Patents

Literature

32results about How to "Reduce factory cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Management system of wafer acceptable test procedure and application method thereof

ActiveCN103199041AReduce factory costImprove test efficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTest efficiencyProbe card

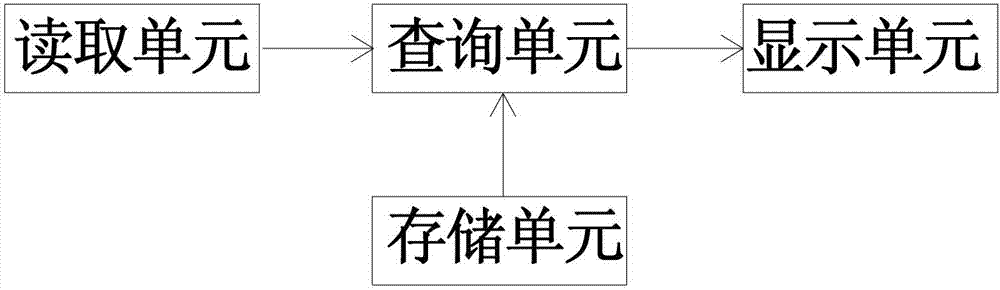

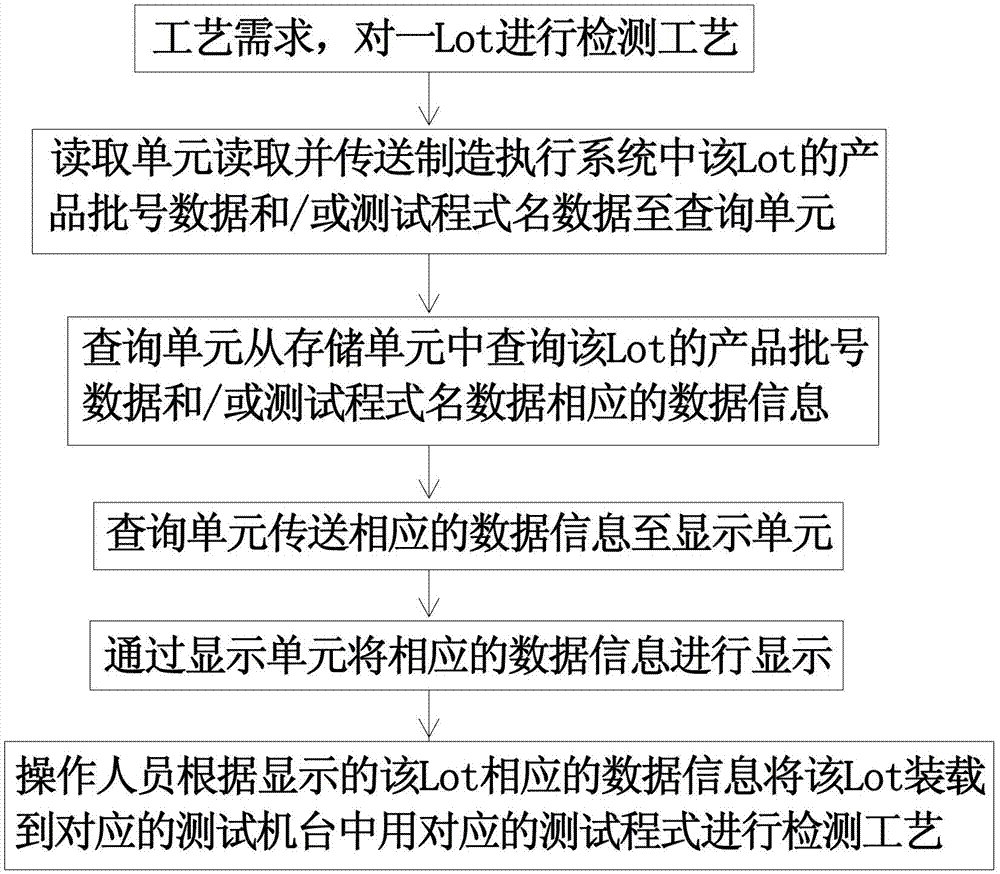

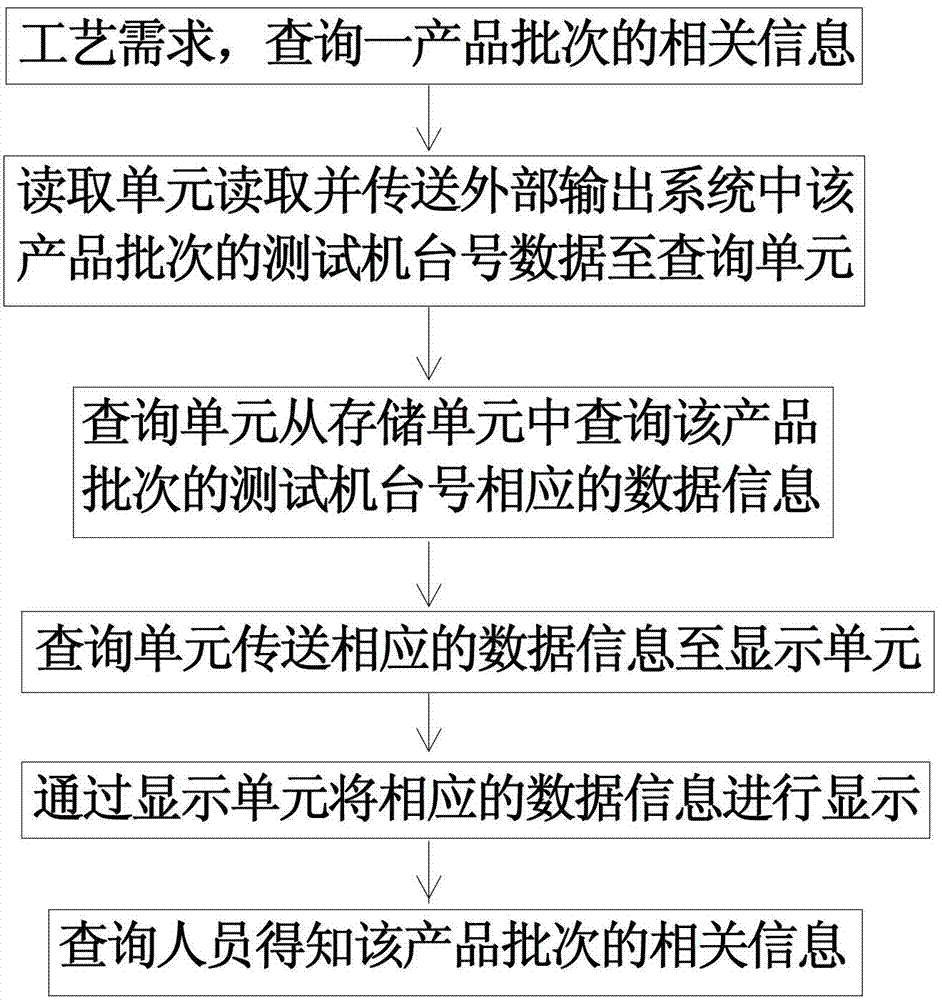

The invention relates to a management system of a wafer acceptable test procedure and an application method of the management system. The management system of the wafer acceptable test procedure comprises a reading unit, a storage unit, an inquiry unit and a display unit. The storage unit is provided with product lot number data of a plurality of batches of products, testing machine number data, testing procedure name data, probe procedure name data, probe card type data, procedure grouping name data, machine property data, copper / non-copper wiring data, procedure establishing personnel job number data and test procedure detailed description data, wherein the testing machine number data, the testing procedure name data, the probe procedure name data, the probe card type data, the procedure grouping name data, the machine property data, the copper / non-copper wiring data, the procedure establishing personnel job number data and the test procedure detailed description data correspond to the product lot identification numbers of the various batches of products. The reading unit obtains operational data as required and transmits the operational data to the inquiry unit. The inquiry unit inquires data information which is stored in the storage unit and corresponds to the operational data and the corresponding data information is displayed through the display unit. According to the management system of the wafer acceptable test procedure and the application method, an operator is enabled to be clear about the fact that the wafer acceptable test procedure is carried out in a corresponding testing machine, testing efficiency is improved, and the factory cost of semiconductors is reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

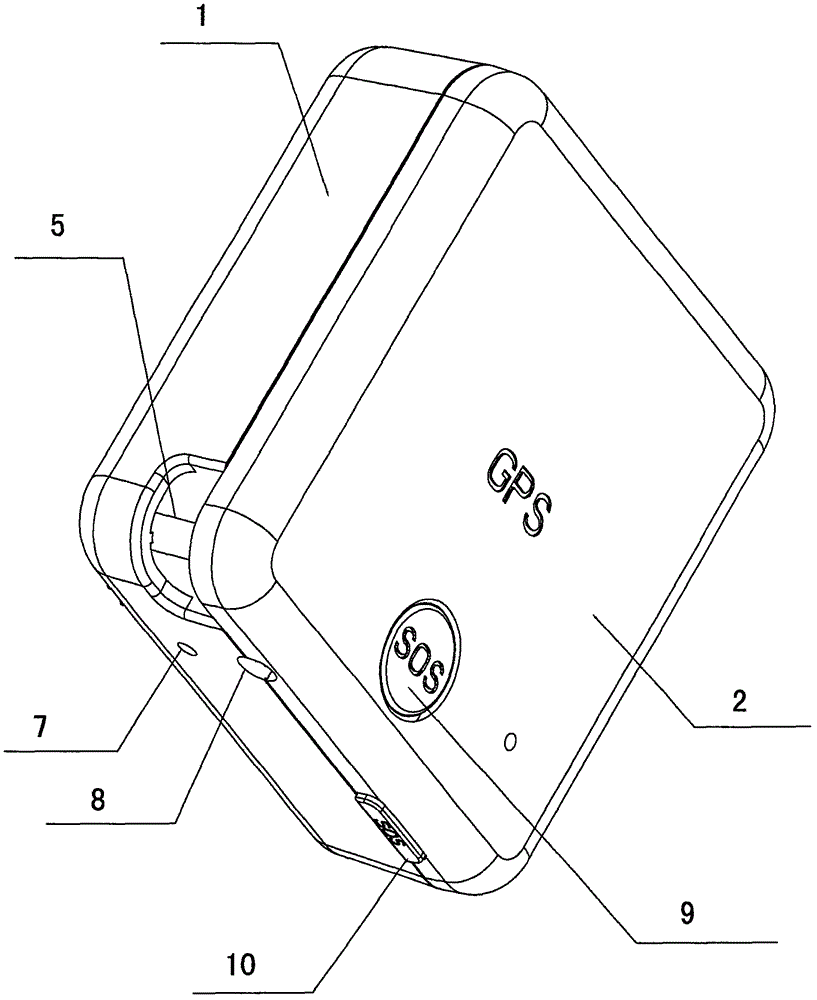

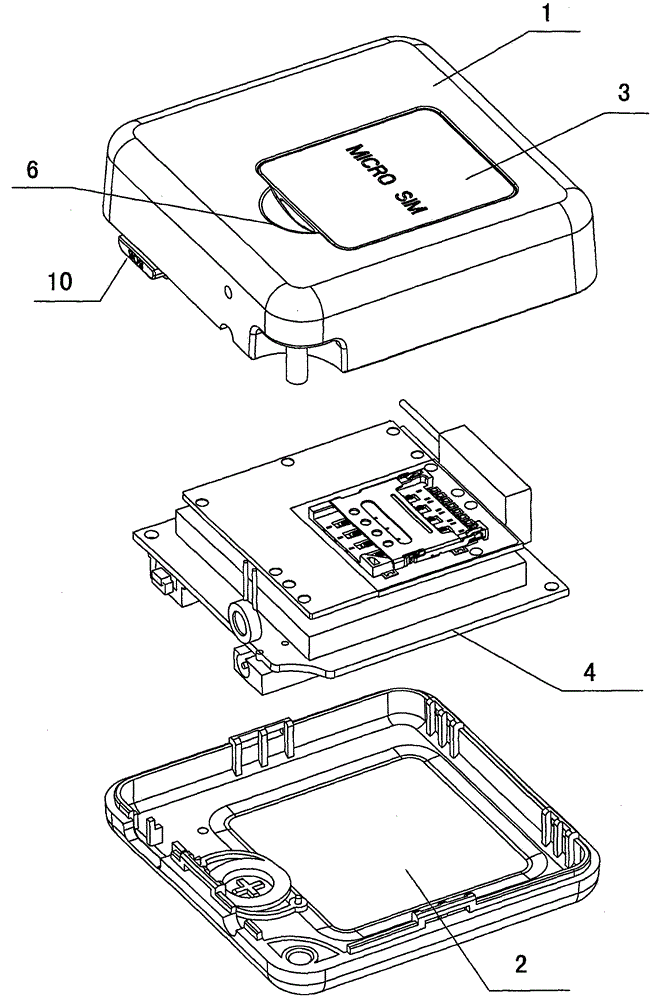

General full-automatic intelligent safety automobile block box and system

InactiveCN104952124AReduce factory costFunction increaseRegistering/indicating working of vehiclesSatellite radio beaconingKey pressingData synchronization

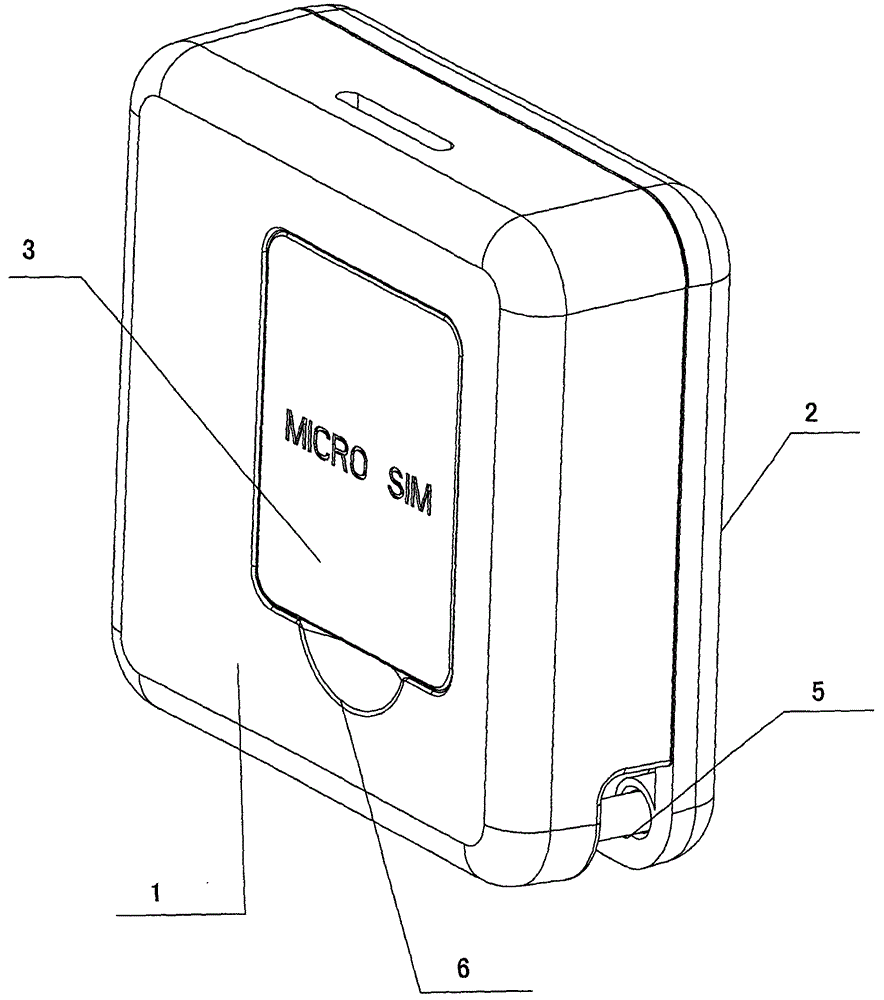

The invention discloses a general full-automatic intelligent safety automobile block box and a system. The automobile block box comprises a face shell, a bottom shell, a protection cover and a circuit module, wherein the face shell and the bottom shell are fixedly mounted together to form a housing; the circuit module is arranged in the housing; the protection cover is mounted on the face shell; an SIM card mounting groove is formed in the face shell, and corresponding to the position of the protection cover; an SIM card connector is arranged below the protection cover and in the SIM card mounting groove; the circuit module comprises a CPU, a signal output connector, a GPS module, a GSM chip, a microphone, a loudspeaker, an SOS key, a charging connector and a battery; the signal output connector, the GPS module, the GSM chip, the microphone, the loudspeaker and the SOS key are respectively connected to the CPU. The general full-automatic intelligent safety automobile block box and the system have the advantages that the structure is simple, the use is convenient, the satellite signal receiving function of a conventional GPS antenna can be obtained, a function of a common GPS module of an original automobile is replaced, and besides, data are uploaded to a cloud server synchronously.

