Production management method and system for stamping workshop

A production management, stamping workshop technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the problem of not being able to quickly respond to production changes, and difficult to ensure the accuracy and timeliness of information required for production activities , the inability to obtain key data on the production site in real time, etc., to achieve the effect of improving production efficiency, reducing labor costs, and improving enterprise management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

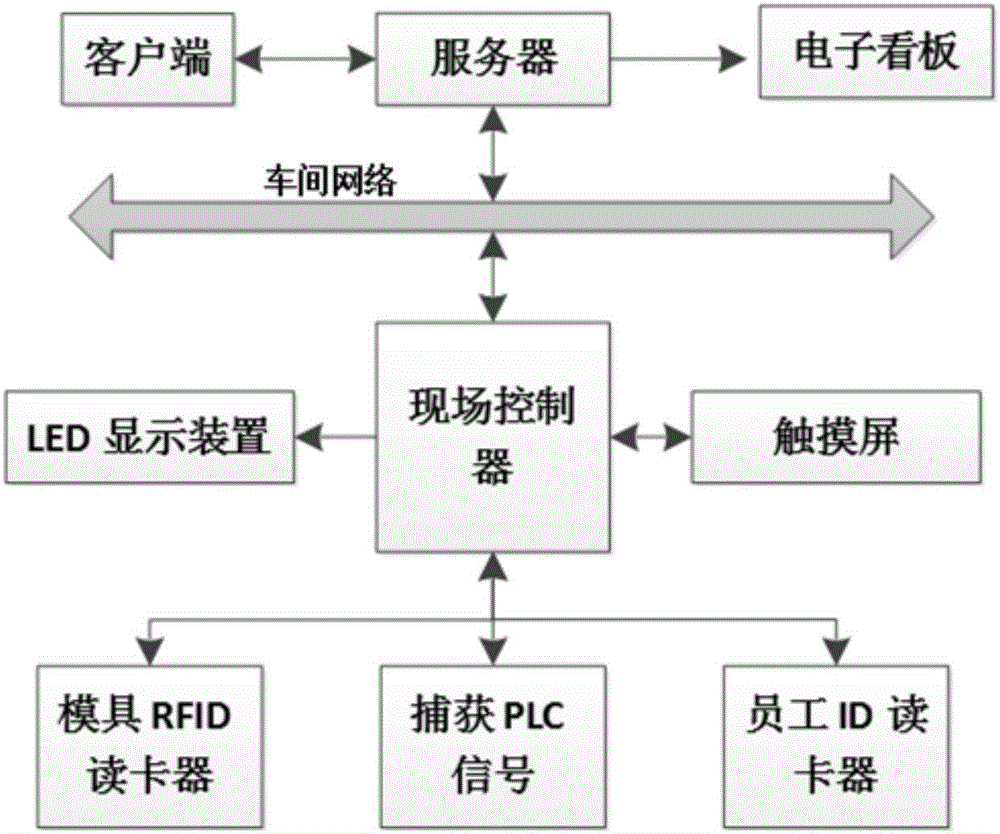

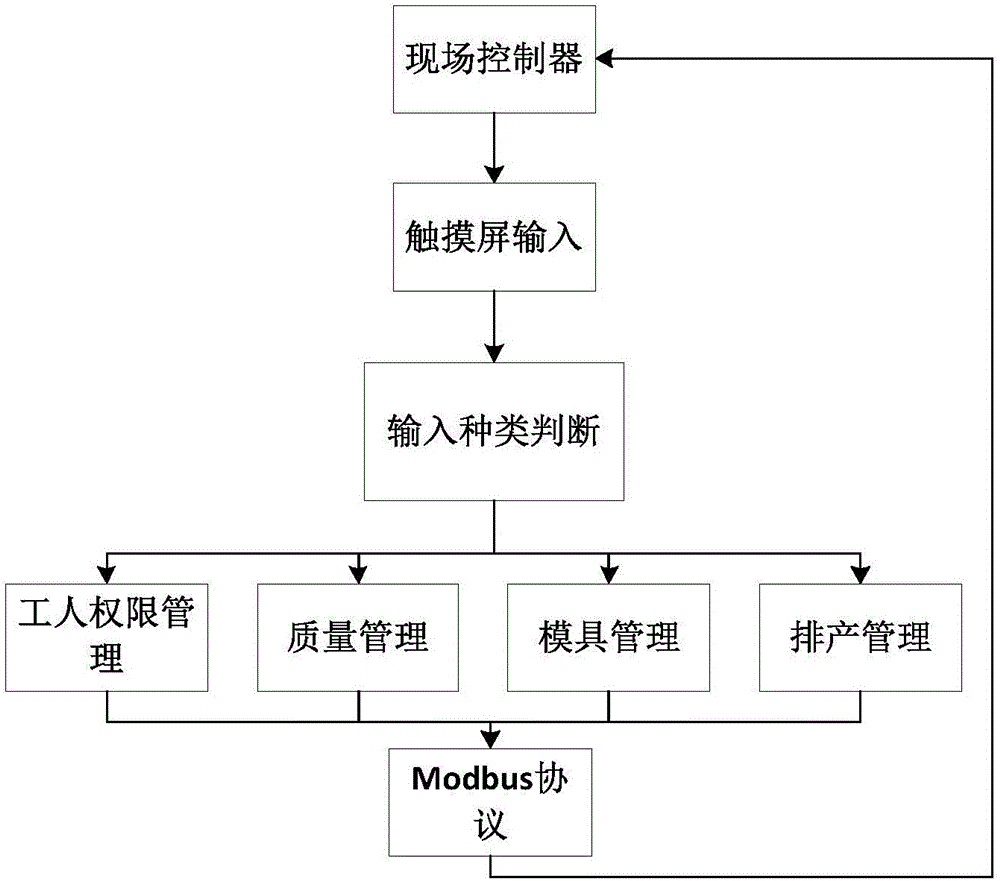

[0012] Such as figure 1 As shown, the production management method of the stamping workshop of the present invention includes the following steps: the server receives the production order and stores it in its own relational database; The PLC signal points on the board are combined to obtain the production data of the punching machine; LED lights of different colors on the LED display device are lit to correspond to different real-time status information. The on-site controller sends the collected information to the server through the workshop network for processing and storage in two ways of timing and irregular timing respectively, and forms a real-time synchronously updated production record. The server compares the obtained number of production pieces with the production order to determine whether the production task has been completed, and if it has been completed, it will issue an instruction to stop production.

[0013] The production order of the stamping workshop is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com