Patents

Literature

60results about How to "Leakage will not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

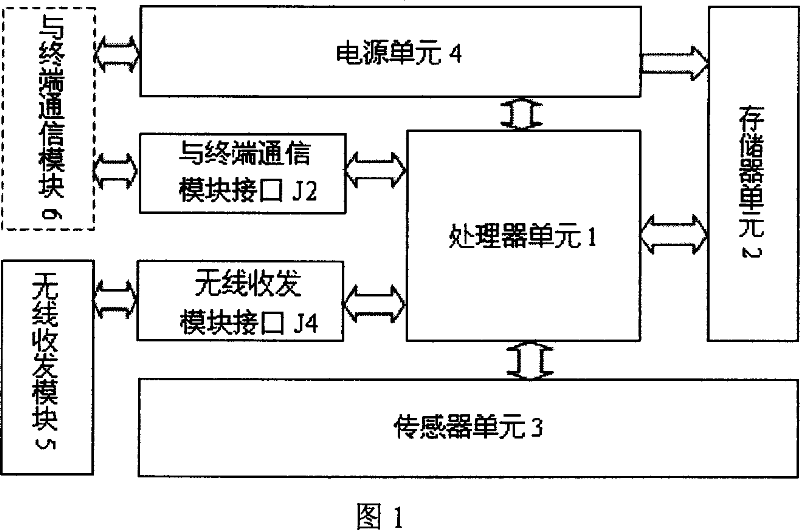