Owner:深圳市超级柒科技有限公司

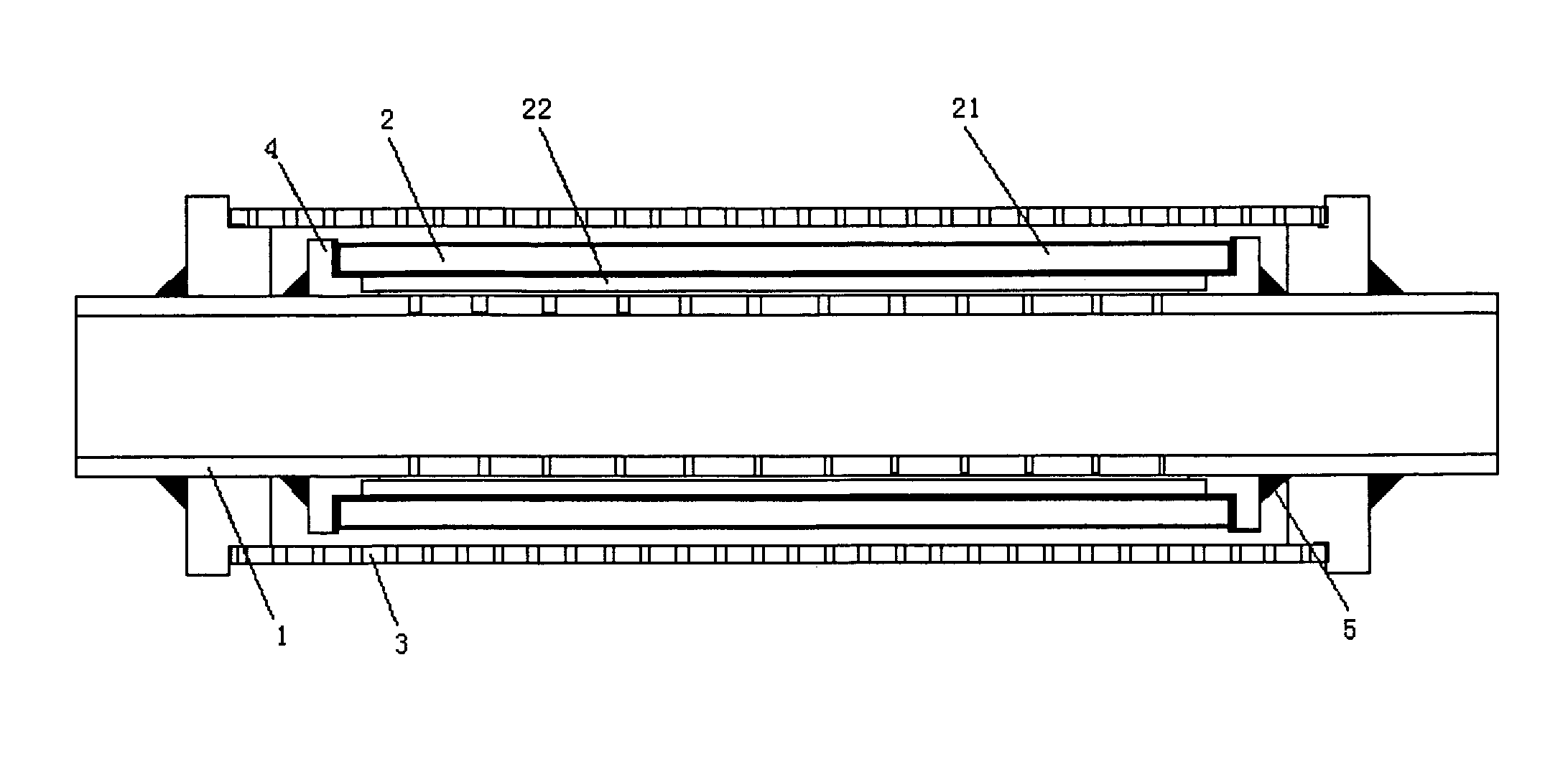

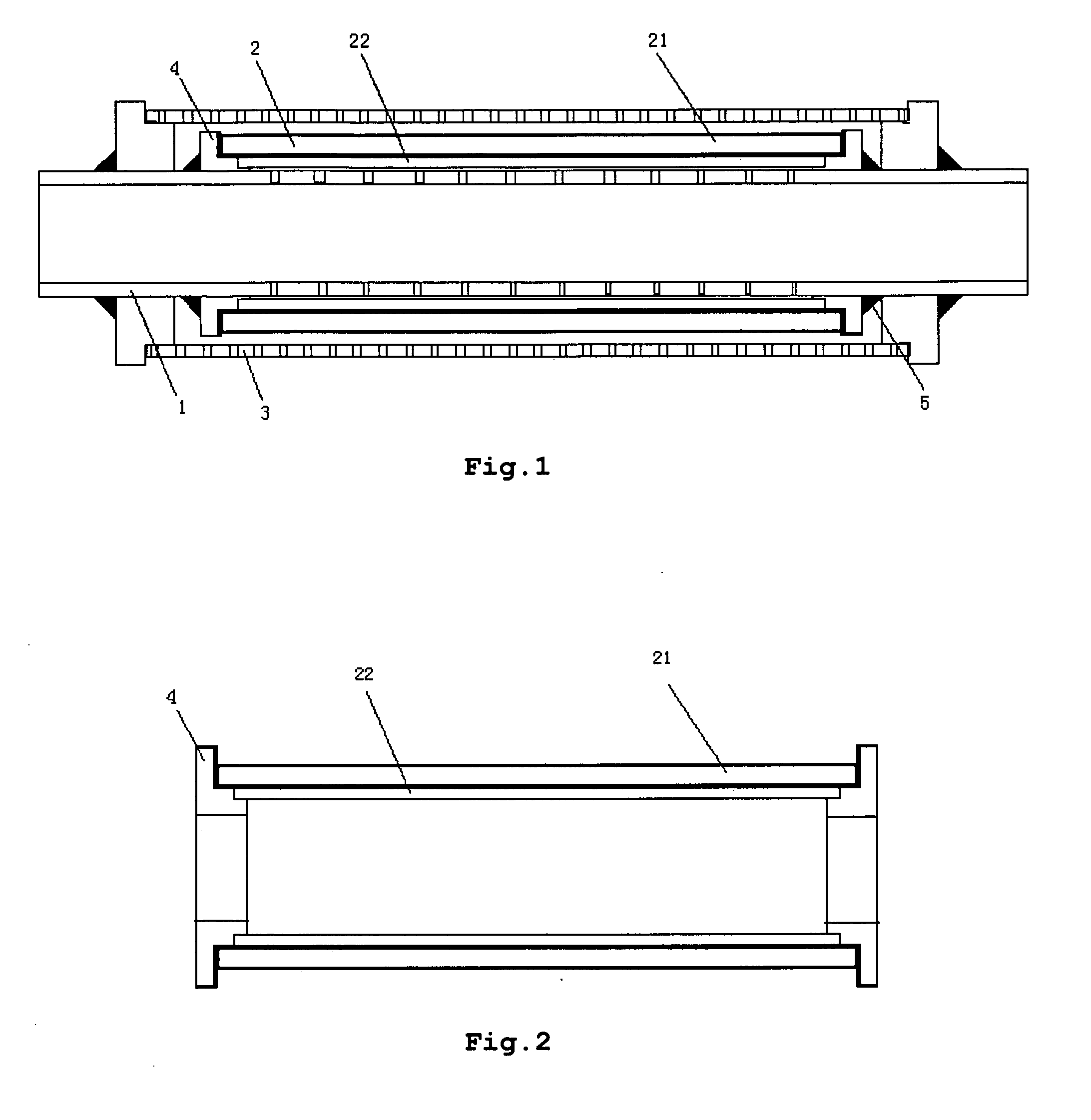

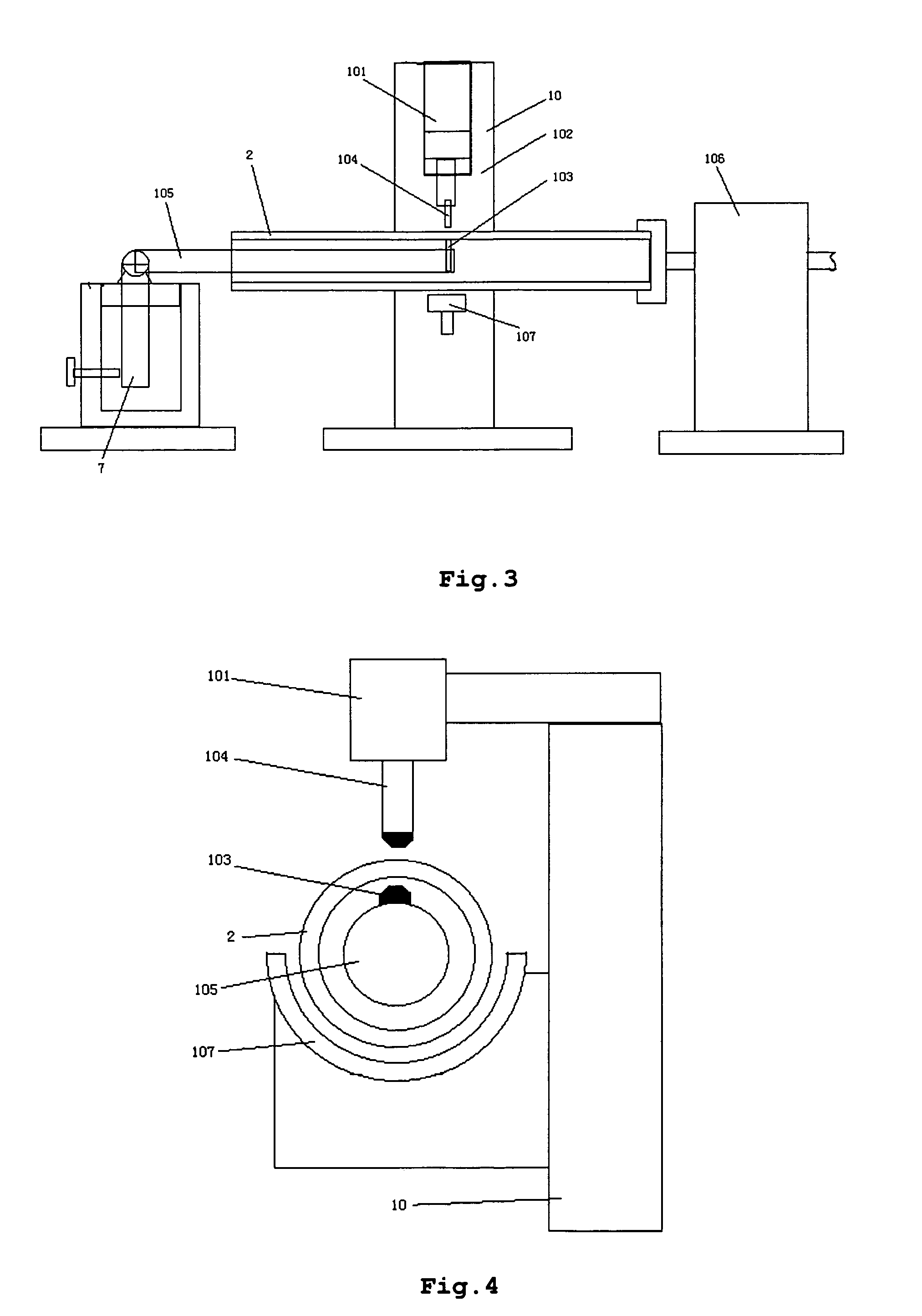

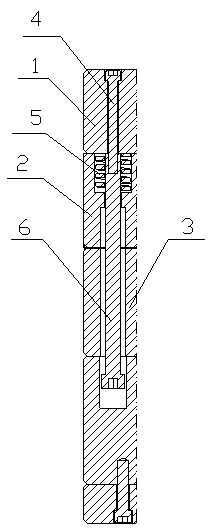

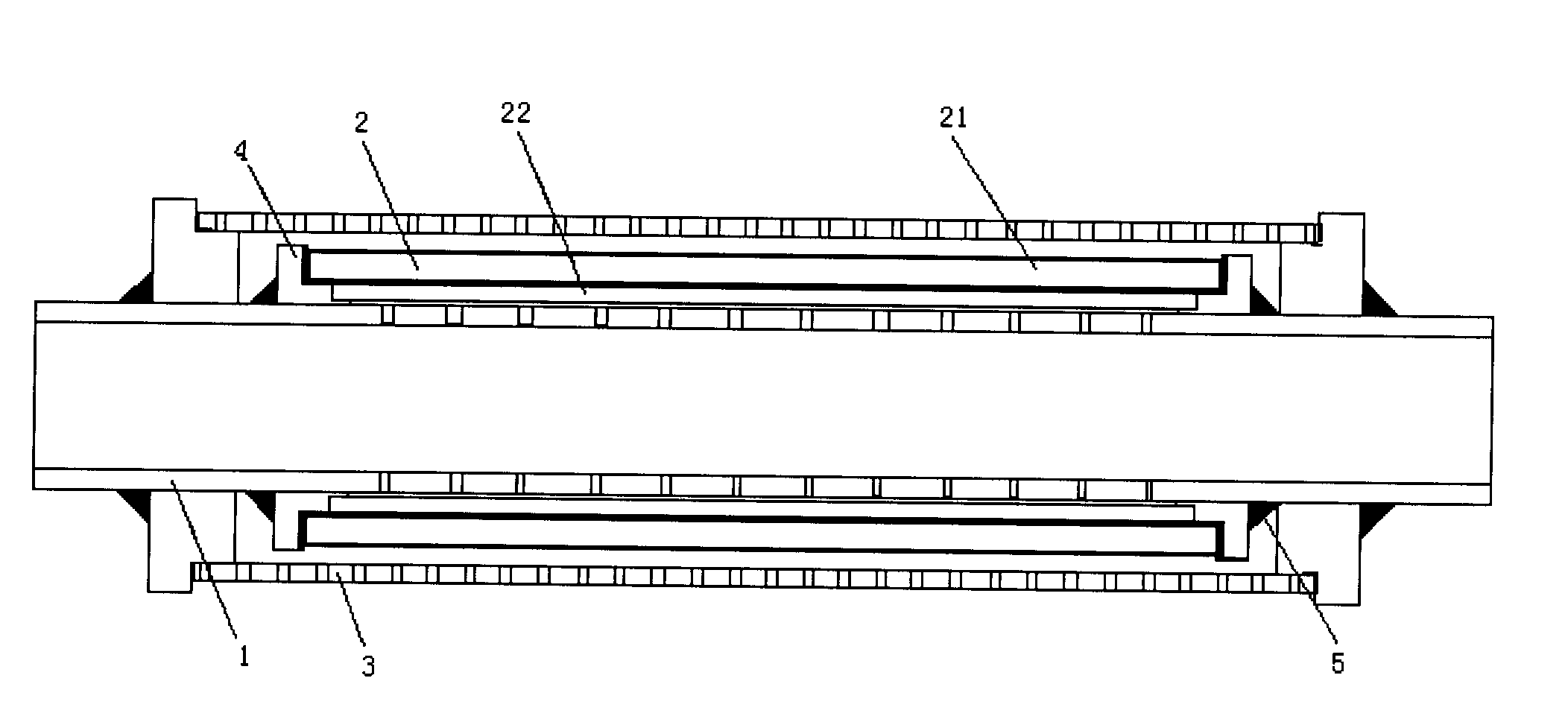

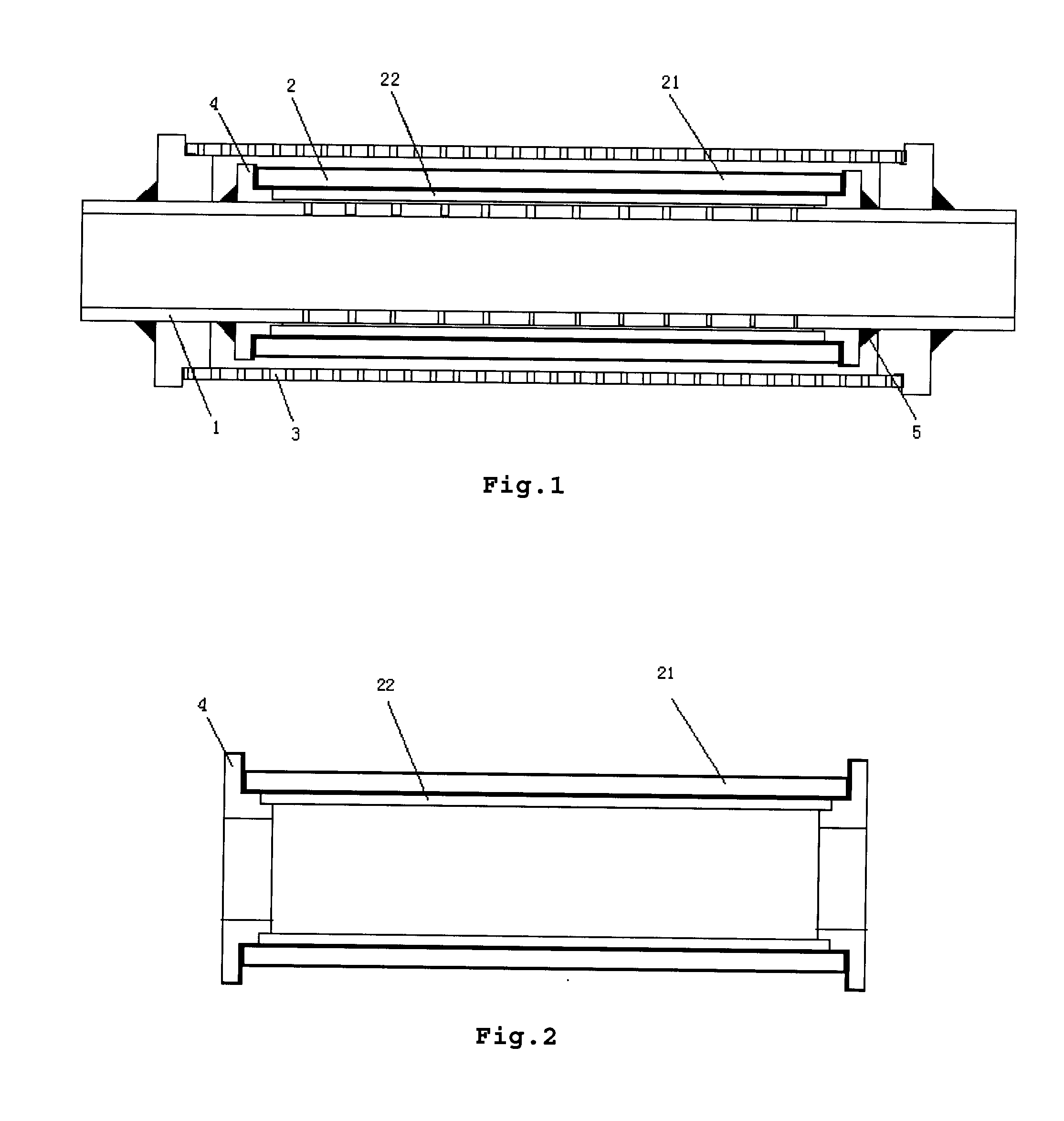

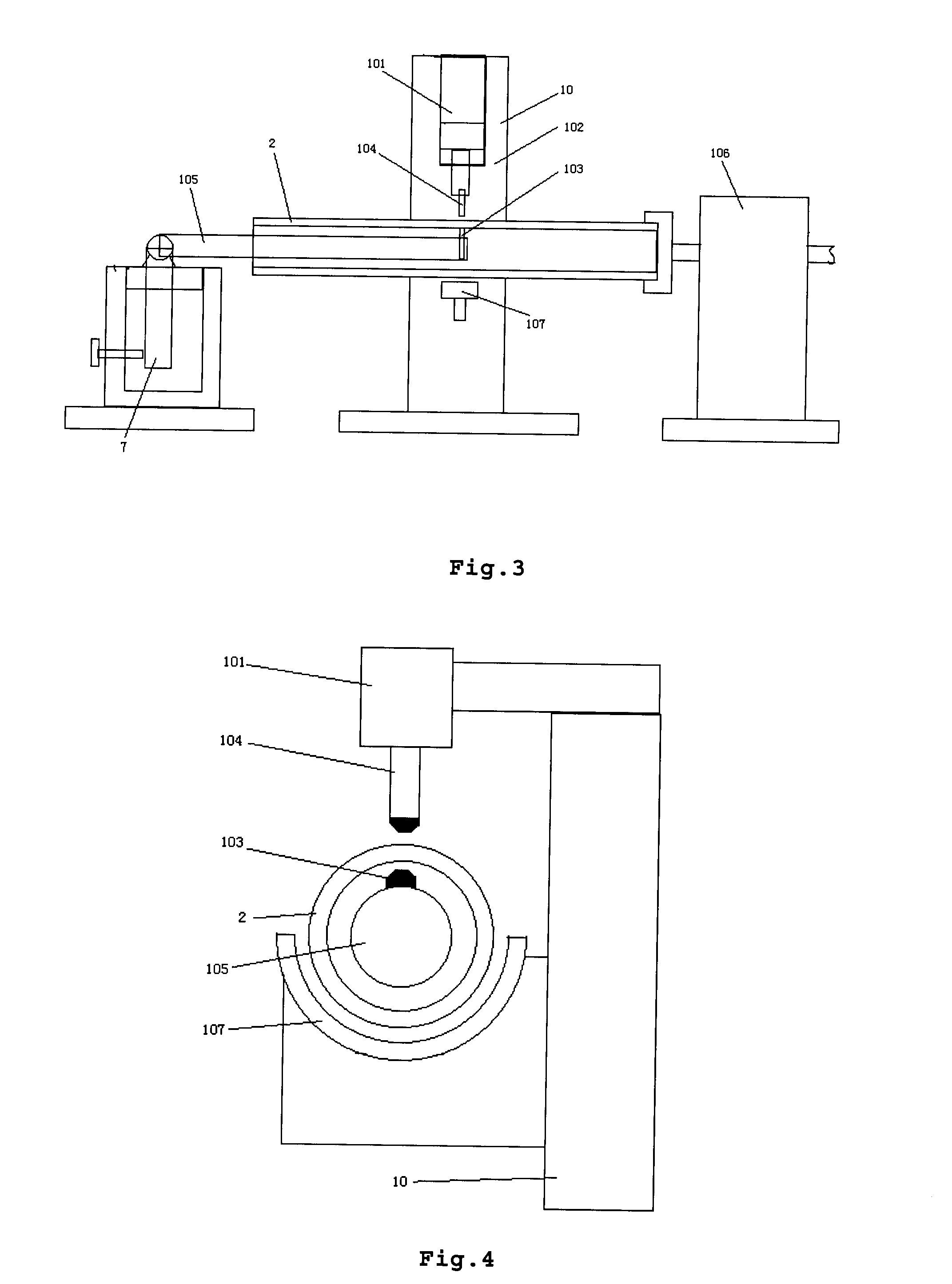

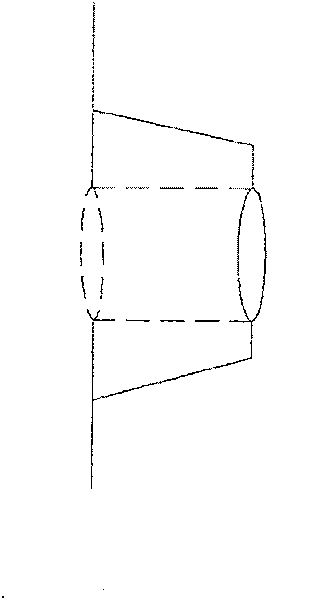

Screen manufacturing method and welding apparatus thereof

ActiveUS20070204465A1Eliminate leaksImprove controlWelding/cutting auxillary devicesFluid removalEngineeringSpot welding

The present invention relates to a method for manufacturing a screen and welding apparatus thereof, putting a metal filter net around the outside of a support sheath and fixing the metal filter net to the outside of the support sheath by way of welding, such that the metal filter net completely covers all filter holes of the support sheath to form a filter sheath with; fixing the filter sheath to the outside of the base pipe and the filter sheath completely covering all penetrated holes on the base pipe; putting a jacket around the outside of the filter sheath and fixing it to the outside of the base pipe such that the jacket completely covers the outside surface of the filter area of the filter sheath. The present invention uses direct spot welding and seam welding technology to fix the metal net to the outside of the support sheath directly, eliminates leakage hole phenomena appearing on jointing parts of the metal net and forms the screen with multi-layer metal nets with improved sand control capability and life time. The present invention also discloses the apparatus for above-said screen to realize penetrated welding of the filter sheath so as to improve the welding quality of the metal net and lower the factory cost of the screen.

