Banana picking device and picking method

A technique for holding bananas and holding hands, which is applied to banana picking devices and picking fields, and can solve problems such as low picking efficiency, impact on picking, and injury to pickers, achieve broad market application and promotion prospects, improve applicability and work efficiency, and clamp Tight process stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

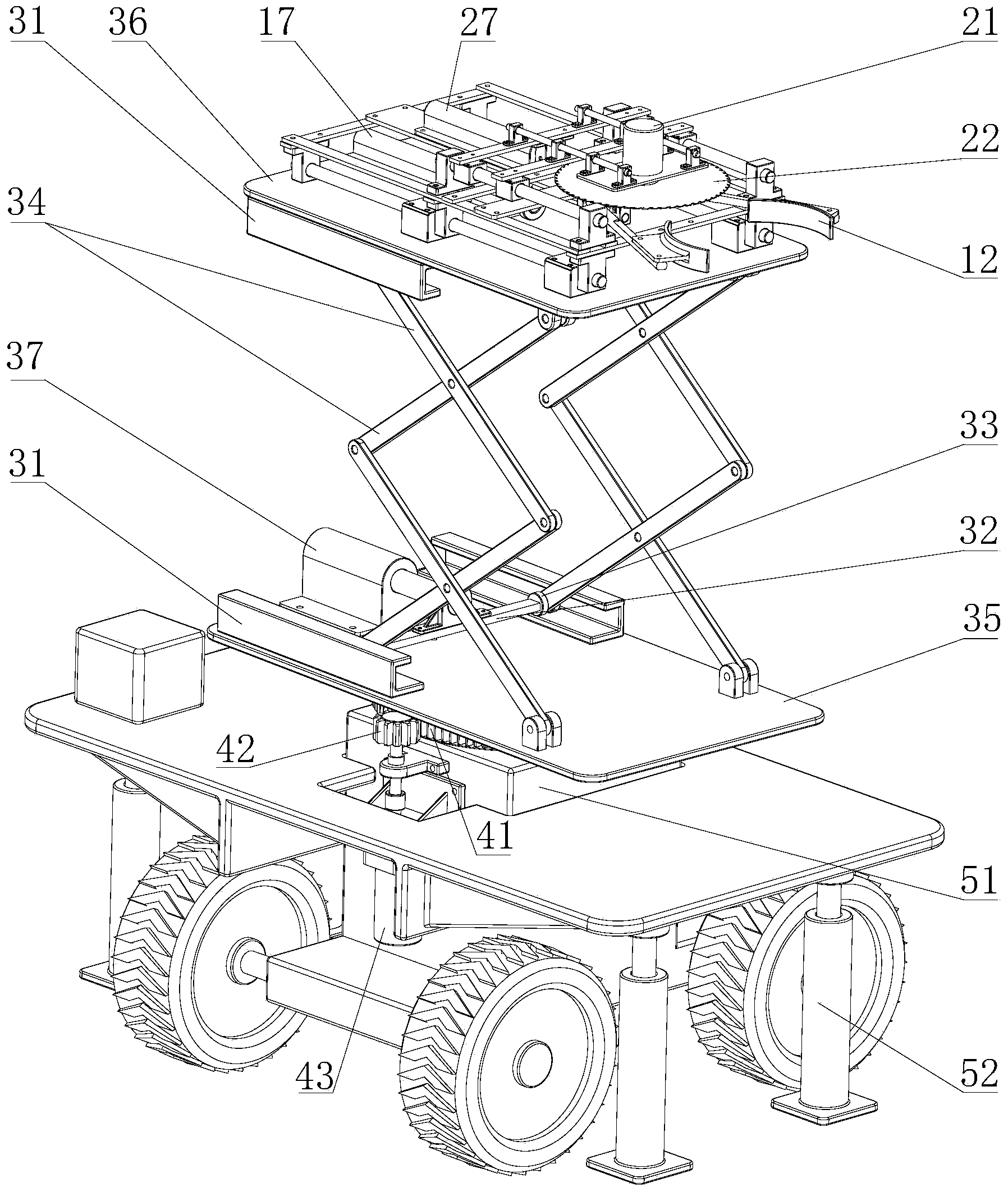

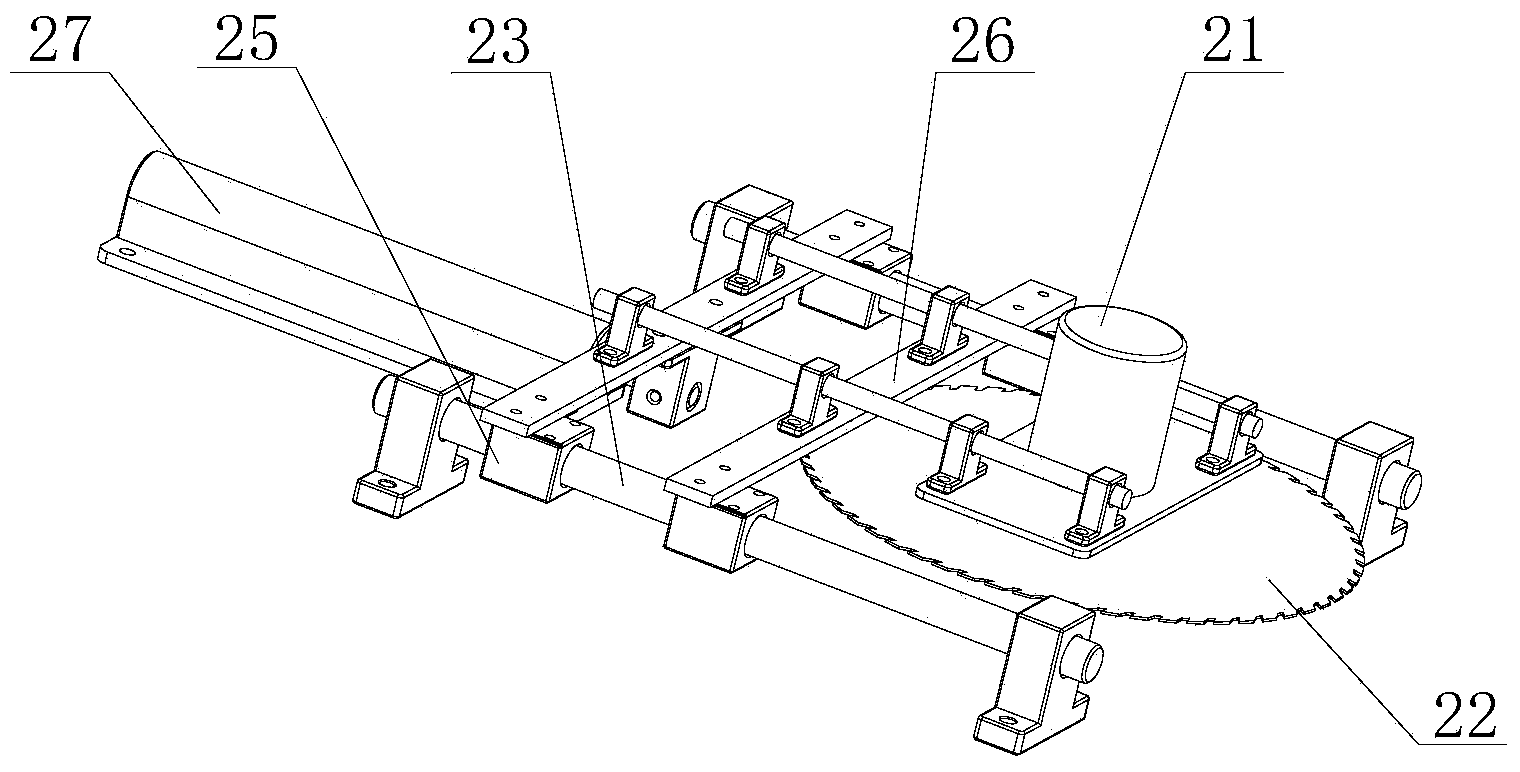

[0043] Such as Figure 1-3 As shown, a banana picking device includes a frame, a cutting tool arranged on the top of the frame and used for cutting off the fruit handle, a clamping hand arranged at the front end of the frame and clamping the fruit handle, and the clamp The handle includes a clamping rod 11, one end of the clamping rod 11 is hinged on the frame, and the other end is provided with a clamper 12, and also includes a slider 13 and a driving assembly, and the slider 13 is slidably connected to the clamping rod 11 ,Such as figure 1 As shown, it also includes a scissor lifting mechanism and a walking trolley 51 for raising or lowering the frame, cutting tools and clamping hands, and the scissor lifting mechanism is installed on the walking trolley 51, and the walking trolley 51 and the scissor-type lifting mechanism are provided with a rotating mechanism that can drive the scissor-type lifting mechanism to rotate. When the walking trolley 51 is provided with operatio...

Embodiment 2

[0047] A method for picking bananas based on the above-mentioned banana picking device, comprising the following steps:

[0048] Step 1: Drive the walking car 51 to the banana tree where the bananas need to be picked;

[0049] Step 2: The hydraulic support feet 52 on the walking trolley 51 support the walking trolley 51 horizontally, so that the walking trolley 51 is in a horizontal state; specifically: start the control system, and measure the inclination angles between the X and Y axes and the horizontal plane with a dual-axis inclination sensor , and the measured value is sent to the embedded processor through the data collector, and the embedded processor performs inverse solution of the posture of the walking trolley 51 according to the inclination angle of the two axes, and calculates the amount of displacement that each hydraulic support foot 52 should compensate, and finally The main controller in the control system controls each hydraulic support foot 52 to expand and...

