Binding steel bar connecting assembly and connecting method applied to PC component assembly

A technology of connecting components and binding strips, which is applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of discontinuous threads on the surface of butt joint steel bars and high fault tolerance rate, so as to avoid joint deformation hazards, high fault tolerance rate, and reduce The effect of factory cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

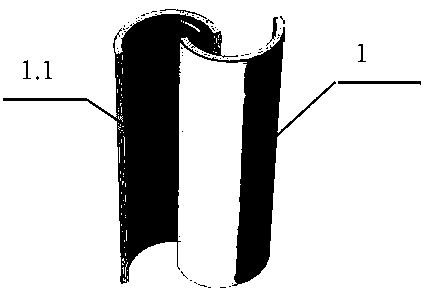

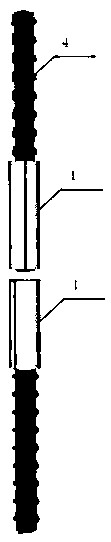

[0040] The present invention is a tie bar type steel bar connection assembly, such as Figure 6 , Figure 7 As shown, it is mainly composed of a combined inner sleeve core 1, a combined middle sleeve 2 and an outer hoop 3 layers tightly enclosed at the ends of two butt steel bars 4. The above three connecting components can all be metal material. Such as figure 1 , figure 2 As shown, the combined inner layer core 1 is composed of two pairs of semicircular tubes ≦1 / 2 round respectively fastened to the ends of two butt steel bars 4, and the inner side of the semicircular tubes is inclined to the outer surface of the butt steel bars 4. Groove 1.1 in which the rib of the transverse thread coincides. Such as image 3 , Figure 4 As shown, the combined middle casing 2 is surrounded by arc-shaped slats that are divided into three to four equal parts in the radial direction of the circumference, and the inner diameter is equal at all places. Variable cross-section combined pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com