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

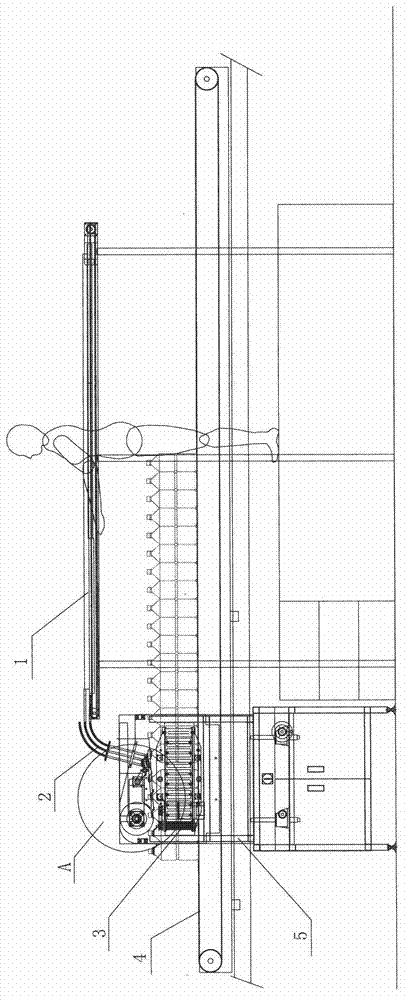

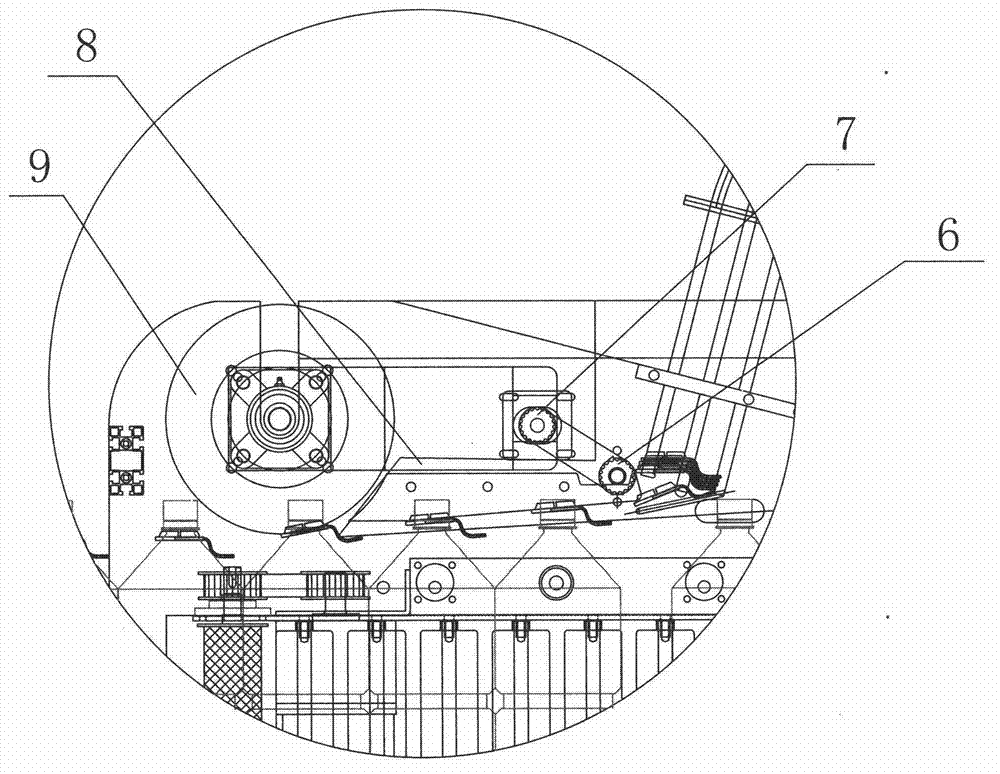

Automatic holder sheathing machine and technological method thereof

The invention relates to an automatic holder sheathing machine and a technological method thereof. The automatic holder sheathing machine comprises a conveyer belt, a bracket is arranged on the conveyer belt, a holder conveying belt is arranged above the conveyer belt, a holder guiding groove is arranged at the outlet end of the holder conveying belt, a pressing strip and a pinch roller are sequentially arranged at the outlet end of the holder guiding groove and in the forward direction of the conveyer belt, and the pinch roller is driven by a pinch roller motor to rotate; the technological method comprises the following steps: (a) holders are placed in the holder conveying belt by an operator, and the holders are conveyed to the holder guiding groove by the holder conveying belt; (b) the holders are separated by a holder poking wheel to enter a waiting area, bottle bodies enter the machine, and then holders are automatically sheathed on the bottle bodies; (c) the bottle bodies on which holder are sheathed move to the lower side of the pressing strip and continuously move forwards, and then the holders are pressed down by the pressing strip; and (d) the bottle bodies move to the lower side of the pinch roller, each holder is bucked at the bottle mouth of the corresponding bottle body through the rolling of the pinch roller and the forward movement of the bottles, and the operation process is finished. With the automatic holder sheathing machine and the technological method thereof, the automation of the holder sheathing step is realized, and the delivery cost of products is reduced.

Owner:KUNSHAN CHENGFENGDA IND EQUIP

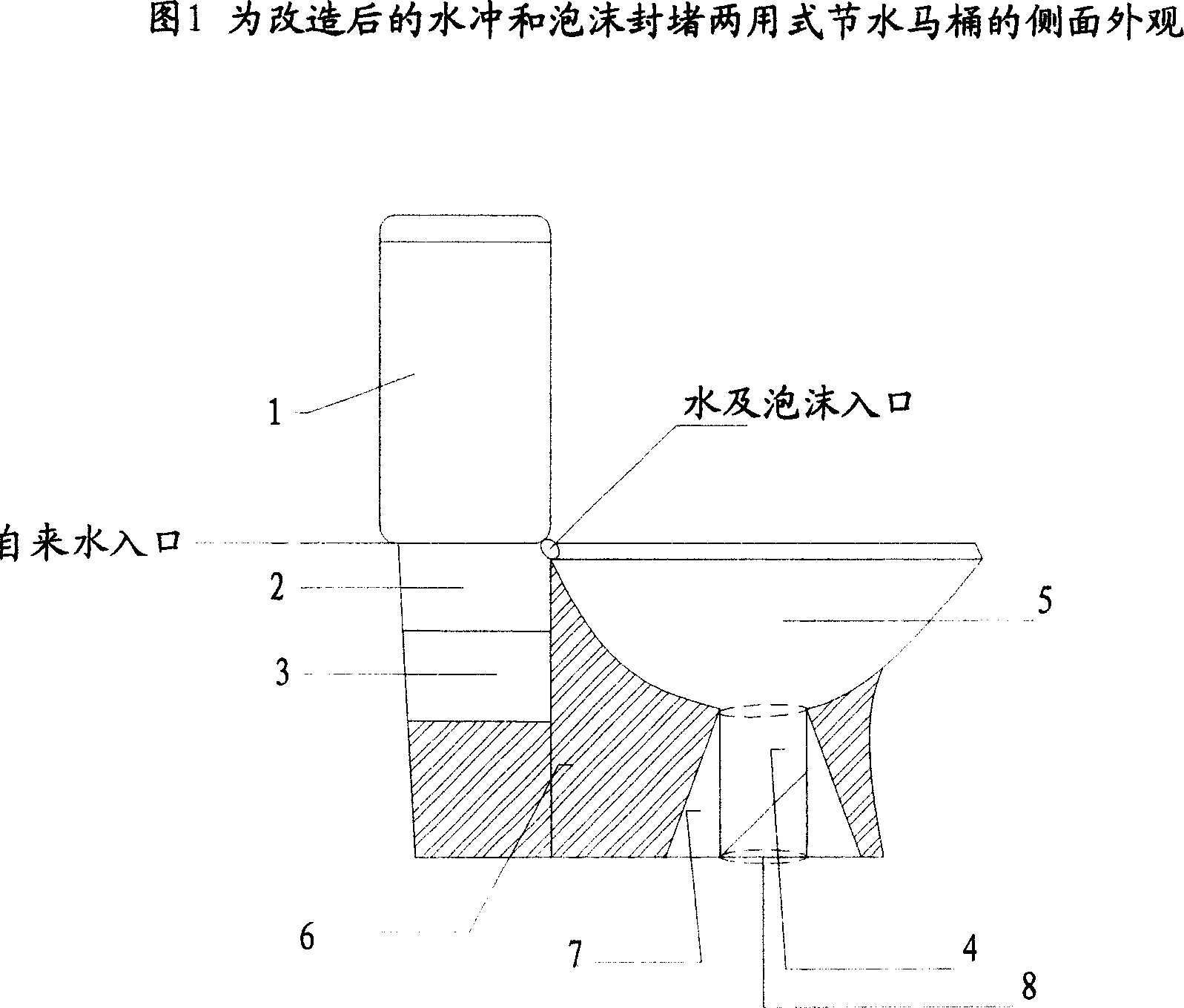

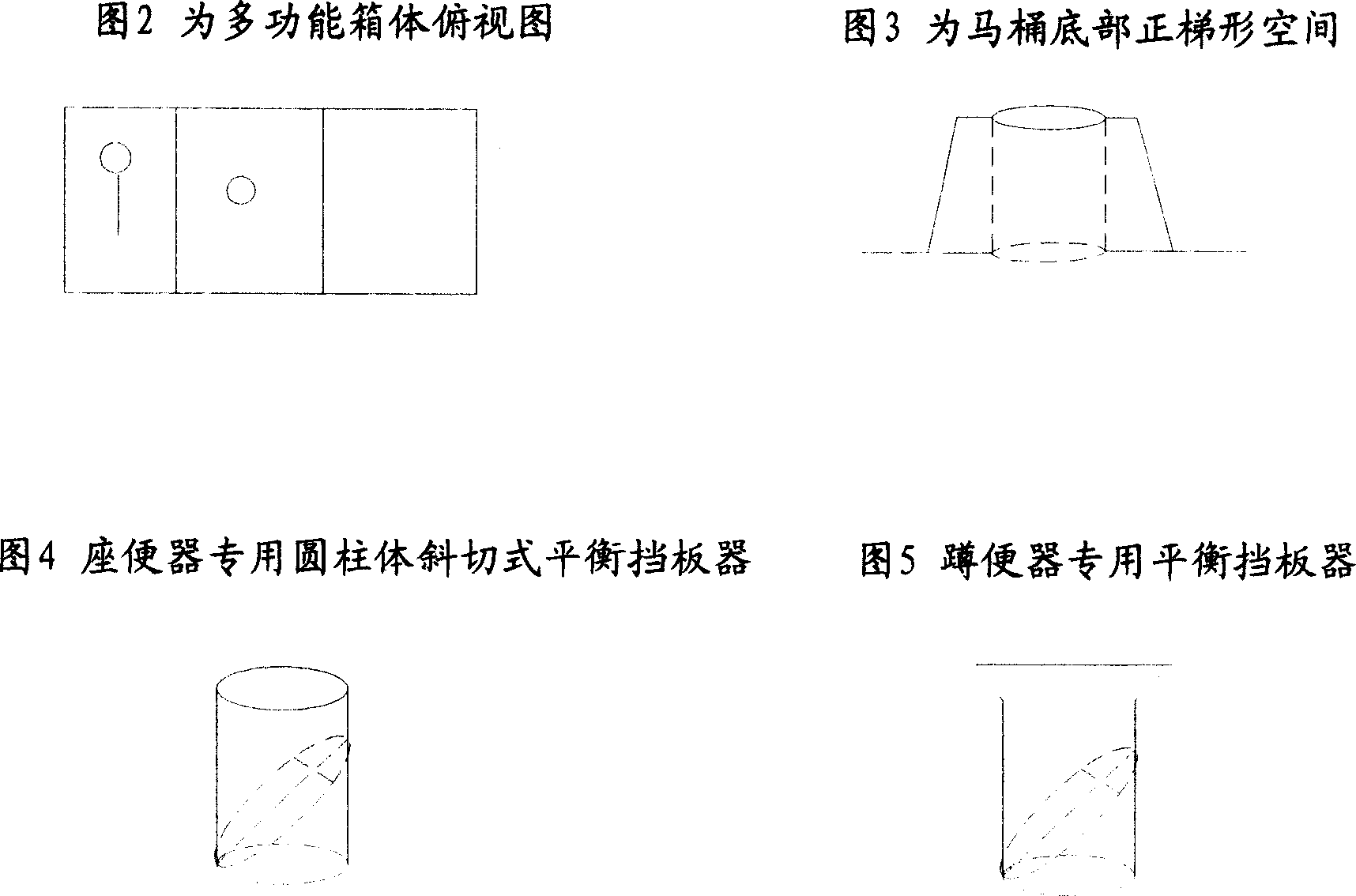

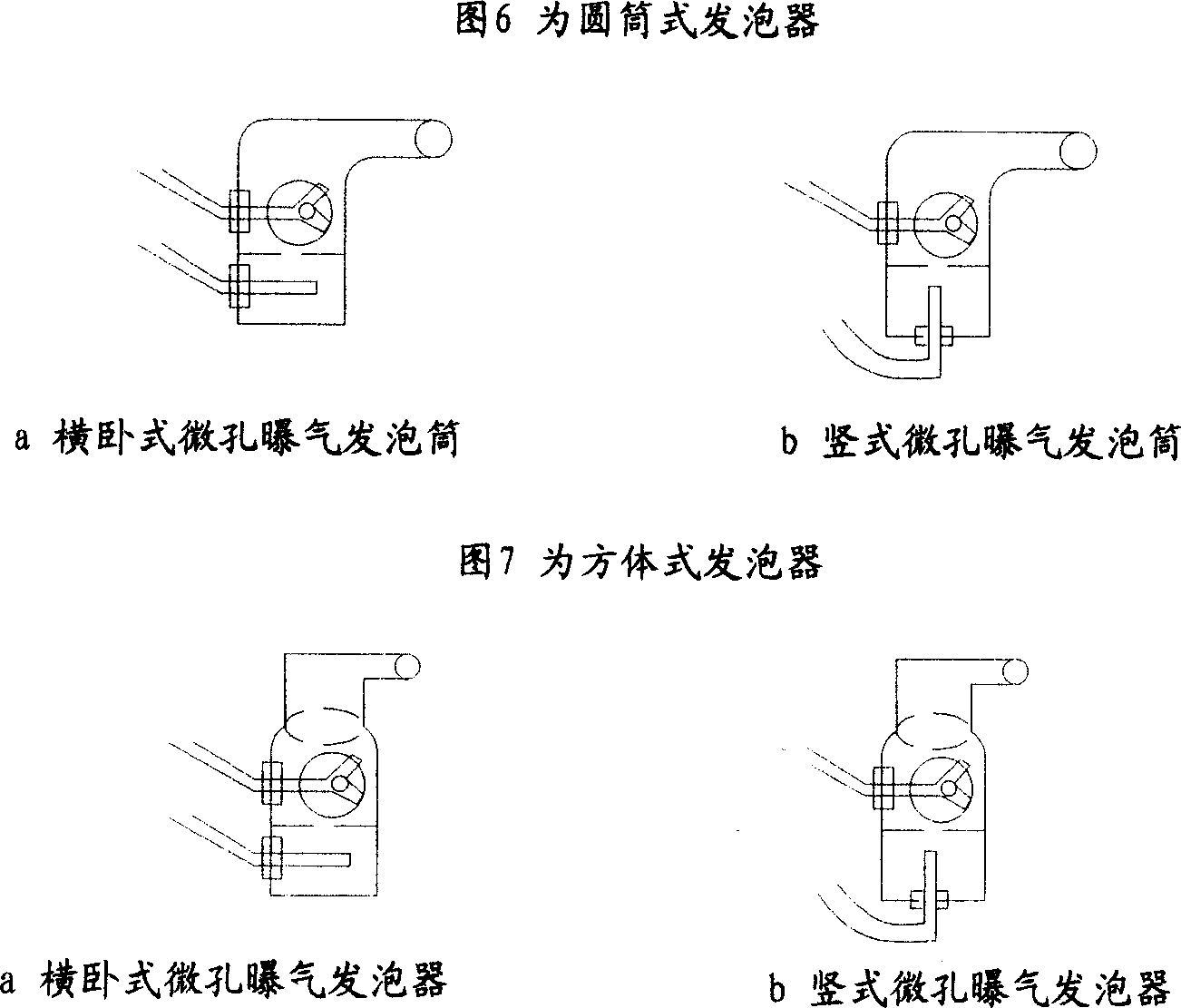

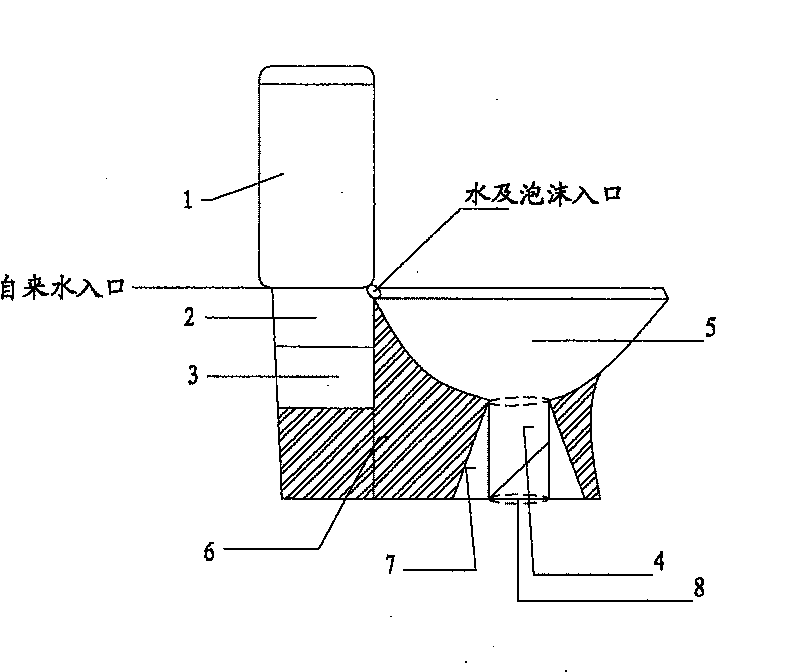

Doubleduty water saving closestool of using water flush and plugback of bubble foam, and relevant sets

InactiveCN101003982AReduce weightSave raw materialsWater closetsFlushing devicesWater savingDual purpose

The present invention relates to a water-flushing foam-blocking dual-purpose water-saving toilet and its related device. It is characterized by that the appearance of traditional toilet is changed, the upper and lower bent portions of traditional toilet are removed; a foaming system position is added and mounted. It foaming device has two types of barrel type and tube type, so that the water tank structure of improved toilet has two functions of storing water and flushing toilet.

Owner:淄博市开远节水环保设备有限公司 +1

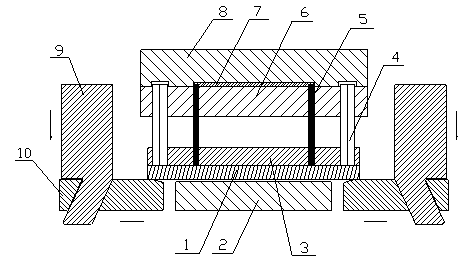

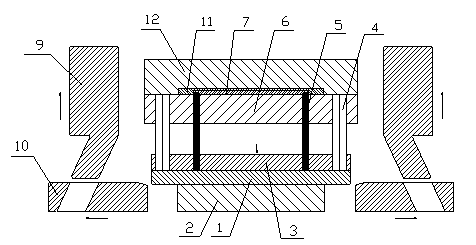

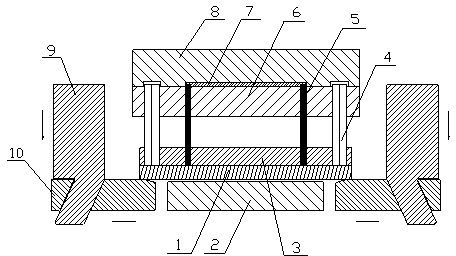

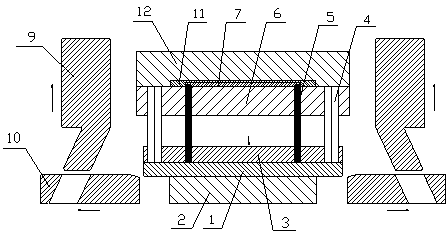

Inlay type combined die structure

ActiveCN102814386AGuaranteed roughness requirementsExtended service lifeStress concentrationWire cutting

The invention relates to an inlay type combined die structure comprising a die sleeve, wherein a back pad is arranged in the die sleeve; a die body is arrange on the back pad in the die sleeve; a forming groove is arranged on the die body; an inlaid piece slot is arranged in the forming groove; an inlaid piece is arranged in the inlaid piece slot; the upper forming surface of the forming groove is shaped like an arc; the inlaid piece is of a + shape or a linear shape or a +- shape; the inlaid piece slot is a through hole on the die body; the die body is made from a material with good toughness; and the inlaid piece is made from an abrasion-proof material. By adopting the structure, the inlay type is adopted to replace an integral type, so that stress concentration is avoided and the phenomenon that root is easy to break off does not happen; the mold is processed by adopting wire cutting, so that the processing is easy, the polishing can be carried out, the roughness requirement of the mold can be guaranteed, the service life of the mold is prolonged and the factory cost of products is reduced.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

