Processing method of quartz sand proppant

A processing method and sand proppant technology, which are applied in the field of shale fracturing, can solve the problem of high processing cost, and achieve the effects of reducing processing cost and making the processing process simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

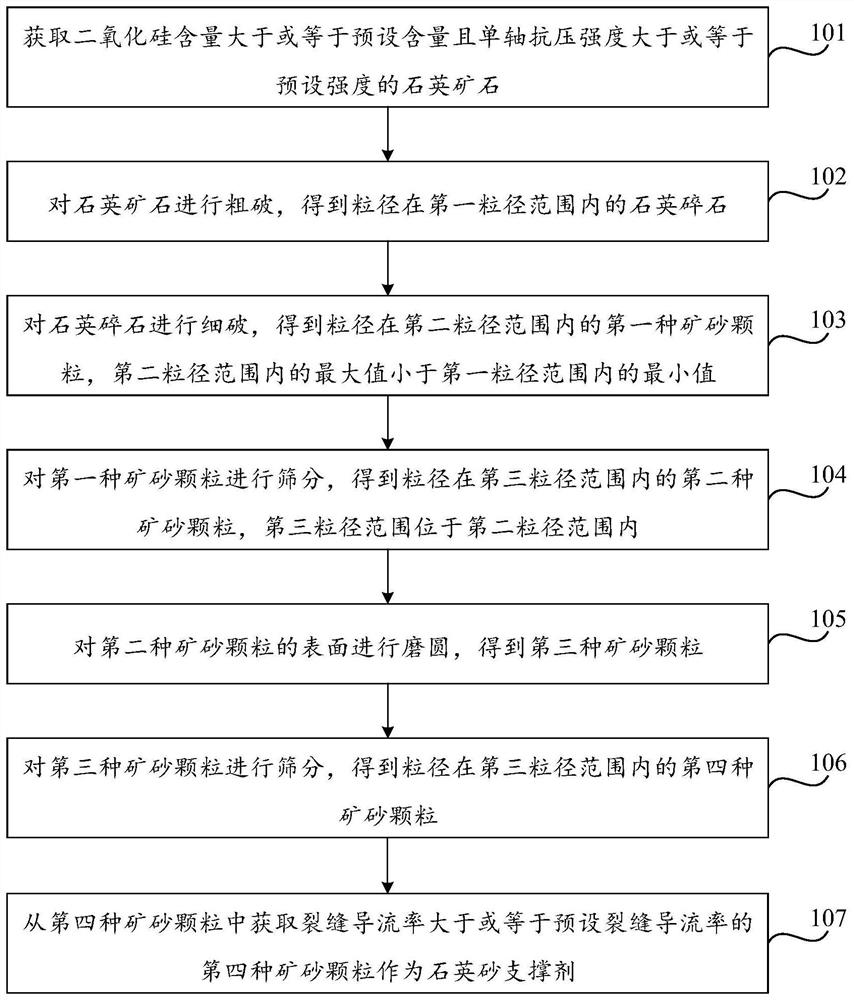

[0051] figure 1 It is a flowchart of a processing method for a quartz sand proppant provided by an embodiment of the present invention. see figure 1 , the method includes:

[0052] Step 101: Obtain quartz ore with a silica content greater than or equal to a preset content and a uniaxial compressive strength greater than or equal to a preset strength.

[0053] Step 102: Perform coarse crushing on the quartz ore to obtain quartz gravel with a particle size within the first particle size range.

[0054] Step 103: Perform fine crushing on the quartz gravel to obtain the first type of ore sand particles with a particle size within a second particle size range, the maximum value within the second particle size range being smaller than the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com