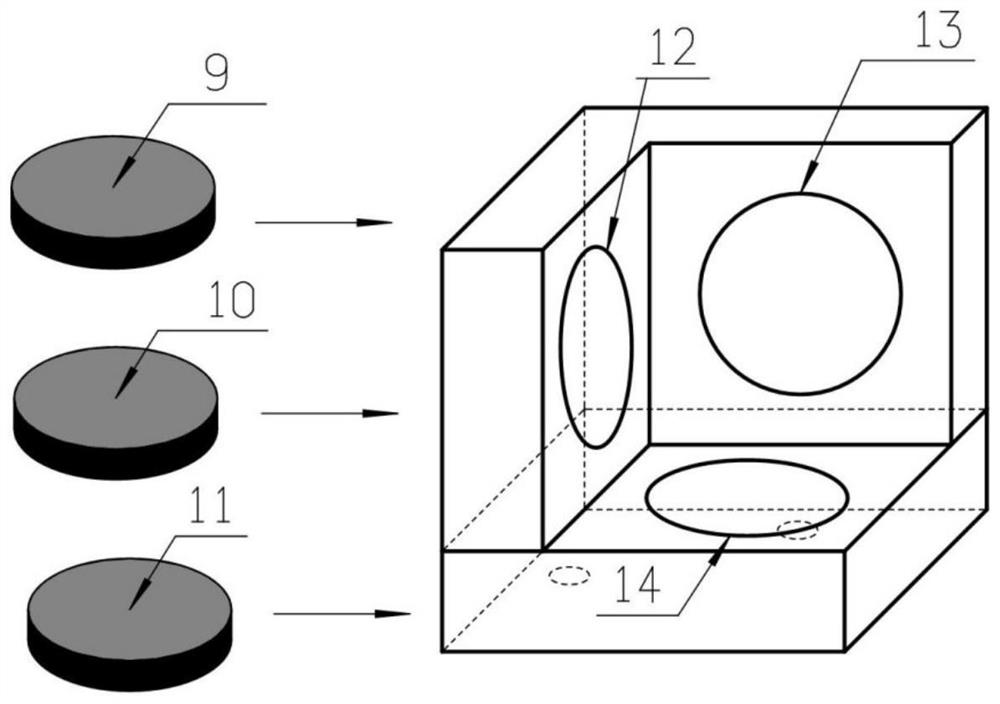

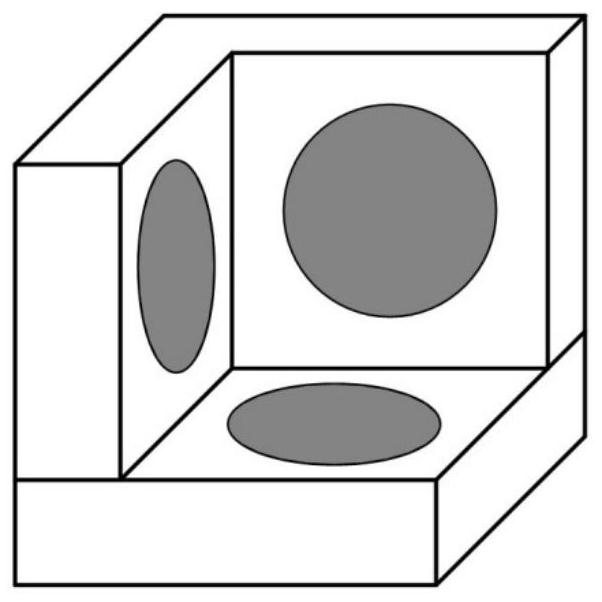

High-precision cube-corner prism and manufacturing method thereof

According to the high-precision cube-corner prism and the manufacturing method, the problems that in the prior art, the optical cube-corner machining process is extremely complex, and the machining cost is high are solved, the machining precision is high by adopting a mechanical cube-corner machining method, and the high-precision optical cube-corner can be achieved. The invention comprises a square substrate and an integral-structure right-angle substrate, and three planar substrates of the square substrate and the integral-structure right-angle substrate, which are mutually vertical in pairs, form three-dimensional space cubic corners. A mounting base I, a mounting base II and a mounting base III which are matched with the optical plane mirror I, the optical plane mirror II and the optical plane mirror III are respectively arranged on the three plane substrates, and the optical plane mirror I, the optical plane mirror II and the optical plane mirror III are respectively arranged on the mounting base I, the mounting base II and the mounting base III.

