Manufacturing method of double-layer bamboo surface window shutter

A production method and technology of curtains, applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of inability to make venetian blinds, limit the variety of venetian blinds, increase the difficulty of processing, etc., and achieve novelty and easy processing , Enhance the effect of vertical and horizontal toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] A kind of manufacture method of multi-layer bamboo face venetian blind sheet, comprises the following steps:

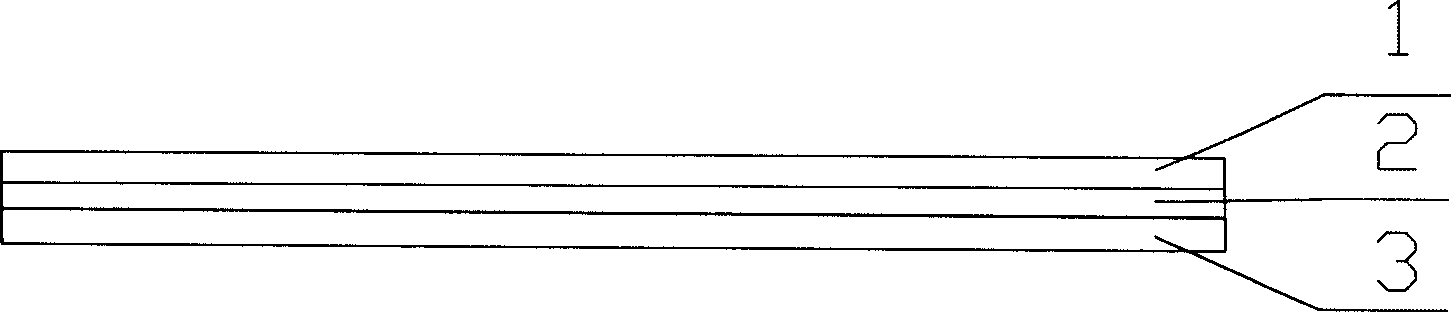

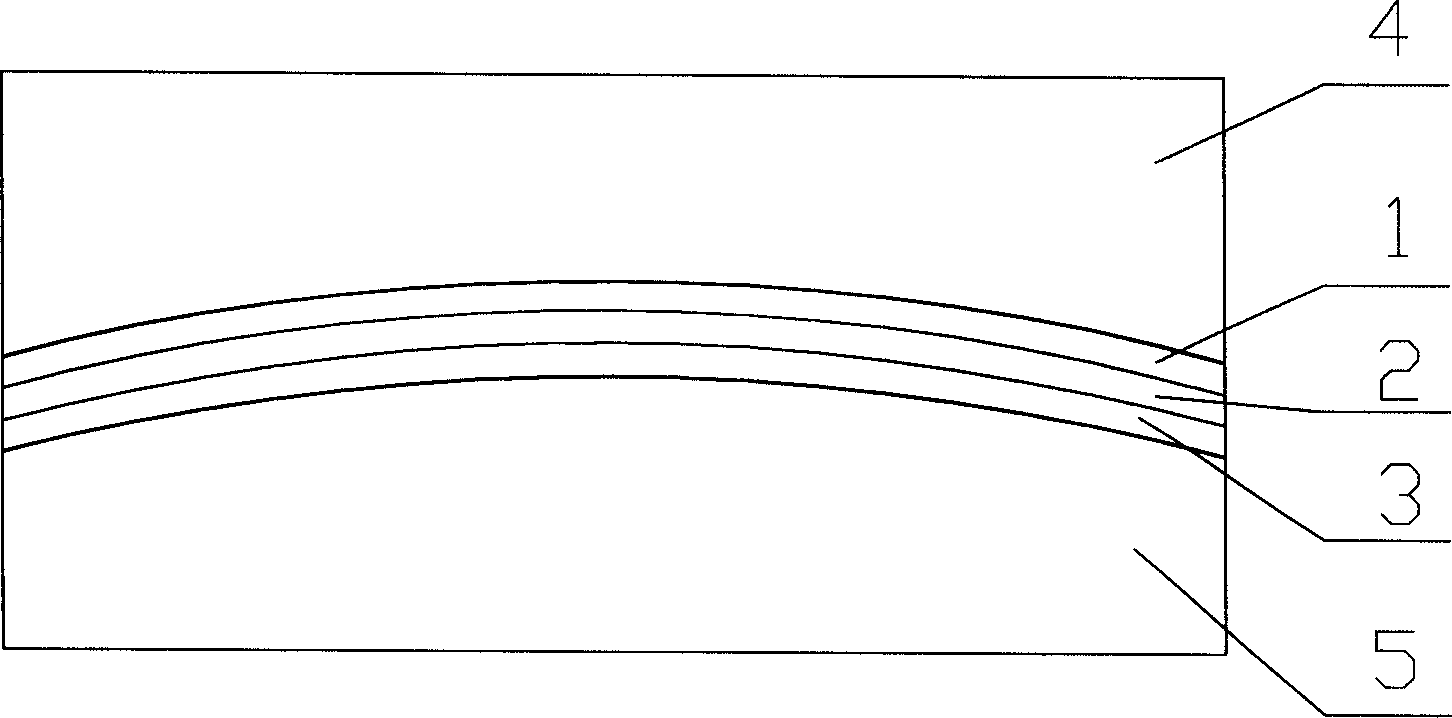

[0037] (1) choose the thickness that is purchased from the market and be 0.4mm bamboo slice, be cut into length and be 1200mm and width be 30mm bamboo slice small block 1 and bamboo slice small block 3;

[0038] (2) Select the wood through the insect-proof, mildew-proof and anti-corrosion treatment, cut into the same length and width as step (1) and have a thickness of 1mm filler small block 2;

