Oil, gas and water three phase oil well continuous metering device and its measurement method

A metering device and water three-phase technology, applied in the direction of mass flow measurement device, measurement, earthwork drilling and production, etc., can solve problems such as the impact of continuous operation of oil wells, and achieve the effects of accurate and reliable measurement, wide range of flow patterns, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

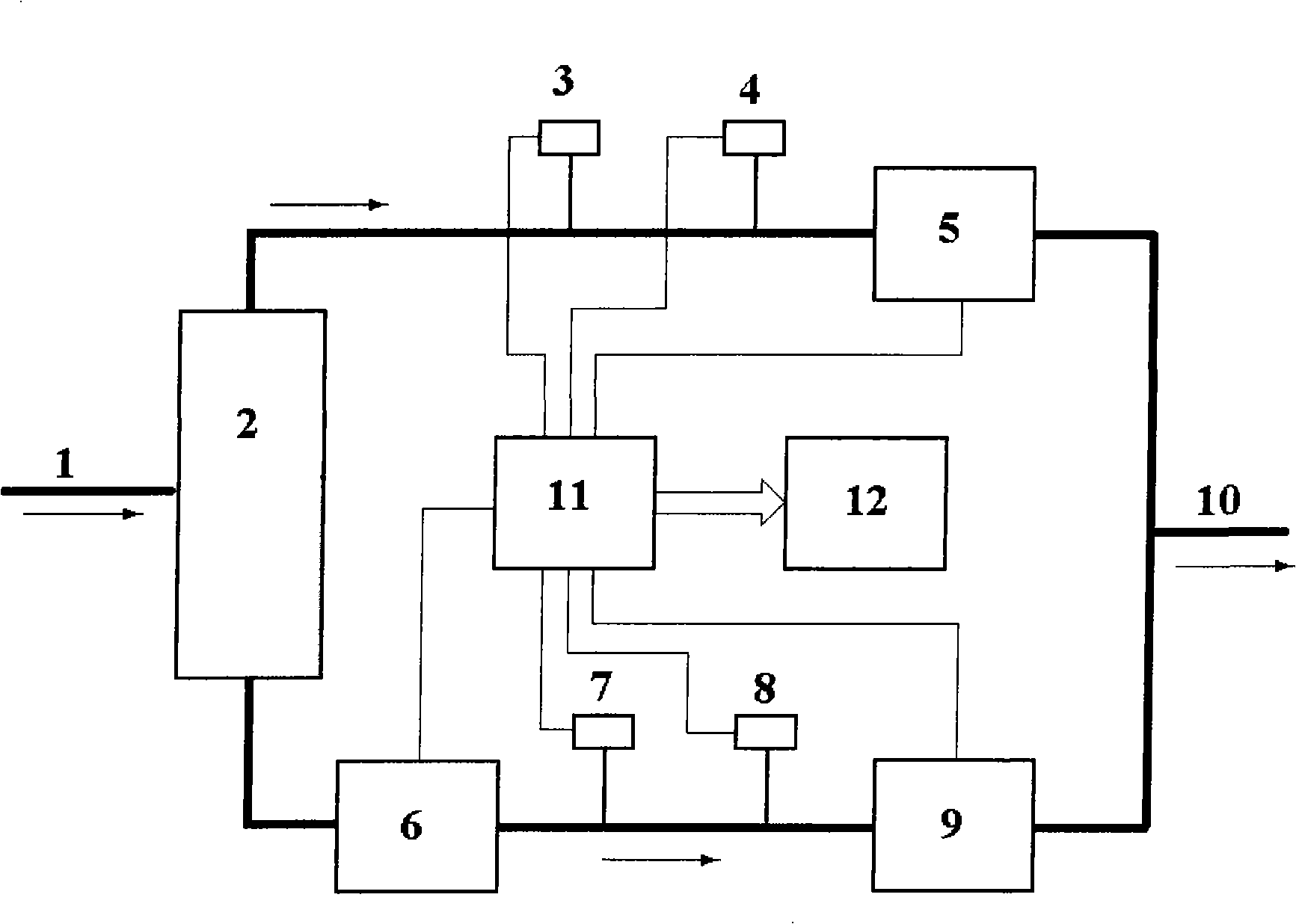

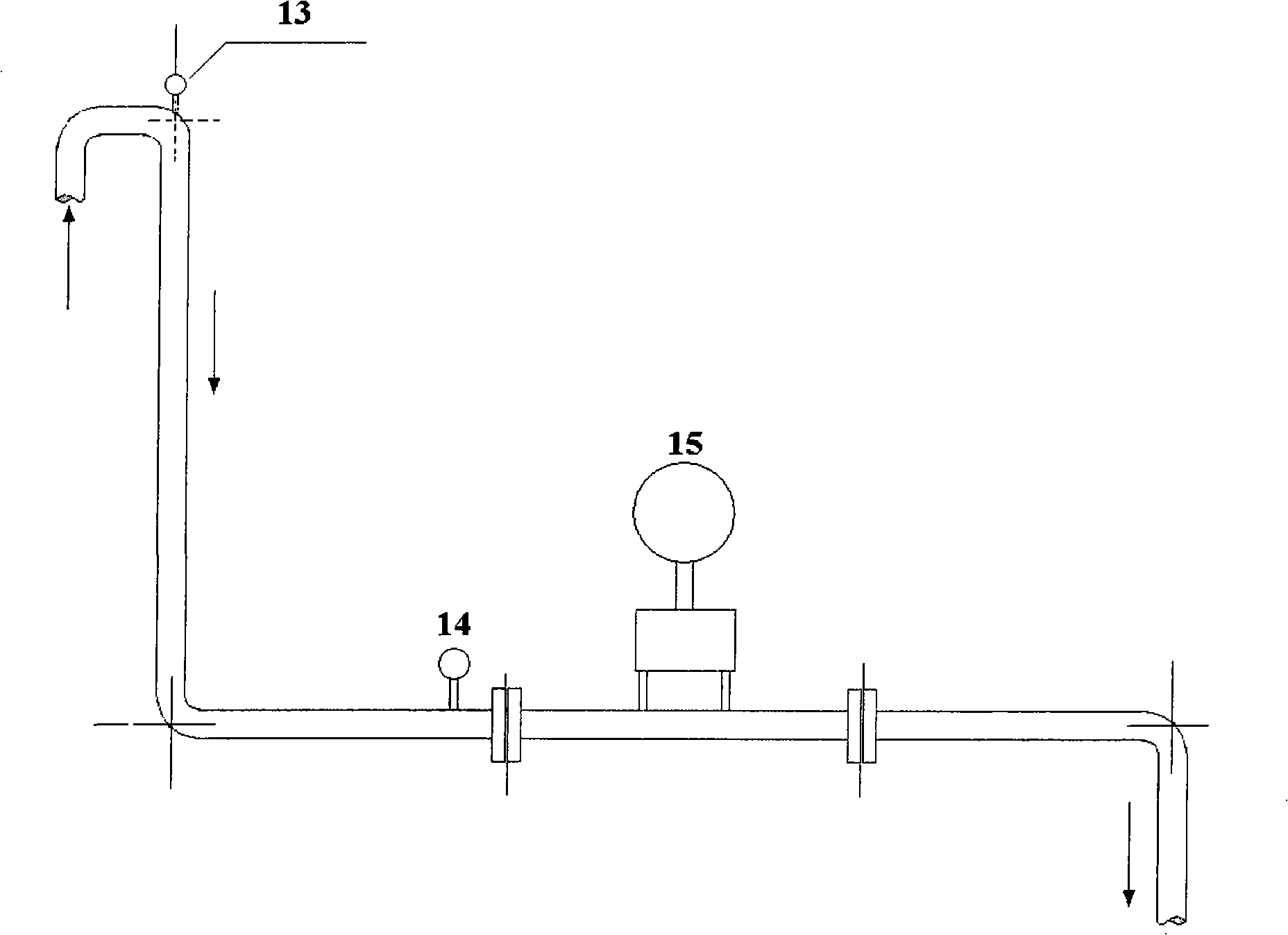

