Secondary injection molding method for toothbrush handles and system for implementing same

A secondary injection molding and forming method technology, applied in the field of fixtures, can solve the problems of complex mold structure, large size, high manufacturing cost, etc., and achieve the effects of good product quality, fast speed, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

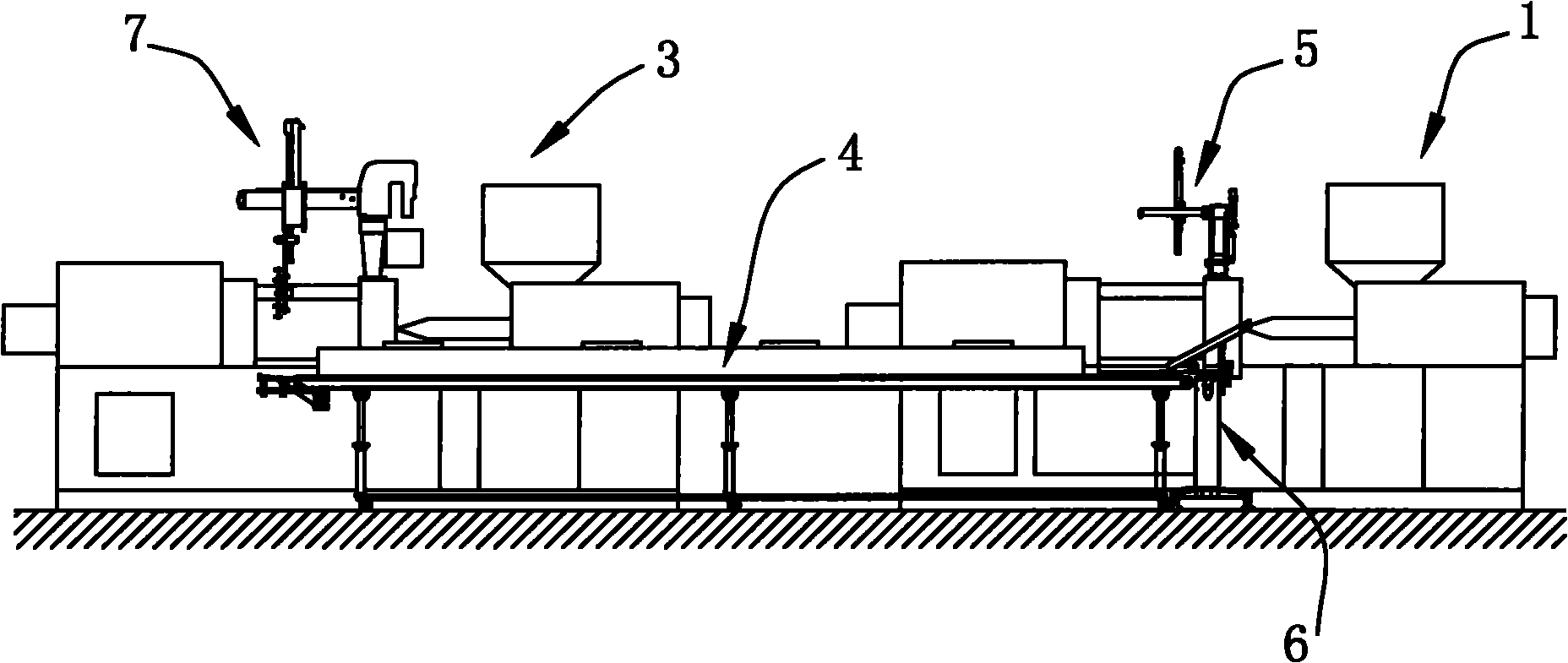

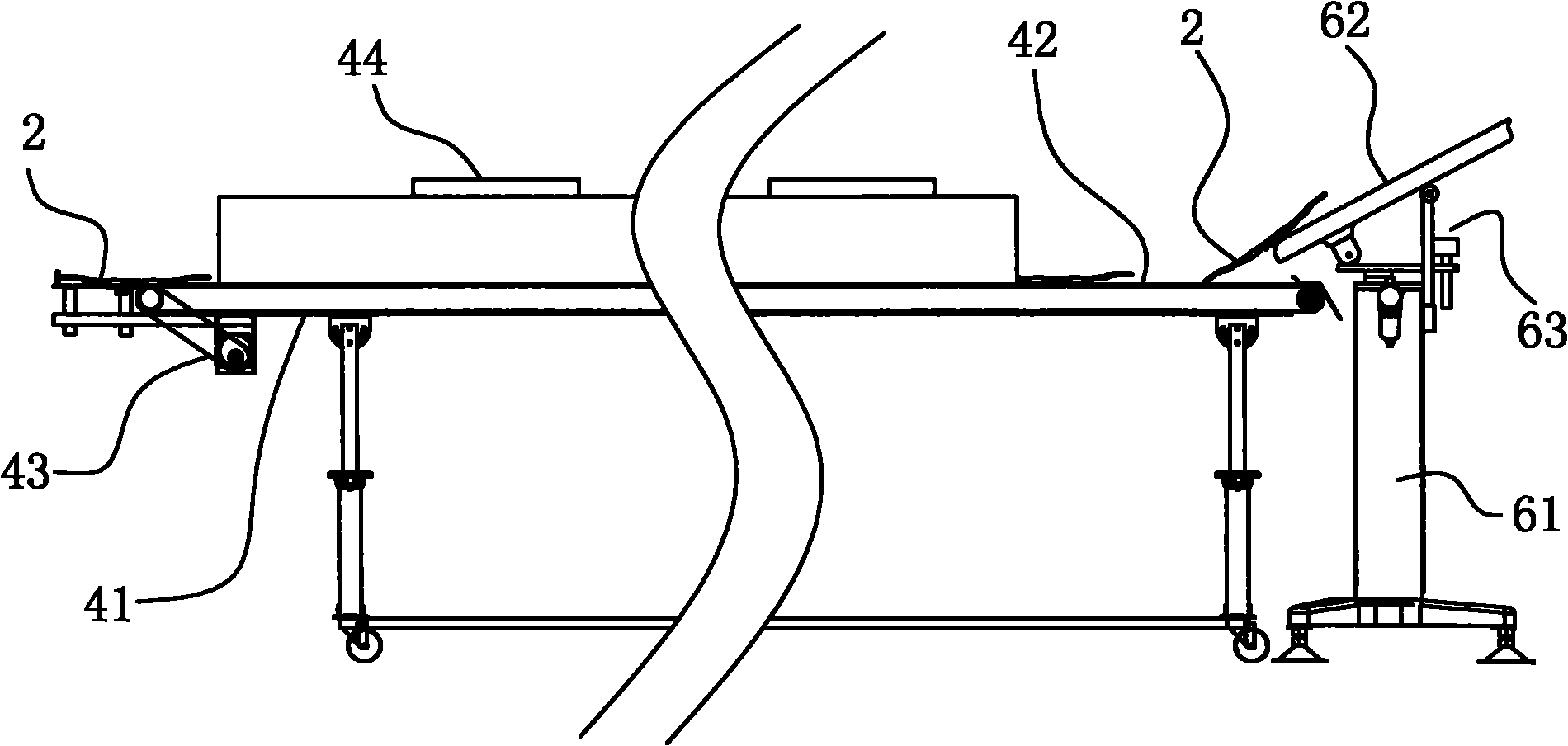

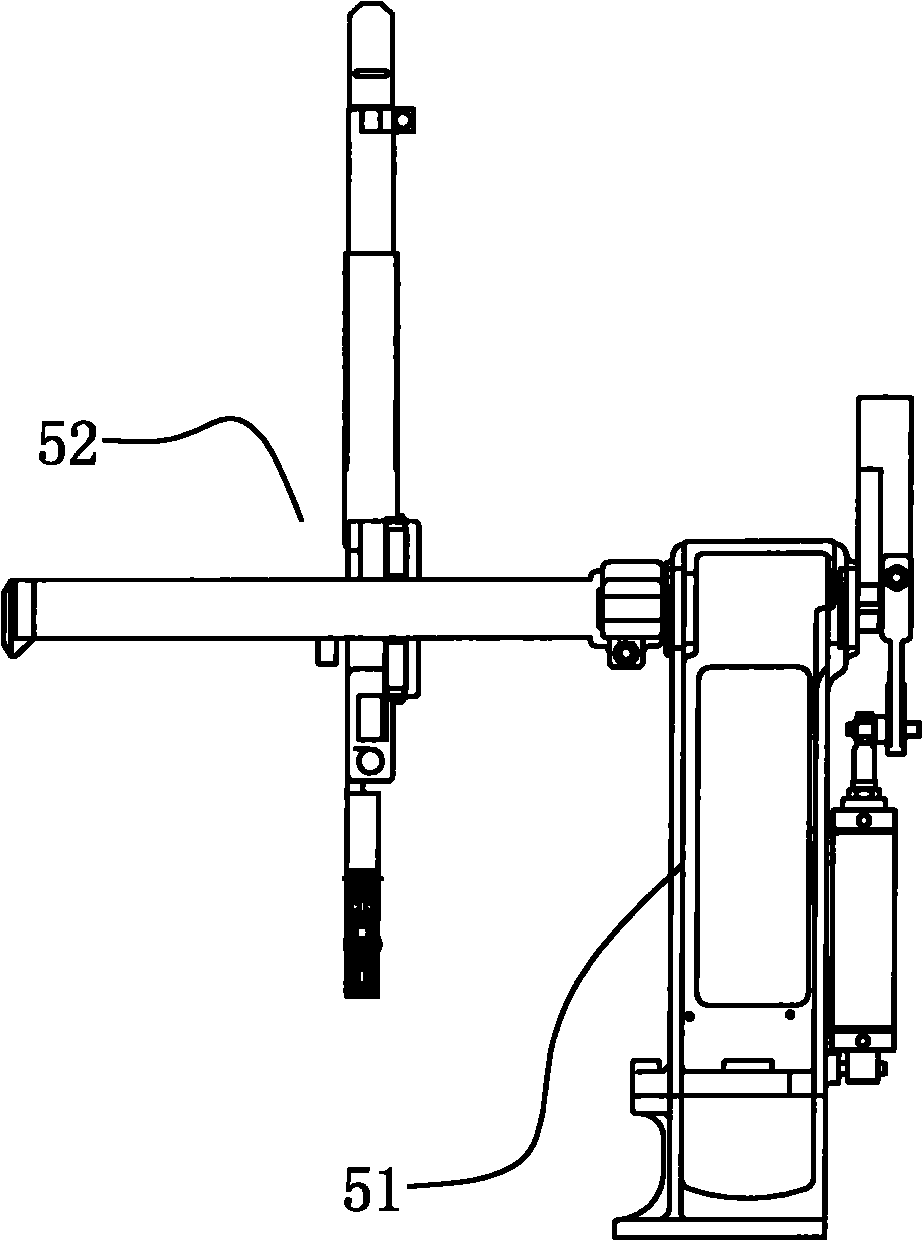

[0040] Example: see figure 1 , figure 2 , image 3 ,and Figure 4 , the embodiment of the present invention provides a toothbrush handle secondary injection molding method, characterized in that it comprises the following steps:

[0041] (1) a forming injection molding machine 1 is set, and the toothbrush body 2 is injection-molded with rice;

[0042] (2) An overmolding injection molding machine 3 is set, which is used to carry out secondary overmolding injection molding on the toothbrush body 2 to obtain a finished product;

[0043] (3) A control system is provided, which is respectively connected with the forming injection molding machine 1 and the overmolding injection molding machine 3, and controls their working states. The method provided by the invention can realize secondary injection molding on the basis of not changing the existing structure of the mould, effectively reduces the production cost, and has good product quality.

[0044] (4) set one and be connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com