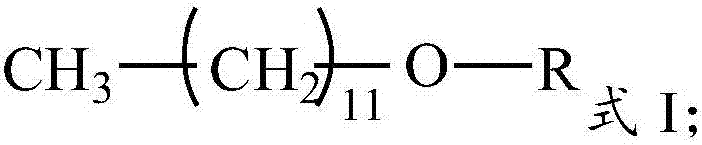

Laurinol alkyl ether, as well as preparation method and drilling fluid thereof

A technology of lauryl alcohol alkyl ether and lauryl alcohol, which is applied in the directions of ether preparation, chemical instrument and method, drilling composition, etc., can solve problems such as poor biodegradation performance, application limitation, environmental toxicity, etc., and achieve good product quality , mild conditions, good inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

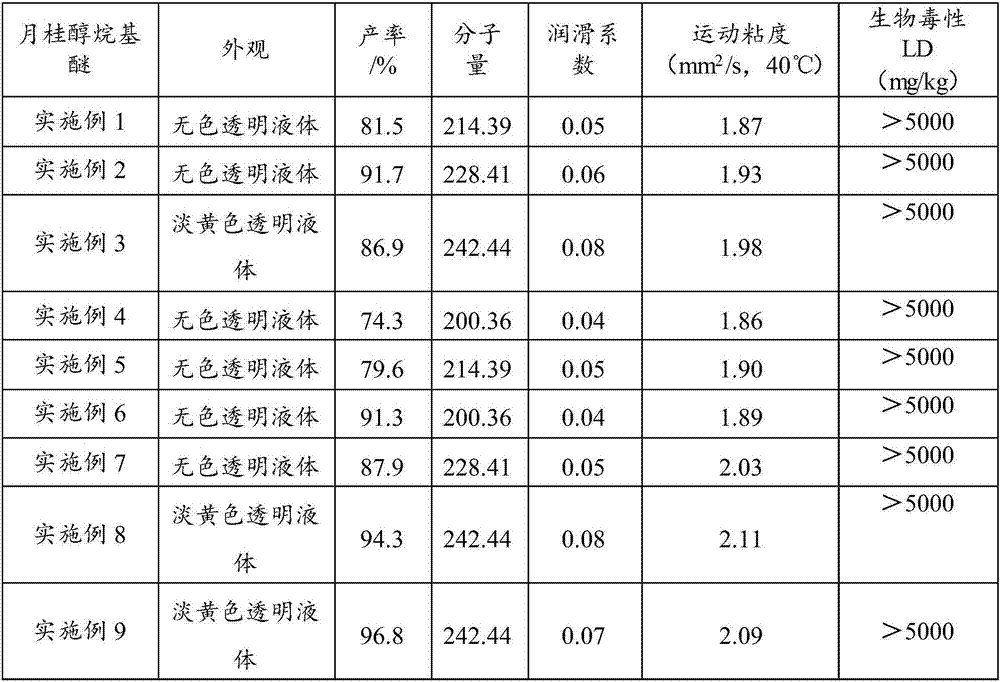

Examples

preparation example Construction

[0030] The invention provides a preparation method of the lauryl alkyl ether described in the above technical scheme, comprising:

[0031] Under the action of catalyst, react lauryl alcohol, alkyl reagent and basic compound to obtain lauryl alcohol alkyl ether;

[0032] The number of alkyl groups in the alkyl reagent is 1-10.

[0033] In the present invention, the temperature of the reaction is preferably 60°C to 120°C, more preferably 80°C to 100°C, and most preferably 85°C to 95°C. In the present invention, the reaction time is preferably 18 hours to 24 hours, and more preferably 20 hours to 22 hours. In the present invention, preferably lauryl alcohol, an alkyl reagent, a basic compound and a catalyst are added to the reaction kettle, mixed and then reacted to obtain lauryl alcohol alkyl ether. In the present invention, the reactor is preferably a reactor with stirring, condensing and heating equipment. The present invention preferably conducts the reaction under stirrin...

Embodiment 1

[0056] Add 1mol lauryl alcohol, 0.5mol chloroethane, 0.5mol sodium hydroxide and 0.025mol 1-butyl-3-methylimidazole hexafluorophosphoric acid ionic liquid catalyst into the reactor with stirring, condensation and heating device, stir and mix Homogeneous, reacted at 60°C and 200rpm for 12h, then lowered to room temperature to obtain a crude solution;

[0057] Add 1mol n-hexane extractant in three times to the above-mentioned crude solution, and the addition amount of each time is 0.33mol. After mixing evenly, let stand, the obtained solution is divided into two layers; use a separatory funnel with a capacity of 1000mL to separate to obtain The lower layer is 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid, and the upper layer is lauryl ether-n-hexane solution; the 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid can be directly used in the lower layer. For the preparation of one-time lauryl alcohol alkyl ether, the lauryl alcohol ethyl ether-n-hexane so...

Embodiment 2

[0061] 1mol lauryl alcohol, 1.5mol chloropropane, 1.5mol potassium hydroxide and 0.25mol 1-hexyl-3-methylimidazole hexafluorophosphoric acid ionic liquid catalyst are added in the reactor with stirring, condensation and heating device, and stirring and mixing are uniform, The reaction was carried out at 120 °C and 300 rpm for 24 h, and then lowered to room temperature to obtain a crude solution;

[0062] A total of 1.5mol of cyclohexane extractant was added to the above-mentioned crude solution in three times, and the amount of each addition was 0.5mol. After mixing, the resulting solution was left standing, and the resulting solution was divided into two layers; Separation, the obtained lower layer is 1-hexyl-3-methylimidazolium hexafluorophosphoric acid ionic liquid, and the upper layer is lauryl alcohol propyl ether-cyclohexane solution; the 1-hexyl-3-methylimidazolium hexafluorophosphoric acid ionic liquid can be directly For the next preparation of lauryl alcohol alkyl et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com