Owner:XIAN TECHNOLOGICAL UNIV

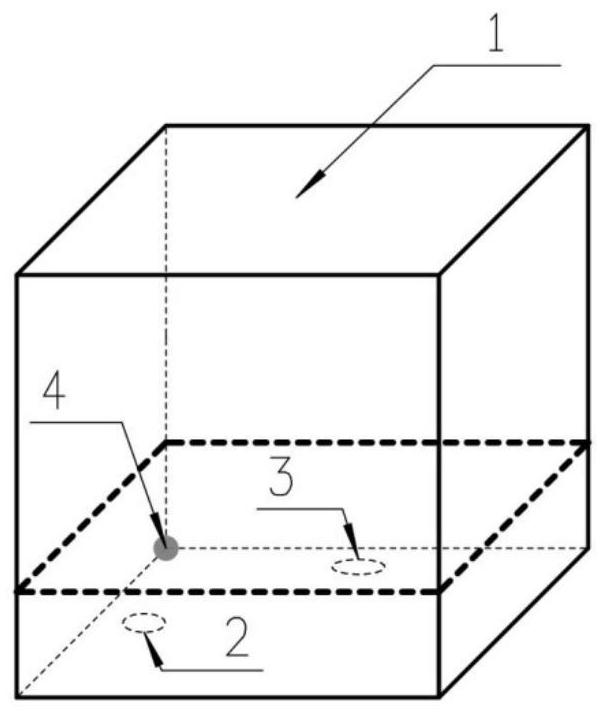

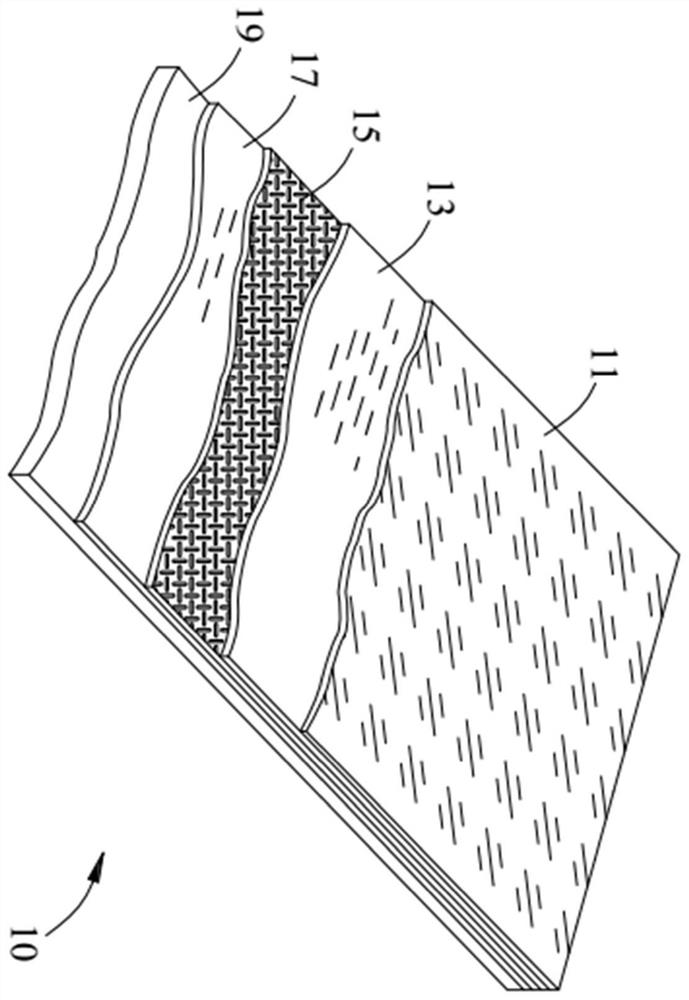

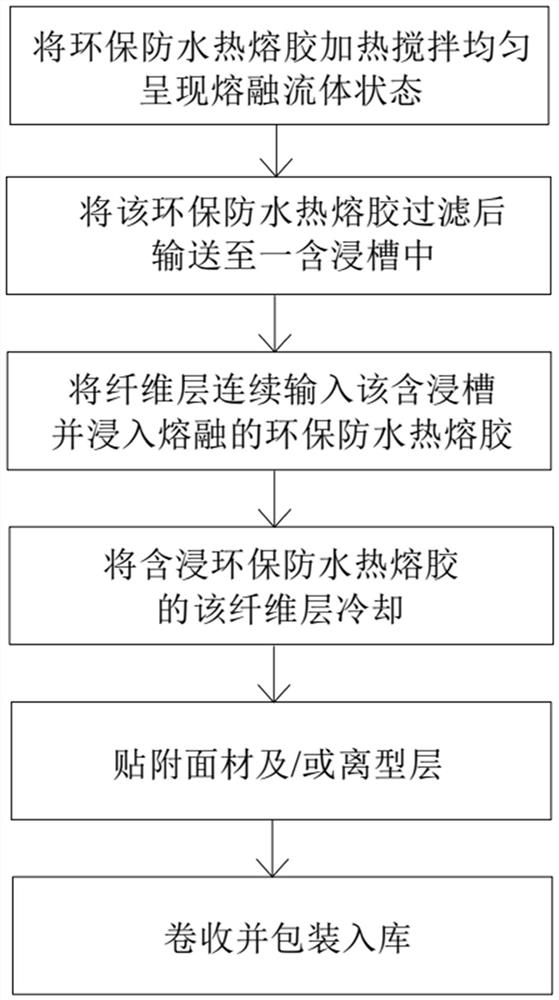

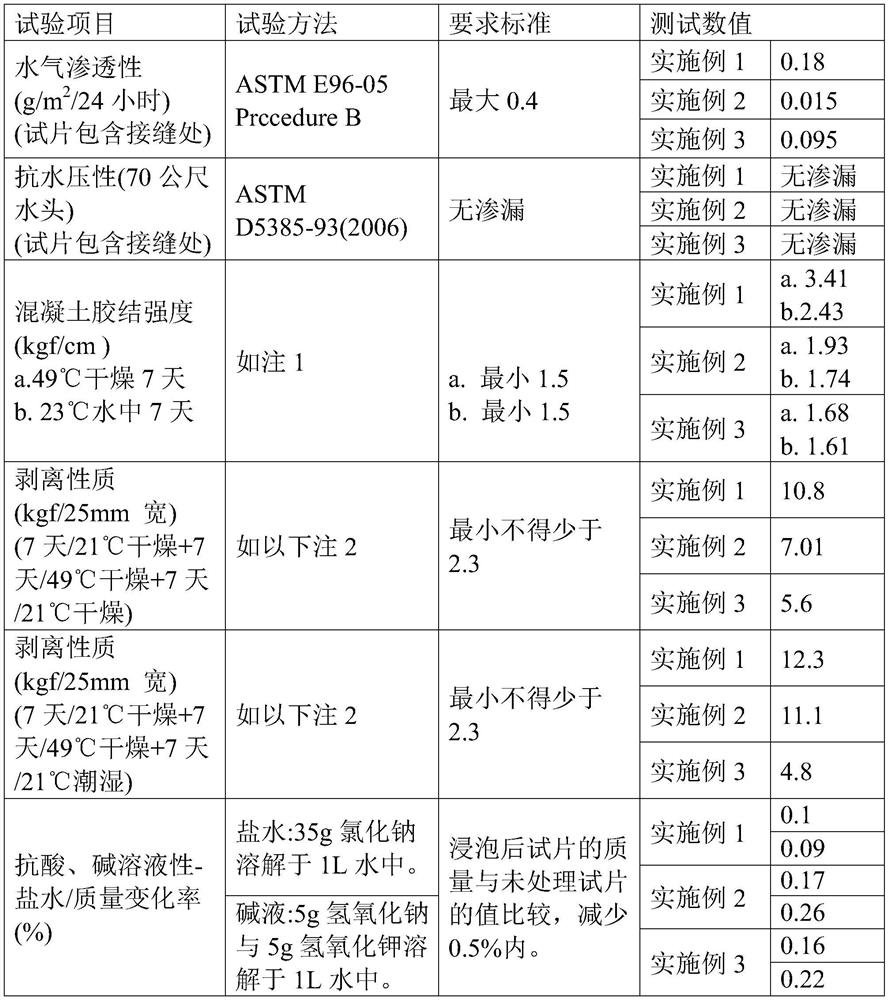

Environment-friendly waterproof hot melt adhesive formula and membrane material and production process thereof

PendingCN112852358AEnvironmentally friendlyDoes not produce volatile substancesMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesOrganic solventProcess engineering

The invention discloses a waterproof hot melt adhesive environment-friendly formula and a membrane material and a production process thereof, the raw materials of the waterproof hot melt adhesive formula do not contain asphalt components or organic solvents, the waterproof hot melt adhesive formula has the advantage of environmental protection, volatile substances or pungent and odorous smell cannot be generated in the production and manufacturing process of manufacturers, and is environment-friendly for factory workers and the environment, is easy to produce, the waterproof hot melt adhesive membrane material has excellent waterproof, weather-proof and self-adhesion properties through tests, is easy to process and construct, has excellent product quality and reasonable price, and really has good practical and economic values.

