Production equipment of high-purity superfine active zinc powder and method for preparing same

A technology for production equipment and active zinc, which is applied in the field of production equipment and the preparation of high-purity ultrafine active zinc powder, can solve the problems of zinc powder oxidation and moisture absorption, low yield of zinc powder fine-grained grade, high impurity content of zinc powder, etc., to achieve The effect of low production cost and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

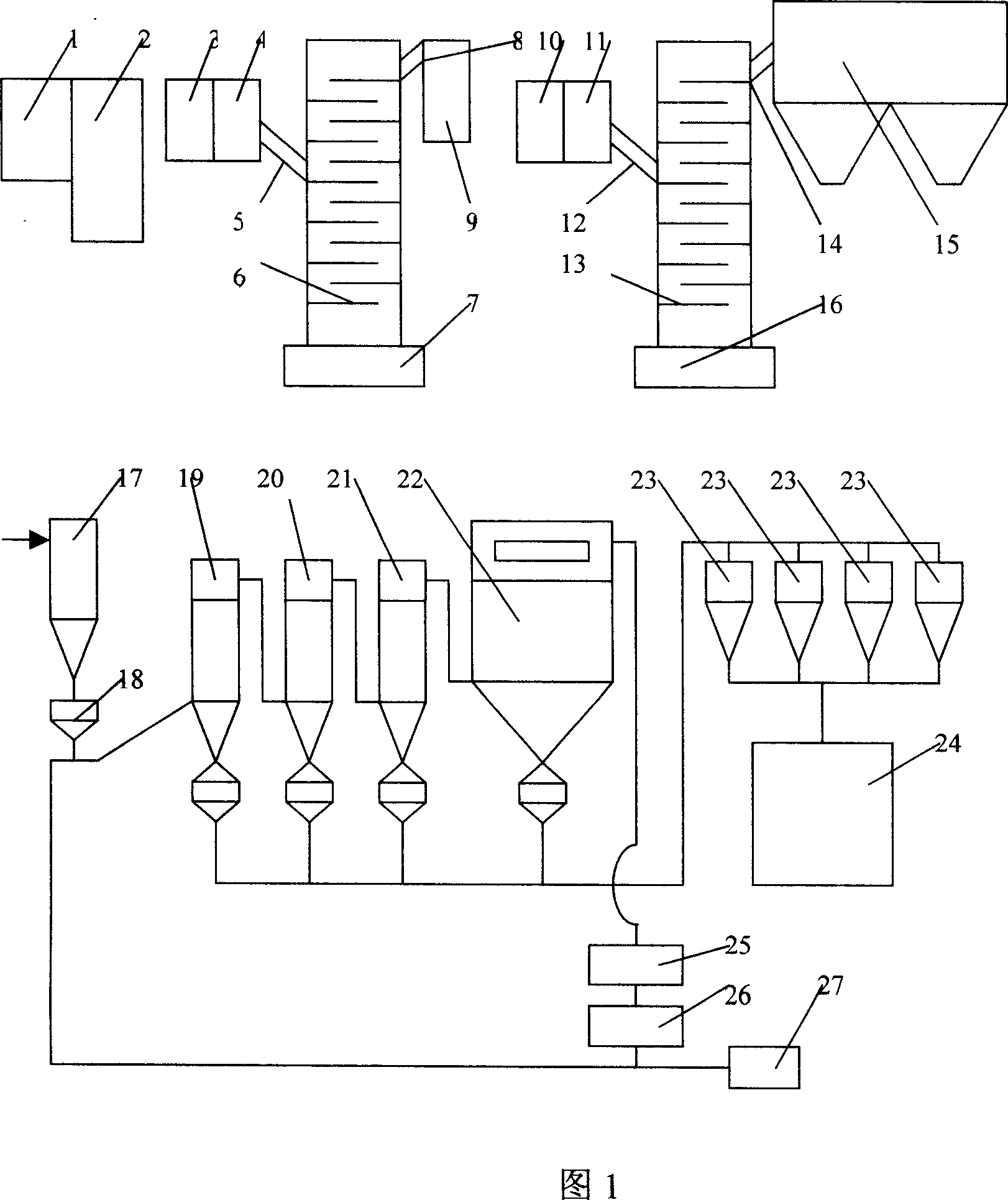

[0041]See Figure 1. Use crude zinc to produce high-purity ultra-fine active zinc powder. Put the zinc ingot into the melting furnace 1, melt it into zinc liquid at a temperature of 600-650°C and introduce it into the melting furnace 2, and separate part of the lead and iron after smelting at a temperature of 460-550°C for 60-80 hours After removing impurities, put the preliminary purified crude zinc liquid into the holding furnace 3 at 600-650°C for heat preservation. Through the feeder 4, the zinc liquid in the holding furnace 3 is quantitatively added to the cadmium tower 6 through the zinc liquid conduit 5 to distill and remove cadmium. The cadmium condenser 9 is condensed into crude cadmium. The temperature of each part of the cadmium tower is as follows: the temperature during combustion is 1000-1300°C, the temperature of the split chamber is 800-900°C, the temperature of the cadmium condenser is 600-800°C, and the temperature of the cadmium-free zinc storage tank is 60...

Embodiment 2

[0044] See Figure 1. High-purity ultra-fine active zinc powder is produced by a mixture containing impurities such as lead and iron and a small amount of zinc. The mixture liquid containing impurities such as lead and iron and a small part of zinc is directly added to the lead tower holding furnace 10 at 600-650° C. for heat preservation. The zinc liquid in the lead tower holding furnace 10 is quantitatively added to the lead tower 13 through the feeder 11 through the cadmium-free zinc liquid conduit 12 (temperature 650-1300°C) to distill and remove high-boiling impurities such as lead and iron, and the pure zinc vapor passes through the zinc The steam air duct 14 enters the zinc powder condenser 15 to condense into zinc powder, and the mixture liquid containing impurities such as lead and iron and a small part of zinc flows into the zinc storage tank 16 at the lower part of the lead tower. The temperature of each part of the lead tower is as follows: the temperature during c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com