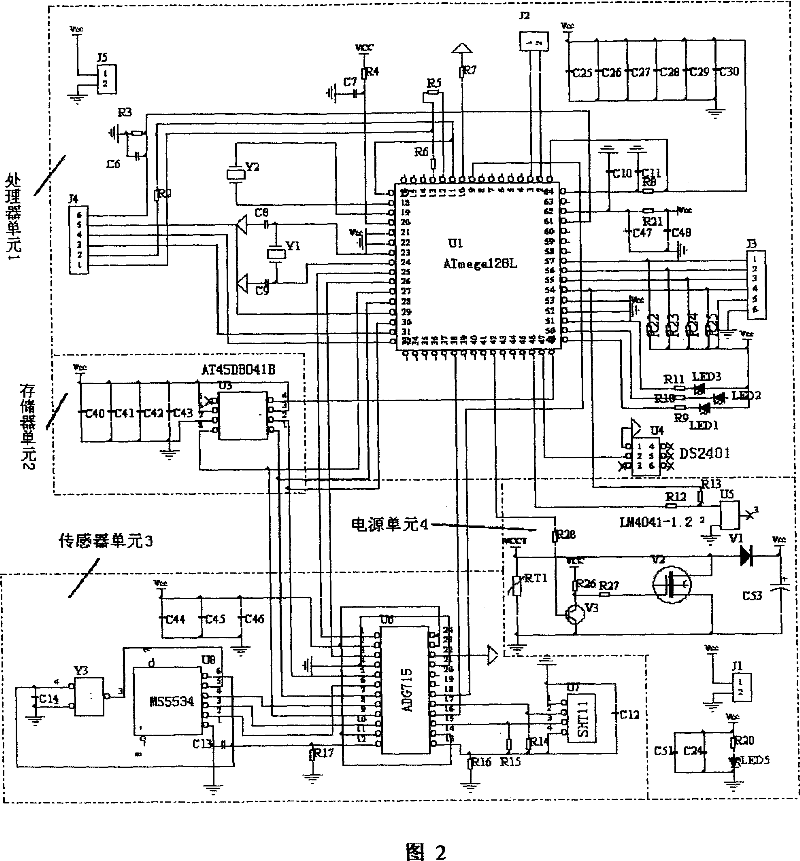

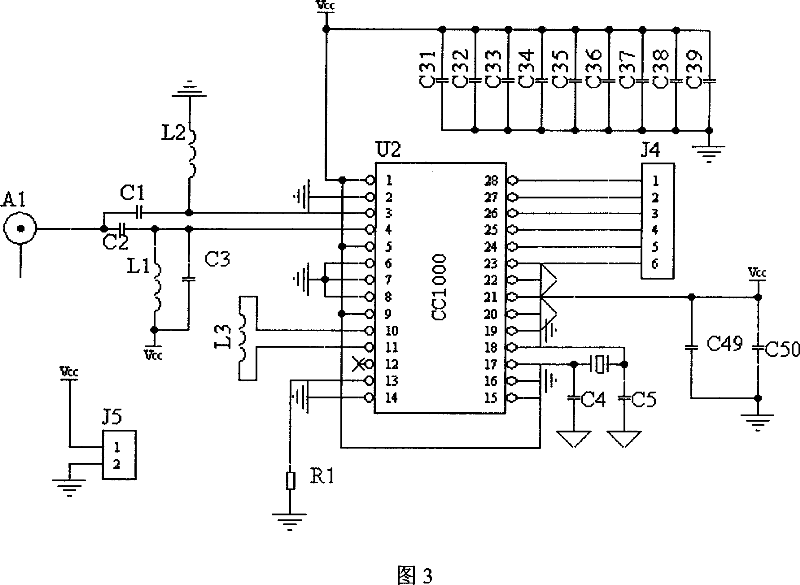

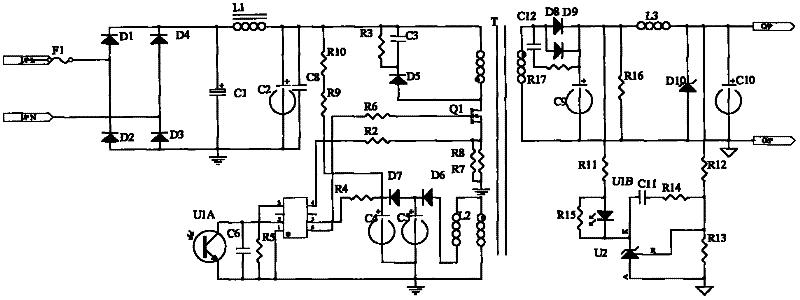