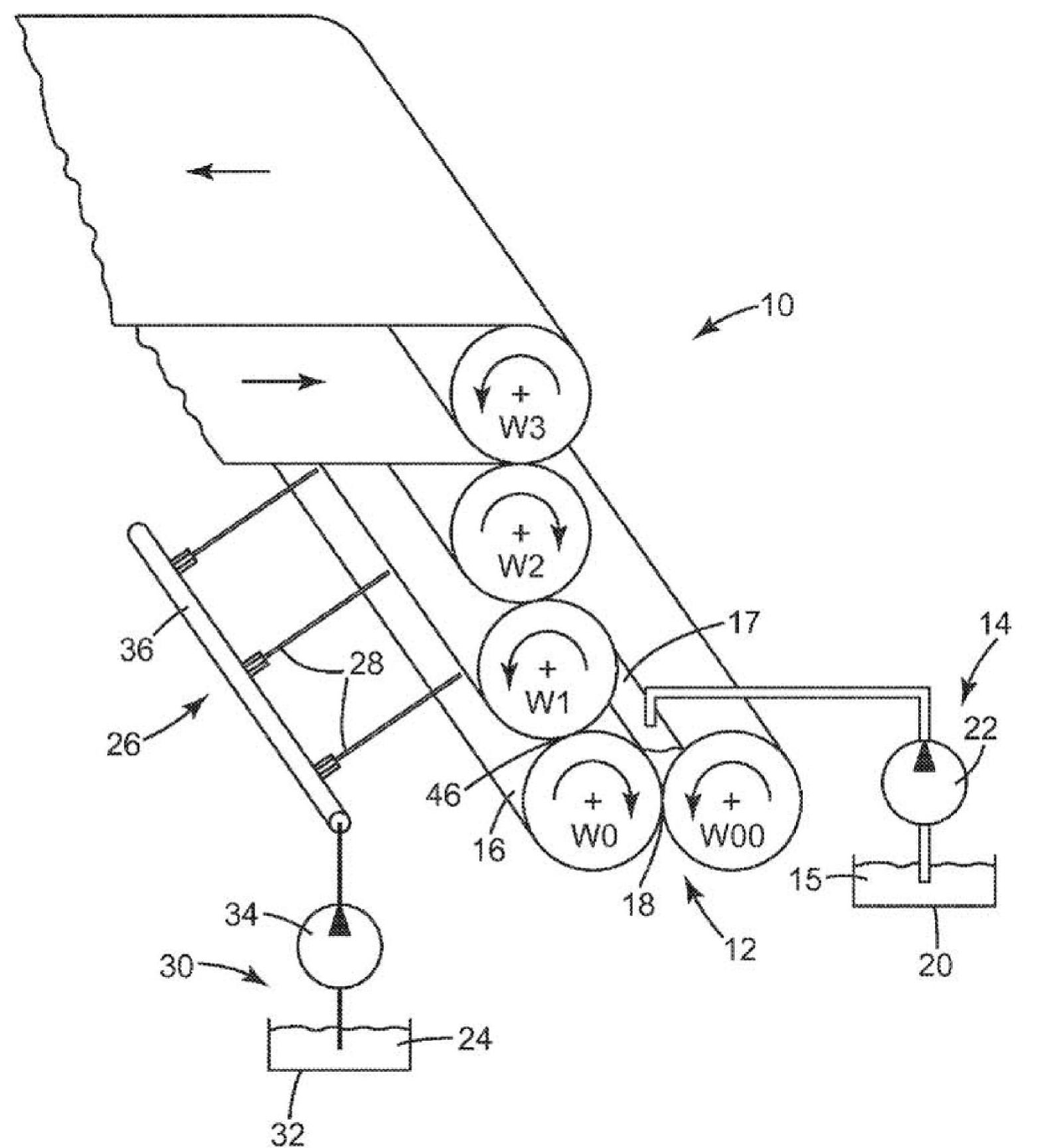

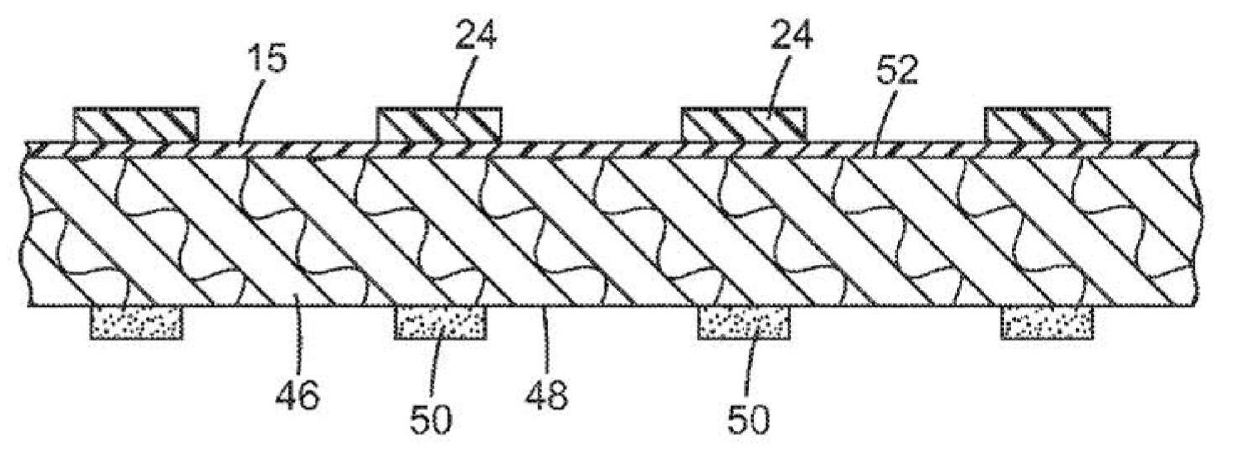

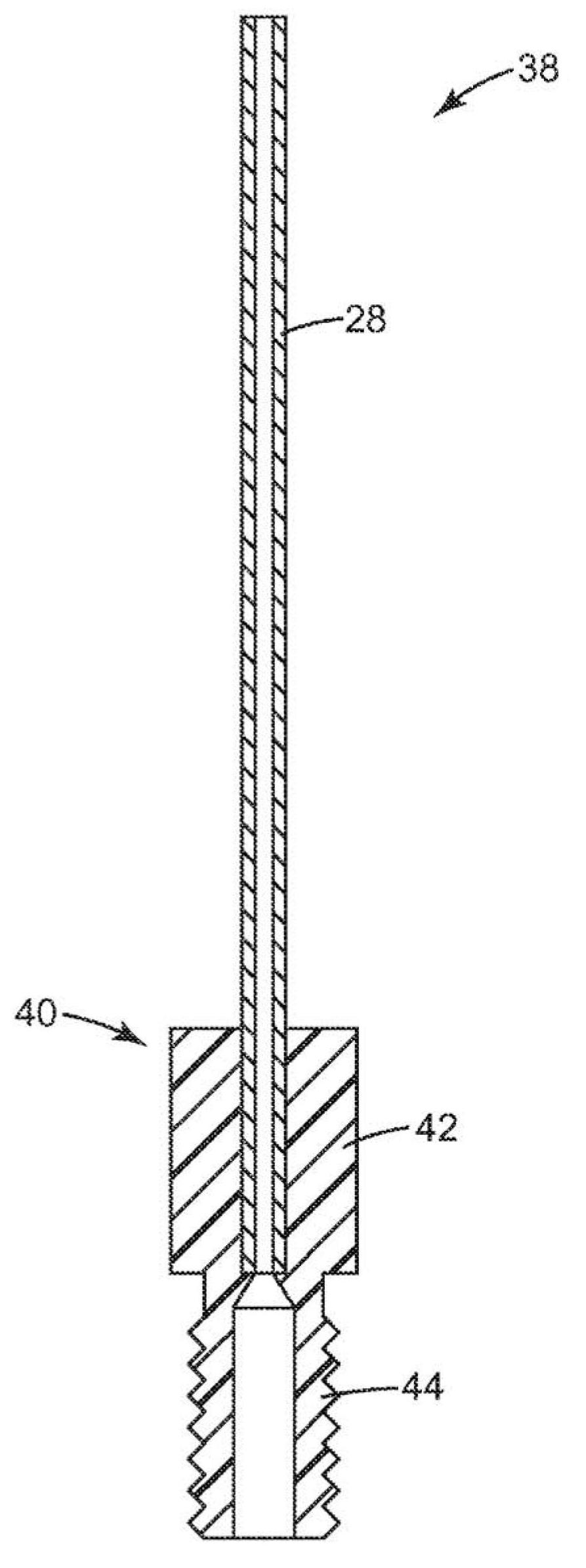

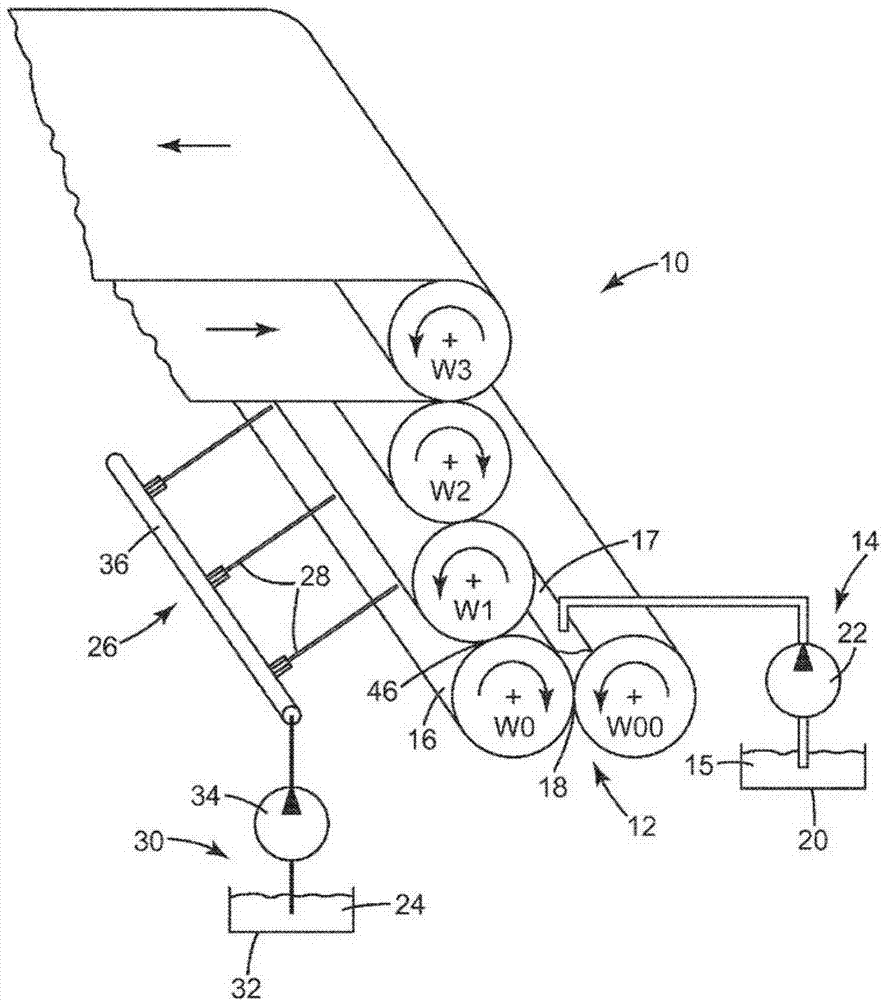

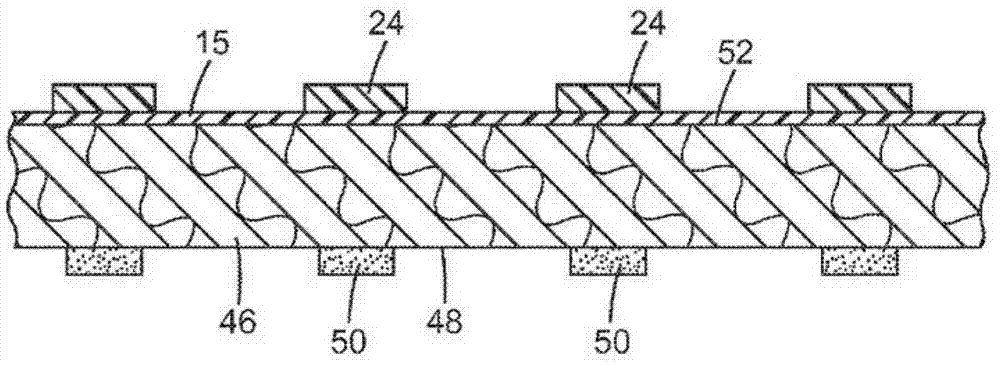

Method and apparatus for producing a non-uniform coating on a substrate

InactiveCN102665935AReduce factory costFilm/foil adhesivesSpecial surfacesEngineeringCoating materials

A roll coater can be modified by the addition of one or more needle tubes that supply coating fluid to the roll coater in discrete locations across the face of the coating roll. The needle tubes supply a localized band of coating material onto the coating roll superimposed over the uniform coating layer already present on the surface of the coating roll from an upstream coating pond creating a stripe pattern over the uniform coating layer. By varying the relative speeds of the coating rolls in the coater, the width of the stripe can also be adjusted.

Owner:3M INNOVATIVE PROPERTIES CO

Binding steel bar connecting assembly and connecting method applied to PC component assembly

PendingCN109881845AReduce factory costAvoid deformation hazardsBuilding reinforcementsBuilding material handlingButt jointArchitectural engineering

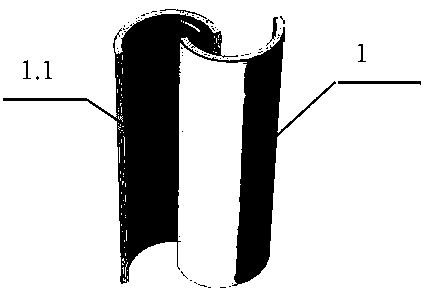

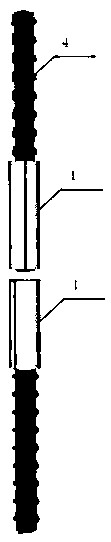

The invention relates to a binding steel bar connecting assembly and a connecting method applied to PC component assembly, and belongs to the field of construction engineering. The binding steel bar connecting assembly is formed by closely enclosing the ends of two butt-jointed steel bars with a combined-type inner layer sleeve core, a combined-type middle layer sleeve and an outer sleeve hoop layer; the inner layer sleeve core is composed of two pairs of semi-circular tubes which are correspondingly fastened to the ends of two butt-jointed steel bars, wherein each semi-circular tube is less than or equal to 1 / 2 of a circle, and grooves are formed in the inner sides of the semi-circular tubes, wherein the grooves coincide with oblique transverse thread flanges on the outer surfaces of thebutt-jointed steel bars; the middle layer sleeve is combination pipe with vertical seams and variable cross sections, the combination pipe is defined by arc-shaped plate strips which are divided intothree-four equal parts in the circumferential radial direction, the inner diameter of the combination pipe is equal everywhere, and the outer diameter is reduced from the middle section to both ends;outer layer sleeve hoops are a pair of taper sleeves, wherein each of the inner diameter gradients of the taper sleeves is matched with the outer diameter gradient of the middle layer sleeve, and thetaper sleeves can be sleeved with the two ends of the middle layer sleeve; the distance between the two sleeve hoops is forcibly shortened by special tools, and the inner diameter of the combined-typemiddle layer sleeve is enabled to be reduced, so that the friction and the bond stress at the end of a steel bar are obtained, and thus an effective steel bar joint is obtained.

Owner:王玉峰

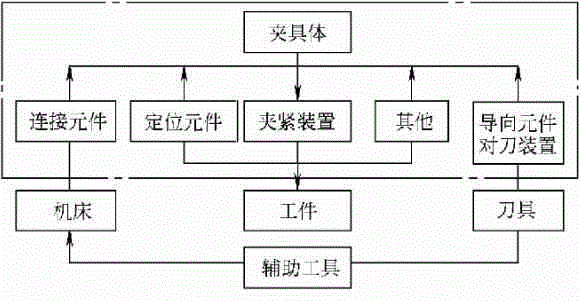

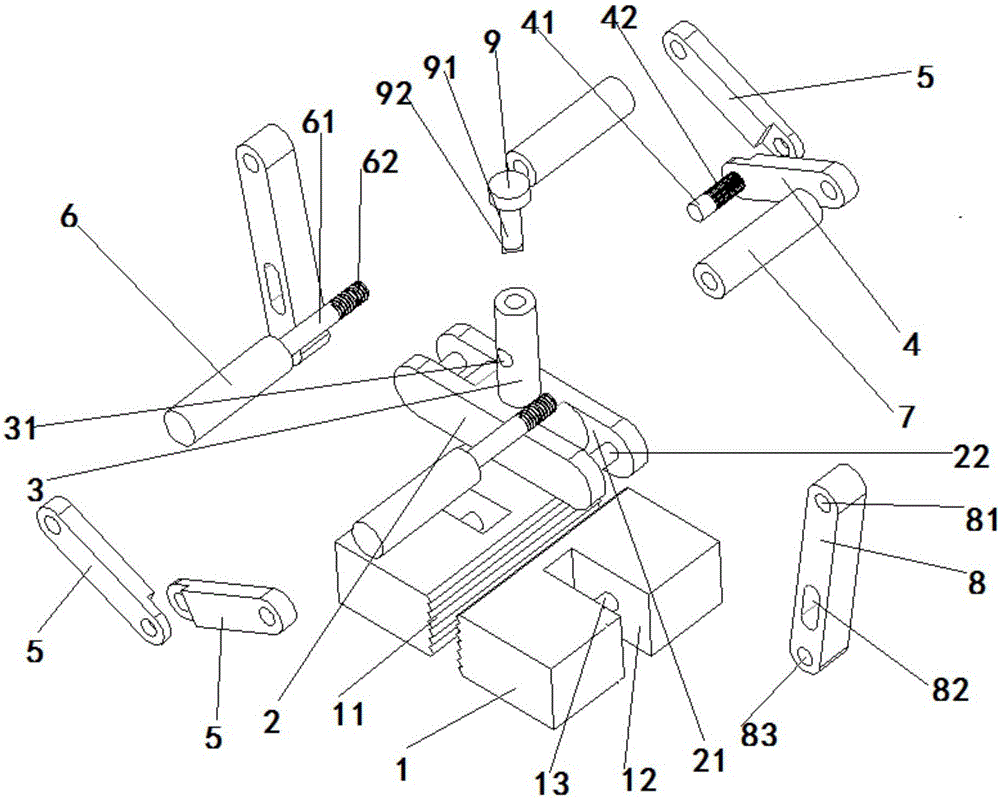

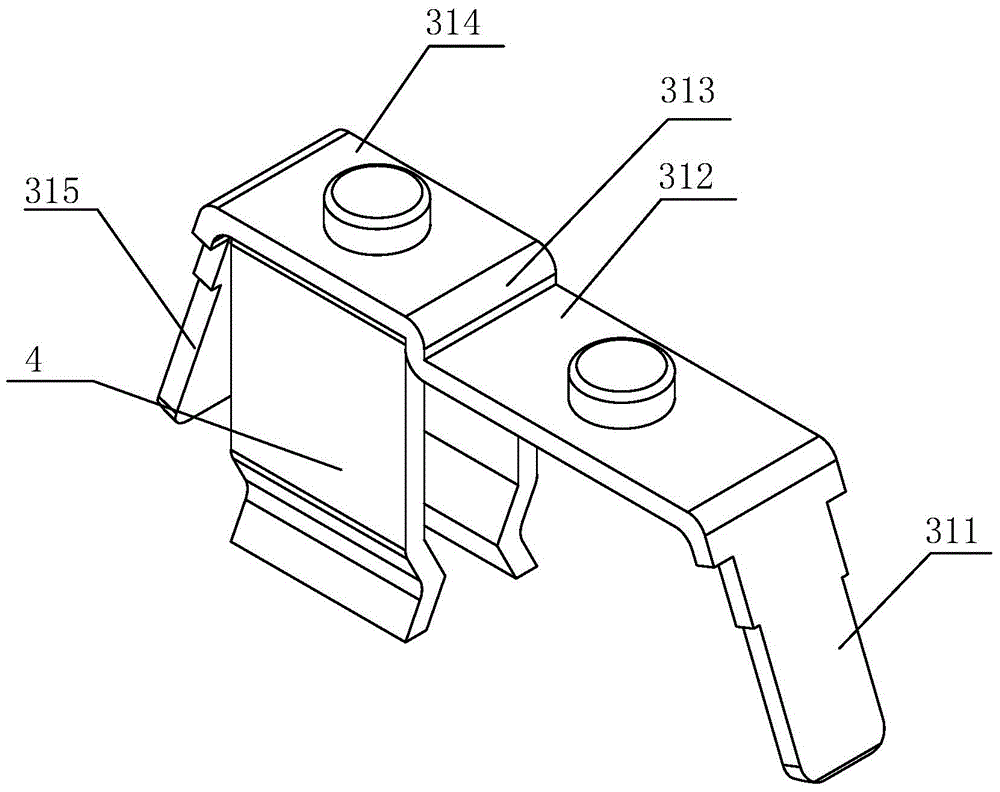

Intelligent clamp fast-replacement device

InactiveCN105269201AQuick releaseQuick clampingWelding/cutting auxillary devicesAuxillary welding devicesForcepsEngineering

The invention relates to an intelligent clamp fast-replacement device. The intelligent clamp fast-replacement device comprises a clamp top plate and a clamp bottom plate; a welding air cylinder and a welding head located on the welding air cylinder are arranged on the clamp top plate and between the clamp top plate and the clamp bottom plate; a workpiece clamping structure is arranged on the clamp bottom plate and between the clamp top plate and the clamp bottom plate; a fast clamp forceps structure is disposed on the clamp top plate; a fast inserting structure is disposed on the clamp bottom plate. By means of the structure, the clamp structure can be fast dismantled and mounted for clamping; fast error correction can be achieved through a workpiece detector and a nut detector; operation is convenient; defective products are reduced; time is saved; the working efficiency of a welding machine is improved; the ex-factory cost of products is reduced.

Owner:阮明鑫

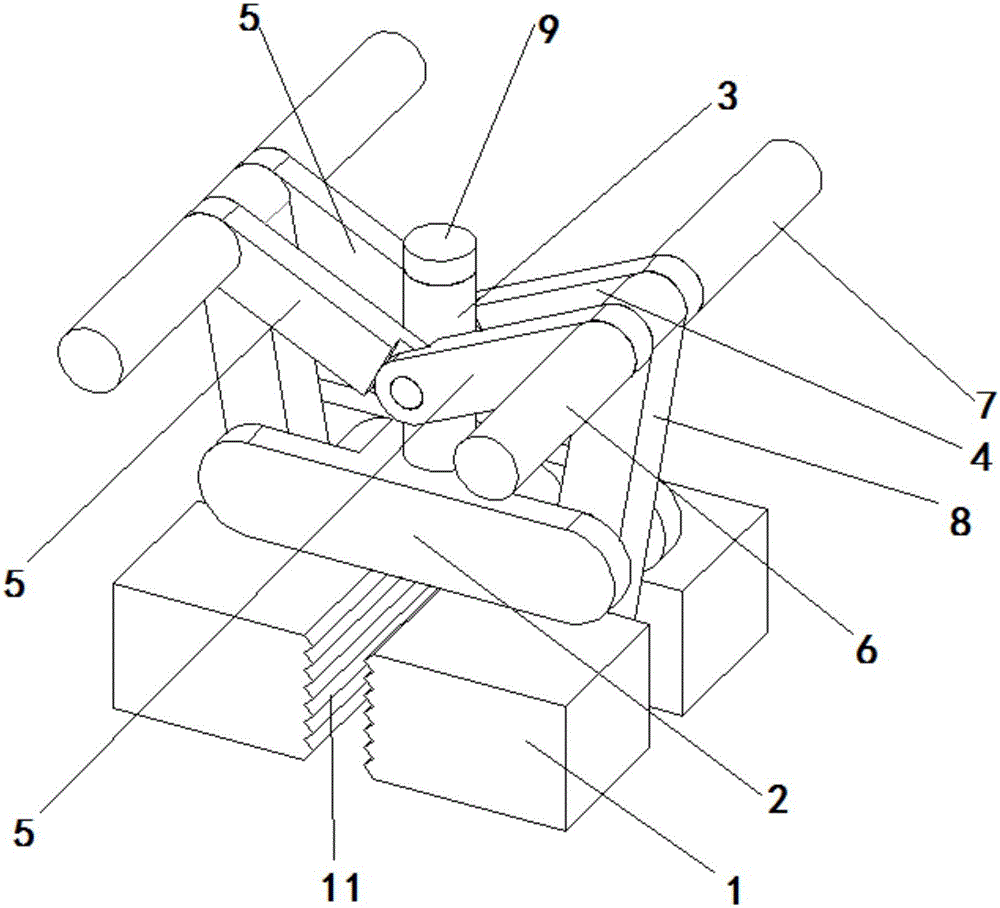

Manual welding and clamping device

InactiveCN106378565AReduce generationImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a manual welding and clamping device which comprises a base. Installing grooves are symmetrically formed in the two ends of the base. A rotating shaft is arranged in each installing groove. A fixed cylinder is fixed right above the base. A locating hole is horizontally formed in the middle of the fixed cylinder. A top cover is installed on the upper portion of the fixed cylinder. A locating shaft is arranged below the top cover. A limiting piece is arranged at the bottom end of the locating shaft. A main rotating plate is installed on the front side of the fixed cylinder. An installing shaft is arranged at one end of the inner side of the main rotating plate. A tooth groove surrounding the installing shaft by one circle is formed in the middle of the installing shaft. The installing shaft is installed in the locating hole. Two auxiliary rotating plates with the structure the same as that of the main rotating plate are hinged to the tail end of the installing shaft, wherein the two auxiliary rotating plates are arranged symmetrically. Auxiliary rotating plates are symmetrically arranged on the outer side of the main rotating plate. The manual welding and clamping device can achieve fast disassembling and clamping, fast error correction can be achieved through a workpiece detector and a nut detector, operation is convenient, generation of inferior-quality products is reduced, time is saved, the working efficiency of a welding machine is improved, and the ex-factory cost of the products is reduced.

