Split structure of probe and switch box

A switch box, split technology, applied in the structural field of probes and switch boxes, can solve problems such as waste, leakage, and cost increase, and achieve the effect of saving resources, increasing benefits, and reducing factory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

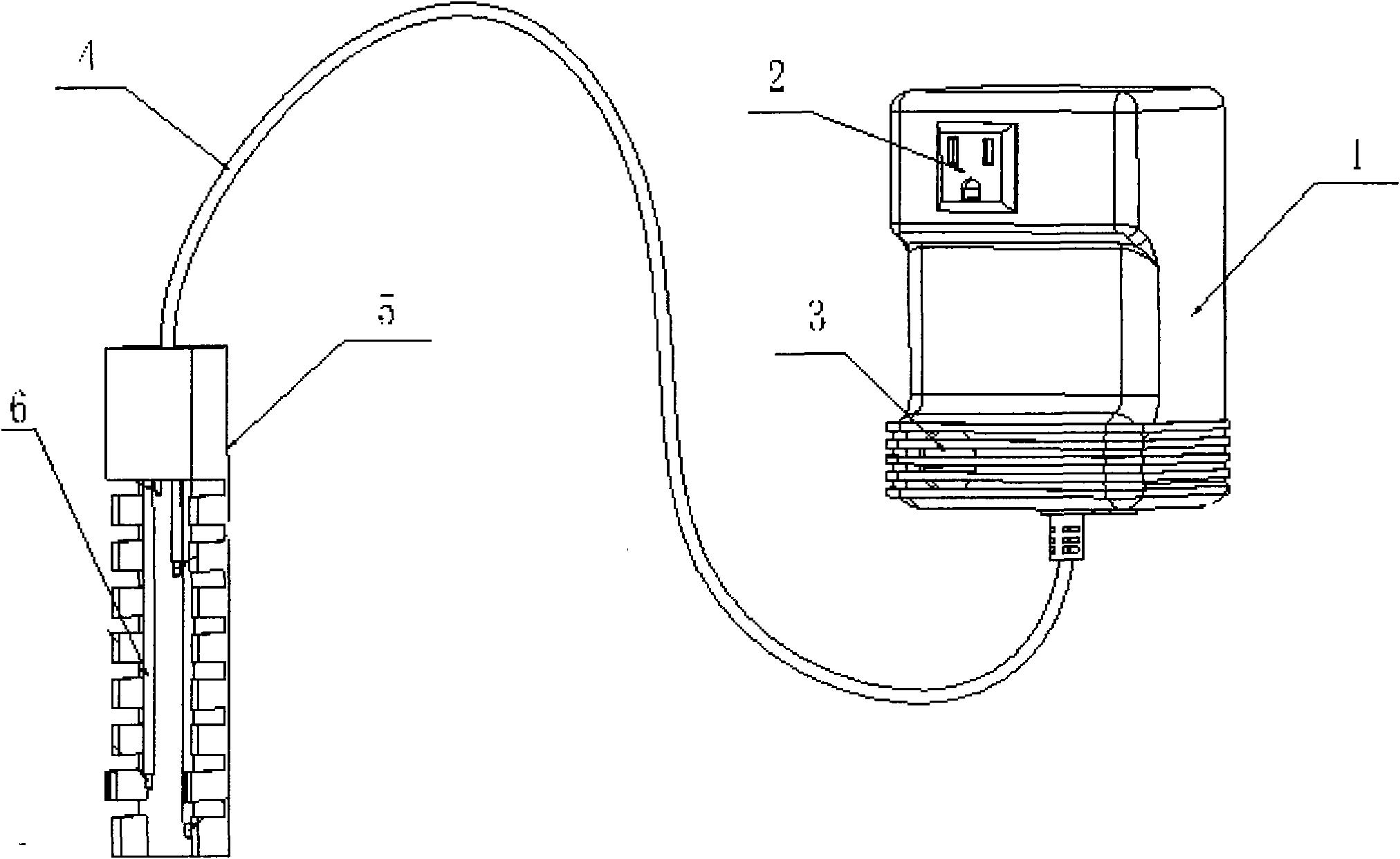

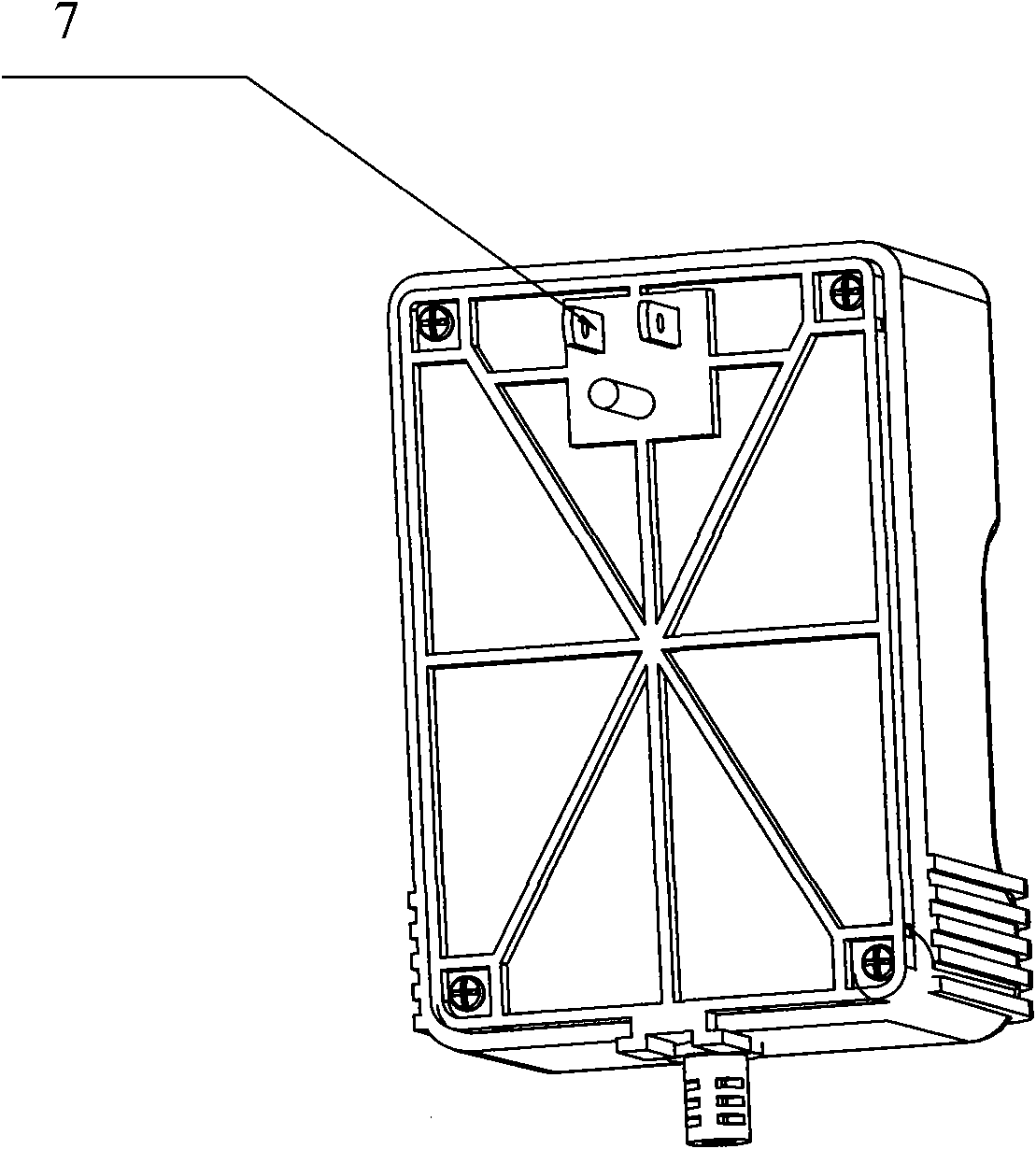

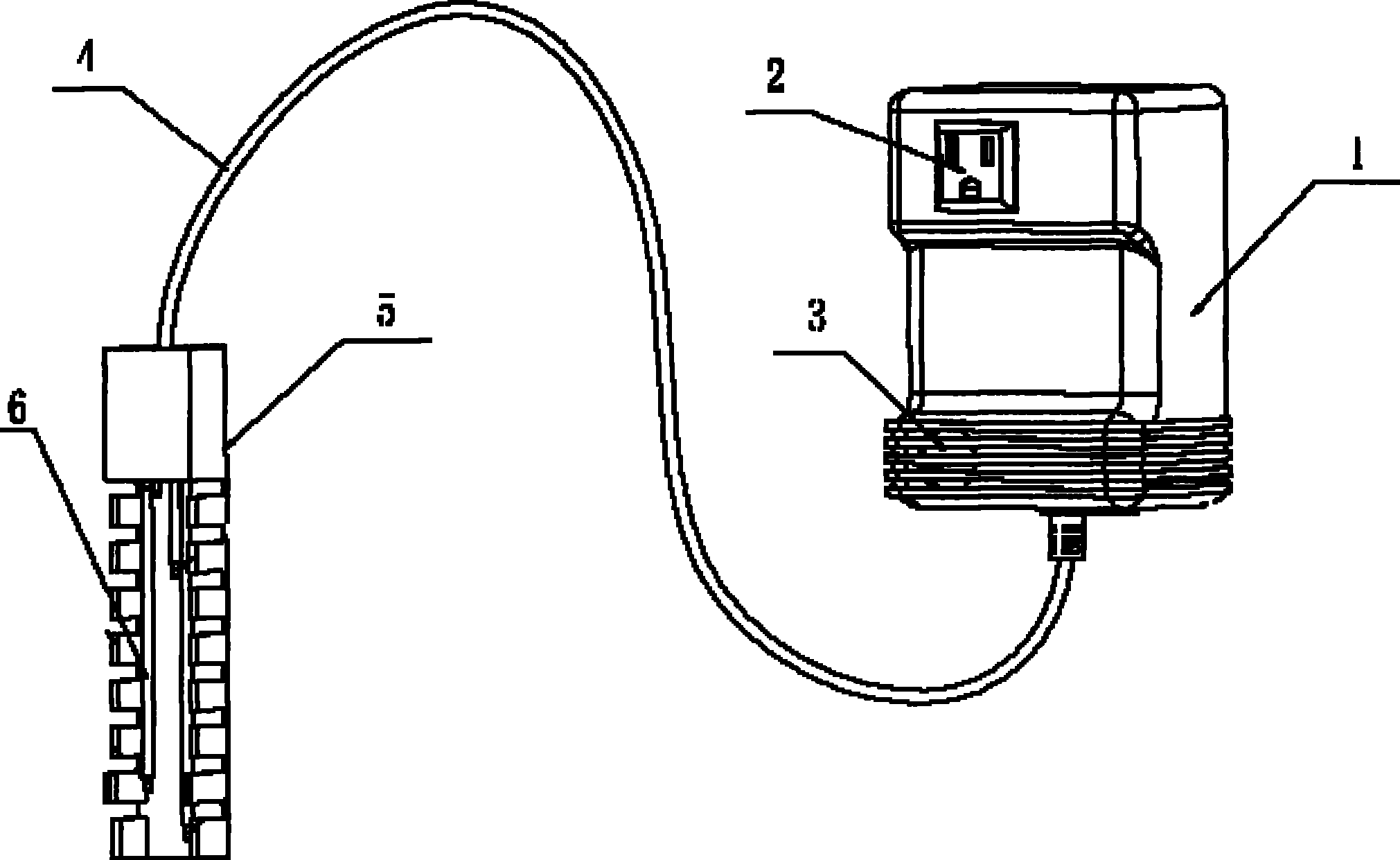

[0014] Such as figure 1 and figure 2 A split structure of a probe and a switch box is shown, including a probe 6 and a switch box 1, the switch box 1 and the probe 6 are connected by wires 4; the front of the switch box 1 is provided with a three-hole socket 2 , a three-pin plug 7 is provided on the back; a buzzer 3 is provided on the switch box 1; the probe 6 is arranged in the probe box 5.

[0015] The probe 6 is designed separately from the switch box 1, which reduces safety accidents and the production cost of the manufacturer. The probe box 5 is placed on the water surface to be measured, and the switch box 1 is plugged into the power supply through the three-pin plug 7 on the back, and the water pump The plug of the power cord is inserted on the three-hole socket 2 on the front of the switch box 1, which facilitates the insertion of the water pump on the switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com