System for measuring evaporation rate of cryogenic vessel with stable back pressure

A low-temperature container and measurement system technology, which is applied in the direction of mass flow measurement devices, etc., can solve problems such as large evaporation rate measurement errors, achieve good voltage stabilization effect, ensure pressure, and control the effect of high degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

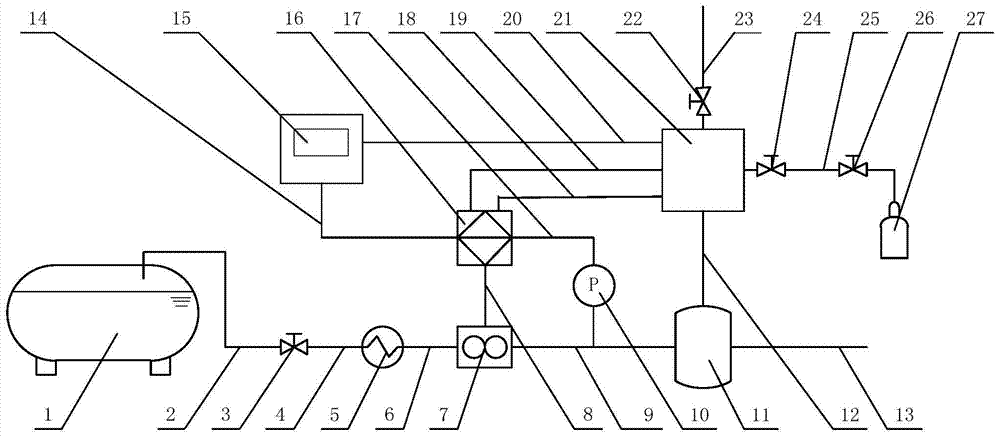

[0017] The present invention will be further described in detail below in conjunction with the above-mentioned embodiments of the accompanying drawings.

[0018] The cryogenic container 1 is used to store cryogenic media, such as liquid oxygen and liquid nitrogen. Since the cryogenic container 1 cannot be absolutely insulated, it will inevitably evaporate naturally. In order to accurately measure the amount of gas emitted by evaporation, in figure 1 In the embodiment, a heat exchanger 5, a connecting pipe 6, a gas mass flow meter 7, a connecting pipe 8, and a buffer tank 11 are sequentially arranged on the discharge pipeline of the cryogenic container 1, that is, after the vent pipe 2, the vent valve 3 and the connecting pipe 4, The gas is then discharged to the atmosphere through the discharge pipe 13 . The system also includes a back pressure control system for regulating the pressure of the buffer tank 11, which includes a pressure sensor 10, a programmable controller 16, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com