Owner:周峰

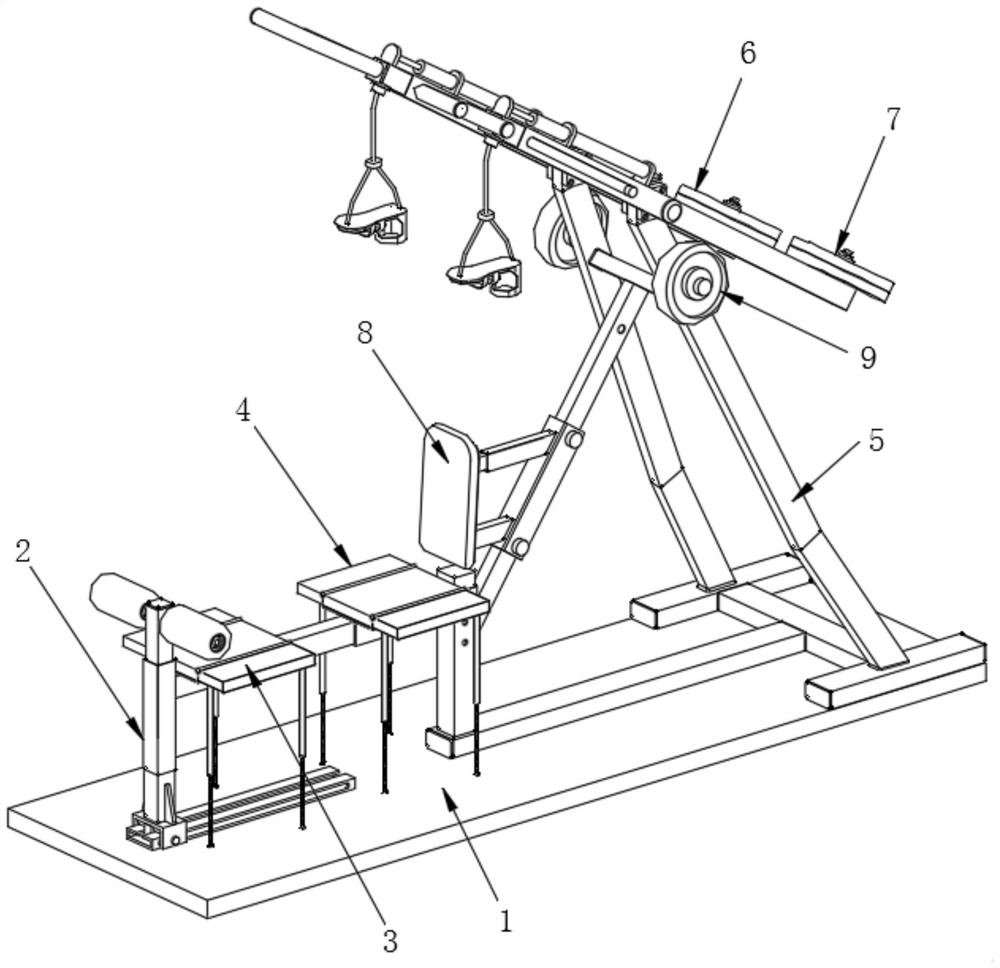

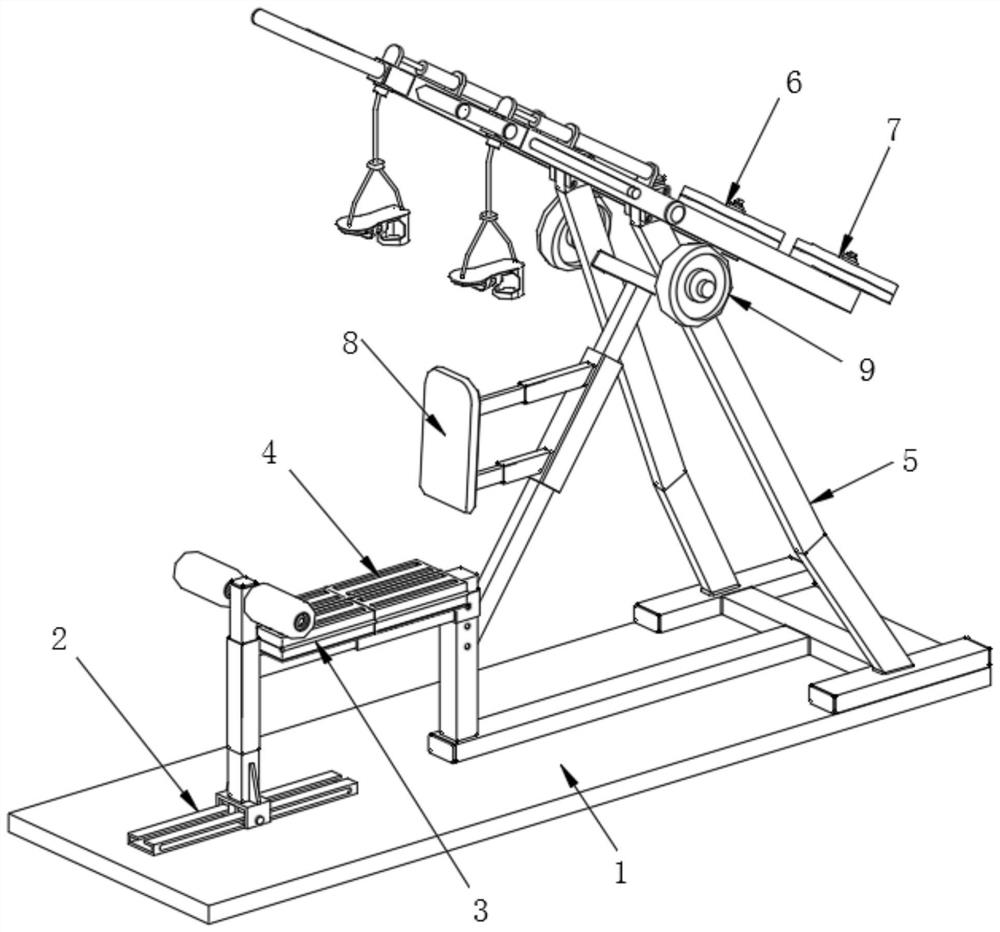

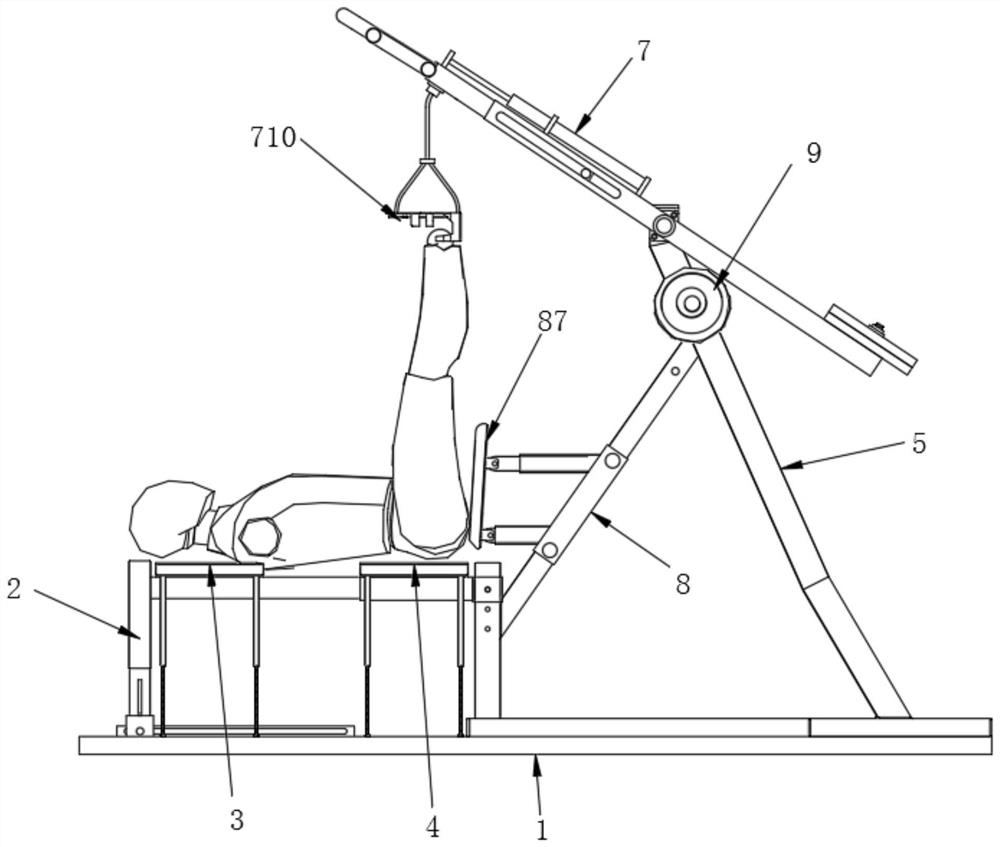

Multifunctional exercise equipment for fitness and rehabilitation

InactiveCN112774132AReduce factory costChange training intensityWeightsPhysical medicine and rehabilitationEngineering

The invention discloses multifunctional exercise equipment for fitness and rehabilitation, and relates to the technical field of fitness and rehabilitation, a first limb exercise unit and a second limb exercise unit are symmetrically arranged at the top end of a supporting frame, and during actual use, the first exercise unit and the second limb exercise unit can perform exercise operation independently, a user does not need to be limited to limbs to apply acting force at the same time, in addition, the first exercise unit and the second limb exercise unit both utilize the lever principle, the training intensity is changed, the length of a force arm is changed in an electric mode, and adjustment can be conducted even under the condition that the number of balancing weights is not changed. Therefore, the whole set of fitness exercise equipment does not need to be provided with a large number of balancing weights, the manufacturing cost, the factory cost and the market price of the whole set of fitness exercise equipment are reduced, and the market competitiveness of the whole set of fitness exercise equipment is improved.

Owner:朱成香

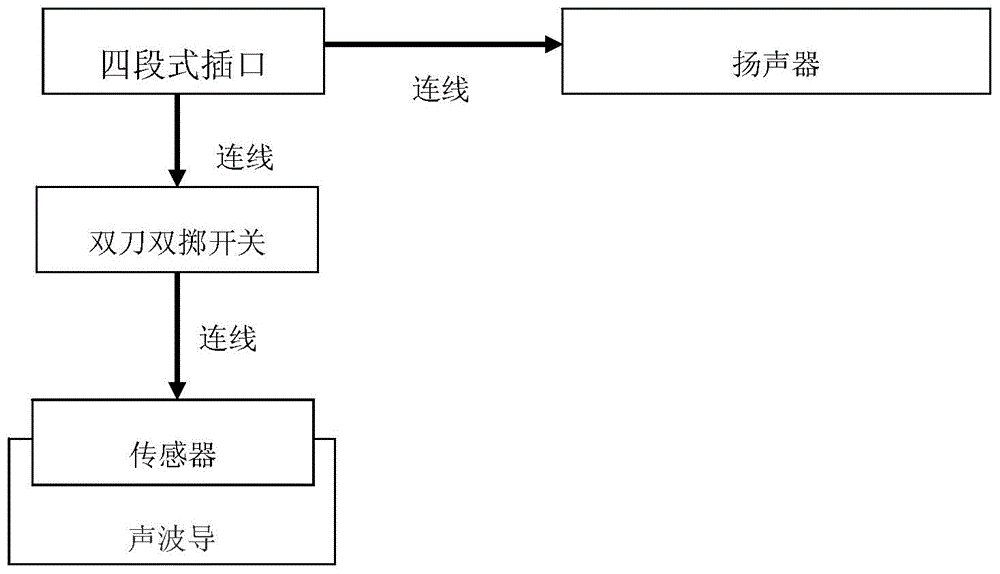

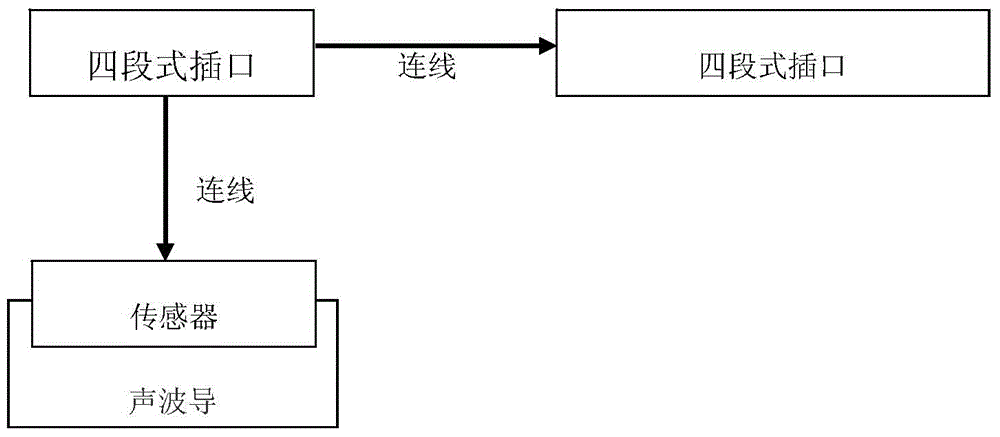

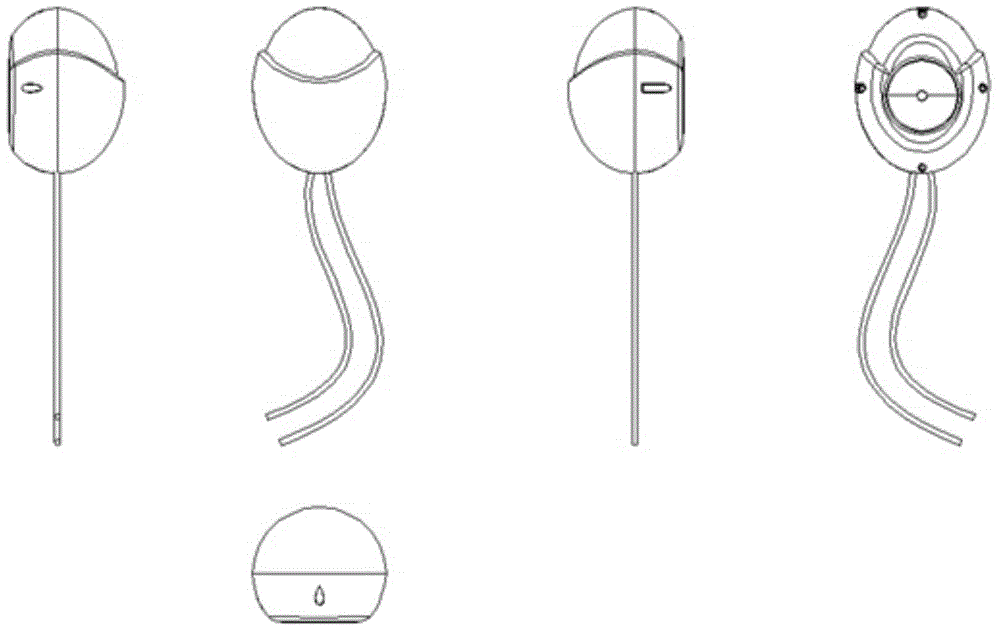

Pick device for fetal heartbeat sound

ActiveCN104586428AAvoid inconvenienceSmall volumnHeart/pulse rate measurement devicesInfrasonic diagnosticsFetal organLoudspeaker

The invention discloses a pick device for a fetal heartbeat sound. The pick device comprises an interface, a sensor, a sound gathering device, a lead, a loudspeaker or a set of loudspeakers, and a selector switch, wherein the interface is connected with an audio frequency socket of an intelligent device; the sensor is used for receiving the fetal heartbeat sound, and a sound made by a fetal organ is converted into an electric signal by the sensor; the sound gathering device is used for gathering the fetal heartbeat sound, and like an acoustic duct of a horn mouth, the sound gathering device is used for gathering the sound made by the fetal organ; the loudspeaker or the loudspeakers is or are connected with the intelligent device through the interface, and is or are used for playing the sound; the selector switch is used for switching connection between the sensor and the ground so as to meet the OMTP (open mobile terminal platform) standard or the CTIA (cellular telecommunications industry association) standard. According to the pick device disclosed by the invention, the ability of the existing intelligent device of a user is exerted, so that an external device can become simplest, and further, the cost is lowest; the function of the pick device is equal to or more powerful than the existing product.

Owner:张敏

Die opening/closing structure system used for injection mold

InactiveCN103009587AEliminate shoveling phenomenonImprove pass rateCoatingsStructure systemSurface plate

The invention relates to a die opening / closing structure system, which comprises a panel, a plate A and a plate B, and further includes a small pull rod mechanism, a rubber plug mechanism, a push / stop block mechanism and a sliding block mechanism, wherein the small pull rod mechanism includes pull rod screws mounted in the panel, a small pull rod arranged on the pull rod screws and penetrating the plate A and the plate B, and a small pull rod spring arranged on the outer side of the small pull rod and in the plate A; a limit step matched with the head part of the small pull rod is arranged in the plate A; the rubber plug mechanism includes a rubber plug rod and a rubber plug fixed at the rod part of the rubber plug rod, wherein the head part of the rubber plug rod is matched with the step in the plate A, and the rubber plug is plugged into a hole in the plate B; the push / stop block mechanism includes a push block mounted on the panel, a stop block capable of sliding in the plate A, and block springs mounted in the stop block and the plate A. According to the system, the sliding block can move first during die opening and move last during die closing, so that the rubber shoveling phenomenon can be avoided, the product yield can be greatly improved, and the factory cost of the product is further lowered.

Owner:SUZHOU BENTENG PLASTIC

Injection molding encapsulation die structure

Owner:SUZHOU BENTENG PLASTIC

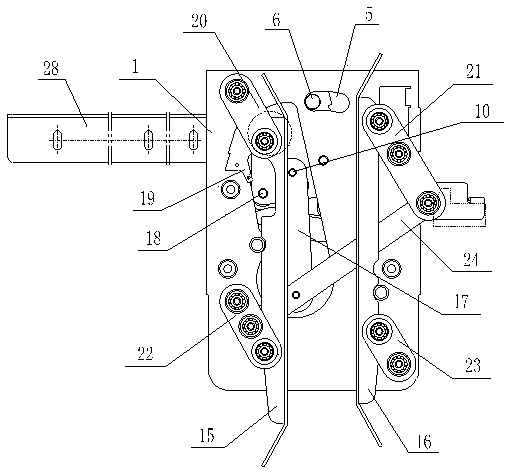

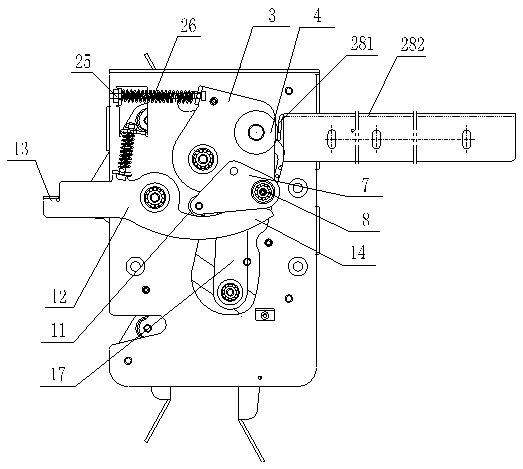

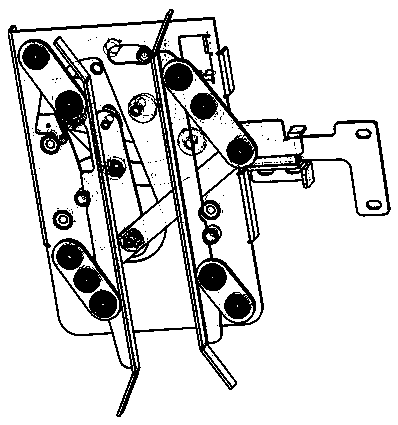

Anti-scrabbling door vane structure for elevator

The invention relates to an anti-scrabbling door vane structure for an elevator; a climbing motion of a rotating ball of a vane lifting plate on a guide rail urges the rotation of the vane lifting plate so as to drive an unlocking plate to move; the unlocking plate drives a connecting rod mechanism through a transmission arm to perform a relative staggered motion; when the connecting rod mechanism clamps a door locking ball, the unlocking plate rotates to drive an interlocking plate to rotate to realize an unlocking function; and the motion stability of a left door vane and a right door vane is guaranteed through a limiting stop shaft and a limiting baffle plate. The structure realizes the use effect of an asynchronous door vane and a synchronous door vane, improves the debugging and mounting efficiency, and realizes the electrified satisfaction of door scrabbling force requirements and the car scrabbling distance requirements in a non-flat floor state.

