Diesel engine fuel consumption measuring apparatus

A technology of fuel consumption and measuring device, which is applied to measuring device, mass flow measuring device, internal combustion engine test, etc., can solve the problems of affecting the accuracy of measurement, large capacity of measuring fuel tank, large fuel consumption of high-power diesel engine, etc. The effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]This embodiment is applied to the measurement of the fuel consumption of the diesel engine during the test run of the diesel engine platform. The diesel engine test platform requires a relatively large site and a long oil transmission line, so the fuel circulation line is also long, and the diesel cycle in the fuel circuit requires relatively high pressure, which requires multiple pressurization of the fuel in the cycle.

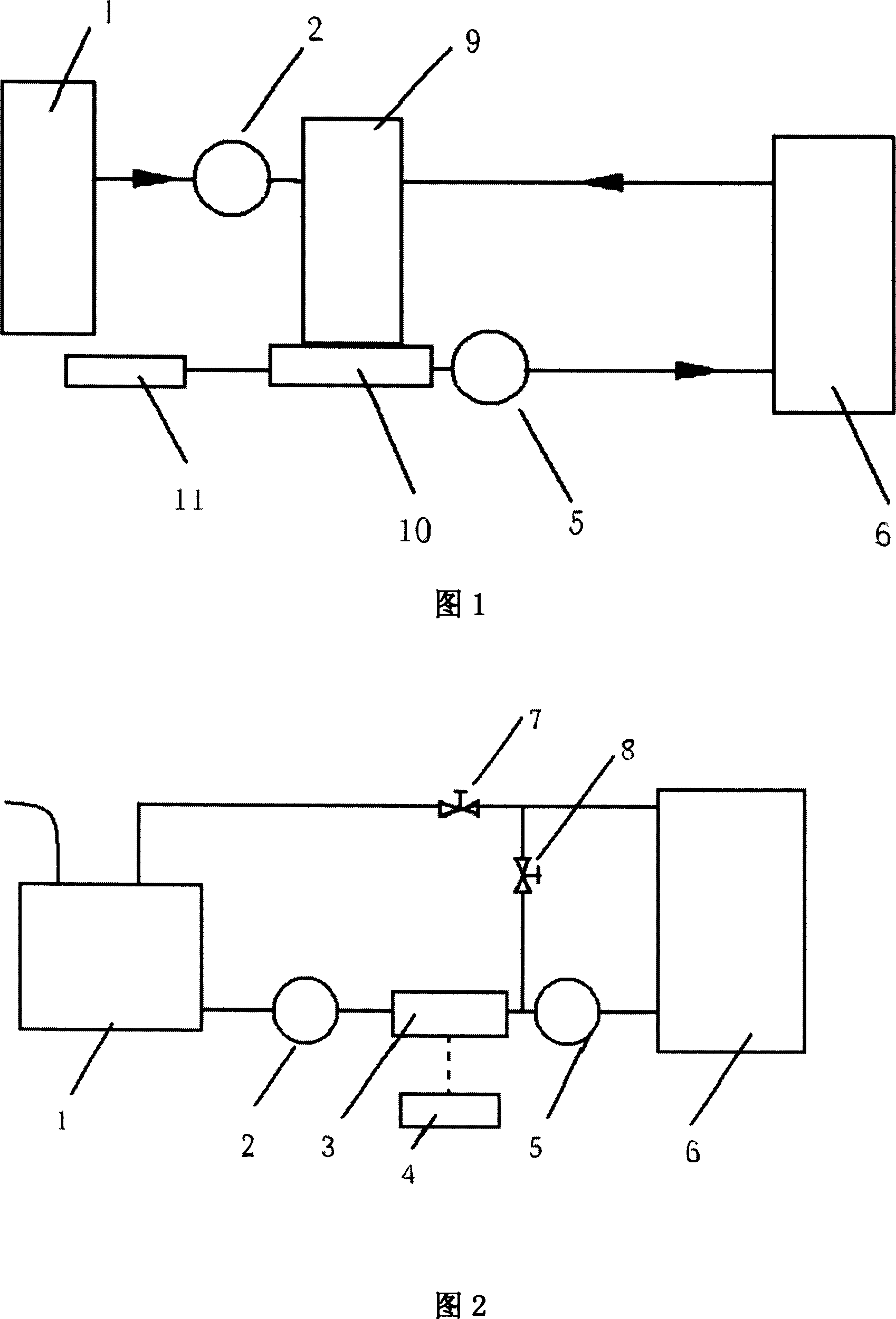

[0050] Please refer to Fig. 2, Fig. 2 is a schematic diagram of a measuring device using a single mass flow meter in the fuel consumption measuring device of a diesel engine according to the present invention. It can be seen from the figure that the diesel engine fuel consumption measurement device using a single mass flowmeter consists of fuel oil tank 1→fuel supply pump 2→first mass flow meter 3→circulation pump 5→diesel engine 6→fuel oil tank 1 to form a large main fuel oil tank. circuit. The electrical signal output by the first mass flow meter 3 ...