[0039] (3) select wood glue to stick bamboo slice small block 1, filler small block 2 and bamboo slice small block 3 successively to form curtain sheet block;

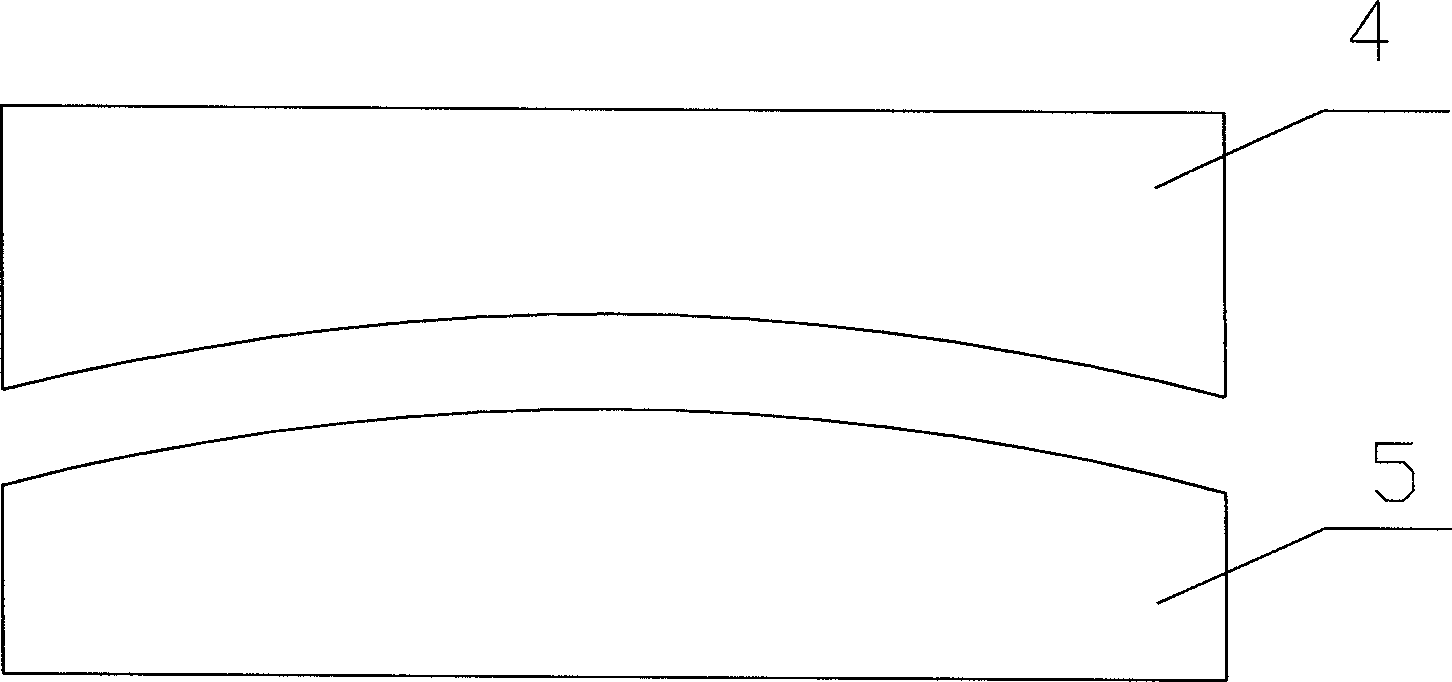

[0040] (4) Place the curtain sheet block in the metal mold corresponding to the upper and lower arcs, use steam to control the temperature to 100 ° C, heat the glue for about 5 seconds, take it out and cool down naturally to form the curtain sheet composite layer;

[0041] (5) Sanding, arc-reversing, and varni...

specific Embodiment 2

[0043] A kind of manufacture method of multi-layer bamboo face venetian blind sheet, comprises the following steps:

[0044] (1) Select bamboo materials that have been treated with insect-proof, mildew-proof, and anti-corrosion treatments, and process them into bamboo boards of predetermined length and width, use domestic No. 214 resin glue to paste and laminate the bamboo boards in the vertical and horizontal directions to form bamboo plywood, and peel the bamboo plywood from the bamboo plywood Thin bamboo slices with a thickness of 0.5 mm are taken out, and a non-woven lining is pasted on the inner layer of the bamboo slices; the bamboo slices are taken, and cut into lengths of 1000 mm and width 25 mm bamboo slice small blocks 1 and bamboo slice small blocks 3;

[0045] (2) Select the bamboo sheet through the insect-proof, mildew-proof and anti-corrosion treatment as the filling material, cut into the filling small block 2 with the same length and width as step (1) and a thic...

specific Embodiment 3

[0049] A kind of manufacture method of multi-layer bamboo face venetian blind sheet, comprises the following steps:

[0050] (1) Select bamboo materials that have been treated with insect-proof, mildew-proof, and anti-corrosion treatments, and process them into bamboo boards of predetermined length and width. Use gum to paste and laminate the bamboo boards in the vertical and horizontal directions to form bamboo plywood, and cut out a thickness of 0.4 from the bamboo plywood. mm thin bamboo slices, paste the non-woven lining in the bamboo slices; the bamboo slices are cut into length 1100mm and width 20mm bamboo slice small blocks 1 and bamboo slice small blocks 3;

[0051] (2) Select synthetic paper with a thickness of 1.2mm as the filling material through insect-proof, mildew-proof, anti-corrosion treatment, and cut it into filling small blocks 2 with the same length and width as step (1);

[0052] (3) select gum agent to stick bamboo slice small block 1, two filler small bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com