Low dynamic multiplying power antifatigue neoprene material and preparation method thereof

A neoprene, fatigue-resistant technology, applied in the field of low dynamic ratio, fatigue-resistant neoprene materials and its preparation, can solve the problems of reduced shock absorption performance, limited use of neoprene, large hysteresis loss, etc., and achieve fatigue resistance The effect of improved performance, convenient and easy processing technology, and reduced dynamic magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

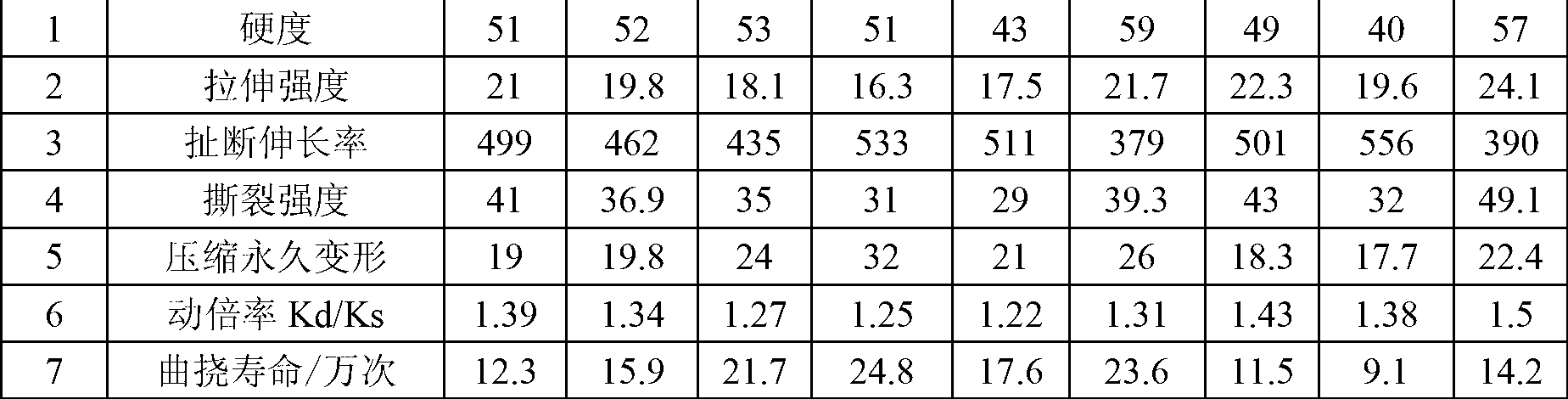

Examples

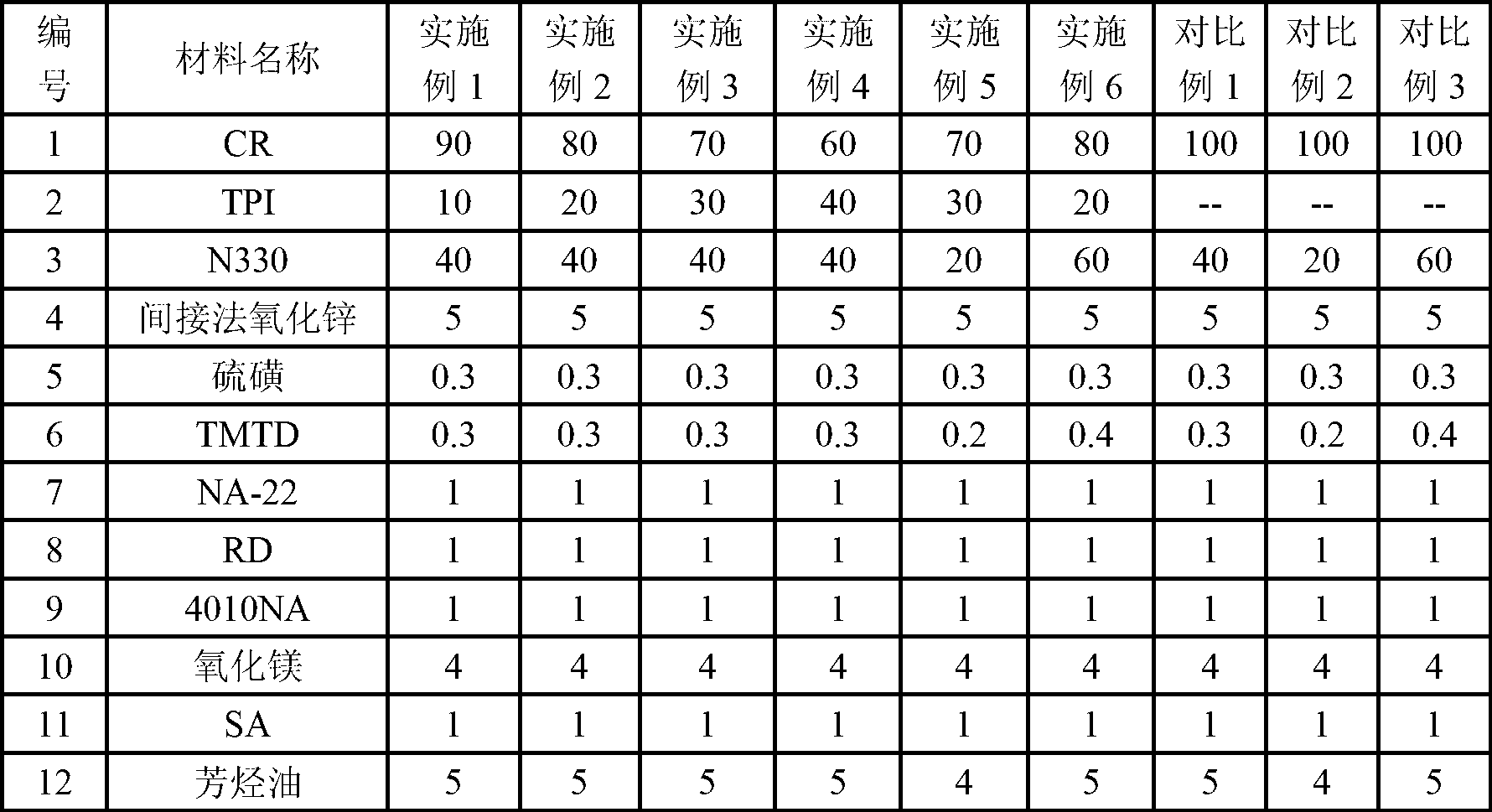

Embodiment 1

[0029] Neoprene CR90 parts, trans-1,4 polyisoprene TPI10 parts, carbon black N33040 parts, indirect zinc oxide 5.0 parts, sulfur 0.3 parts, accelerator TMTD0.5 parts, accelerator NA-221.0 parts, anti-aging 1.0 parts of anti-aging agent RD, 1.0 parts of anti-aging agent 4010NA, 4.0 parts of active agent (magnesium oxide), 1.0 parts of active agent (stearic acid SA), 5.0 parts of operating aid aromatic oil.