Embodiment 2

[0064] This embodiment is applied to the measurement of fuel consumption of diesel engines on ships. This embodiment and embodiment 1 are similar technical solutions based on the same invention purpose, but they cannot replace each other, and each has its own advantages.

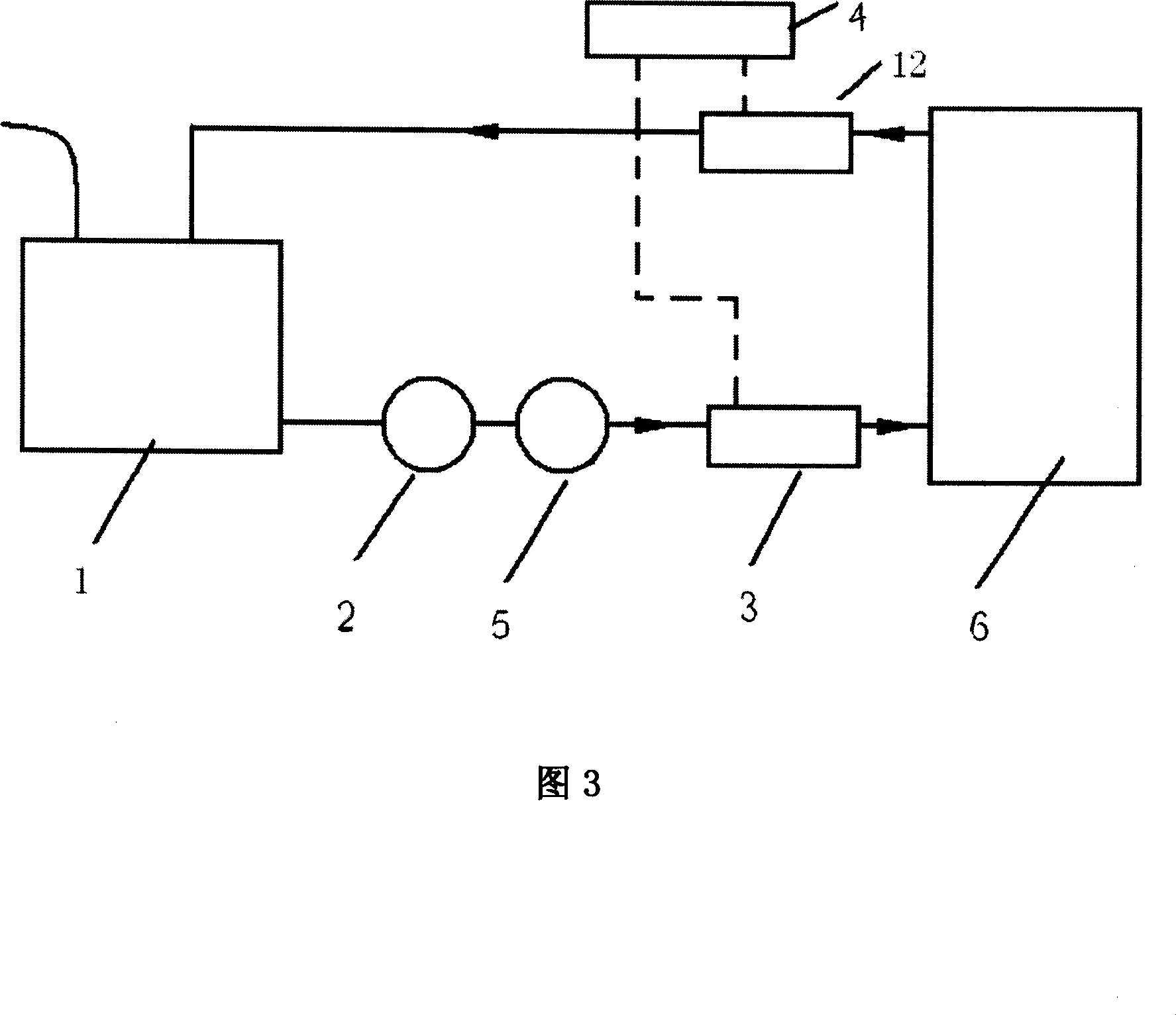

[0065] Please refer to Fig. 3, Fig. 3 is a schematic diagram of a measuring device using dual mass flowmeters in the fuel consumption measuring device of a diesel engine according to the present invention. As can be seen from the figure, the diesel engine fuel consumption measurement device in the present invention includes fuel oil tank 1→fuel supply pump 2→circulation pump 5→first mass flow meter 3→diesel engine 6→second mass flow meter 12→fuel oil tank 1 composed of a large fuel circuit. The electrical signals output by the first mass flow meter 3 and the second mass flow meter 12 are respectively connected to different input ports of the fuel consumption meter 4 through wires.

[0066] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com