Diameter change type hydraulic buffer structure automobile shock absorber assembly

A hydraulic buffer and variable diameter technology, applied in the field of auto parts, can solve the problems of shock absorber failure, small elastic force, damage of shock absorber parts, etc., and achieve the advantages of convenient processing technology, low production cost and strong buffer effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

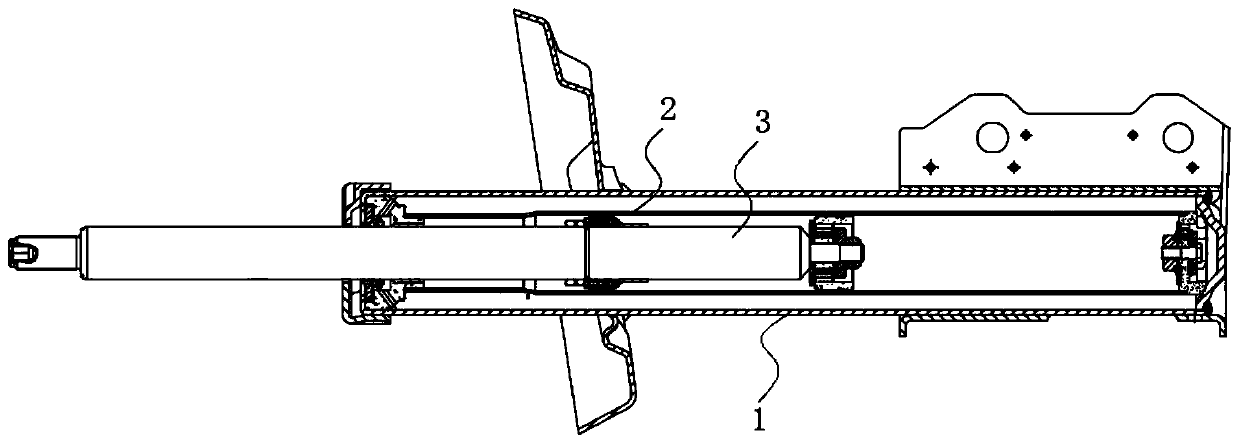

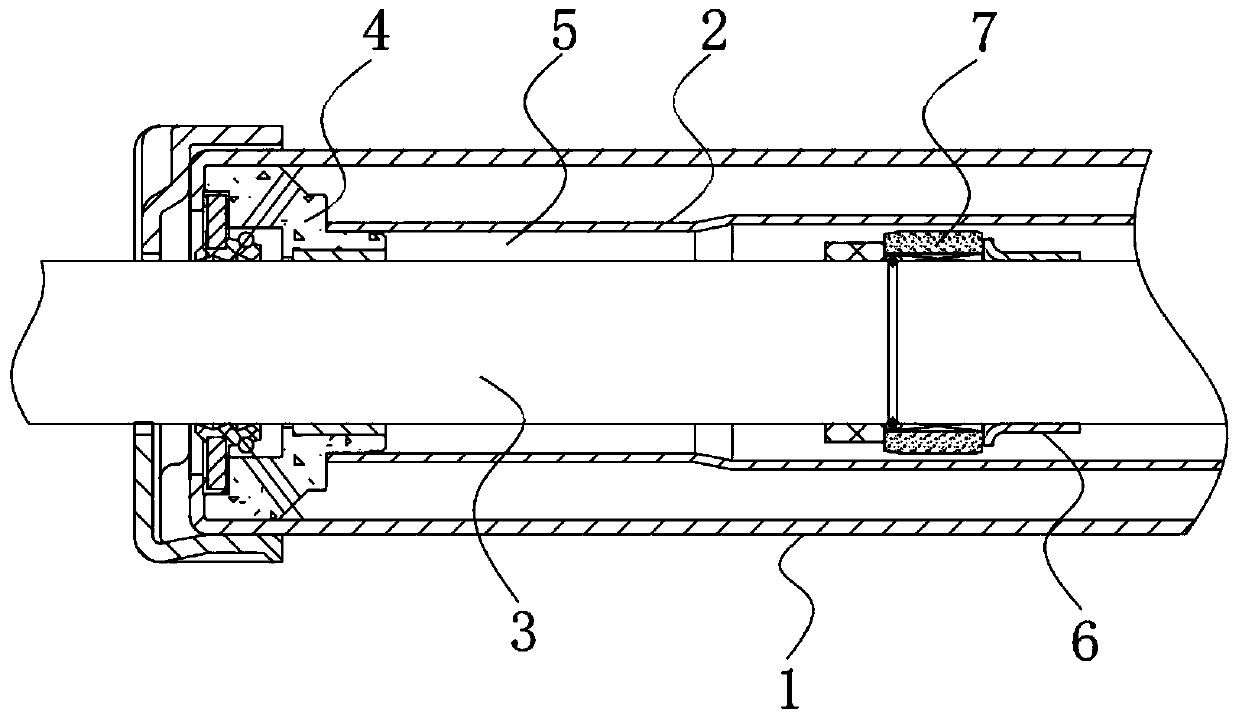

[0021] Such as Figure 1-2 As shown, the embodiment of the present invention provides a variable-diameter hydraulic buffer structure automotive shock absorber assembly, including a body 1, a working cylinder 2 is arranged inside the body 1, a guide 4 is arranged at the end of the working cylinder 2, and the working cylinder 2 The end close to the guide 4 is reduced in diameter. The inside of the working cylinder 2 is provided with a piston rod 3. The free end of the piston rod 3 runs through the guide 4 and extends to the outside of the body 1. The inside of the working cylinder 2 is located The area where the mouth is reduced is set as a buffer zone 5, and the outer surface of the piston rod 3 is provided with an inner limiter 6, and the outer surface of the inner limiter 6 is fixedly installed with a buffer 7. The diameter of the mouth is reduced, and an inner limit 6 is welded on the piston rod 3, and a buffer 7 is installed on the inner limit 6. When the piston rod 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com