Owner:CHERNG TAY TECH CO LTD

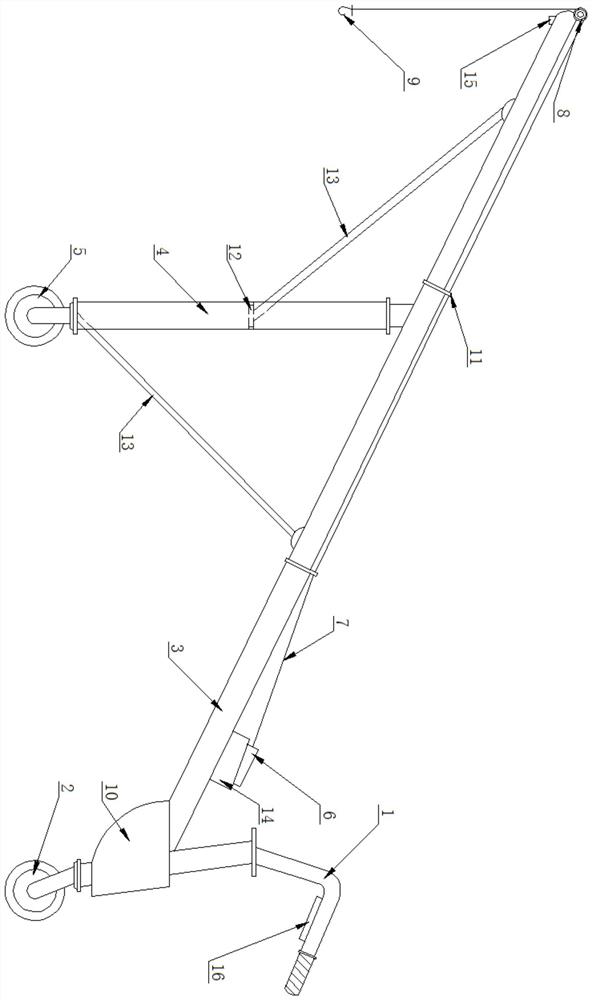

Simple hoisting equipment

PendingCN114132836ASimple structureEasy processingBase supporting structuresBraking devices for hoisting equipmentsCantileverMotronic

The invention discloses simple hoisting equipment, and belongs to the technical field of engineering hoisting equipment. The device comprises an operation dragon, a steering wheel is arranged below the operation faucet, and a cantilever connecting frame is arranged on the front side of the operation faucet; a pressure-bearing bracket is arranged in the middle of the cantilever connecting frame; movable rollers are arranged at the lower bottom of the pressure-bearing bracket; an electric crane is further mounted on the cantilever connector; one end of the lifting rope is wound on the crane, and the other end bypasses the roller at the top of the pressure cantilever connecting frame to be connected with the lifting hook; the method effectively solves the problem that reliable hoisting feasibility cannot be provided for electric power construction under the environment that infrastructure cannot meet the requirement for operation of a hoisting crane vehicle.

