Automatic carrying device of spool of stranding machine

A technology of handling device and I-shaped wheel, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problem that the picking and placing position of the workpiece cannot be accurately positioned, the angle of the workpiece in the horizontal direction is difficult to adjust, and the production process cannot be automated. and other problems, to achieve the effect of precise positioning, stable action, and large clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

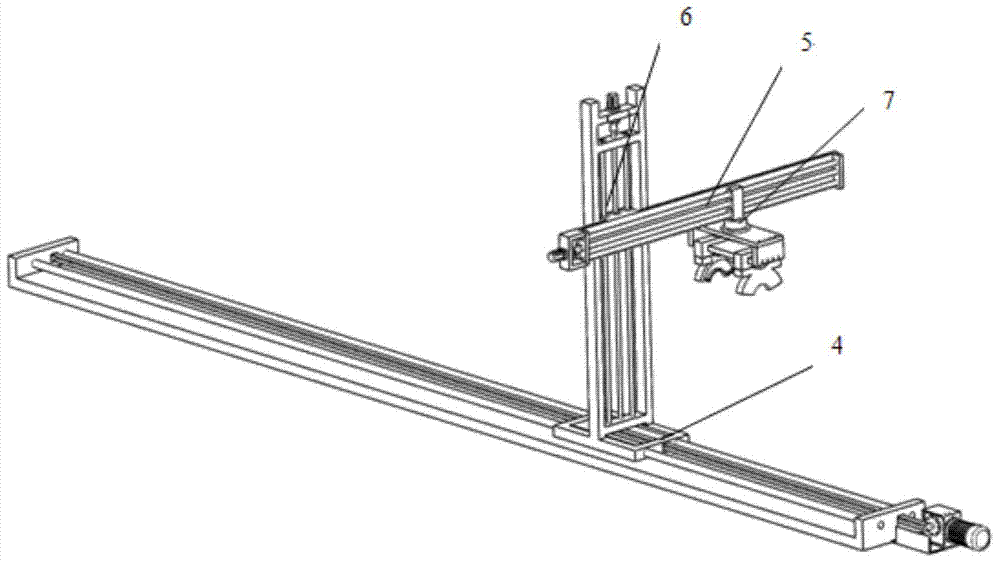

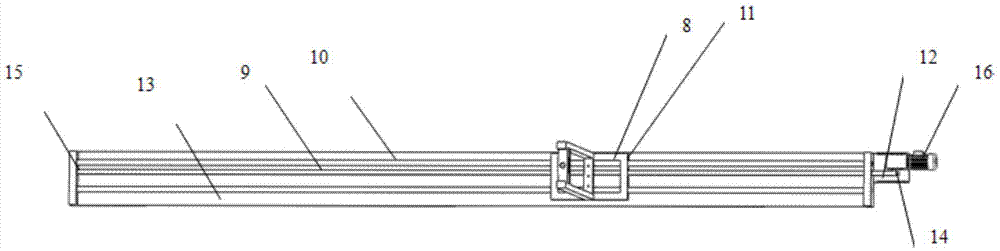

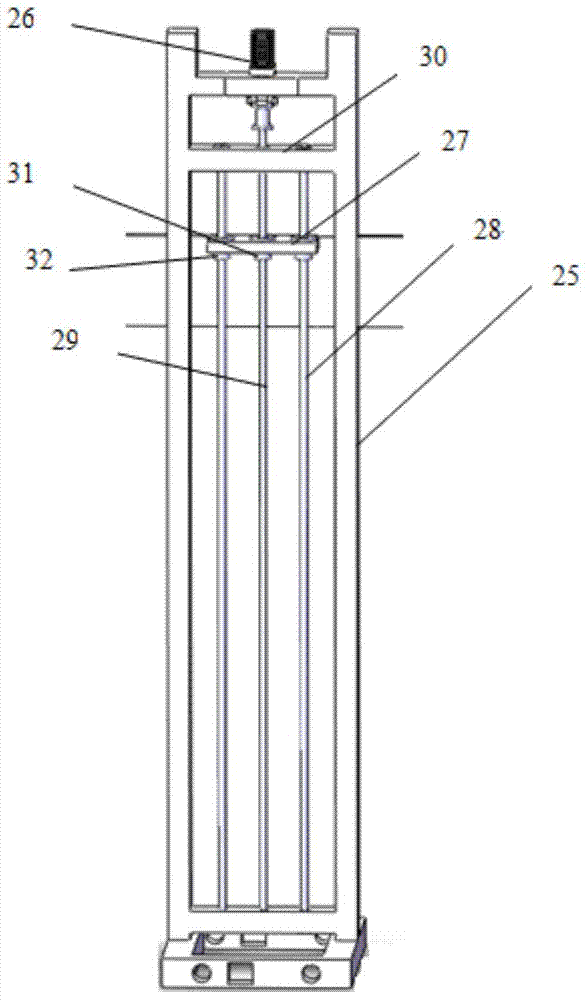

[0023] See attached image, as figure 1 As shown, an automatic handling system for the I-shaped wheel of a stranding machine is characterized in that it includes a handling robot 1 and an I-shaped wheel gripper 2, and the described handling robot 1 is composed of a longitudinal movement mechanism 4, a lateral movement mechanism 5, and a vertical movement Mechanism 6, rotating mechanism composition 7; described longitudinal movement mechanism 4 is connected with longitudinal guide column 10 by moving pairs, and described longitudinal movement mechanism 4 is fixedly connected with synchronous belt 9, moves longitudinally along longitudinal guide column; The mechanism 7 is affixed to the lower end of the horizontal slider 18; the said I-shaped wheel gripper 2 is affixed to the lower end of the said rotating mechanism 7; said longitudinal movement mechanism 4, lateral movement mechanism 5, vertical movement mechanism 6, rotation The mechanism 7 jointly realizes the movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com