Vehicle base inner shunting plan implementing device, method and program

A technology of vehicle base and shunting, applied in the direction of calculation, transportation and packaging, railway car body parts, etc., can solve problems affecting the whole plan, burden, manual correction plan, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

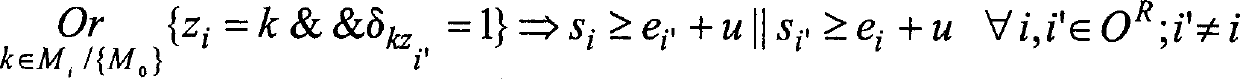

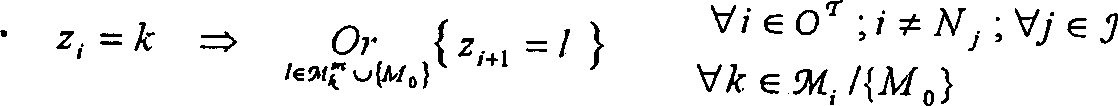

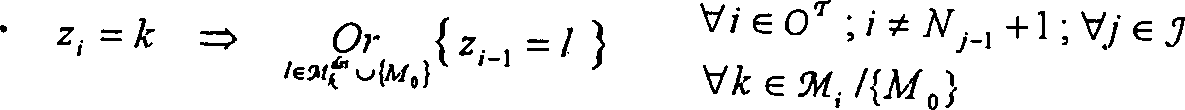

[0072]Embodiment 1 of the present invention will be described below using FIGS. 1 to 21 and Formulas 1 to 11. Embodiment 1 of the present invention is an embodiment in which an on-site shunting plan for all formations is prepared from a blank paper state. The so-called marshalling is a concentrated mobile (interconnected) multi-section vehicles. However, the formation can also be 1 vehicle.

[0073] Fig. 1 is a configuration diagram of a shunting plan creation device in a vehicle base. The shunting plan making device in the vehicle base is a computer system, which is composed of a processing device 0110 , a storage device 0120 connected to the processing device 0110 , an input device 0130 , a display device 0140 and an output device 0150 . The processing device 0110 is connected to the network 0160 . The storage device 0120 stores the composition data 0121 storing the composition information which is the object of creating the on-site shunting plan, the numbered route defin...

Embodiment 2

[0219] Embodiment 2 of the present invention will be described below centering on Fig. 22 and Formulas 12 and 13. Embodiment 2 of the present invention is to add the rest of the formations in stages and then make the overall plan in the state where the on-site shunting plan has been made for several formations; it is used for the plan that the train diagram of the business day is disrupted, etc. Make changes or create plans interactively with planners.

[0220] The device configuration of this embodiment is the same as that of the first embodiment shown in FIG. 1, and the specifications of input and output data are also completely the same. The difference from the first embodiment is the overall processing flow for creating an on-site shunting plan, and an overview of this processing will be described below using the processing flowchart in FIG. 22 .

[0221] At first, in step 2110, read in the plan of the formation group (as A) of the on-site shunting plan that has been made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com