Method for producing low-salt high-quality dense soda ash

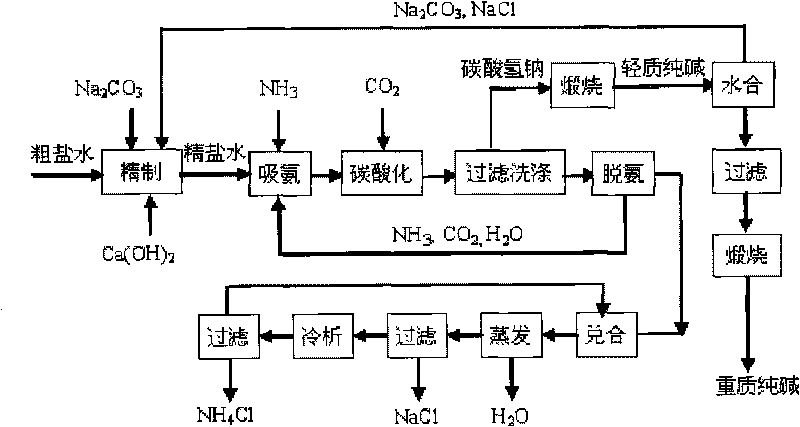

A technology of heavy soda ash and soda ash, which is applied in the manufacturing industry of chemical basic raw material soda ash and the field of preparation of low-salt heavy soda ash, which can solve the problems of large waste liquid discharge and the inability to produce low-salt heavy soda ash by cold method combined with soda , to achieve the effect of good product quality and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The crude brine is refined by the lime-soda ash method, that is, the Ca(OH) 2 Precipitate magnesium with Na 2 CO 3 Precipitates calcium, Mg(OH) 2 and CaCO 3 Precipitation; refined brine absorbs ammonia to make it reach F NH3 100tt,T Cl - 90tt, F NH3 / Na+ 1.11, at a temperature of 38°C, enter the carbonization tower, and the volume fraction of CO entering under the tower is 50% 2 carbonation reaction, the temperature in the middle of the carbonization tower is controlled at 62°C, the take-out temperature is 30°C, and the CO in the carbonization tail gas2 The volume fraction is 5%. After the resulting sodium bicarbonate suspension is taken out from the lower part of the tower, it is filtered with a vacuum filter and spray washed. The washing water temperature is 40°C. The washing water volume per ton of soda ash is 750kg. The sodium bicarbonate filter cake base contains salt The amount is 0.35%, calcining sodium bicarbonate at 180°C, the firing rate is 50%, and the ...

Embodiment 2

[0032] The crude brine is refined by the lime-soda ash method, that is, the Ca(OH) 2 Precipitate magnesium with Na 2 CO 3 Precipitates calcium, Mg(OH) 2 and CaCO 3 Precipitation; refined brine absorbs ammonia to make it reach F NH3 101tt,T Cl - 89tt,F NH3 / Na+ 1.13, the temperature is 35°C, enter the carbonization tower, and the volume fraction of CO entering under the tower is 70% 2 carbonation reaction, the temperature in the middle of the carbonization tower is controlled at 64°C, the take-out temperature is 34°C, and the CO in the carbonization tail gas 2 The volume fraction is 7%. After the resulting sodium bicarbonate suspension is taken out from the lower part of the tower, it is filtered with a vacuum filter and spray washed. The washing water temperature is 42°C. The washing water volume per ton of soda ash is 820kg. The sodium bicarbonate filter cake base contains salt The amount is 0.25%, sodium bicarbonate is calcined at 190°C, the firing rate is 50%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com