Junction box for photovoltaic module

A photovoltaic module and junction box technology, applied in the field of solar photovoltaic power generation, can solve the problems of reducing power generation efficiency per unit space area, cumbersome and complicated process, unfavorable component cost, etc., to achieve increased heat dissipation capacity, convenient processing technology, and strong over-current capability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure, features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings and specific embodiments.

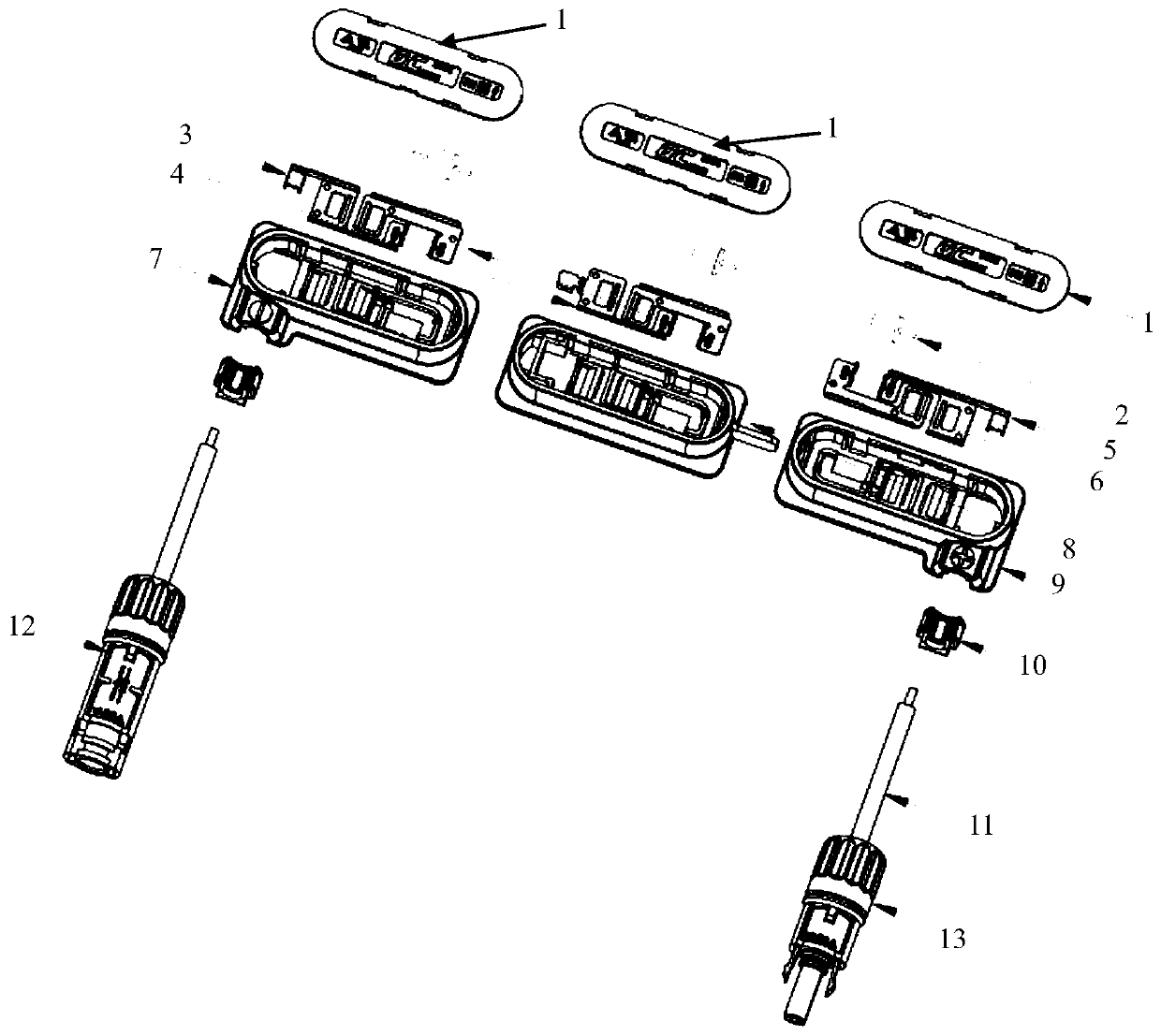

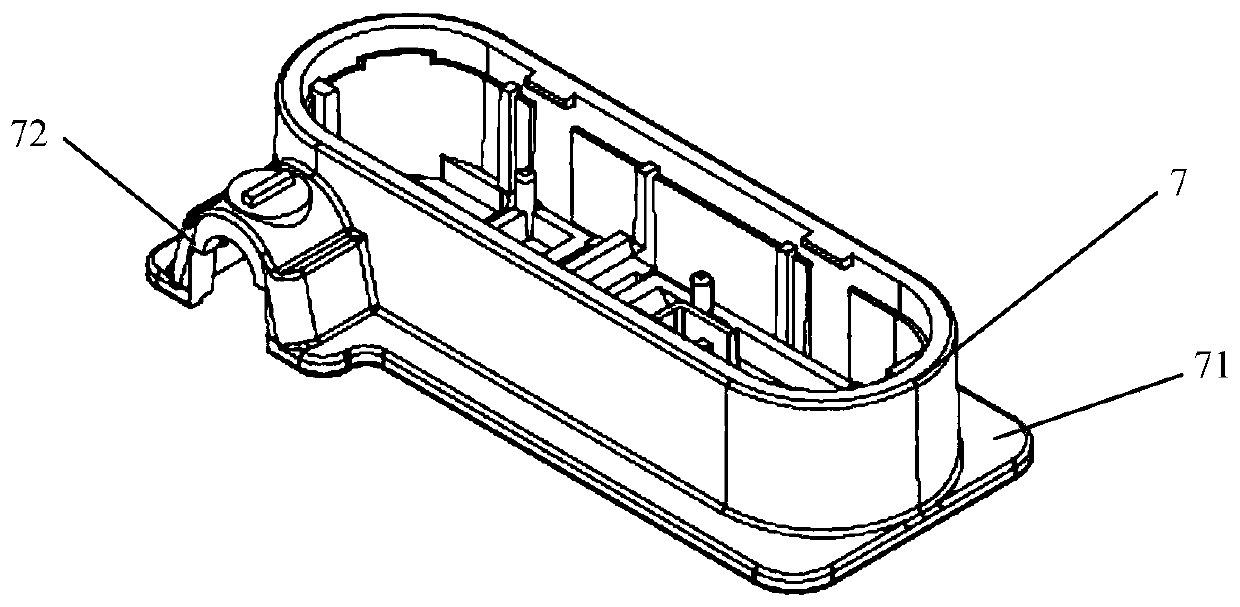

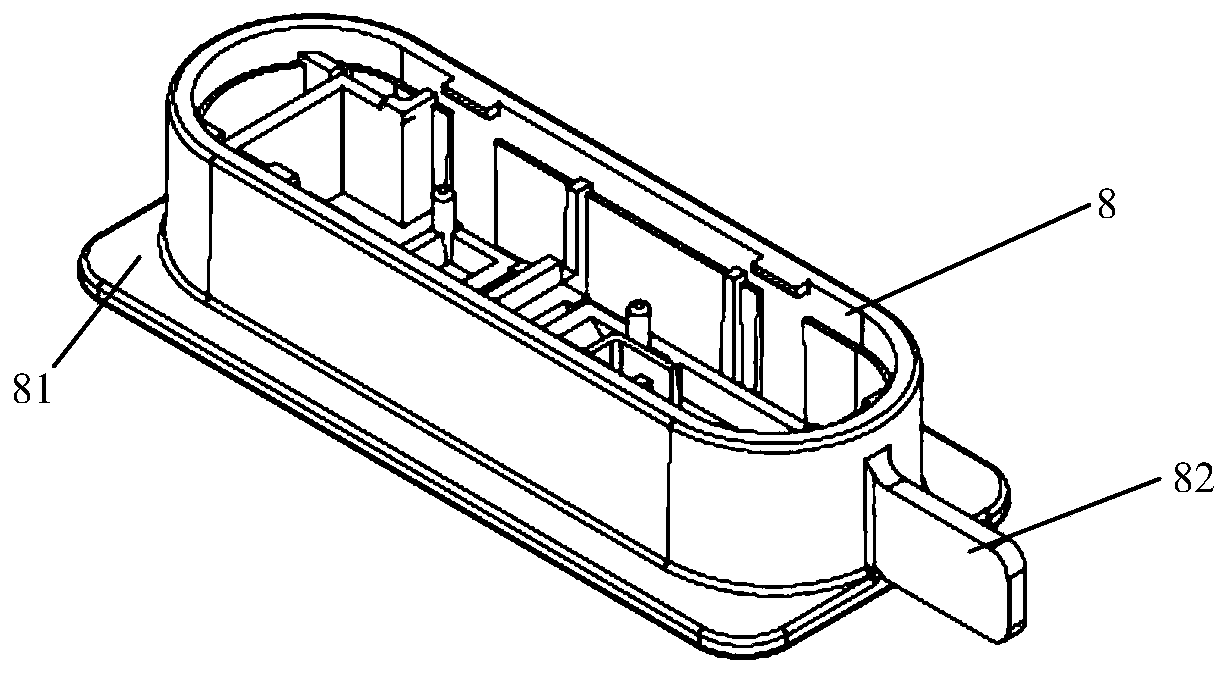

[0034] combined reference Figure 1 to Figure 12 As shown, the photovoltaic module junction box of the present invention includes a left junction box, a middle junction box and a right junction box, the left junction box includes a box cover 1 and a box body 7, and the middle junction box includes a box cover 1 and a box body 7. Box body 8, the right junction box includes a box cover 1 and a box body 9; the bottom length direction of the left junction box body 7 is provided with skirt structures 71 on the upper and lower sides, and the box body 7 is integrally formed with wired The cable outlet part 72, the direction of the cable outlet of the outlet part 72 is perpendicular to the length direction of the box body, the box body 7 includes the first connection terminal 3 and the fourth connection terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com