Dry method dust collecting technique for ferromolybdenum smelting flue gas

A technology for smelting flue gas and ferromolybdenum, applied in the direction of dust removal, separation methods, cleaning methods and appliances, etc., can solve the problems of flue gas not meeting emission requirements, corrosion of fans and pipeline equipment, easy blockage of spraying devices, etc. Achieve the effects of easy processing and matching, easy processing and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

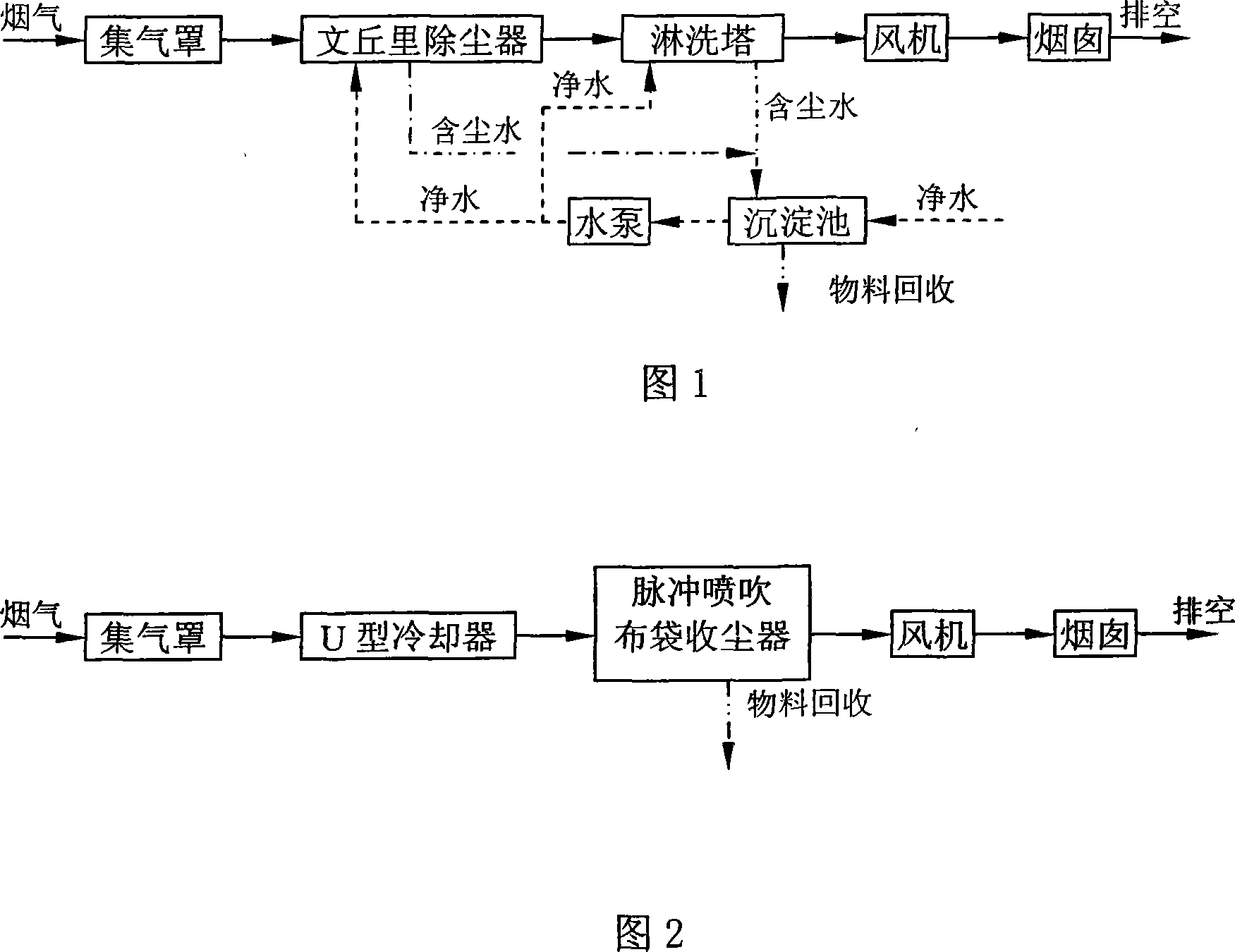

[0030] As shown in Figure 2, the flue gas produced by the ferromolybdenum smelting furnace is collected by the gas collection hood and then enters the U-shaped tube cooler for natural cooling and cooling. The gas collection hood can be an umbrella-shaped cover with a square or circular cross section. The sectional area of the air inlet of the gas collecting hood is 3 to 4 times that of the upper sectional area of the smelting furnace, and the height of the hood is designed with reference to the relevant design manual. The installation position of the gas collecting hood is directly above the smelting furnace and 0.8-1.2m away from the furnace mouth. The gas velocity at the inlet of the gas collecting hood is 1-2.5m / s. At this time, the flue gas temperature at the inlet is 500-700°C, and the smoke concentration is 80-100g / mN 3 . The U-shaped cooler can be arranged according to the actual situation of the project site. The heat dissipation area should be designed to reduc...

Embodiment 2

[0034] The flue gas produced by the ferromolybdenum smelting furnace is collected by the gas collecting hood and then enters the U-shaped tube cooler for natural cooling and cooling. The diameter of the upper opening of the ferromolybdenum smelting furnace is φ2.0m. The air collecting hood can be an umbrella cover with a square or circular cross section. The cross-sectional area of the inlet of the gas collecting hood is 3.5 times that of the furnace mouth, the inlet size of the gas collecting hood is determined to be 3.32m×3.32m, the installation height is 1.0m, and the inlet gas velocity is taken as 2.0m / s. At this time, the flue gas temperature at the inlet of the hood is 650°C, and the flue gas volume is 23500mN 3 / h.

[0035] The U-shaped cooler can be arranged according to the actual situation of the project site. The heat dissipation area should be designed to reduce the flue gas temperature to 120-250°C, and the resistance should be controlled at 900-1100Pa. To fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com