[0030] The production process includes the following steps and process conditions: In the first step, the trans-1,4 polyisoprene TPI is masticated in the general rubber mixing equipment at a temperature range of 60-100°C for 2-3 minutes, and then mixed with chlorine Butadiene rubber CR blending; the second step is to prepare the mixed rubber according to the usual rubber mixing method; the third step is to park the mixed rubber for more than 8 hours and vulcanize according to the usual rubber vulcanization process.

Embodiment 2

[0033] Neoprene CR80 parts, trans-1,4 polyisoprene TPI20 parts, carbon black N33040 parts, indirect method zinc oxide 5.0 parts, sulfur 0.3 parts, accelerator TMTD0.5 parts, accelerator NA-221.0 parts, anti-aging 1.0 parts of anti-aging agent RD, 1.0 parts of anti-aging agent 4010NA, 4.0 parts of active agent (magnesium oxide), 1.0 parts of active agent (stearic acid SA), 5.0 parts of operating aid aromatic oil.

Embodiment 3

[0035] Neoprene CR70 parts, trans-1,4 polyisoprene TPI30 parts, carbon black N33040 parts, indirect zinc oxide 5.0 parts, sulfur 0.3 parts, accelerator TMTD0.5 parts, accelerator NA-221.0 parts, anti-aging 1.0 parts of anti-aging agent RD, 1.0 parts of anti-aging agent 4010NA, 4.0 parts of activator (magnesium oxide), 1.0 part of activator (stearic acid SA), 5.0 parts of aromatic oil as operating aid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com