Cracking method machining technology of engine connecting rod

An engine connecting rod and processing technology technology, which is applied in the field of engine connecting rod expansion and breaking method processing technology, can solve the problems of dislocation of the big end hole of the connecting rod, poor matching accuracy, affecting the assembly and use of the engine, etc., to ensure quality and simplify processing. Process, the effect of omitting the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

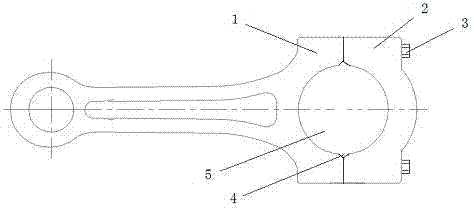

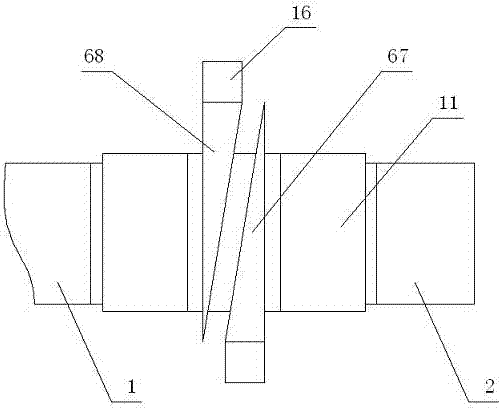

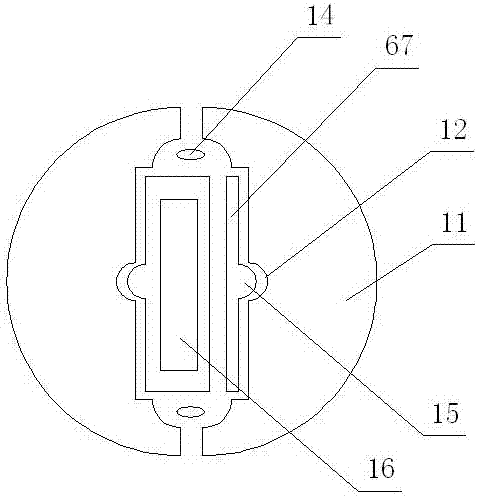

[0035] Below, combine Figure 1-5 , the present invention will be further described.

[0036] Material selection of connecting rod: At present, the commonly used material of engine connecting rod is 40Cr steel. Due to the structure and performance of this material, the connecting rod body 1 and connecting rod cover 2 are separated by the expansion fracture method. Under the action, the plastic deformation is large, and the big head hole is out of round, which hinders the implementation of the expansion breaking method. The material of the connecting rod used in the present invention is C70S6BY high-carbon micro-alloy non-quenched and tempered steel. This steel can not only ensure that the forgings have sufficient strength after air cooling, and meet the needs of the performance of the connecting rod. Under the premise of the index, it shows the characteristics of brittle fracture, and the fracture surface has good meshing. Due to the characteristics of the fracture surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com