Owner:SUZHOU HEYANG METAL PROD

Production method of emergent cut-off valve

ActiveCN107842637AHigh strengthImprove impact resistanceEqualizing valvesSafety valvesUltimate tensile strengthFlange

The invention relates to the technical field of valve production and particularly relates to a production method of an emergent cut-off valve. The production method comprises the following steps: using a stainless steel plate as a raw material, carrying out stamping forming on the raw material to form a main valve body of the cut-off valve, carrying out forging machining to obtain a flange disc, and then welding the main valve body and the flange disc to obtain the valve body. The method is simple, practical and reliable. The strength and impact resistance of the produced cut-off valve are improved, the quality is substantially improved, the service life is long, a great effect is shown in actual production application, the procedures are simple, the operation is safe, the labor intensityof operators is reduced, and the production efficiency and benefit are greatly increased.

Owner:HUAIHAI INST OF TECH +1

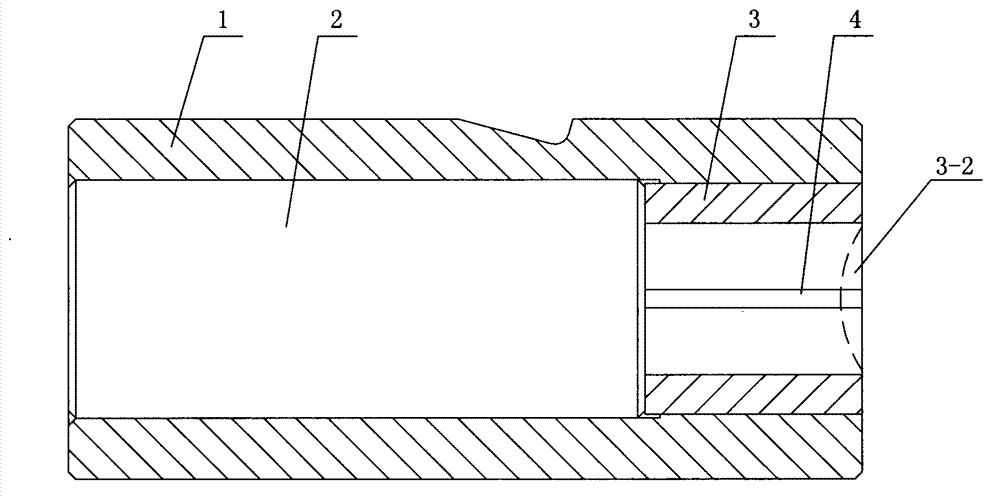

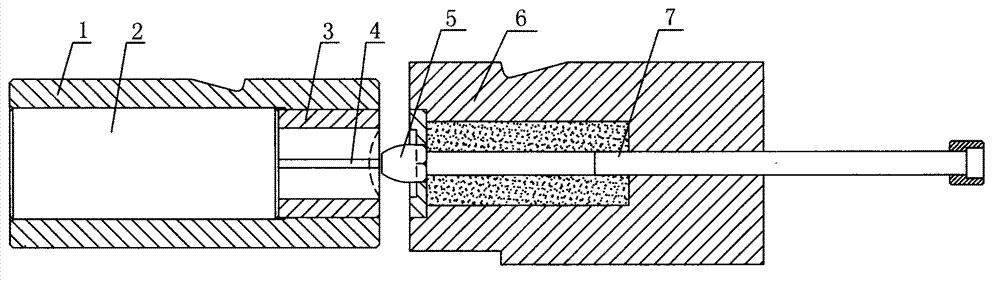

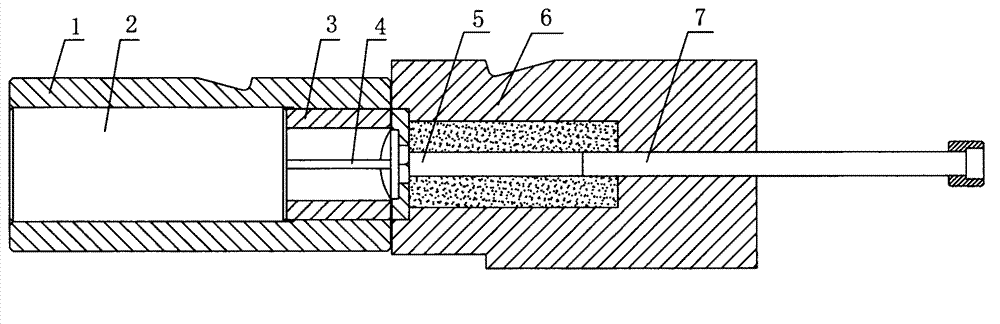

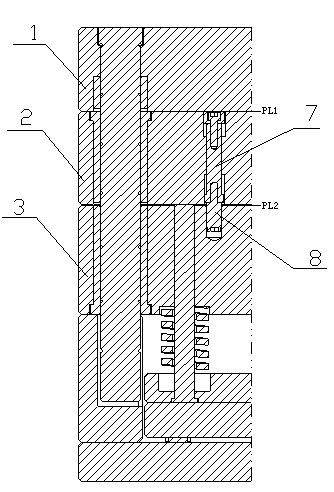

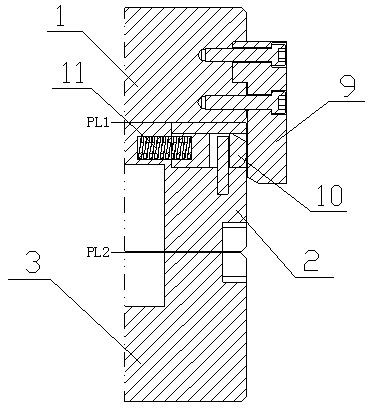

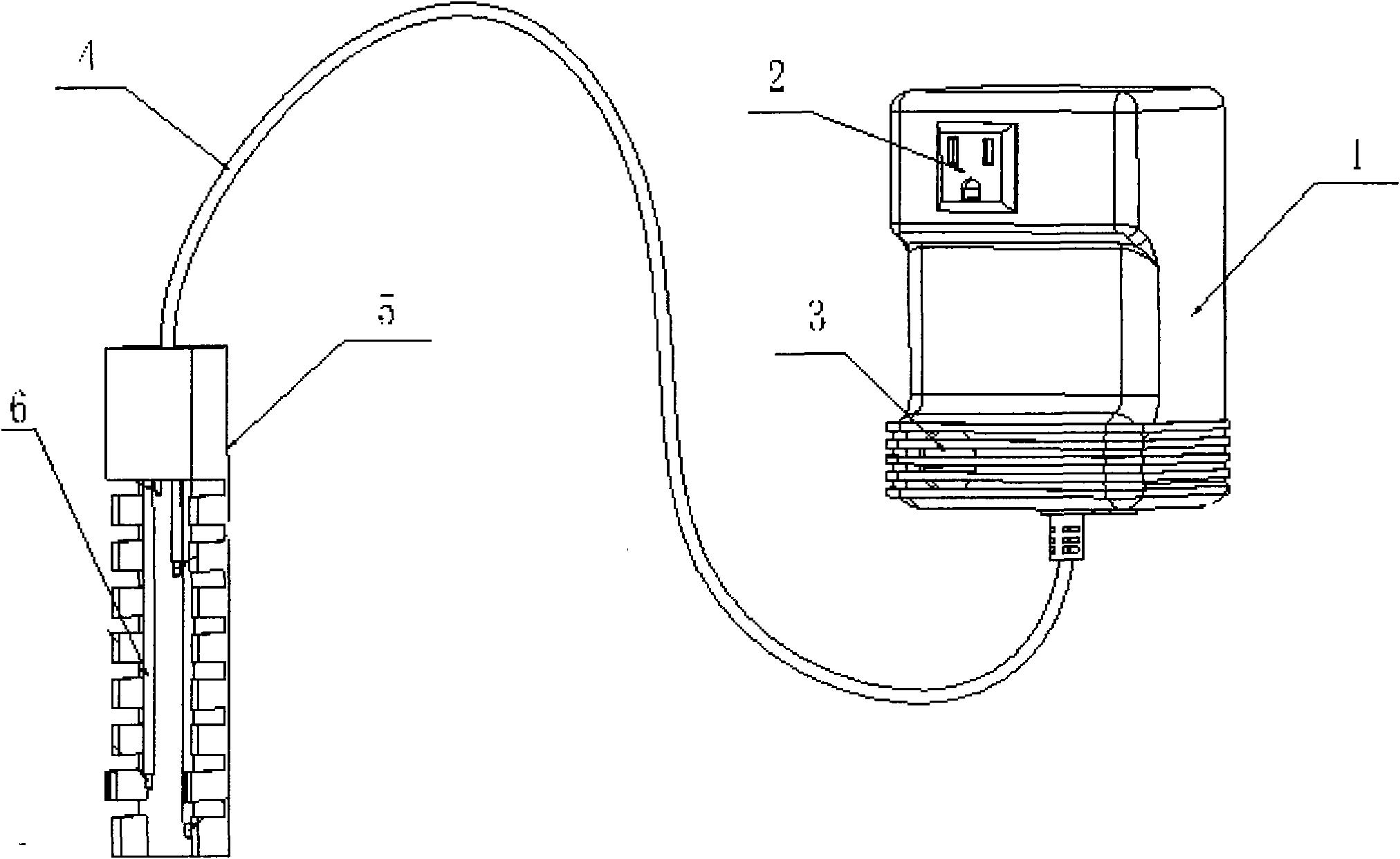

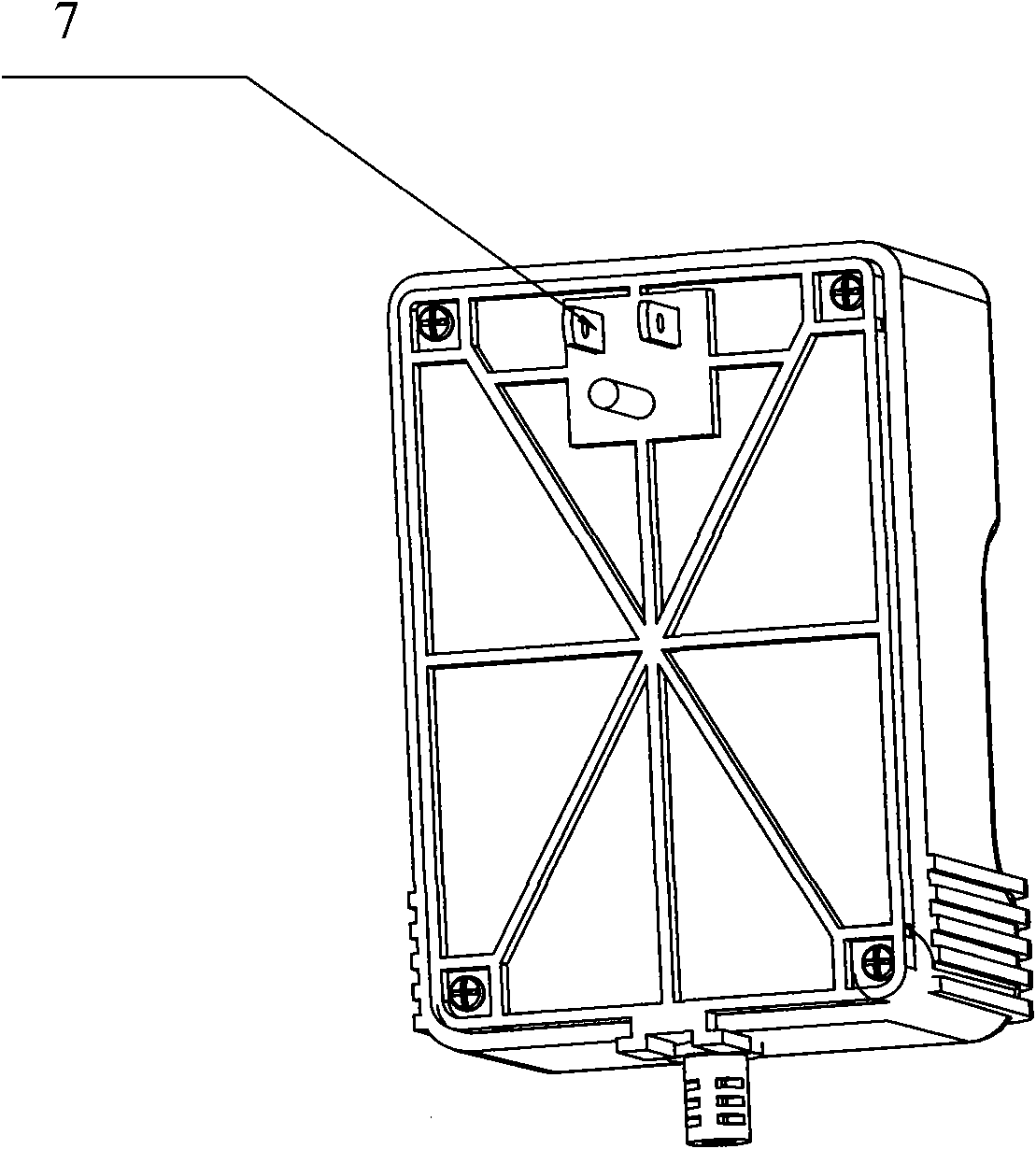

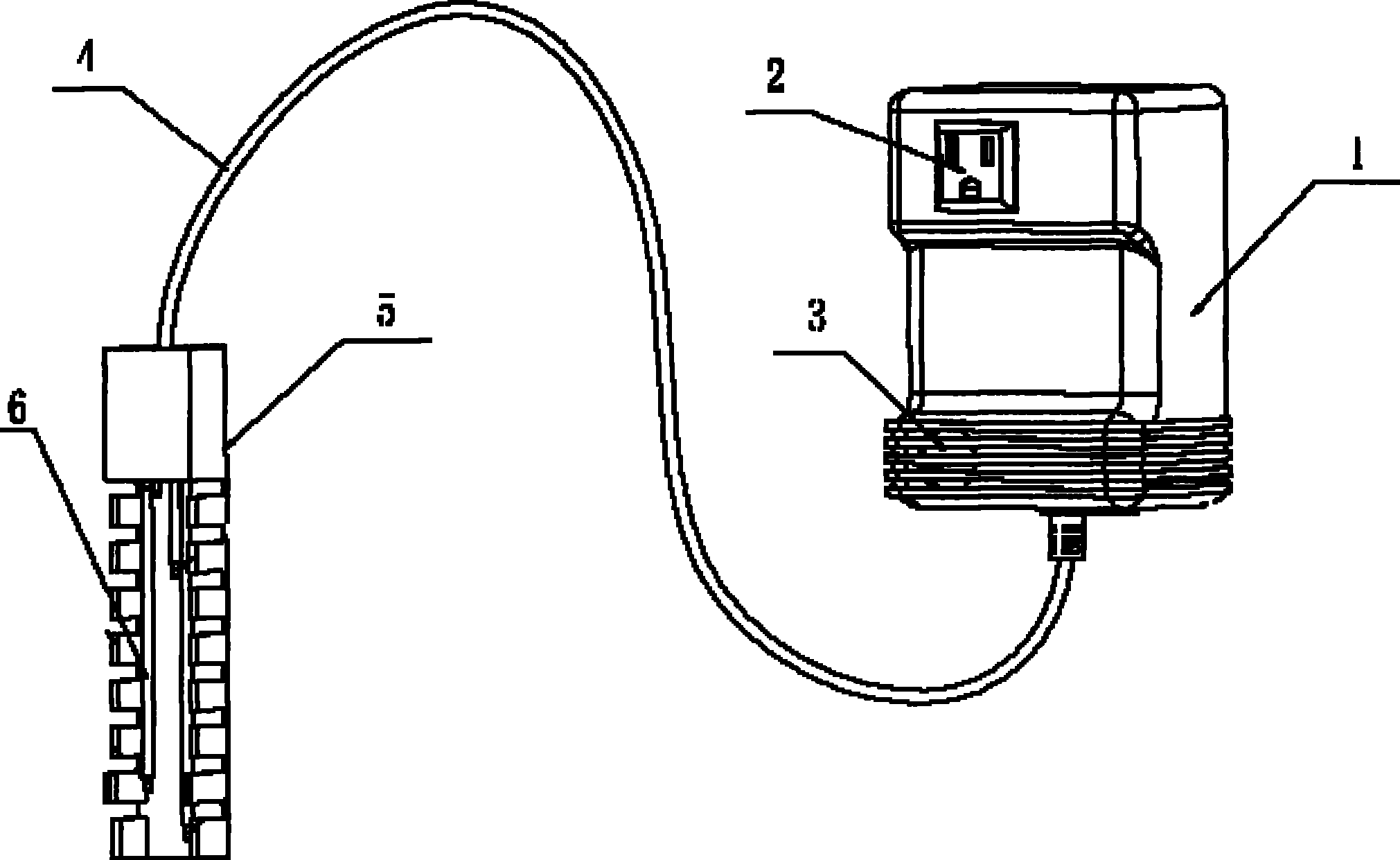

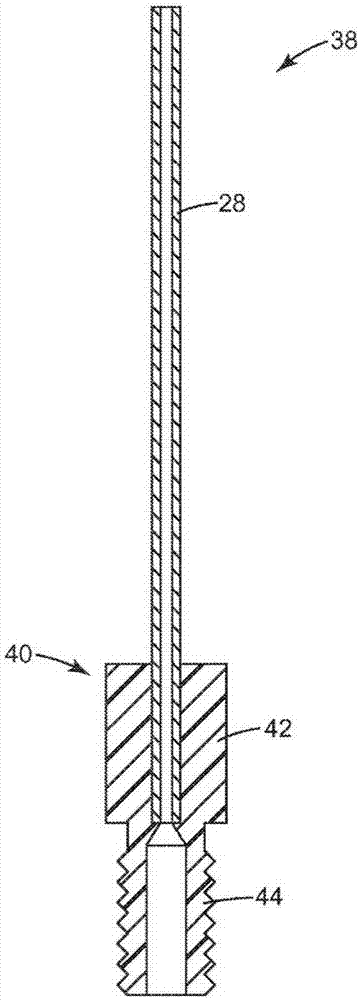

Split structure of probe and switch box

The invention discloses a split structure of a probe and a switch box. The split structure comprises the probe and the switch box which are connected with each other by an electric wire; the front surface of the switch box is provided with a three-hole plug; the back surface is provided with a three-core plug; a buzzer is arranged on the switch box; and the probe is arranged in the probe box. Due to the adoption of the split structure of the probe and the switch box, the switch box is far away from a water resource, a creepage phenomenon is avoided, a seal structure does not need to be adopted, resources are saved, manufacturing cost is reduced and benefits are increased.

Owner:GP ENTERPRISES CO LTD

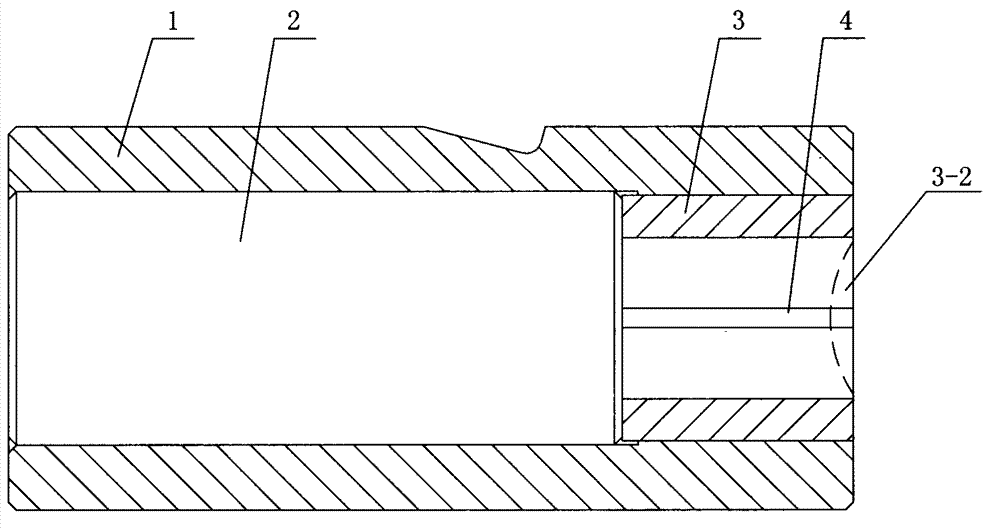

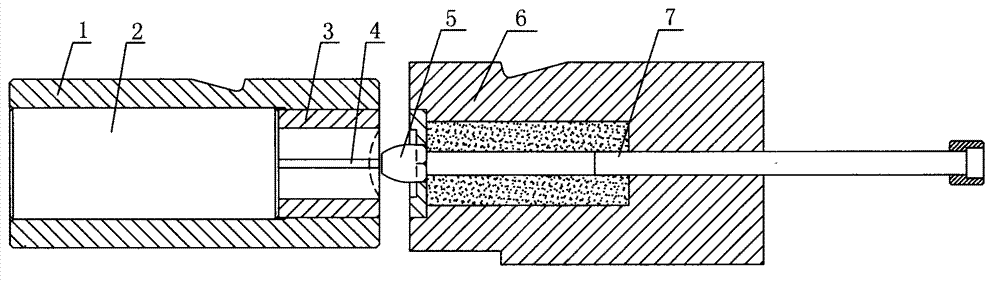

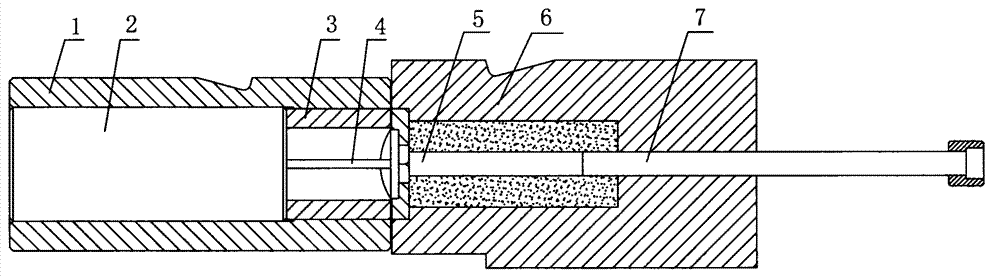

Screen manufacturing method and welding apparatus thereof

InactiveUS20090250438A1Eliminate leaksImprove controlArc welding apparatusFluid removalEngineeringSpot welding

The present invention relates to a method for manufacturing a screen and welding apparatus thereof, putting a metal filter net around the outside of a support sheath and fixing the metal filter net to the outside of the support sheath by way of welding, such that the metal filter net completely covers all filter holes of the support sheath to form a filter sheath with; fixing the filter sheath to the outside of the base pipe and the filter sheath completely covering all penetrated holes on the base pipe; putting a jacket around the outside of the filter sheath and fixing it to the outside of the base pipe such that the jacket completely covers the outside surface of the filter area of the filter sheath. The present invention uses direct spot welding and seam welding technology to fix the metal net to the outside of the support sheath directly, eliminates leakage hole phenomena appearing on jointing parts of the metal net and forms the screen with multi-layer metal nets with improved sand control capability and life time. The present invention also discloses the apparatus for above-said screen to realize penetrated welding of the filter sheath so as to improve the welding quality of the metal net and lower the factory cost of the screen.

