Double-face drilling jig

A drilling fixture, double-sided technology, applied in boring/drilling, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of installation accuracy error, reduce workpiece machining accuracy, low production efficiency, etc. Machining, easy machining, avoiding the effect of repeated positioning accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

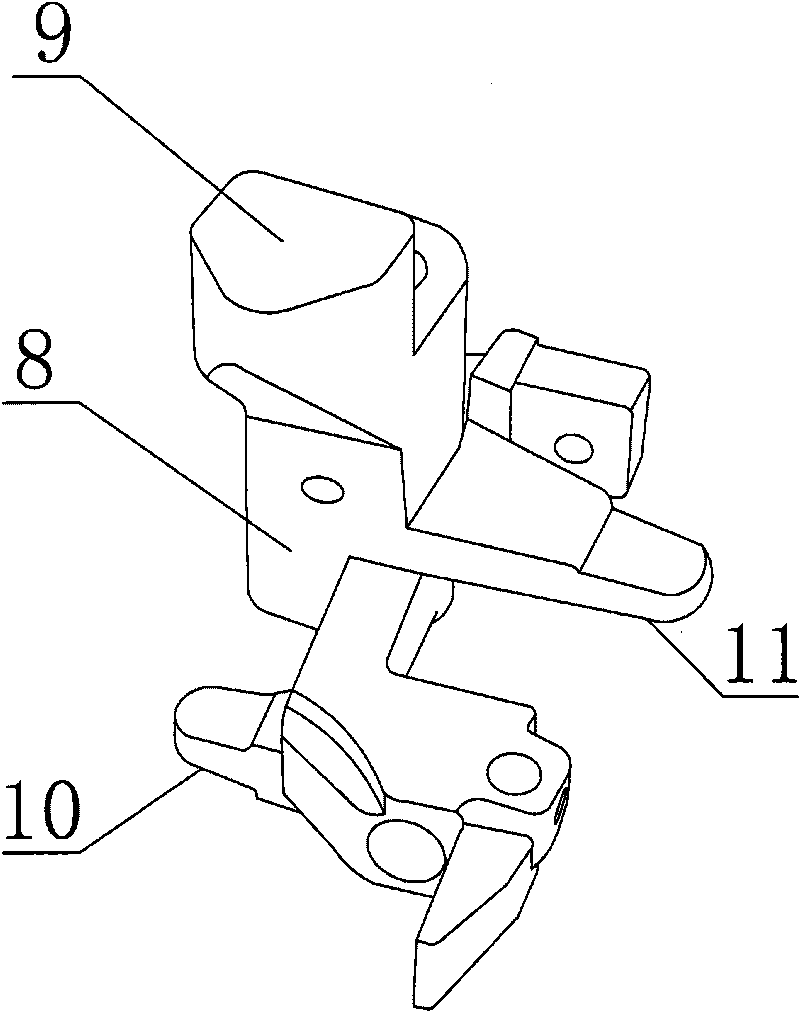

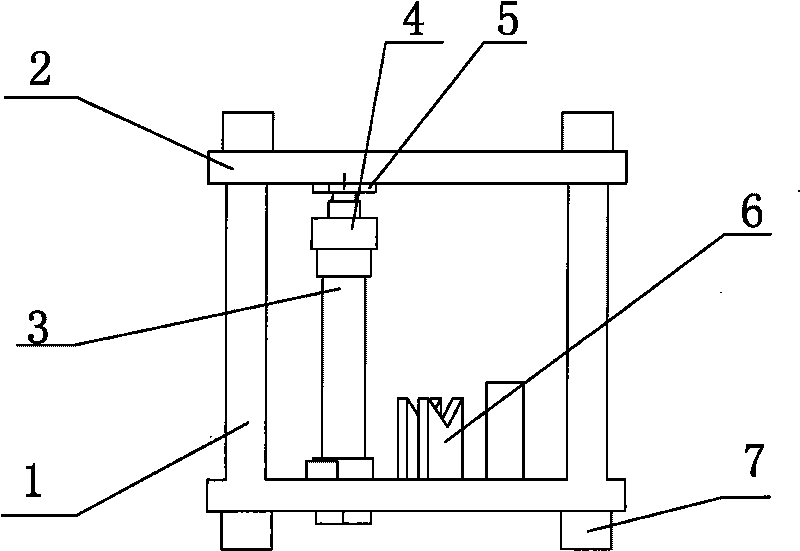

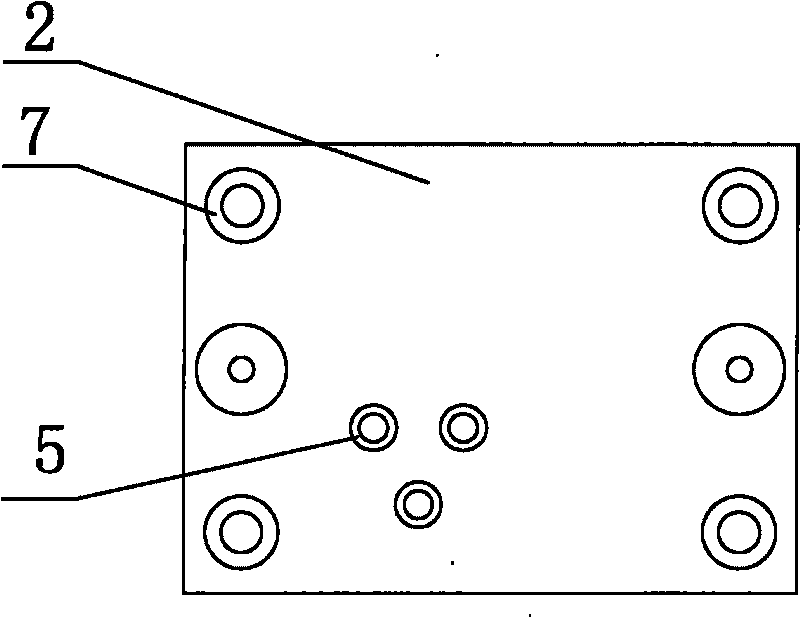

[0011] See attached figure 2 to attach Figure 4 As shown, a double-sided drilling jig includes a clamp body 1, a cover plate 2 positioned on the clamp body 1, located on the lower surface of the clamp body 1 and the upper surface of the cover plate 2 and is connected to the clamp body 1 and the cover plate 2. The support foot 7 fixedly connected to the cover plate 2, the positioning column 3 located on the upper surface of the clamp body 1 and fixedly connected with the clamp body 1, the positioning column 3 has a nut 4 for pressing the workpiece 8, the The upper surface of the clamp body 1 is provided with a V-shaped block 6 fixedly connected with the clamp body 1, and a plurality of holes are provided on the clamp body 1 and the cover plate 2, and a drill bit is fixedly pierced in the holes. The guide sleeve 5 that stretches into.

[0012] The cover plate 2 is detachably connected to the clamp body 1. Before formal processing, the cover plate 2 is firstly taken off, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com