Method for preparing light aromatics from coal tar

A technology of light aromatics and coal tar, applied in the field of light aromatics, can solve the problems of unguaranteed supply of raw materials, low output of crude benzene, shortage of raw materials, etc., and achieve long operation period of the device, high added value of products, and good product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

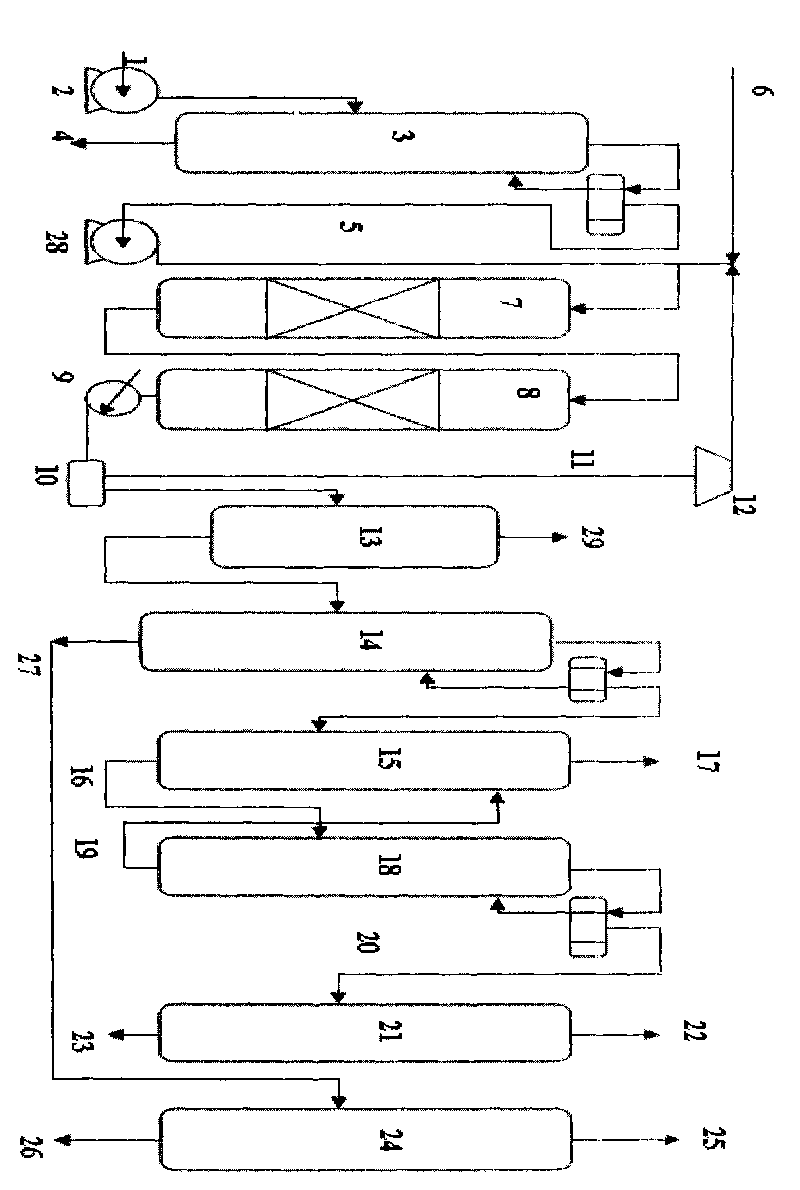

Method used

Image

Examples

Embodiment 1

[0024] A low-temperature coal tar is used as raw material, its properties are shown in Table 1, the selective hydrogenation reaction conditions are the first reactor reaction conditions: temperature 180°C, hydrogen partial pressure 1.0MPa, hydrogen-oil ratio 200, liquid hourly space velocity 0.5h -1 ;Reaction conditions of the second reactor: temperature 260°C, hydrogen partial pressure 1.0MPa, hydrogen-oil ratio 200, liquid hourly space velocity 0.5h -1 ;. See Table 2 for properties of fractions <200°C after cutting low-temperature coal tar and oils produced by selective hydrogenation, and see Table 3 for properties of aromatics, non-aromatics and solvent oil products.

[0025] Table 1

[0026] Analysis Project

[0027] Table 2

[0028] project

[0029] project

[0030] table 3

[0031] project

[0032] project

Embodiment 2

[0034] A medium-temperature coal tar is used as a raw material, its properties are shown in Table 4, and the selective hydrogenation reaction conditions are the first reactor reaction conditions: temperature 210°C, hydrogen partial pressure 2.5MPa, hydrogen-oil ratio 600, liquid hourly space velocity 2.5h -1 ;Reaction conditions of the second reactor: temperature 290°C, hydrogen partial pressure 2.5MPa, hydrogen-oil ratio 600, liquid hourly space velocity 2.5h -1 ;. See Table 5 for properties of cut <200°C fractions and selective hydrogenated oil from low-temperature coal tar, and Table 6 for properties of aromatics, non-aromatics and solvent oil products.

[0035] Table 4

[0036] Analysis Project

value

value

Exterior

black sticky

Composition, w%

/

Density at 20°C, kg / m 3 ,

966.9

saturated hydrocarbon

18.97

24

Aromatics

13.98

Viscosity, mm2 / s

7...

Embodiment 3

[0043] A low-temperature coal tar mixed with 20% of a high-temperature coal tar light oil fraction -1 ;Reaction conditions of the second reactor: temperature 320°C, hydrogen partial pressure 5.0MPa, hydrogen-oil ratio 1000, liquid hourly space velocity 5.0h -1 . See Table 8 for properties of cut <200°C fractions of low-temperature coal tar and oils produced by selective hydrogenation, and see Table 9 for properties of aromatics, non-aromatics and solvent oil products.

[0044] Table 7

[0045] Analysis Project

[0046] Table 8

[0047] project

[0048] project

[0049] Table 9

[0050] project

[0051] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com