Impulse type grain mass flow sensor calibrating and testing device

A mass flow and test device technology, which is applied to mass flow measurement devices, measurement devices, test/calibration devices, etc., can solve the inconvenience of moving the fuselage, the inconvenient adjustment of the installation position of the impulse grain flow sensor, and the vibration intensity of the flow rate and the fuselage Can not be effectively controlled and other problems, to achieve the effect of simple installation, easy disassembly and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

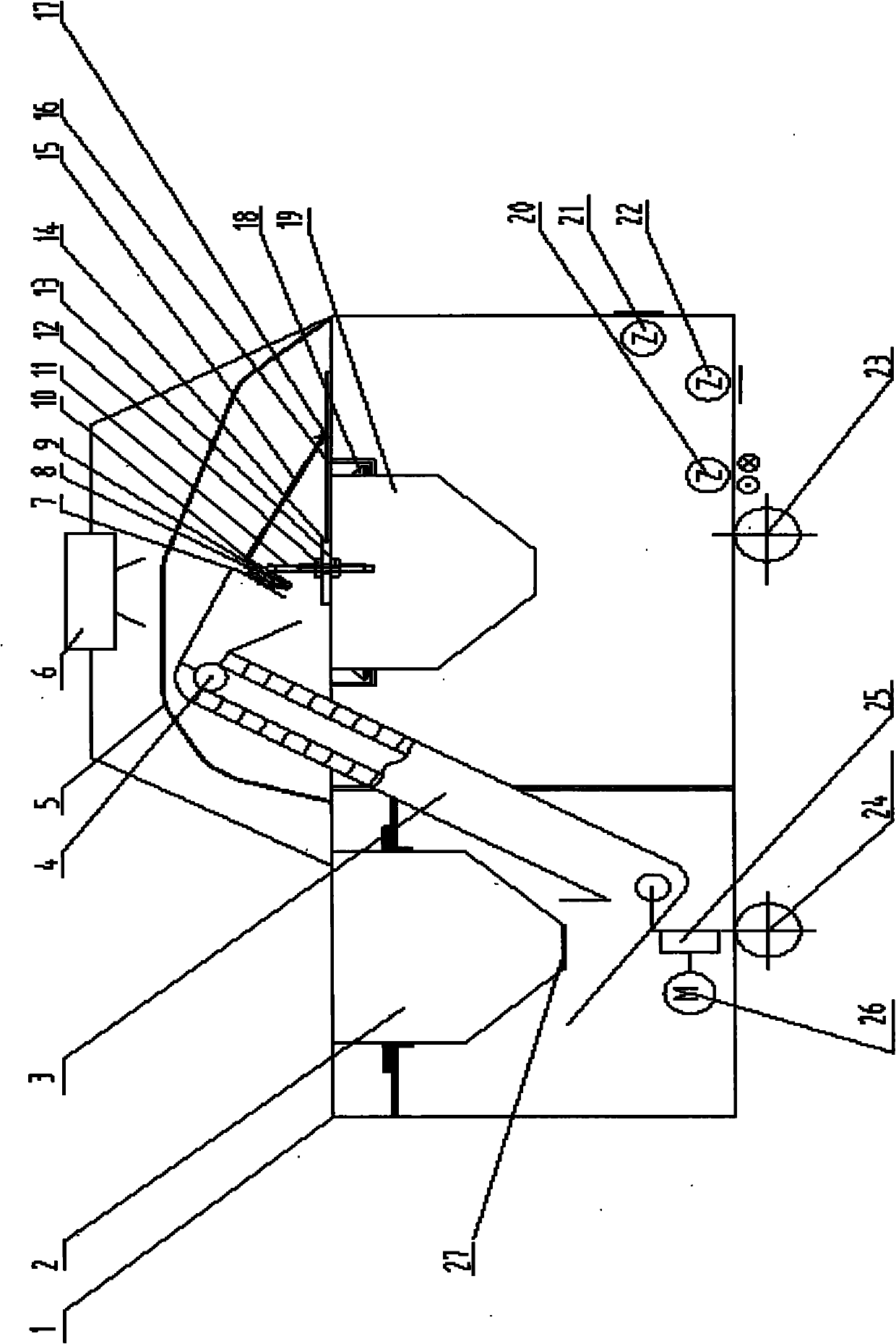

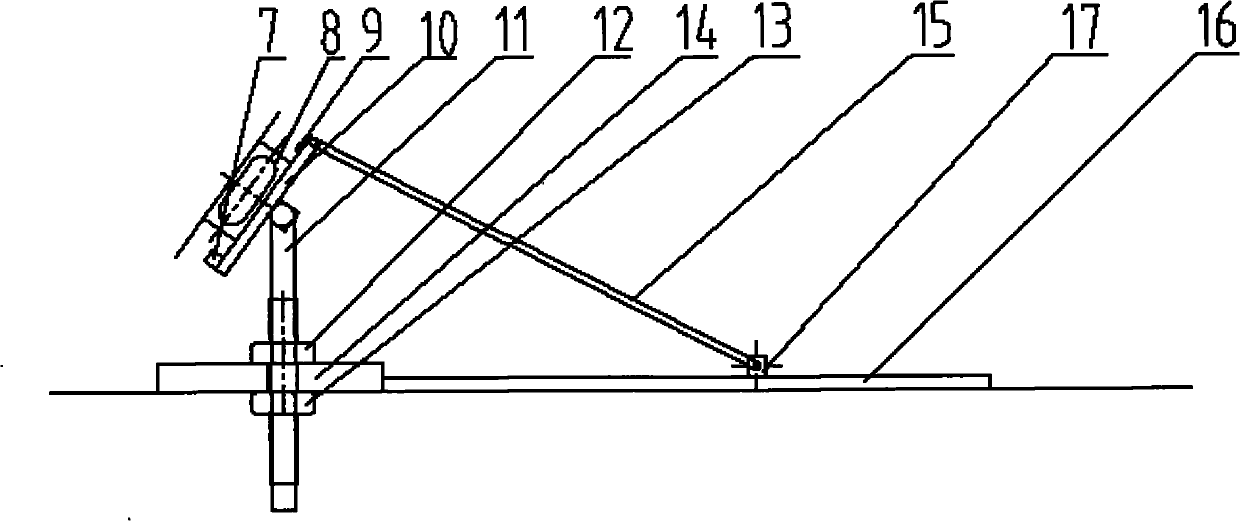

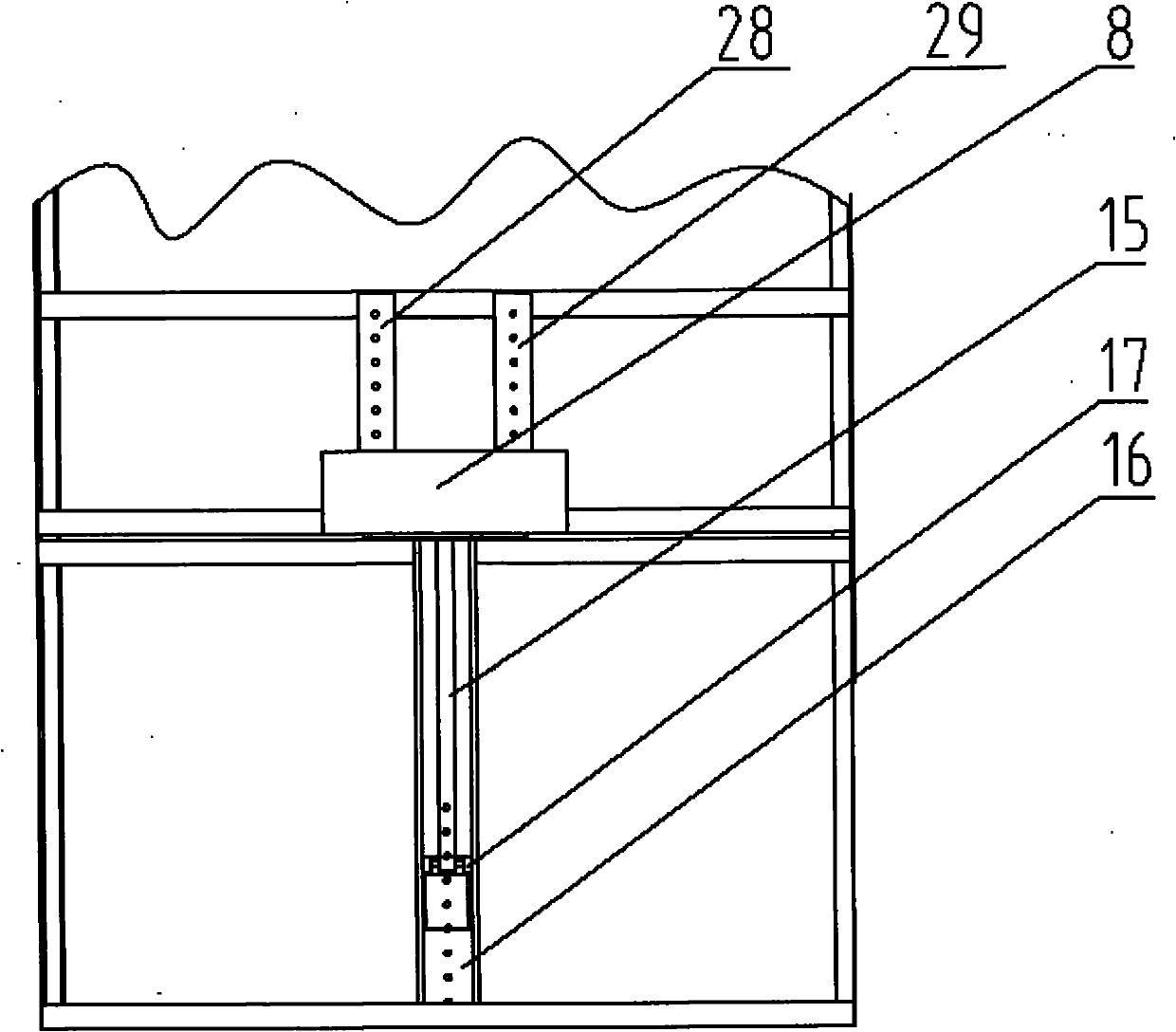

[0025] An impulse type grain mass flow sensor calibration and performance test device, including: frame 1, hopper A2, clean grain elevator 3, speed sensor 4, transparent cover 5, high-speed camera acquisition system 6, vibration sensor 7, impulse type Grain mass flow sensor 8, inclination sensor 9, impulse type grain mass flow sensor mounting base 10, threaded rod 11, nut A12, nut B13, slider A14, connecting rod 15, long linear guide rail 16, slider B17, hopper scale 18 , Hopper B19, vibration motor A20, vibration motor B21, vibration motor C22, wheel A23, wheel B24, reducer 25, three-phase asynchronous motor 26, opening adjustable valve 27, linear guide rail A28, linear guide rail B29.

[0026]Hopper A2, hopper B19, net grain elevator 3, vibration motor A20, vibration motor B21, vibration motor C22 are fixedly installed on the frame 1; hopper A2 is fixed above the grain entrance of net grain elevator 3, and the The opening adjustable valve 27 is opposite to the grain inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com