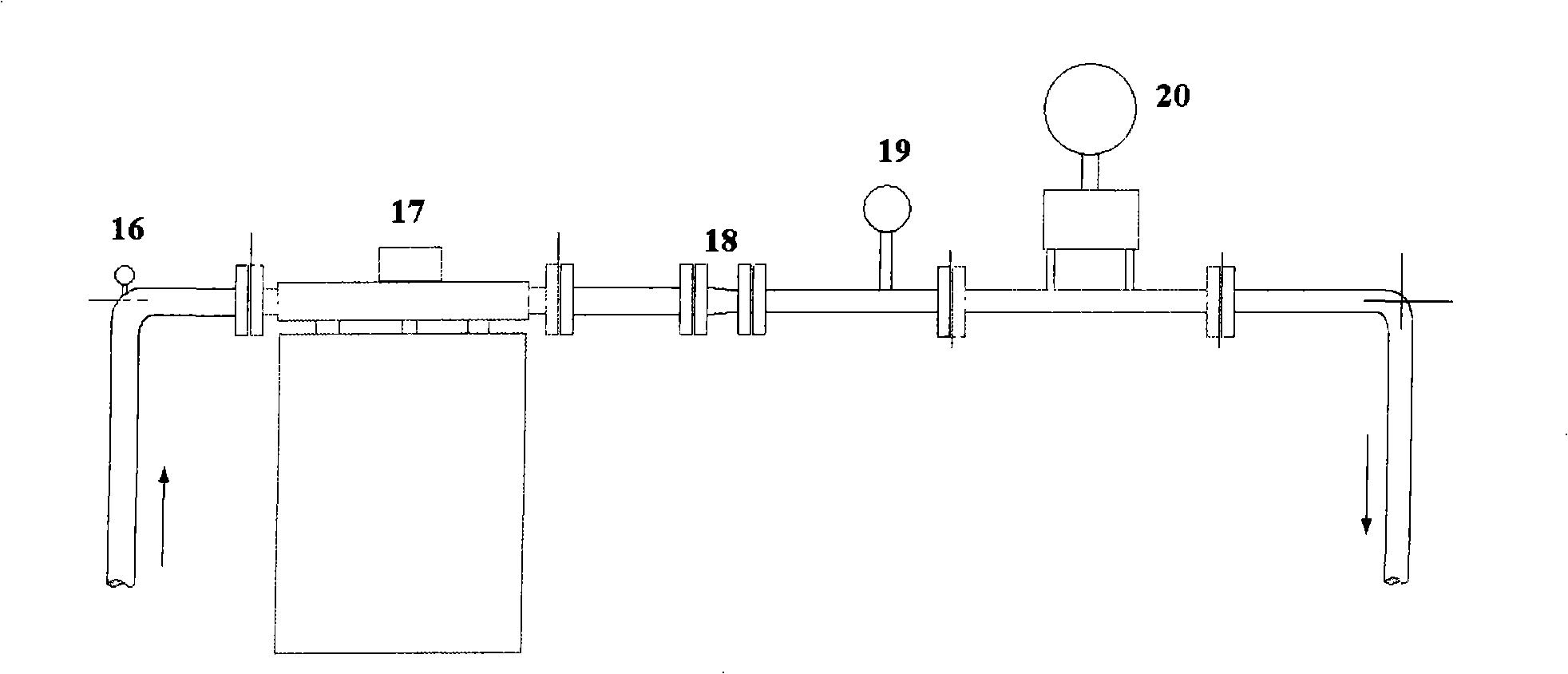

[0022] The structural principle of the present invention will be described with reference to the accompanying drawings. The working principle diagram of oil, gas and water three-phase oil well continuous metering device is as follows figure 1shown. In the figure 1. Oil, gas and water three-phase flow inlet, 2. High-efficiency gas-liquid separator, 3. Gas path temperature sensor, 4. Gas path pressure sensor, 5. Gas path inner cone flowmeter, 6. Liquid path section Force mass flowmeter, 7, liquid temperature sensor, 8, liquid pressure sensor, 9, liquid cone flowmeter, 10, oil, gas, water three-phase outlet. The oil, gas and water three-phase fluid enters the oil, gas and water three-phase inlet 1, and the gas-liquid separation is carried out in the high-efficiency gas-liquid separator 2. The separated fluid is divided into two paths, and the gas phase flows out from the upper part of the separator. Through the gas path temperature sensor 3, the gas path pressure sensor 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com