Flow shop scheduling method based on deep reinforcement learning

A technology of intensive learning and workshop scheduling, applied in the direction of control/adjustment system, instrument, comprehensive factory control, etc., can solve the problems of large changes in network input, and achieve the effects of improved versatility, novel methods, and strong promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

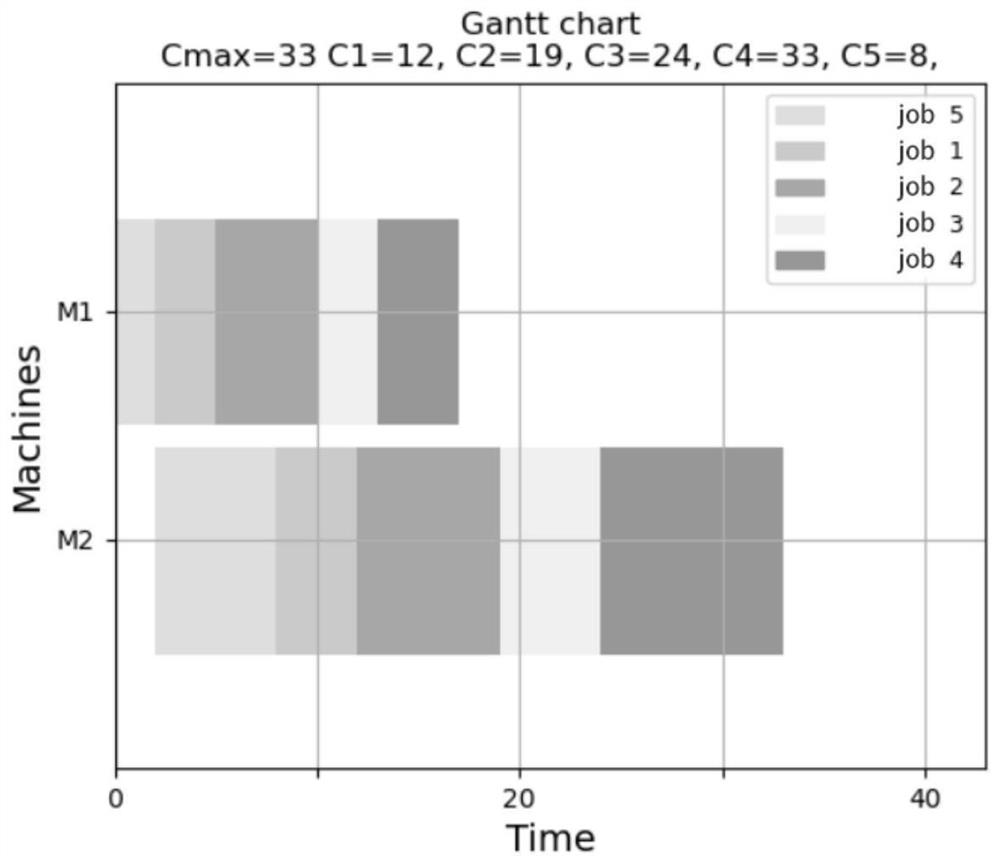

Examples

Embodiment Construction

[0038]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

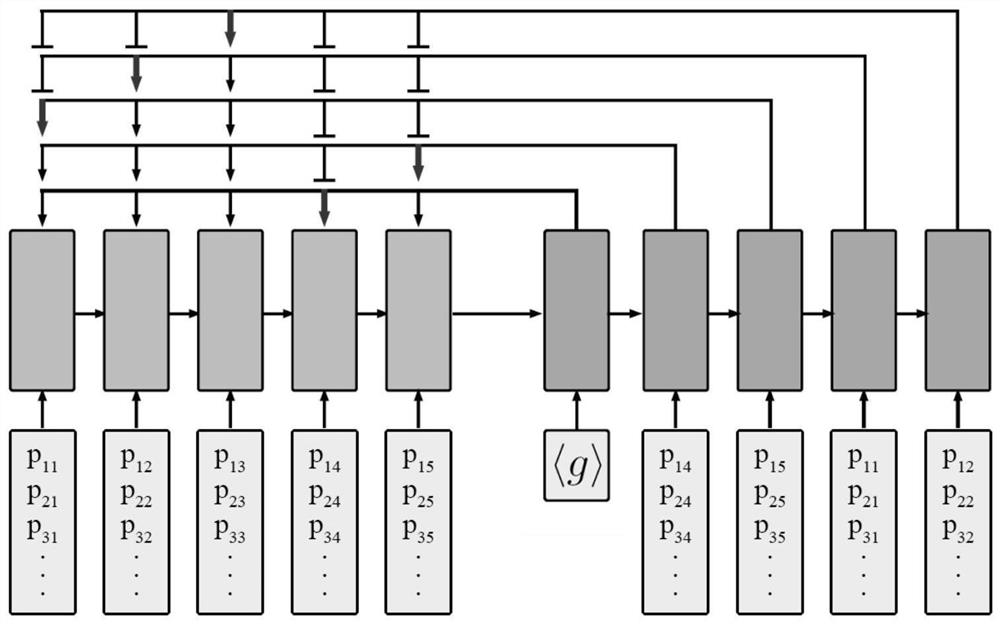

[0039] like figure 1 As shown, the flow shop scheduling method based on deep reinforcement learning in this embodiment is as follows:

[0040] Step 1: Generate the flow shop problem data set for training, and divide it into training set, verification set and test set in proportion;

[0041] In this embodiment, the flow shop problem data set includes 1,000,000 pieces of training data and 10,000 pieces of test data, which are divided into training set, verification set and test set in proportion.

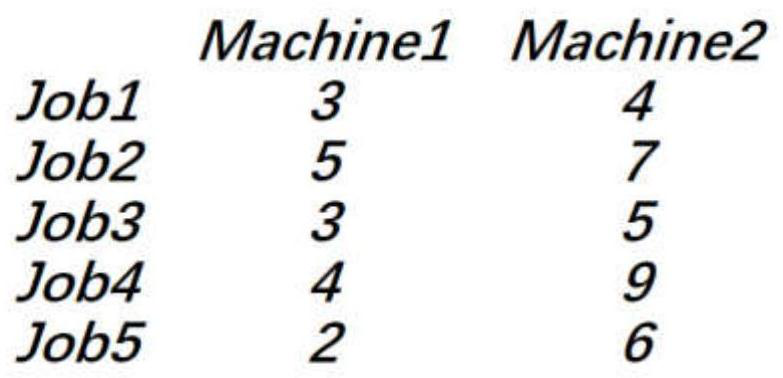

[0042] The flow shop problem data set is a problem matrix of b*j*m size, where b is the batchsize of training or verification samples, j is the number of workpieces, and m is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com