Process for preparing polyvinyl chloride in 70.5 mcube polymeri reactor

The technology of polyvinyl chloride and polymerization kettle is applied in the field of producing polyvinyl chloride by using a 70.5m3 polymerization kettle, which can solve the problems of high labor intensity of workers, unable to keep up with supporting technologies, and low product quality, etc., so as to reduce labor intensity of workers and save money. Non-productive time, significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

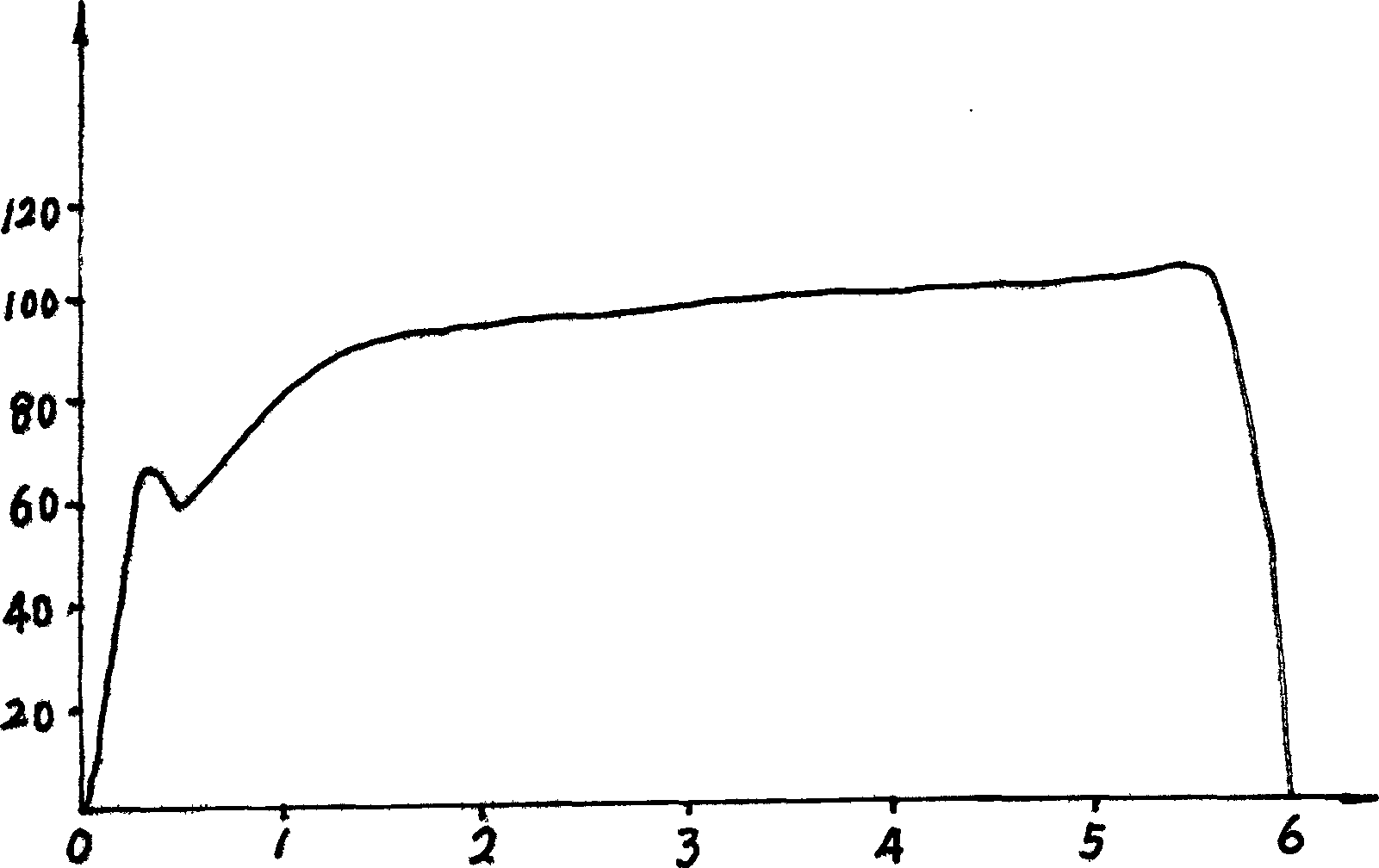

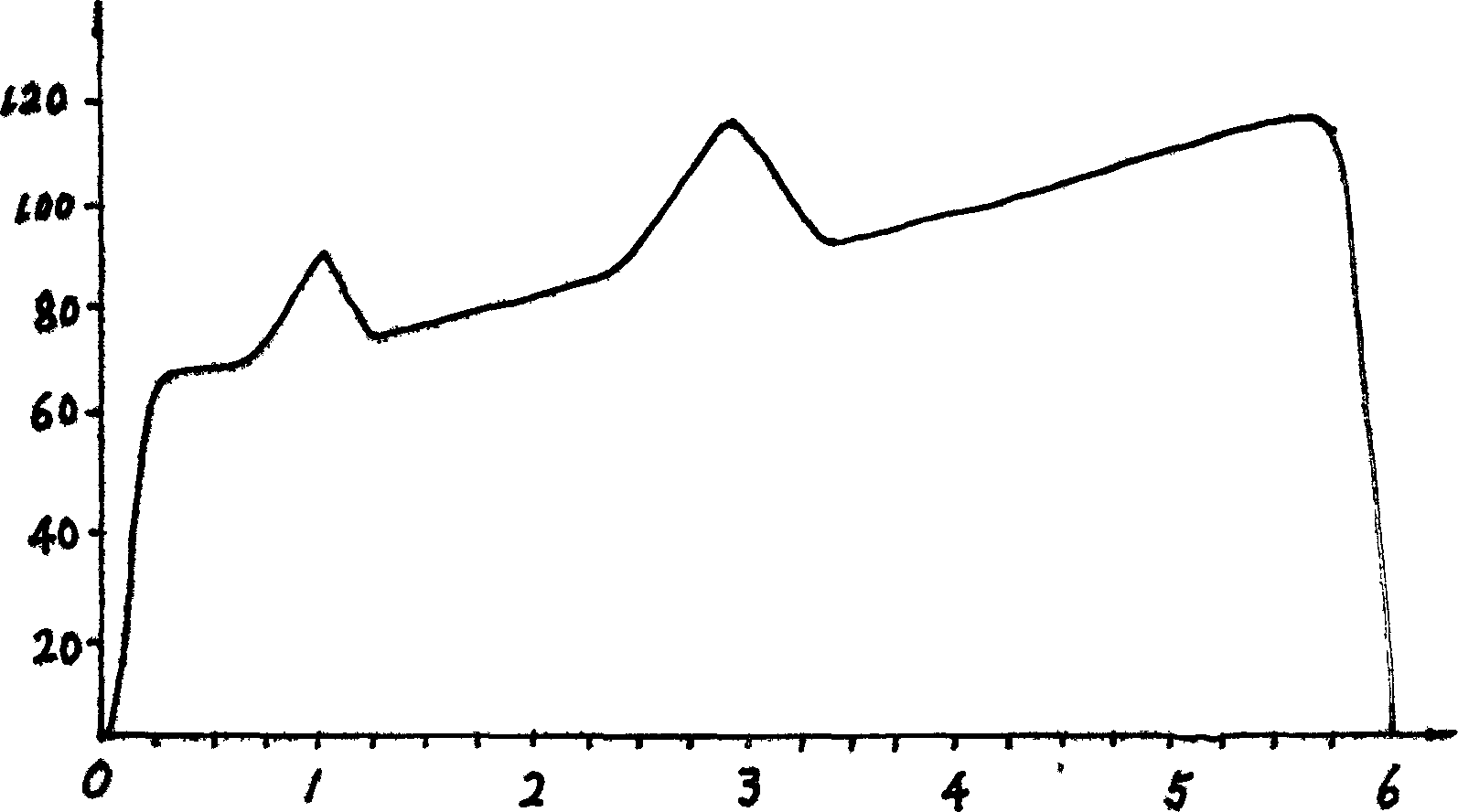

Image

Examples

Embodiment 1

[0025] Take SG-5 type polyvinyl chloride as an example:

[0026] In the closed state of the lid of the kettle, it is fixed at 70.5m 3 The corresponding feeding port in the polymerization kettle shall carry out the following procedures in sequence: rinse the polymerization kettle with deionized water, discharge the waste water into the waste water tank at the same time, then perform steam coating on the wall, and then rinse to remove the unadhered anti-sticking kettle agent and arrange them side by side into the waste water tank, add 49kg of buffer with a solid content of 8%, flush the pipeline with 200kg of deionized water into the polymerization kettle; add VCM28.68m 3 and 30.86m of deionized water at a temperature of 