Owner:GUIZHOU POWER GRID CO LTD

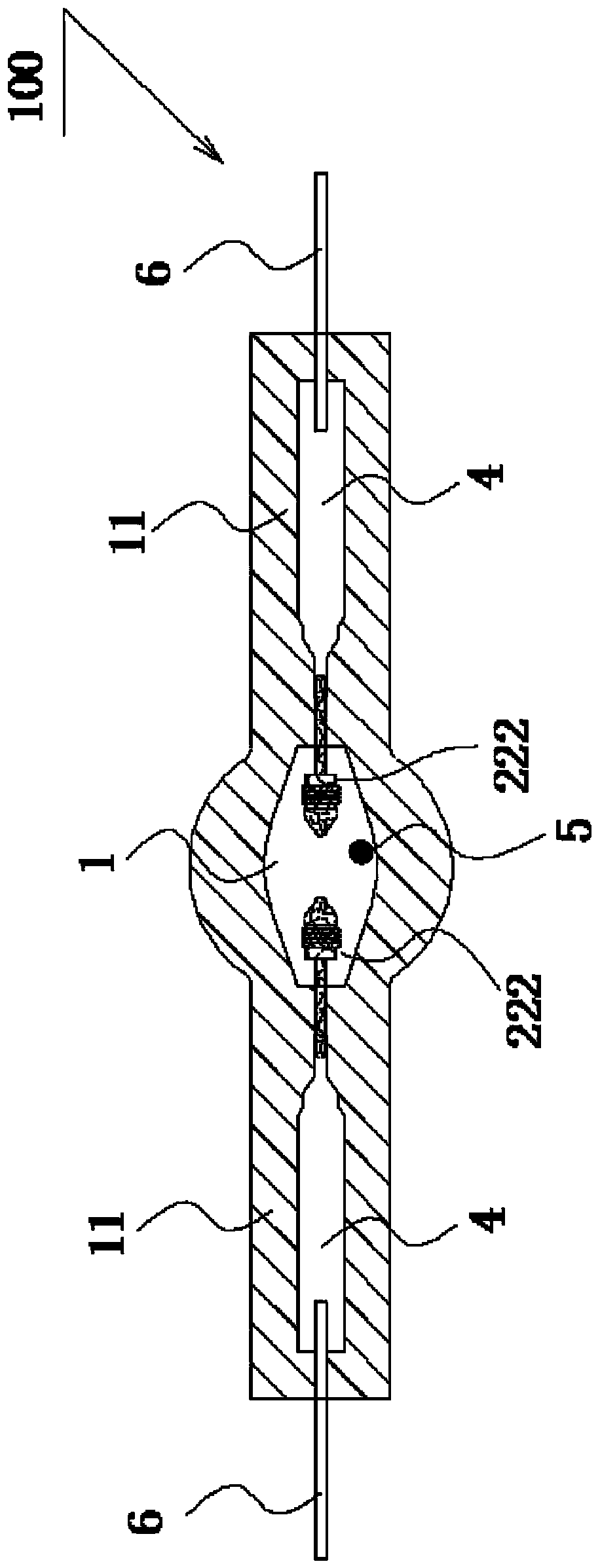

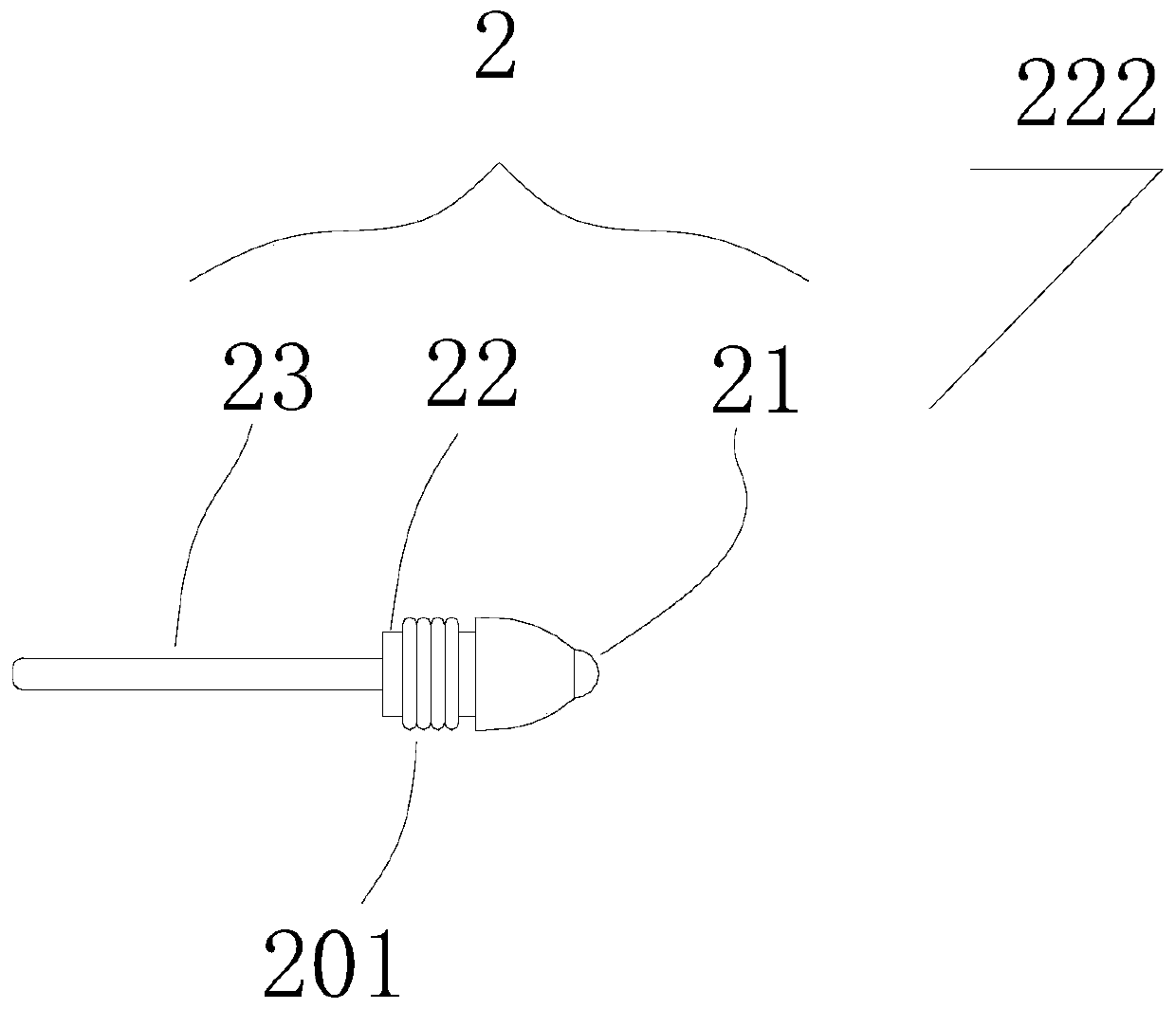

Tungsten electrode, preparation method thereof and high-pressure discharge lamp adopting tungsten electrode

ActiveCN111105985AExtend your lifeEasy processingGas discharge lampsCold cathode manufacturePrismElectrode pair

The invention discloses a preparation method of a tungsten electrode, the tungsten electrode prepared by the method and a high-pressure discharge lamp adopting the tungsten electrode. The preparationmethod comprises the following steps: S1) preparing the tungsten electrode in shape; S2) performing acid etching treatment on the tungsten electrode; S3) performing vacuum high-temperature sintering to roughen crystals; and S4) carrying out secondary acid etching treatment on the surface, so that the surface is similar to the shape of the surface of the polygon prism, peak valley concave-convex parts are formed on the surface, and the height difference of the concave-convex parts is 5-25 [mu]m. When the tungsten electrode (222) prepared by implementing the method is used for the high-pressuredischarge lamp, the phenomena of quartz glass cracks (131) and high-pressure discharge lamp breakage caused by the difference of thermal expansion and cold contraction coefficients between the tungsten electrode (222) and the quartz glass of a side tube part (11) of a discharge container (1) in the manufacturing process or the lamp turning-on and turning-off process of the high-pressure dischargelamp can be restrained, and the service life of the high-pressure discharge lamp is prolonged.

