Pump cap screwing machine

A technology of capping machine and pump cap, which is applied in the direction of threaded bottle caps, etc., which can solve the problem that the direction of the bottle cap mouth is consistent, the suction pipe of the straw-type pump cap cannot be lifted and accurately inserted into the bottom of the bottle, and the cap of the straw-type pump cap cannot be screwed. Work and other problems, to achieve the effect of adjustable cap tightening force, easy maintenance, and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the content of the present invention easier to understand clearly, the following further describes the present invention in detail based on specific embodiments and in conjunction with the accompanying drawings.

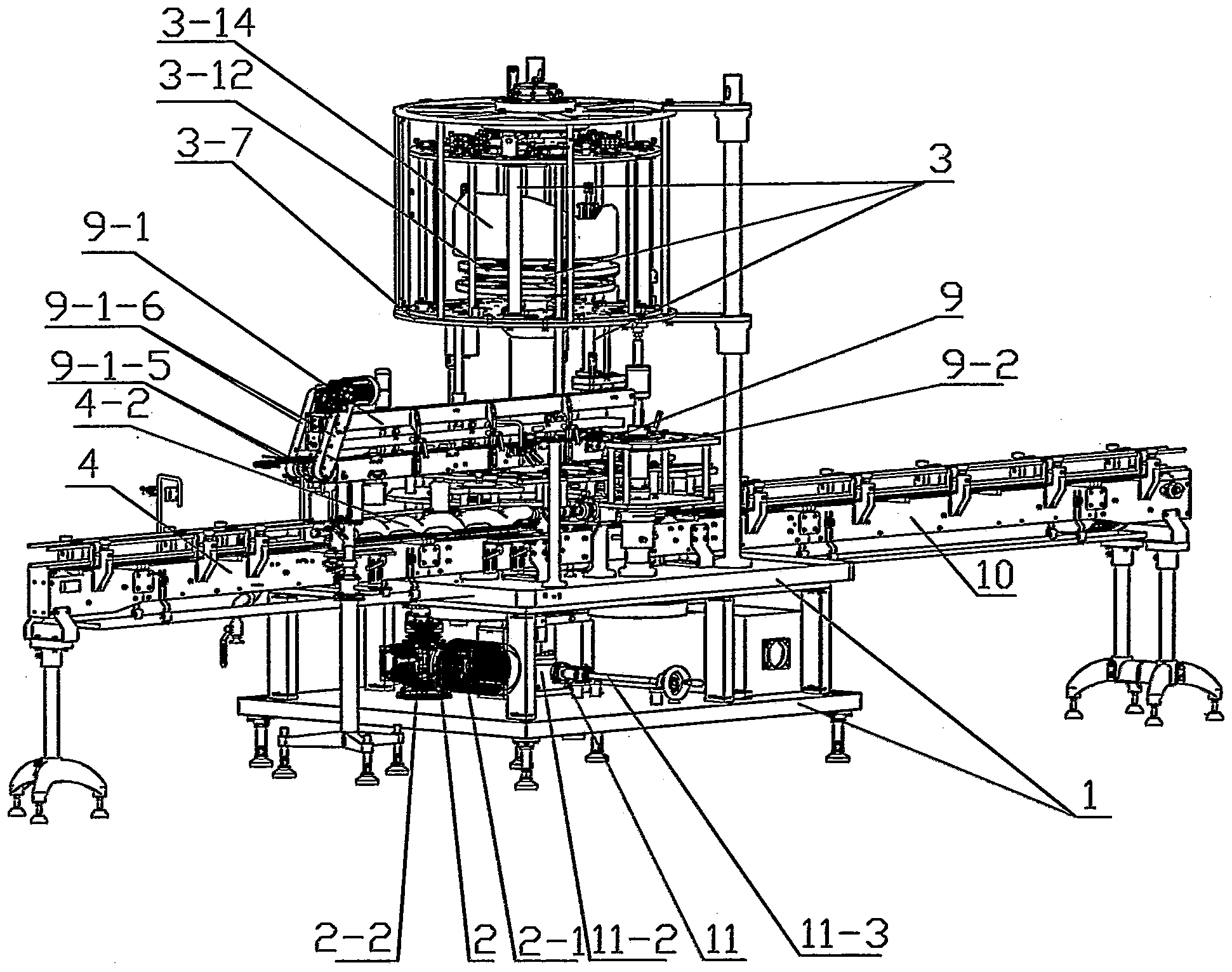

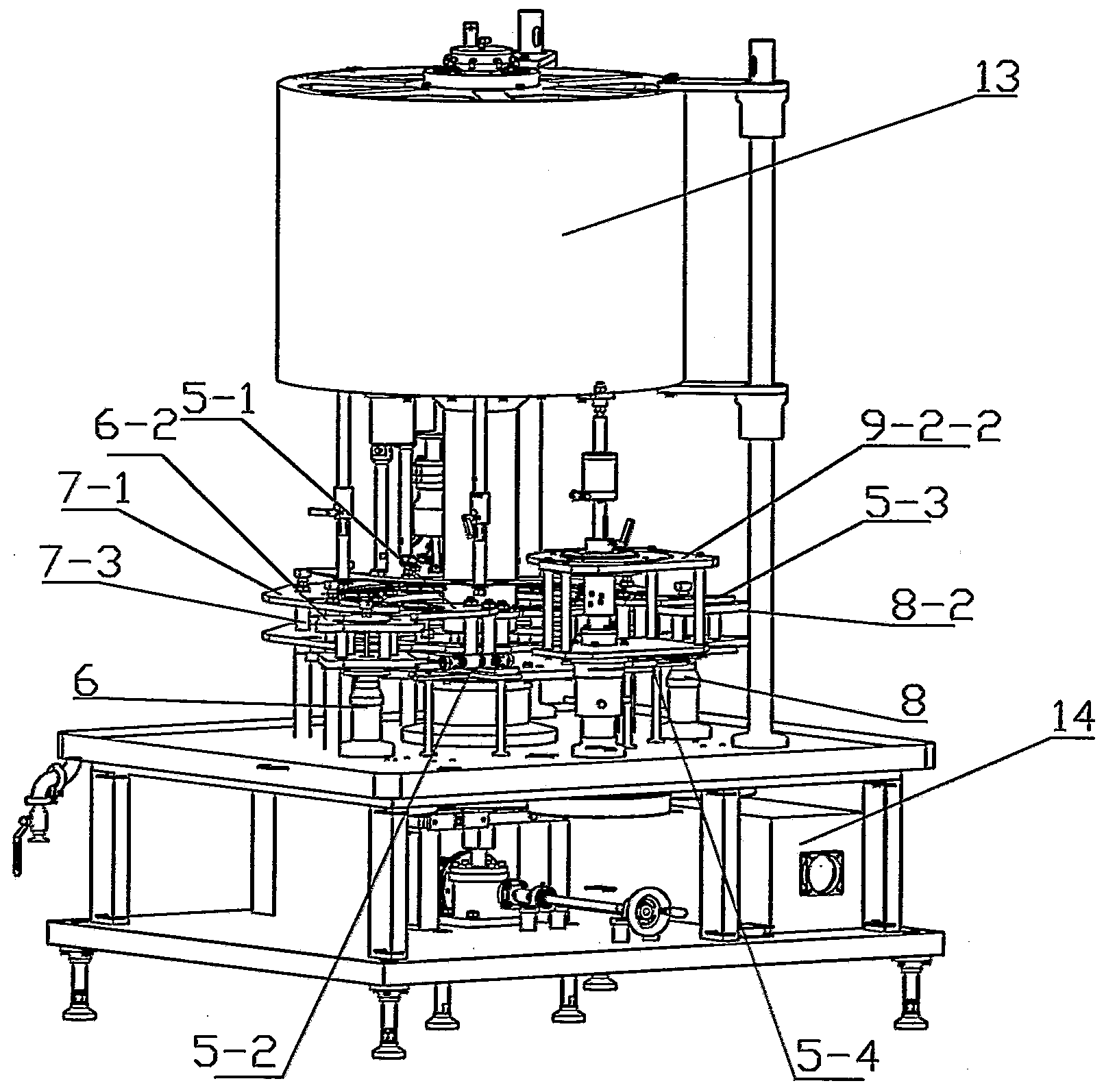

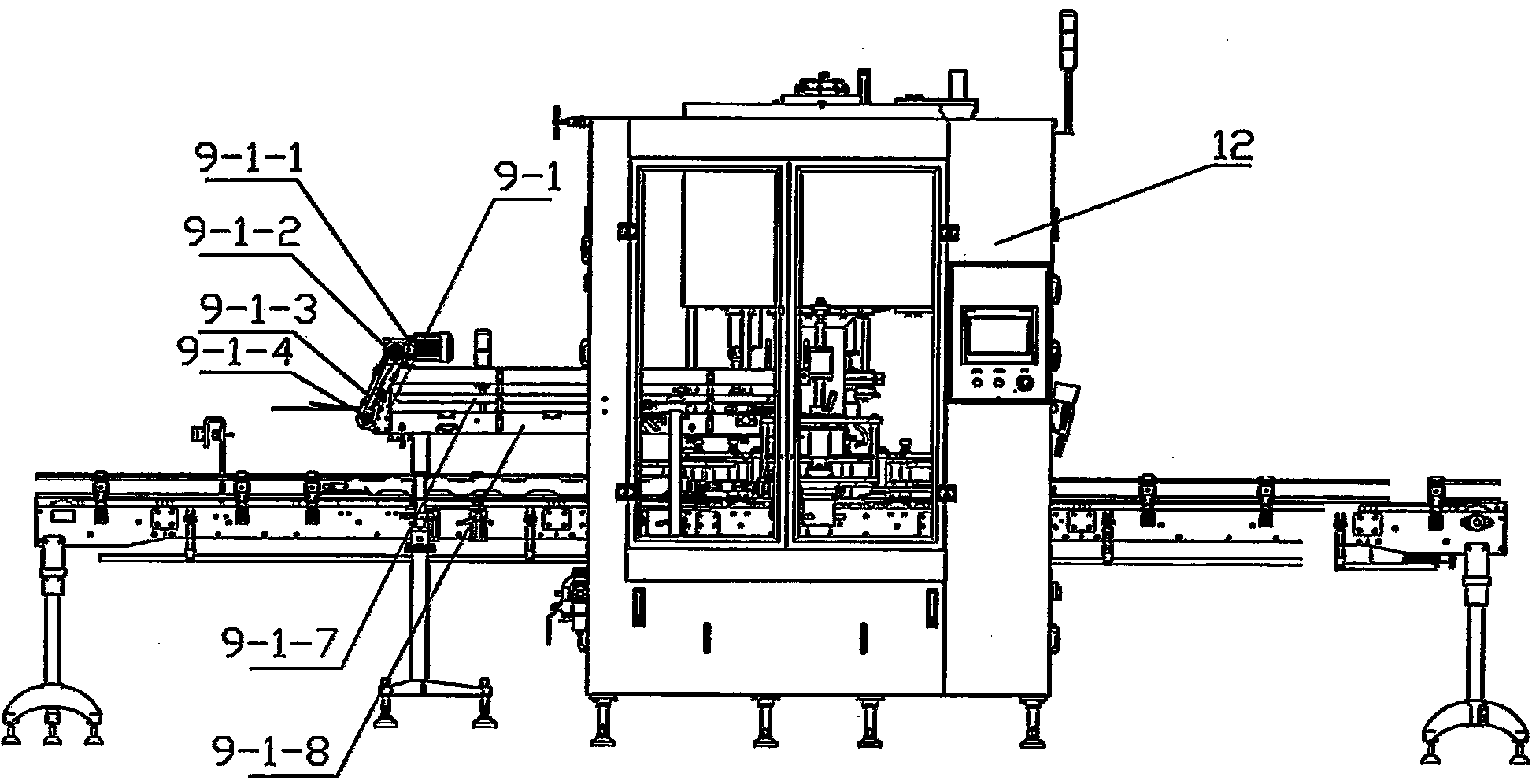

[0045] Such as Figure 1~15 As shown, a pump cap screwing machine includes a frame 1, a power transmission device 2, a cap screwing assembly 3, a bottle body supply device 4, a first bottle guiding device 5, a second bottle guiding device 15, and a bottle feeding device Star wheel device 6, bottle blocking device 7, bottle outlet star wheel device 8, cap supply device 9 and bottle output device 10, among which:

[0046] A. Bottle body supply device 4 includes screw 4-2, cardan shaft coupling 4-3, screw drive power part 4-4, bottle conveyor belt 4-1 for conveying the bottle body, screw drive power part 4-4 The screw 4-2 is connected to the screw 4-2 through the universal joint shaft coupling 4-3. The screw 4-2 is arranged on the side above the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com