Fault diagnosis method for rotary machine

A technology for fault diagnosis and rotating machinery, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problem that it is difficult to give the strength structure, it is difficult to distinguish the vibration state of the long semi-axis, and the resolution of the map is low. and other problems to achieve the effect of avoiding misjudgment, high sensitivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The response of rotating machinery to changes in certain process parameters and operating parameters is a complete set of process signals, which are of great value for analyzing the stability of equipment, performing fault diagnosis and parameter identification. Through the analysis of a group of process signals, it is possible to analyze the vibration characteristics of the rotor, query the reasons for the amplitude and phase changes, obtain key parameters such as the critical speed of the actual operation of the unit, determine the unbalanced response of the rotor, and study the resonance of structures and components, etc. It is one of the important basis for fault diagnosis.

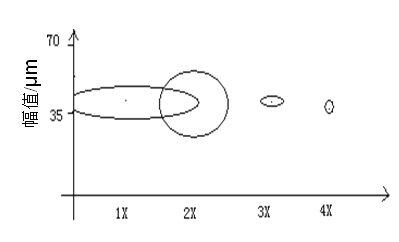

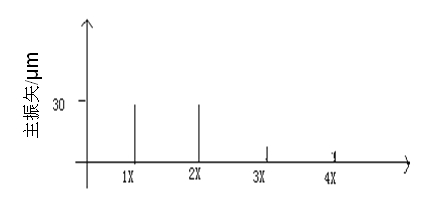

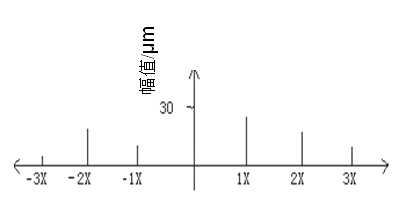

[0035] In the present invention, on the basis of the existing holographic spectrum, full vector spectrum, and full spectrum analysis technology, the relationship between each parameter, the rotor system parameter, and the excitation force parameter is systematically analyzed, and the existing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com