87±2°C 3 , the temperature of adding water is based on the fact that after adding VCM and water, the reaction temperature reaches 57°C; adding dispersant PVA-224E is 105kg, and the solid content is 4%, adding dispersant Alcotex72.5 and HPMC is 200.7kg, of which...

Embodiment 2

[0032] Embodiment two is basically the same as embodiment one, except that what is produced is SG-3 type polyvinyl chloride, and its process formula is shown in Table 3:

[0033] Table 3 SG-3 type polyvinyl chloride production process formula

[0034] h 2 O vcm Coating Agent Buffering Agent PVA-224E Alcotex72.5 HPMC EHP TBPP Trigonox99 Chain Transfer Agent Terminating Agent Reaction Temperature

[0035] m 3 m3 m 3 kg kg kg kg kg kg kg kg m 3 ℃

[0036] 31.86 27.68 0.02 3.92 4.2 11.238 1.405 12 4 0.01 52

Embodiment 3

[0038] Embodiment three is basically the same as embodiment one, except that what is produced is SG-7 type polyvinyl chloride, and its process formula is shown in Table 4:

[0039] Table 4 SG-7 type polyvinyl chloride production process formula

[0040] h 2 O vcm Coating Agent Buffering Agent PVA-224E Alcotex72.5 HPMC EHP TBPP Trigonox99 Chain Transfer Agent Terminating Agent Reaction Temperature

[0041] m 3 m 3 m 3 kg kg kg kg kg kg kg kg m 3 ℃

[0042] 30.86 28.68 0.02 3.92 3.8 11.238 1.405 3 9 1 4 0.1 60

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com