Tungsten electrode, preparation method thereof and high-pressure discharge lamp adopting tungsten electrode

A high-pressure discharge lamp and tungsten electrode technology, applied in the field of optoelectronics, can solve problems such as short life, high price and cost, and no practical effect, and achieve the effects of increased life, low processing cost, and convenient processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the embodiment of the preparation method of tungsten electrode of the present invention:

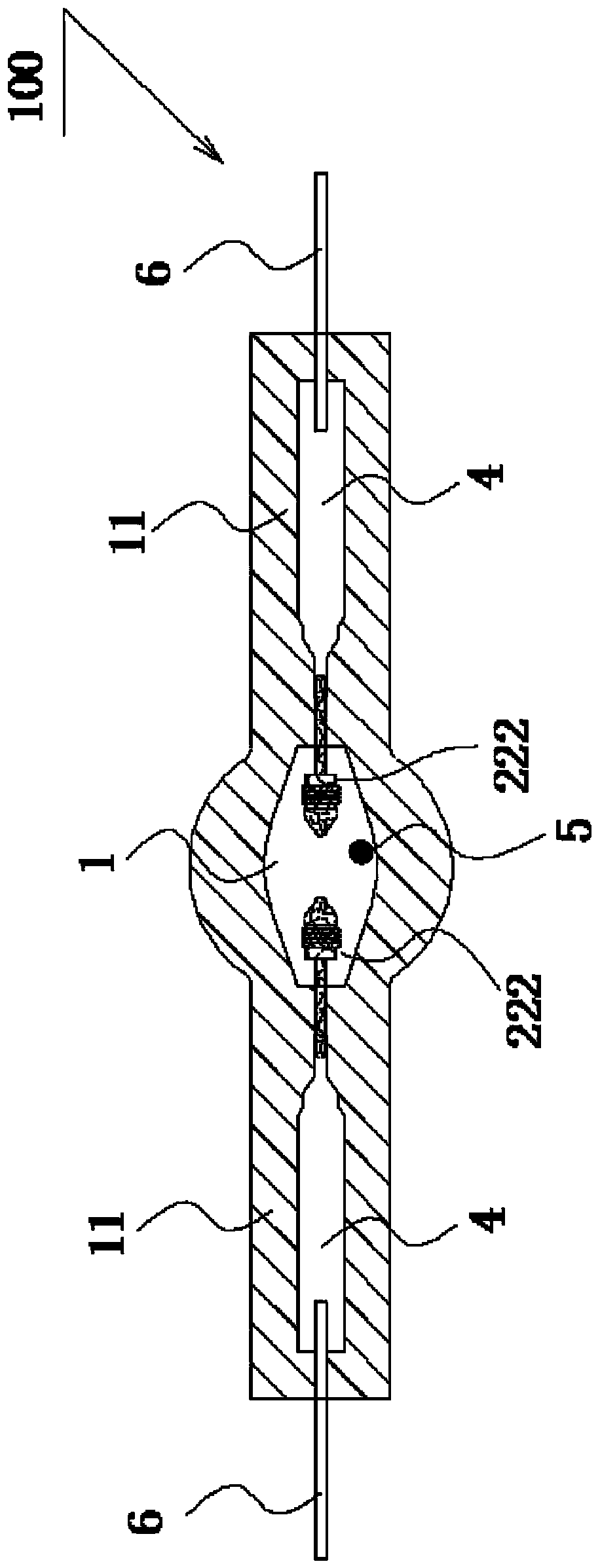

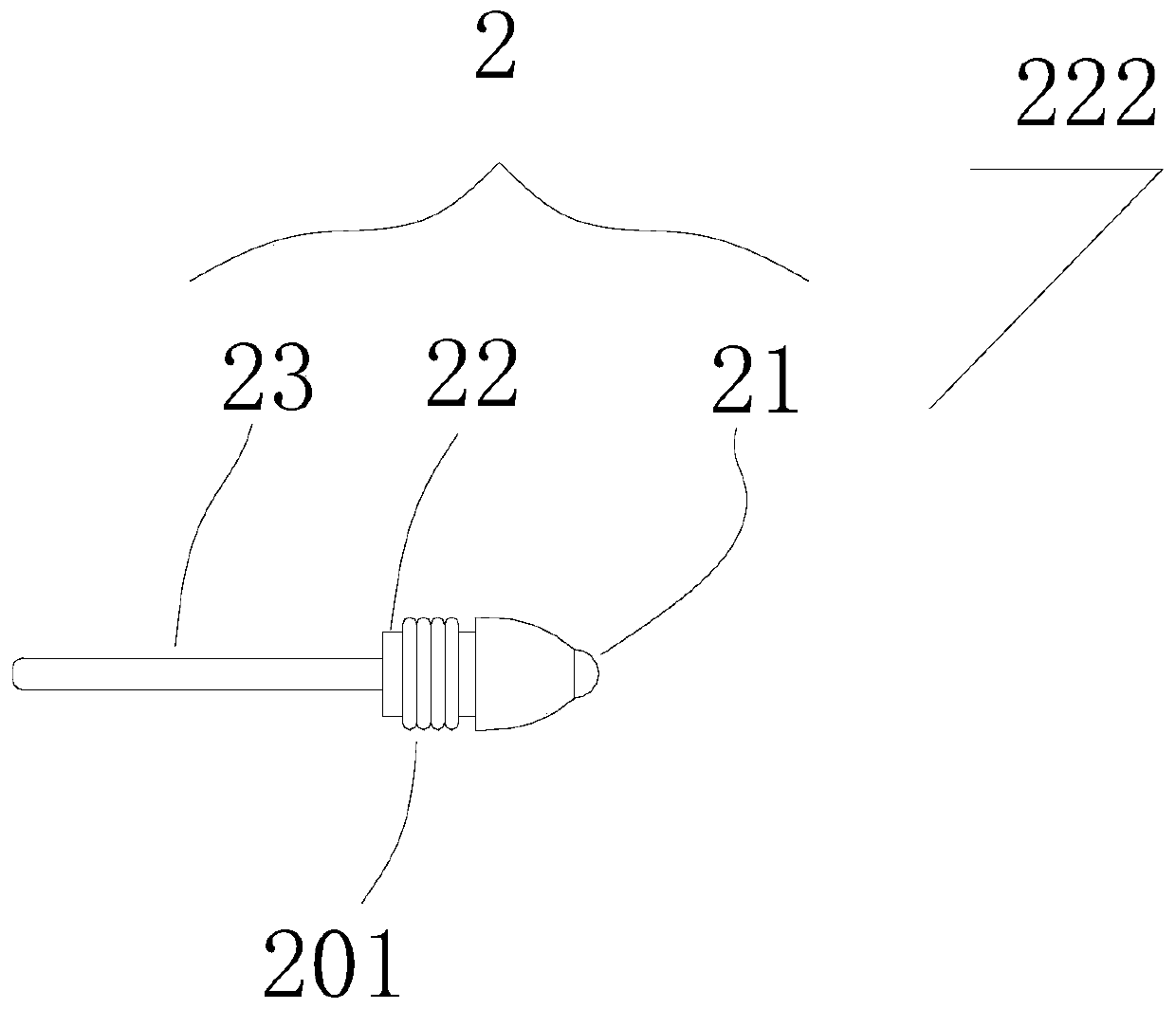

[0039] S1) Select a tungsten rod material with a diameter of 0.9 to 3.0 mm or a tungsten alloy rod material with tungsten as the main component, such as a rod material with a diameter of 1.6 mm, and turn it into a tungsten electrode body (2) and connect it with a tungsten coil (201 ) assembly, the tungsten coil (201) can be fixed on the turned tungsten electrode main body (2) by mechanical pressing or welding, and is made to have a discharge part (21), an ionization trigger part (22), a support The tungsten electrode (222) of part (23) (as figure 2 ); the number of turns of the tungsten coil (201) can be selected from 4 to 10 turns, for example, 4 turns, and a gap is formed between two adjacent coils and electrodes, which is used for the moment when the high-pressure discharge lamp is loaded and started at ultra-high voltage (above 2KV), in the gap A potential difference is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com