An electroless, environment-friendly magnetic core inductor and its processing technology

A processing technology and environment-friendly technology, applied in the direction of inductance with magnetic core, inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., to meet processing needs, prevent damage, and achieve good induction effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

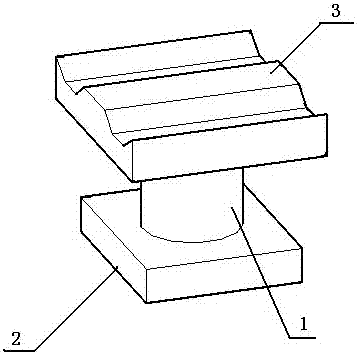

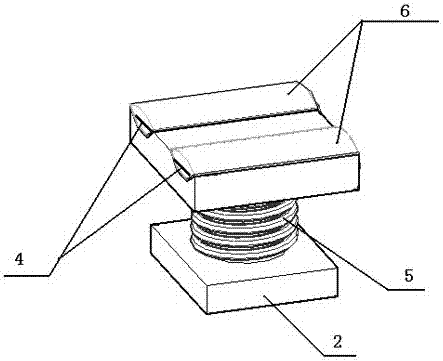

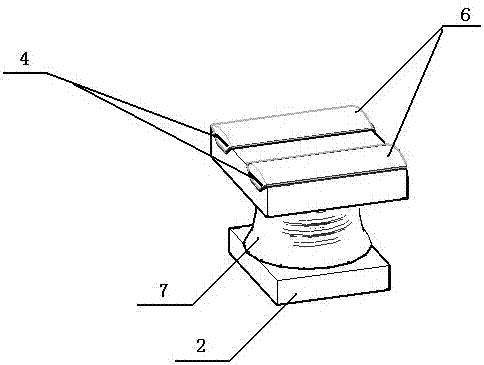

[0027] Such as Figure 1-2 As shown, an electroless, environment-friendly magnetic core inductor includes a substrate 1, the substrate 1 includes an upper end surface 3 and a lower end surface 2, copper foil 4 is provided on both sides of the upper end surface 3, and the upper end surface 3 and the lower end surface The concave part between 2 is wound with an enamelled copper wire 5, and the enameled copper wire 5 extends to the copper foil 4 and is covered by tin 6. The surface of the enamelled copper wire 5 is provided with an adhesive layer 7, and the surface of the substrate 1 is also provided with There is an antirust layer, and the antirust layer is made of acrylic acid, titanium dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com