Owner:永州维尔利电子有限公司

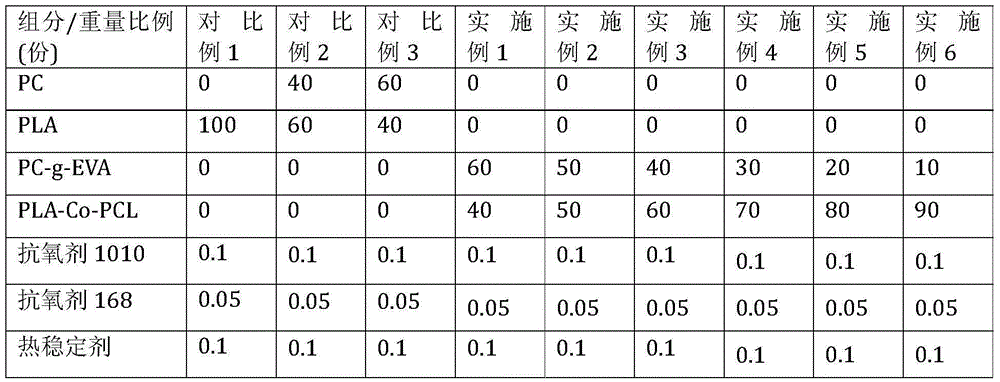

Low-viscosity high-toughness biodegradable pc/pla alloy and preparation method thereof

The invention discloses a preparation method for a PC / PLA alloy with low viscosity, high toughness and bio-degradation characteristic, and belongs to the technical field of high polymer materials. The preparation method comprises the following steps: respectively fusing and blending the PC and EVA (Ethylene Vinyl-Acetate Copolymer), reacting, extruding and slicing to obtain a PC-g-EVA grafted copolymer; fusing and blending the PLA and PCL (Polycaprolactone), reacting, extruding and slicing to obtain a PLA-Co-PCL grafted copolymer; fusing, blending and extruding the PC-g-EVA and the PLA-Co-PCL to obtain a PC / PLA alloy. Compared with the conventional PC / PLA alloy, the material prepared by the preparation method is low in viscosity and is easy to process; the prepared PC / PLA alloy is mainly applied to a three-dimensional printing material; the material contains a PC material, so compared with the traditional three-dimensional printing material PLA, the PC / PLA alloy material has high rigidity and a three-dimensional printing product is not easy to deform; besides, the alloy material contains the PLA and the PCL, is endowed with the biodegradation characteristic and has environment-friendly action.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