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

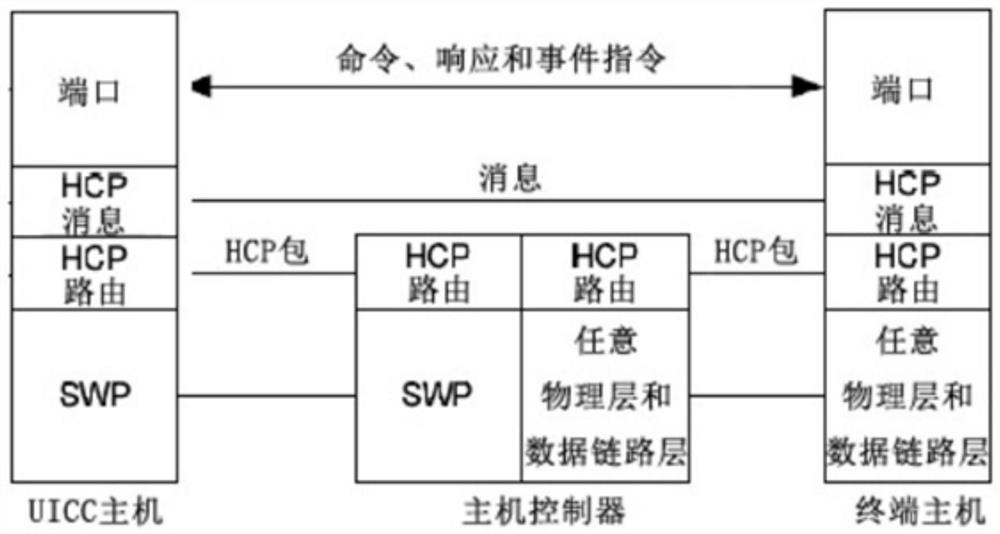

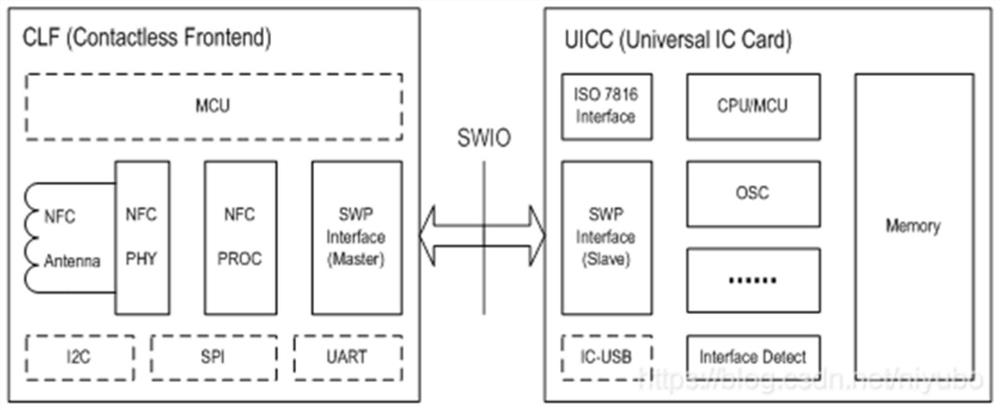

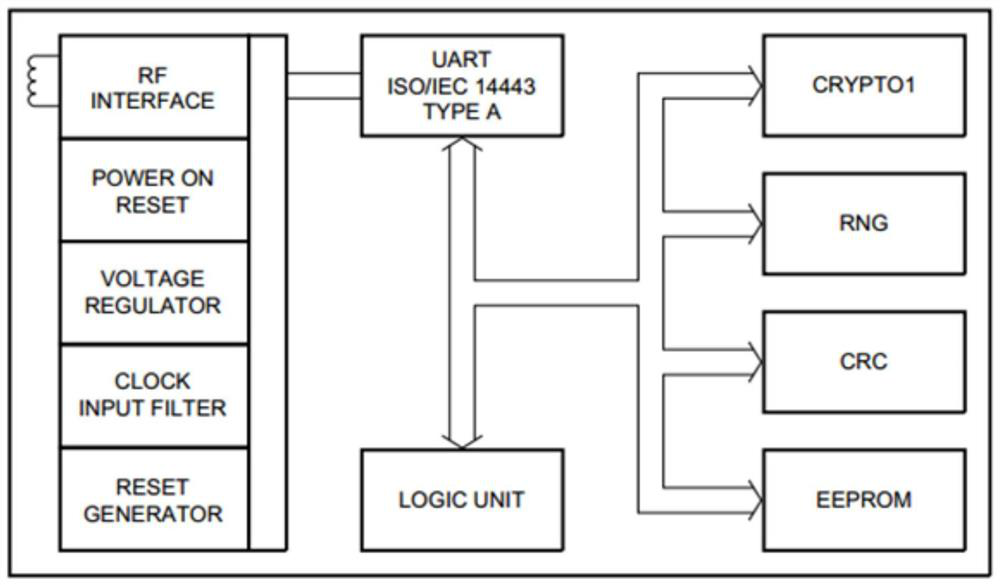

Implementation method for mifare card to simulate and use large-capacity Flash storage

ActiveCN114489493AFulfill storage needsFulfill storage requirementsInput/output to record carriersDigital data protectionInformation CardComputer engineering

The invention provides an implementation method for simulating and using large-capacity Flash storage by Mifare cards. The Mifare 1K card has 16 * 4 = 64 Blocks in total, and 64 * 16 = 1024B; the Mifare 1K card has the advantages that when the Mifare 1K card is in a proper state, one page of a target Flash Page is erased, so that new data can be conveniently written in next time, two 1K Flash spaces are used, data information is alternately written in by taking one Flash page as a unit, each Flash writing operation command of the Mifare 1K card is written in one Flash page in advance according to the 16B + 4B data volume, power failure is prevented, and the data cannot be lost. The method has the advantages that the storage requirement and the performance requirement of the Mifare card are met on the large-capacity Flash, an EEPROM (Electrically Erasable Programmable Read-Only Memory) or small-capacity and small-page Flash hardware does not need to be additionally arranged on the SIM card, and the factory cost of simulation application of the SIM card is greatly reduced.

Owner:广州万协通信息技术有限公司

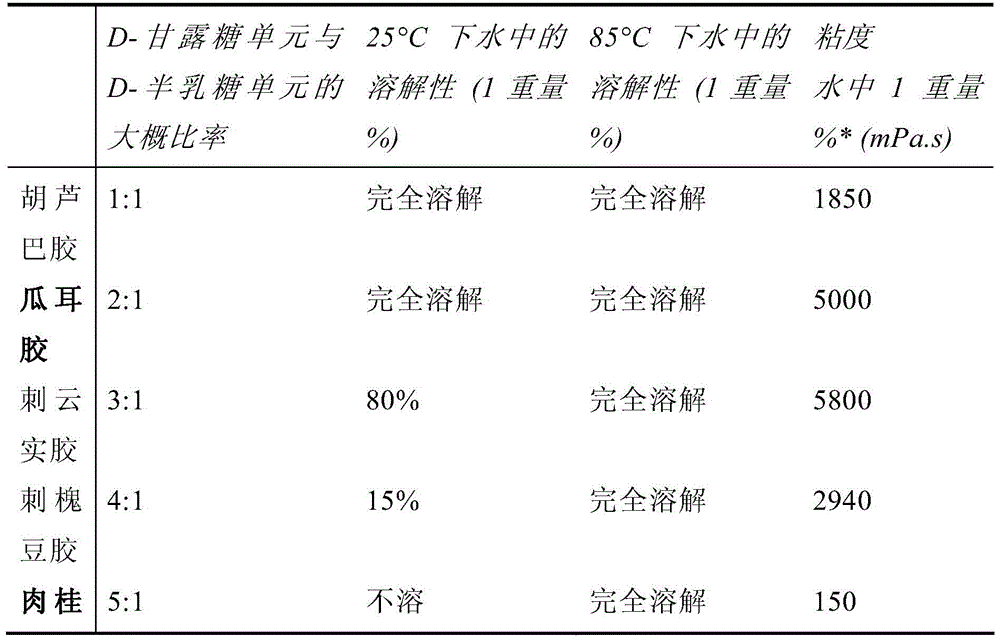

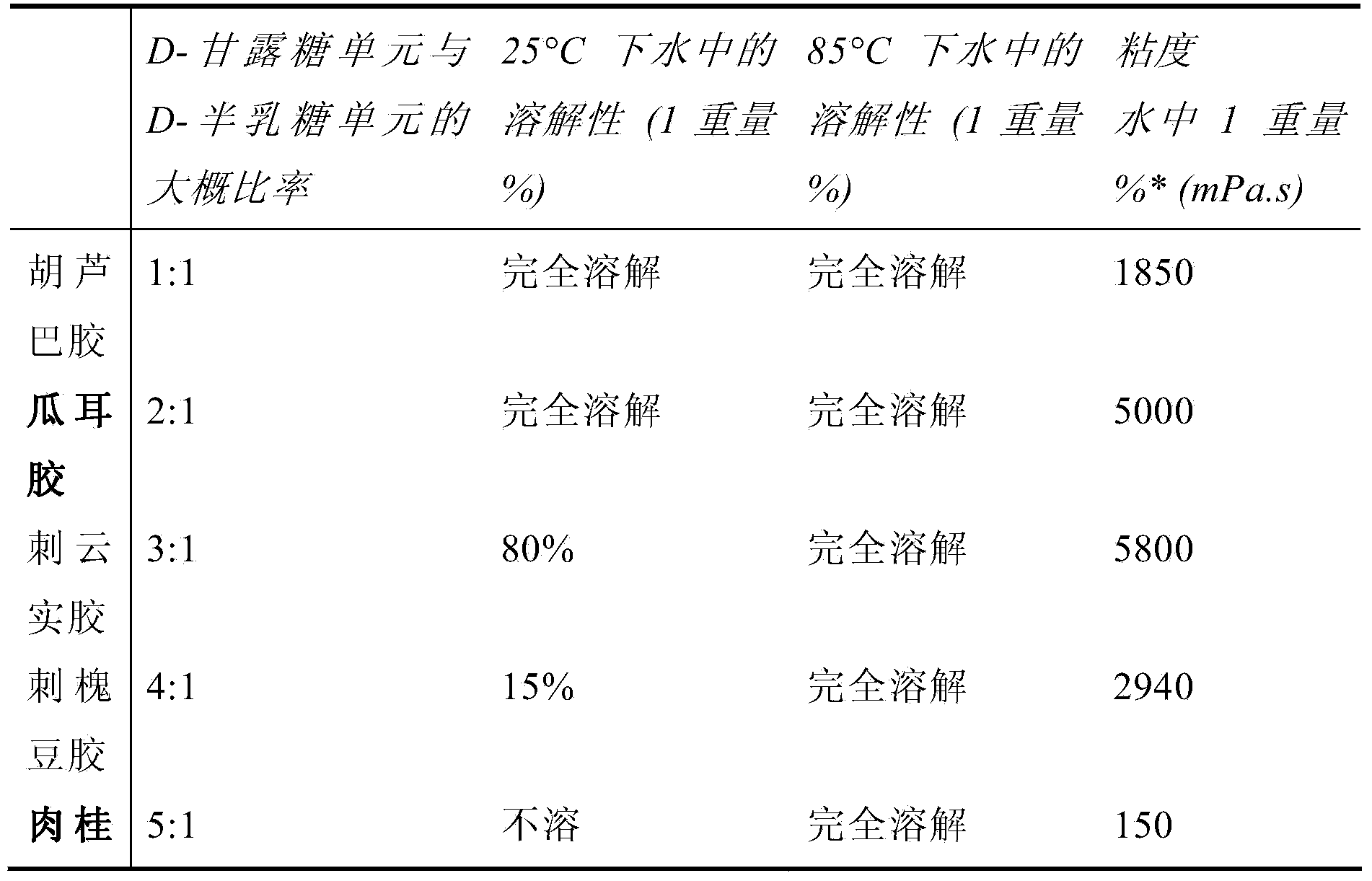

hydraulic binder composition

Dry composition comprising a hydraulic binder, such as cement or gypsum, and a highly substituted C2-C4 hydroxyalkylgalactose having an average ratio of D-mannose to D-galactose units different from 2:1 Mannan, the dry composition provides a paste with good water retention properties and processability.

Owner:LAMBERTI SPA

Injection molding encapsulation die structure

Owner:SUZHOU BENTENG PLASTIC

Hydraulic binder composition

Dry compositions comprising a hydraulic binder, such as cement or gypsum, and a highly substituted C2-C4 hydroxyalkyl galactomannan with average D-mannosyl to D-galactosyl unit ratio different from 2:1 provide pastes having good water retention characteristics and workability.

