Electricity saving method and electricity saving system

A technology of power supply status and forced power-off, applied in the direction of instruments, registration/indication, time registers, etc., can solve the problems of high labor cost, limited verbal publicity, power consumption can not be found, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

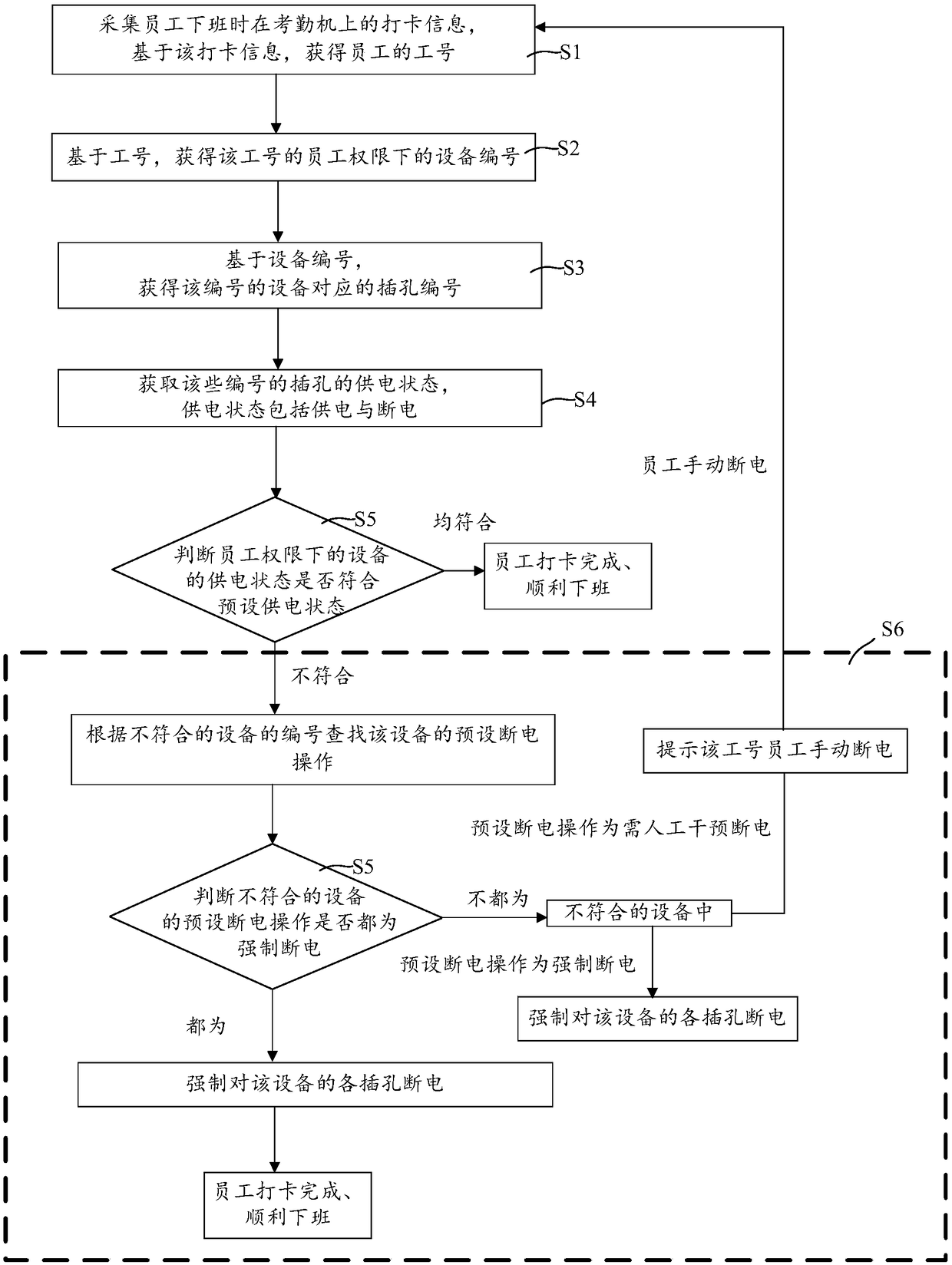

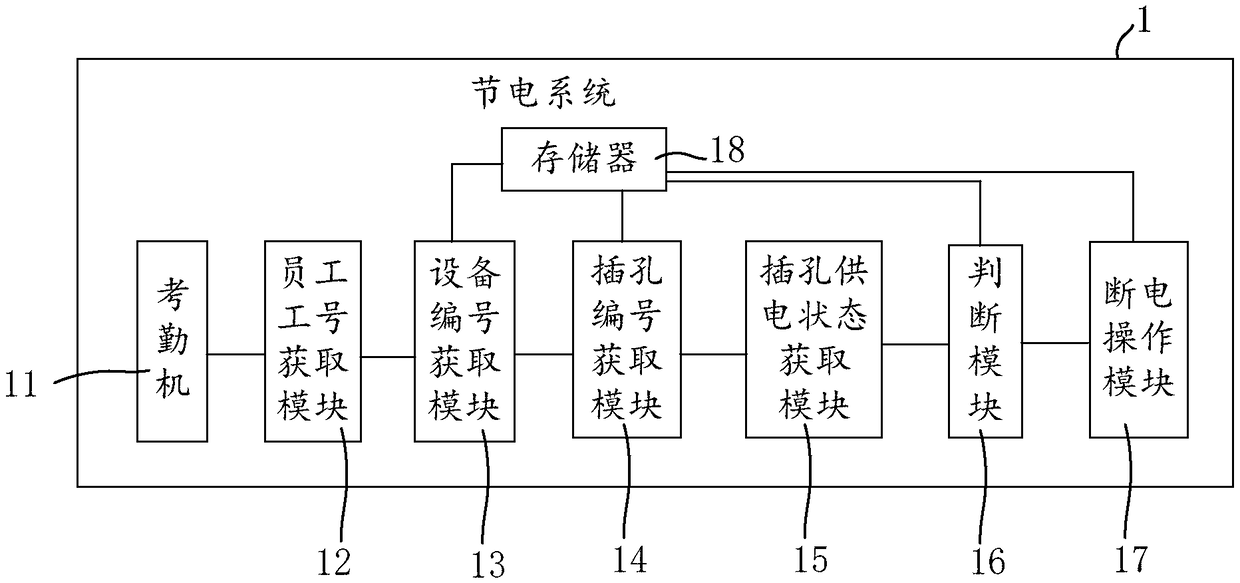

[0046] figure 1 It is a flow chart of the power saving method in an embodiment of the present invention. refer to figure 1 As shown, the power saving method includes a clock-in cycle, which jumps out and ends when the employee clocks in and leaves work smoothly.

[0047] The cycle is described in detail below.

[0048] refer to figure 1 As shown, step S1 is executed first to collect the clock-in information of the employee on the attendance machine when off duty, and obtain the employee's job number based on the clock-in information.

[0049] There is a one-to-one correspondence between employees and job numbers. After the employee clocks in, the attendance machine can obtain some information of the employee, such as job number, clock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com