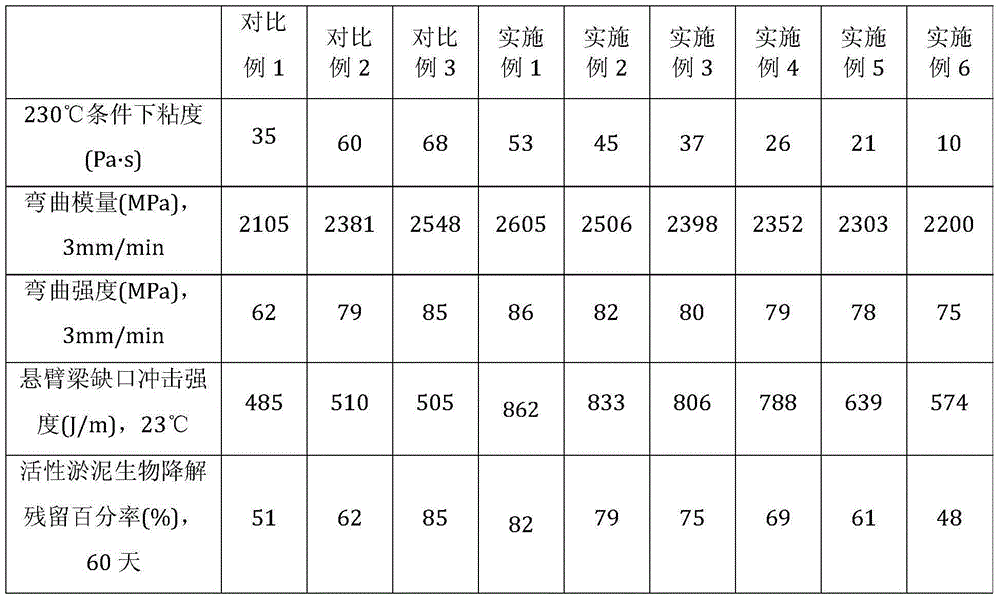

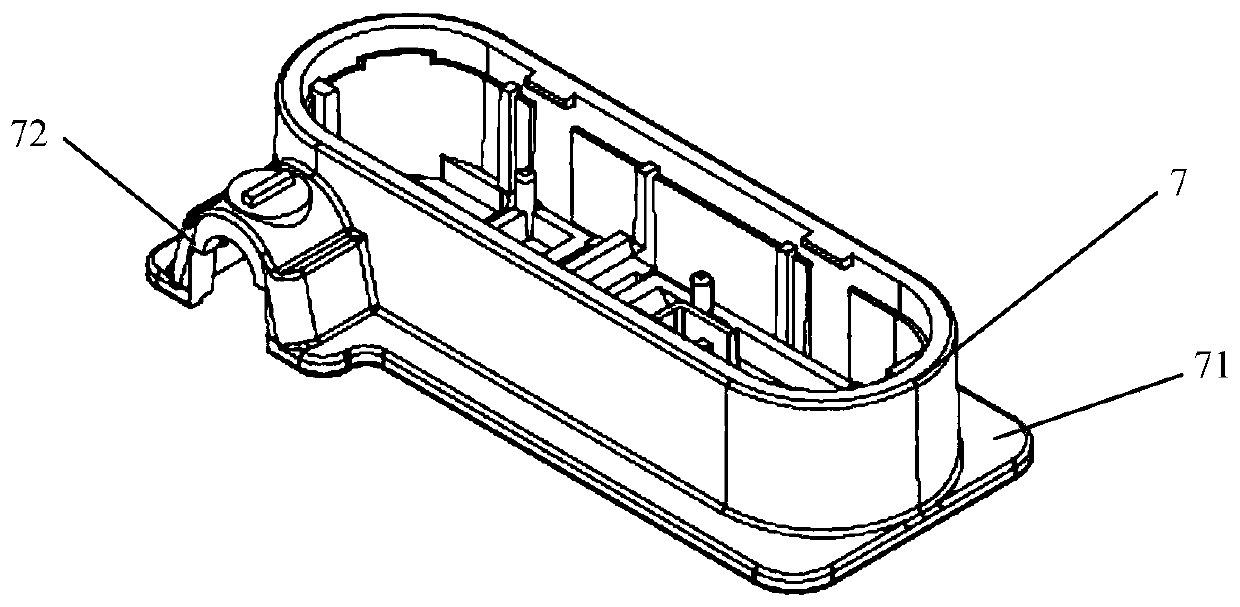

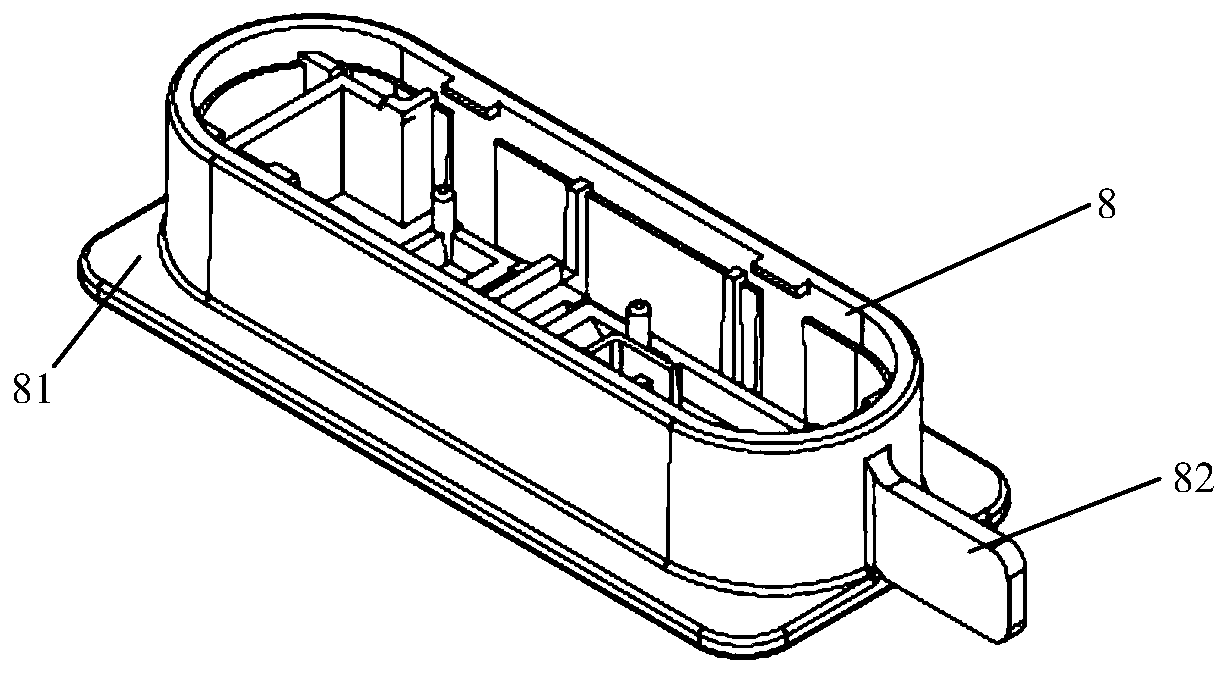

Junction box for photovoltaic module

PendingCN110855237AReduce distanceEasy processingPhotovoltaicsPhotovoltaic energy generationEffective powerEngineering

The invention provides a junction box for a photovoltaic module. The junction box comprises a left junction box, a middle junction box and a right junction box which each comprises a box cover and a box body. Cable outlet parts are integrally formed on the box bodies of the left junction box and the right junction box, and the directions of cable outlets are perpendicular to the length directionsof the box bodies. Each junction box comprises two wiring terminals of which the main bodies are of a concave structure. In the box body of each junction box, two connecting terminals are of a spacedwedge-joint structure similar to that of opposite insertion of fingers of two hands. According to the invention, the wire outlet mode of the left and right junction boxes is optimized to be close to or equal to 90 degrees, so that the distance from a module frame to the wire outlet end of the junction box is reduced, convenience is provided for module processing, the cost is saved, the effective power generation area of the assembly is increased, and the power generation efficiency is improved. Axial diodes are used and form an integral structure with the wiring terminals through electric resistance welding, so that the integral current passing capacity is improved, the heat dissipation capacity of the diodes is greatly improved, and the high current passing capacity is stronger. The junction box is applicable to high-power modules such as imbricate modules, double-sided modules and double-glazed modules.

Owner:QC SOLAR SUZHOU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com