Owner:LAMBERTI SPA

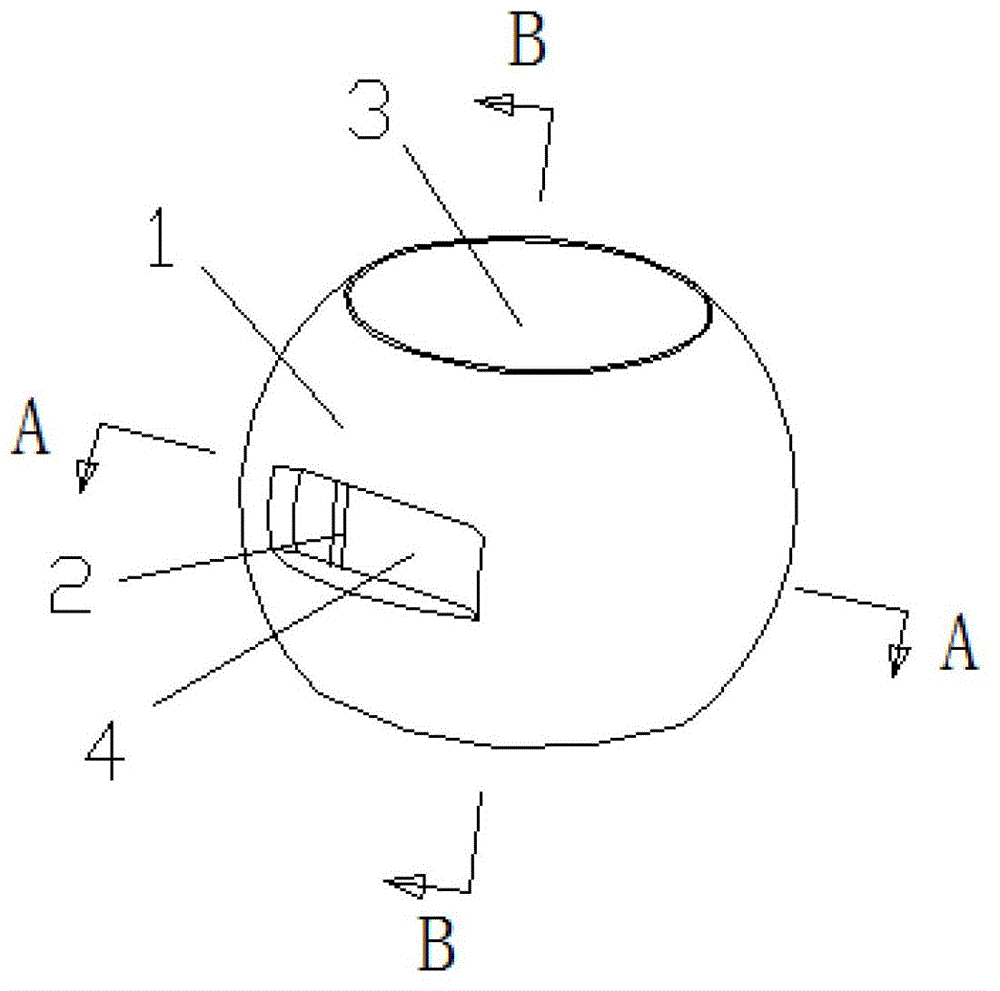

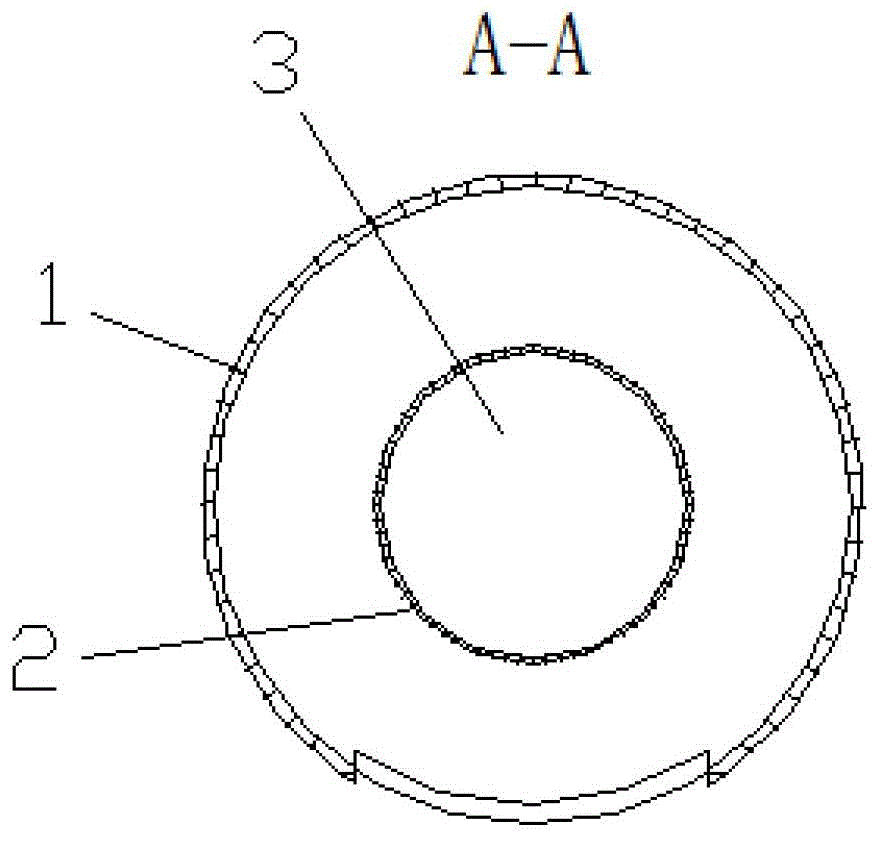

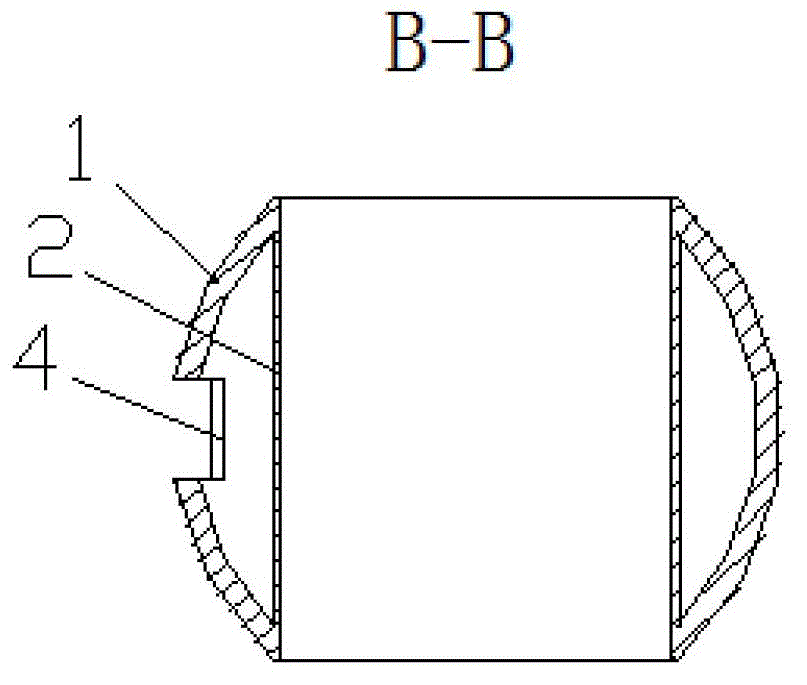

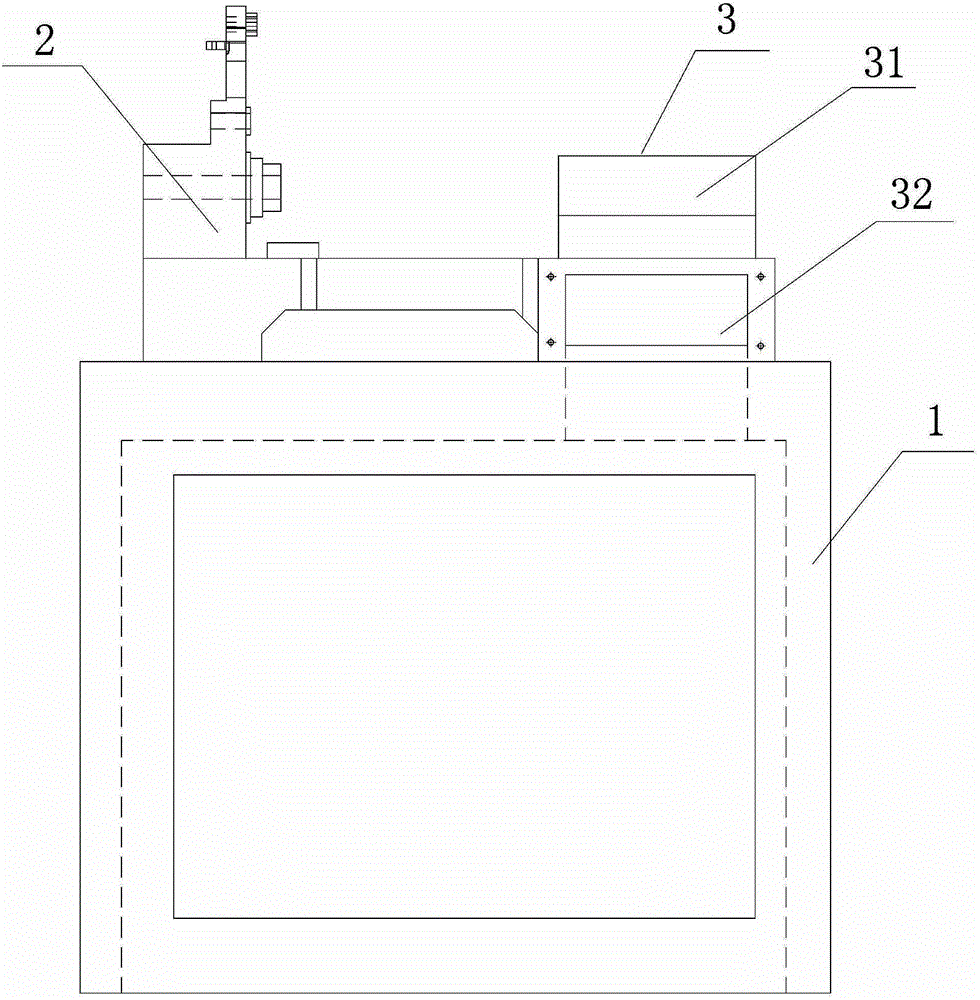

Ball valve spool and production method thereof

The invention provides a ball valve core and belongs to the valve technical field. The ball valve core solves the technical problems that the ball valve core is poor in sealing performance, short in service life and high in factory cost in the existing market. The ball valve comprises a hollow outer ball body and an inner straight pipe, wherein a through hole is formed in the interior of outer ball body, cross sections of the upper end and the lower end of the through hole are mutually parallel and equal circles, a notch which penetrates through inside and outside the outer ball body is formed in the outer ball body, and the inner straight pipe is embedded in the through hole of the outer ball body and joint part of the inner straight pipe and the through hole of the outer ball body is tightly abutted. A production method of the ball valve core comprises the following steps: prefabricating the outer ball body and the inner straight pipe; assembling the outer ball body and the inner straight pipe; chipping off the end portion, exposed to the outer ball body, of the inner straight pipe; opening the notch in a big circle of the outer ball body; and conducting polishing treatment on an assembled blank. The ball valve core and the production method of the ball valve are good in sealing performance and long in service life, and lower factory cost of products.

Owner:杨建国

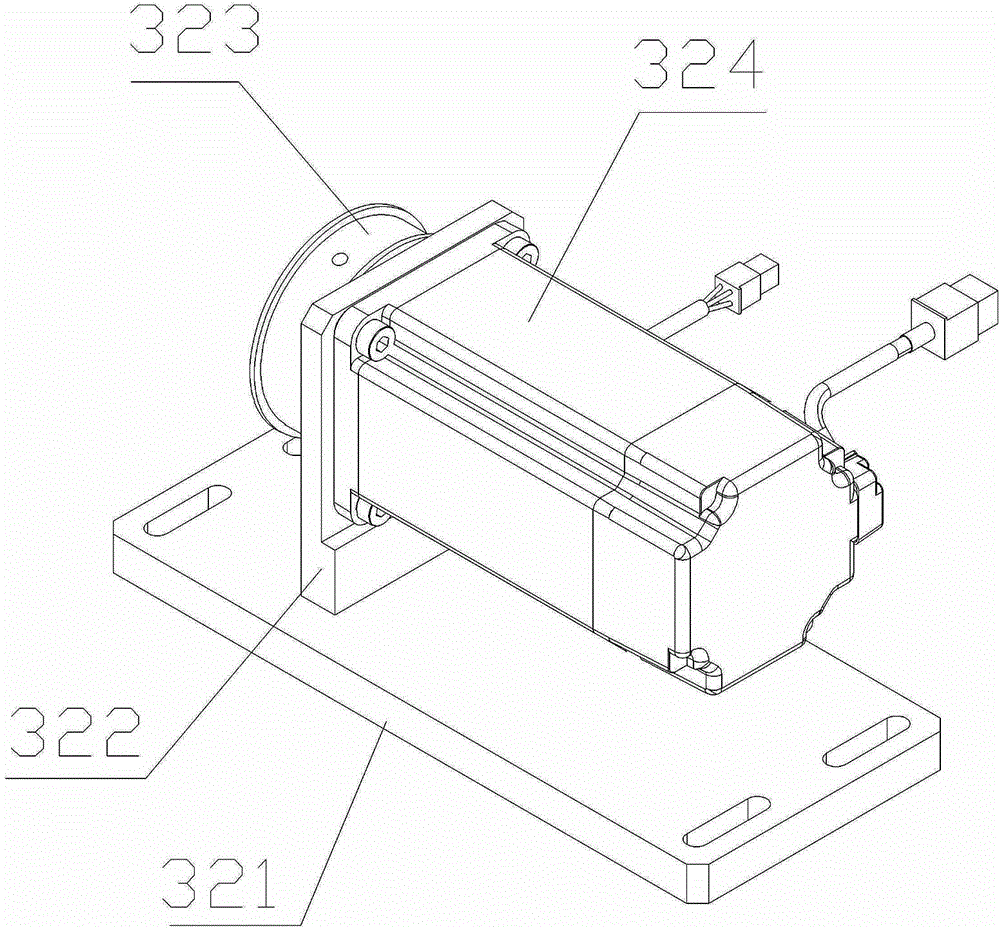

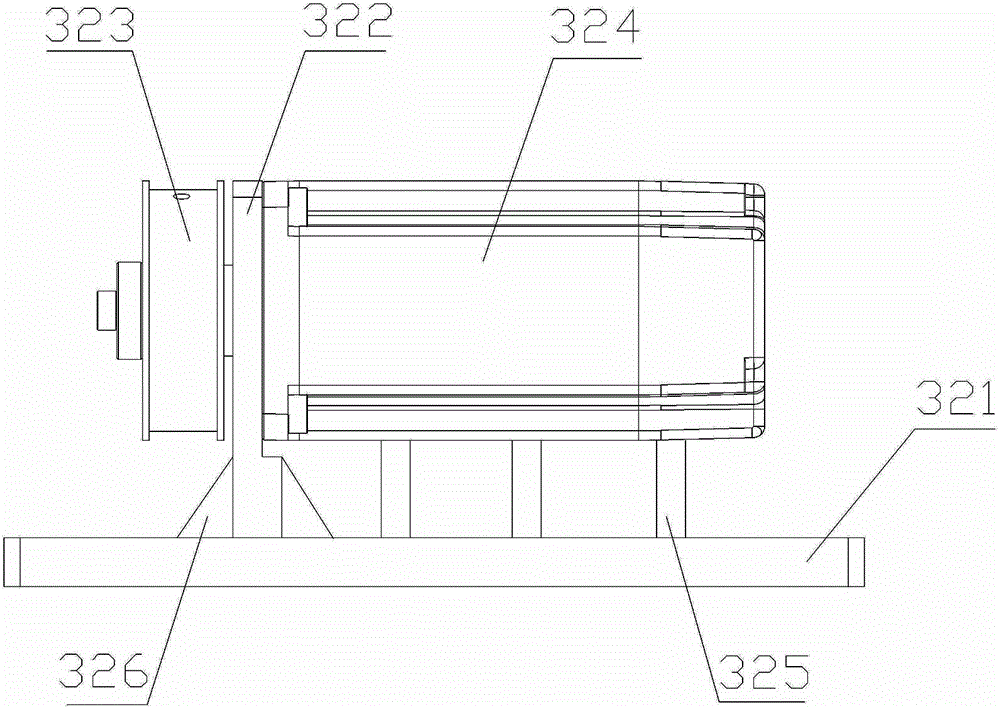

Cam machine with tailstock tapping controlled by servo motor

InactiveCN104439563AConvenient tapping operationStability Dynamics Control SectionThread cutting auxillary apparatusCamControl theory

The invention relates to a cam machine with tailstock tapping controlled by a servo motor. The cam machine comprises a cam machine body, wherein a main shaft unit and a tailstock unit are arranged on the cam machine body; the tailstock unit comprises a tailstock tapping mechanism and a servo motor unit for controlling the tailstock tapping mechanism. After the structure is adopted, a brake clutch and a start clutch are replaced with the servo motor, and the servo motor is controlled by an electric signal, so that the tailstock tapping operation can be conveniently controlled, and the cam machine is high in tapping stability, and stable in power control part, the maintenance cost is reduced and the service life is prolonged; moreover, the production efficiency of the product is improved, and the ex-factory cost of the product is reduced.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

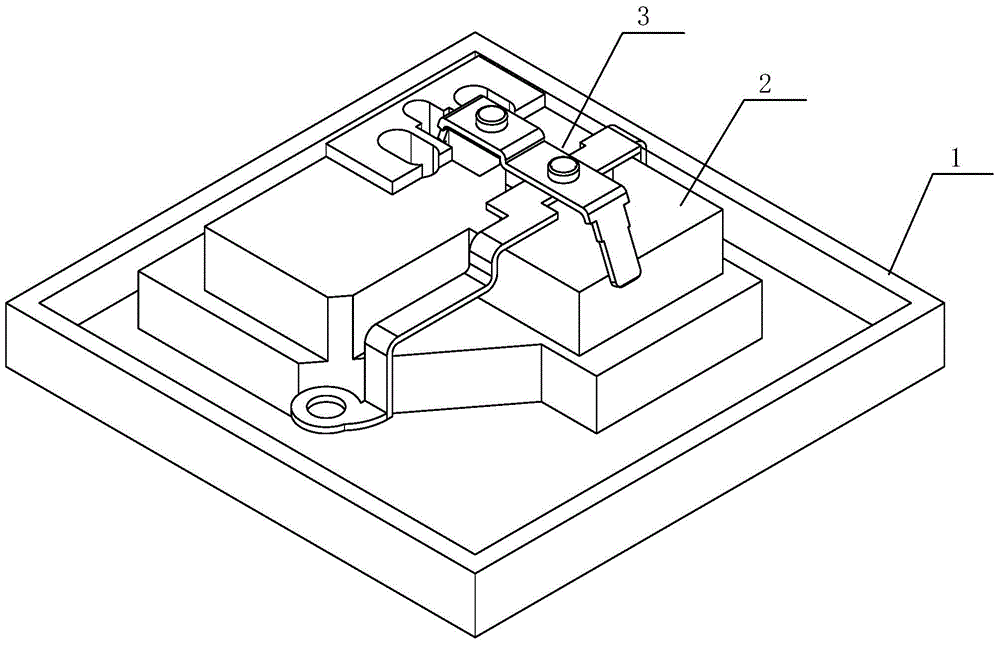

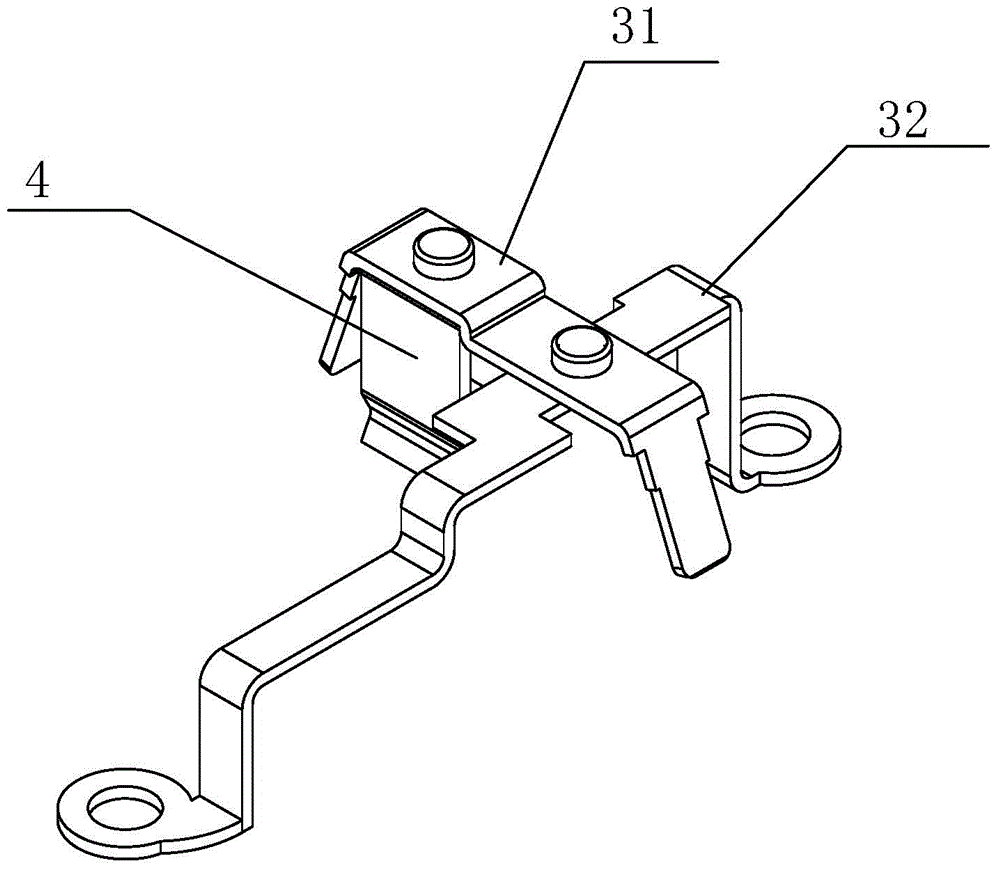

Rivet-free riveting technology for socket conducting plates and socket structure thereof

InactiveCN104009300AOne-time forming of riveting technology can reduce the process reduction of rivet rivetingReduce processCoupling contact membersRiveted connectionsEngineeringMachining time

The invention relates to a rivet-free riveting technology for socket conducting plates and a socket structure. Firstly, the split-type conducting plates are formed through machining, then, the split-type conducting plates are combined through the rivet-free riveting technology, and meanwhile insertion springs are combined with the conducting plates through the rivet-free riveting technology. The socket structure comprises an outer shell. A support is arranged inside the outer shell. A live wire interface, a naught wire interface and a ground wire interface are arranged inside the support. One conducting plate is arranged at the position of the ground wire interface, wherein the conducting plate comprises at least one first conducting plate body and at least one second conducting plate body, the first conducting plate bodies and the second conducting plate bodies are fixedly formed through the rivet-free riveting technology in a one-time stamping mode, and the first conducting plate bodies and the insertion springs are fixedly formed through the rivet-free riveting technology in a one-time stamping mode. The split-type conducting plates are formed at a time through the rivet-free riveting technology, so that the rivet riveting technology is omitted, the machining time is saved, manpower is saved, the machining efficiency is improved, and the product delivery cost is reduced.

Owner:昆山松田工业自动化设备厂 +1

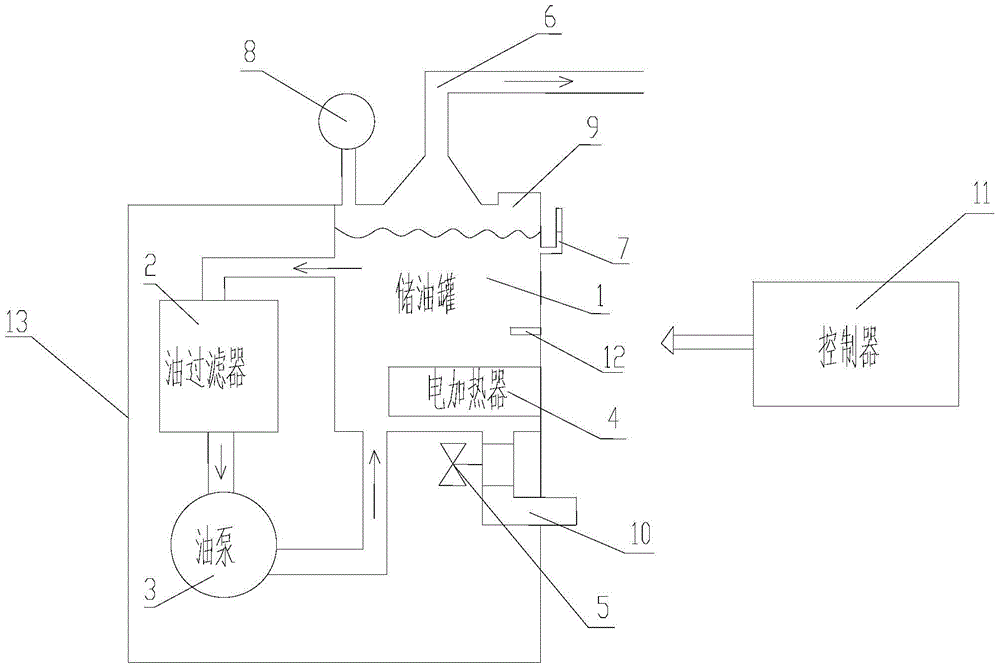

Refrigerated oil recovery device and method

ActiveCN104791222BReduce usageGuaranteed purityPositive displacement pump componentsPositive-displacement liquid enginesVacuum pumpingRecovery method

Owner:GREE ELECTRIC APPLIANCES INC

A production method of an emergency pull-off valve

ActiveCN107842637BHigh strengthImprove impact resistanceEqualizing valvesSafety valvesEngineeringUltimate tensile strength

The invention relates to the technical field of valve production and particularly relates to a production method of an emergent cut-off valve. The production method comprises the following steps: using a stainless steel plate as a raw material, carrying out stamping forming on the raw material to form a main valve body of the cut-off valve, carrying out forging machining to obtain a flange disc, and then welding the main valve body and the flange disc to obtain the valve body. The method is simple, practical and reliable. The strength and impact resistance of the produced cut-off valve are improved, the quality is substantially improved, the service life is long, a great effect is shown in actual production application, the procedures are simple, the operation is safe, the labor intensityof operators is reduced, and the production efficiency and benefit are greatly increased.

Owner:HUAIHAI INST OF TECH +1

Method and apparatus for producing non-uniform coatings on substrates

Roll coaters may be modified by adding one or more needles that provide coating liquid to the roll coater at discrete locations across the surface of the coating roll. The needles provide strips of partial coating material from an upstream coating pool onto the uniform coating already present on the surface of the applicator roll, forming a striped pattern on the uniform coating. By changing the relative speed of the applicator rolls, the width of the strip can also be adjusted.

Owner:3M INNOVATIVE PROPERTIES CO

A mosaic combination die structure

ActiveCN102814386BGuaranteed roughness requirementsExtended service lifeStress concentrationWire cutting

The invention relates to an inlay type combined die structure comprising a die sleeve, wherein a back pad is arranged in the die sleeve; a die body is arrange on the back pad in the die sleeve; a forming groove is arranged on the die body; an inlaid piece slot is arranged in the forming groove; an inlaid piece is arranged in the inlaid piece slot; the upper forming surface of the forming groove is shaped like an arc; the inlaid piece is of a + shape or a linear shape or a +- shape; the inlaid piece slot is a through hole on the die body; the die body is made from a material with good toughness; and the inlaid piece is made from an abrasion-proof material. By adopting the structure, the inlay type is adopted to replace an integral type, so that stress concentration is avoided and the phenomenon that root is easy to break off does not happen; the mold is processed by adopting wire cutting, so that the processing is easy, the polishing can be carried out, the roughness requirement of the mold can be guaranteed, the service life of the mold is prolonged and the factory cost of products is reduced.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

Doubleduty water saving closestool of using water flush and plugback of bubble foam, and relevant sets

InactiveCN101003982BBeautiful blockingEconomic blockadeWater closetsFlushing devicesWater savingDual purpose

The present invention relates to a water-flushing foam-blocking dual-purpose water-saving toilet and its related device. It is characterized by that the appearance of traditional toilet is changed, the upper and lower bent portions of traditional toilet are removed; a foaming system position is added and mounted. It foaming device has two types of barrel type and tube type, so that the water tankstructure of improved toilet has two functions of storing water and flushing toilet.

Owner:淄博市开远节水环保设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com