Embodiment 3

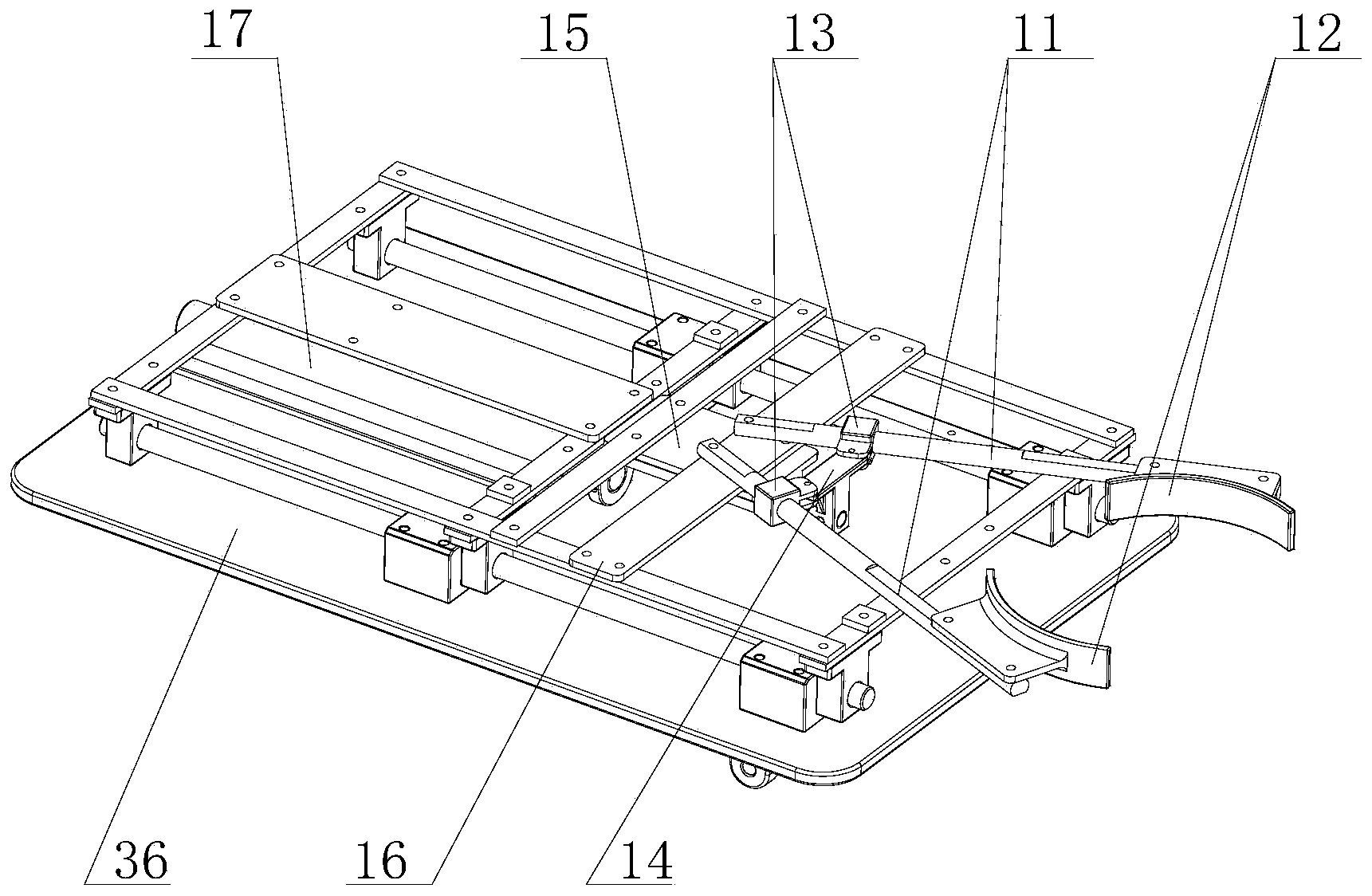

[0056] Such as figure 1 , 2 As shown in and 4, the clamping hand includes two clamping rods 11, two circular arc-shaped clamps 12, two sliders 13, and a generally T-shaped opening and closing mechanism with a vertical bar 141 and a horizontal bar 142. The control part 14, the clamping hand opening and closing drive mechanism 15, the clamping frame 16 and the clamping hand feed drive mechanism 17, wherein the clamping hand opening and closing drive mechanism 15 is installed below the symmetrical center line of the two clamping rods 11 ,Such as Figure 4 As shown, the output end of the clamping hand opening and closing drive mechanism 15 is transmission-connected with the vertical rod 141 of the opening and closing control member 14, one end of the two clamping rods 11 is hinged with the clamping frame 16, and the two sliders 13 are slidably connected to the clamping rods. 11, and respectively hinged with the two ends of the crossbar 142 on the opening and closing control part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com