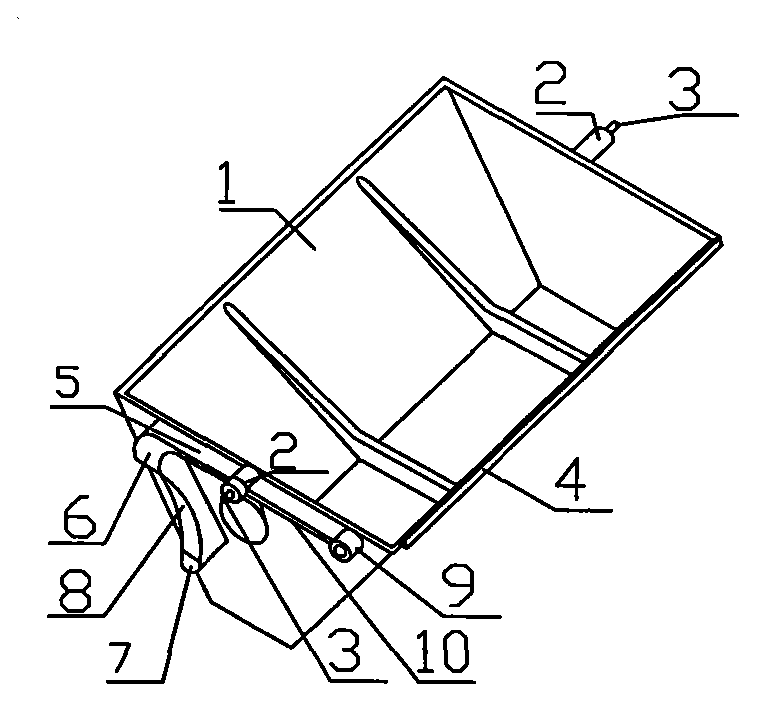

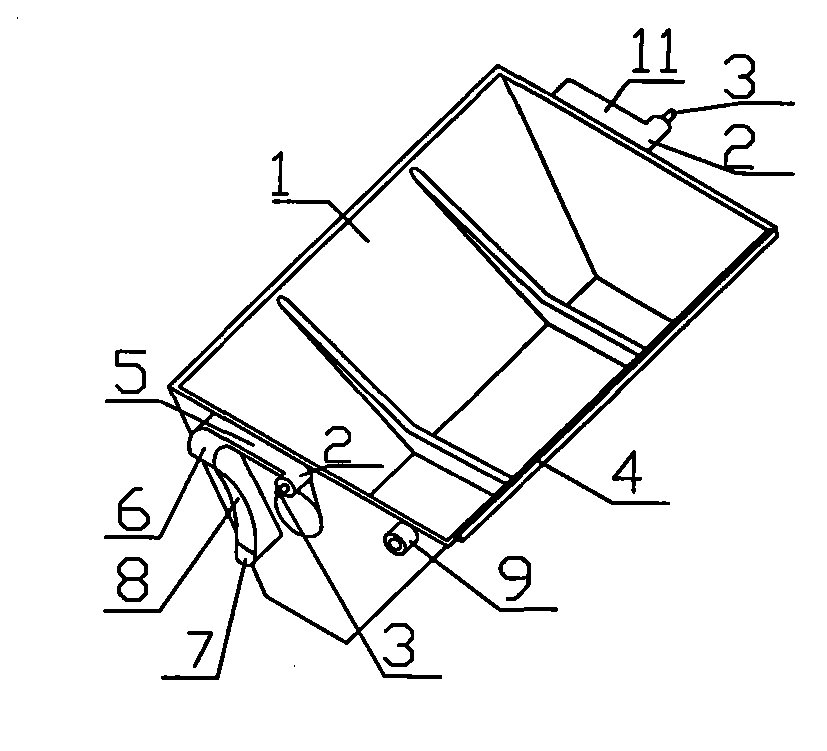

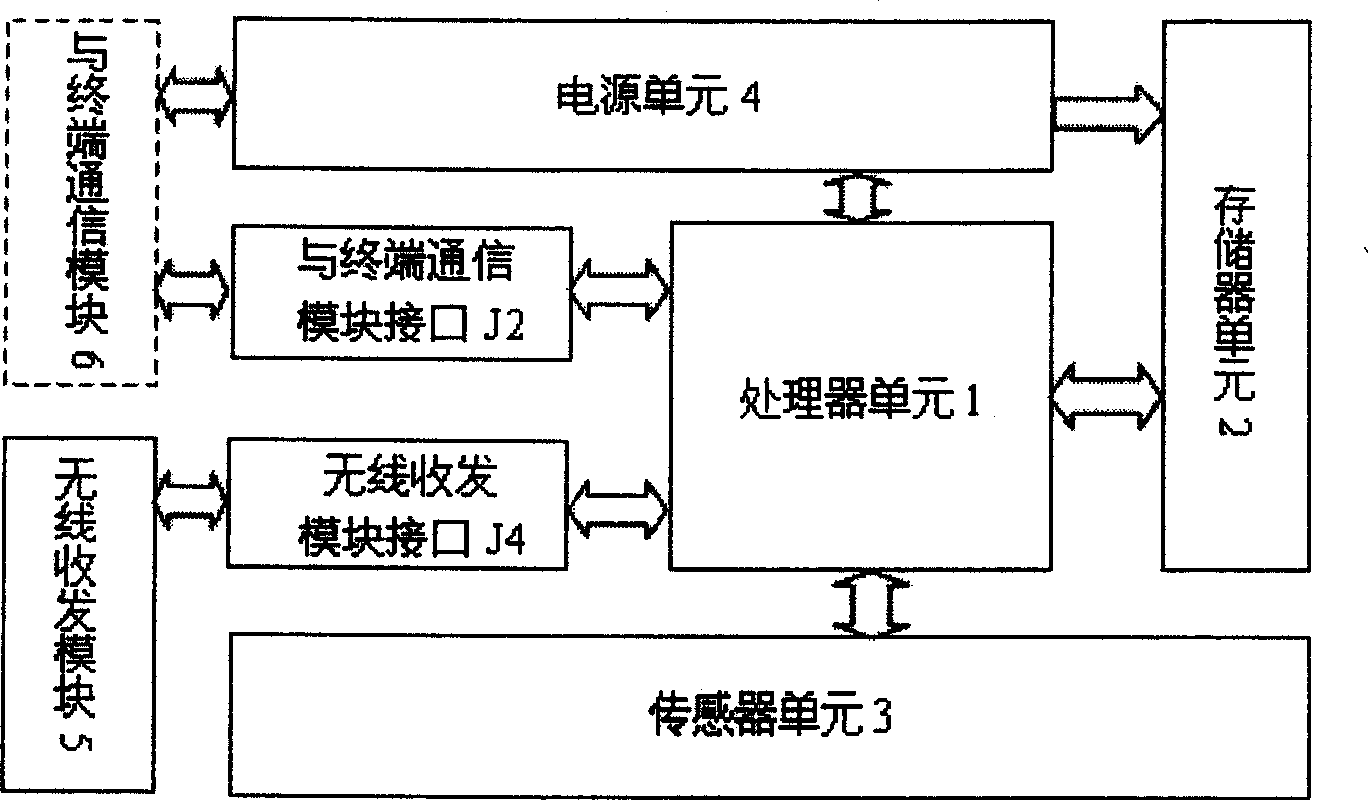

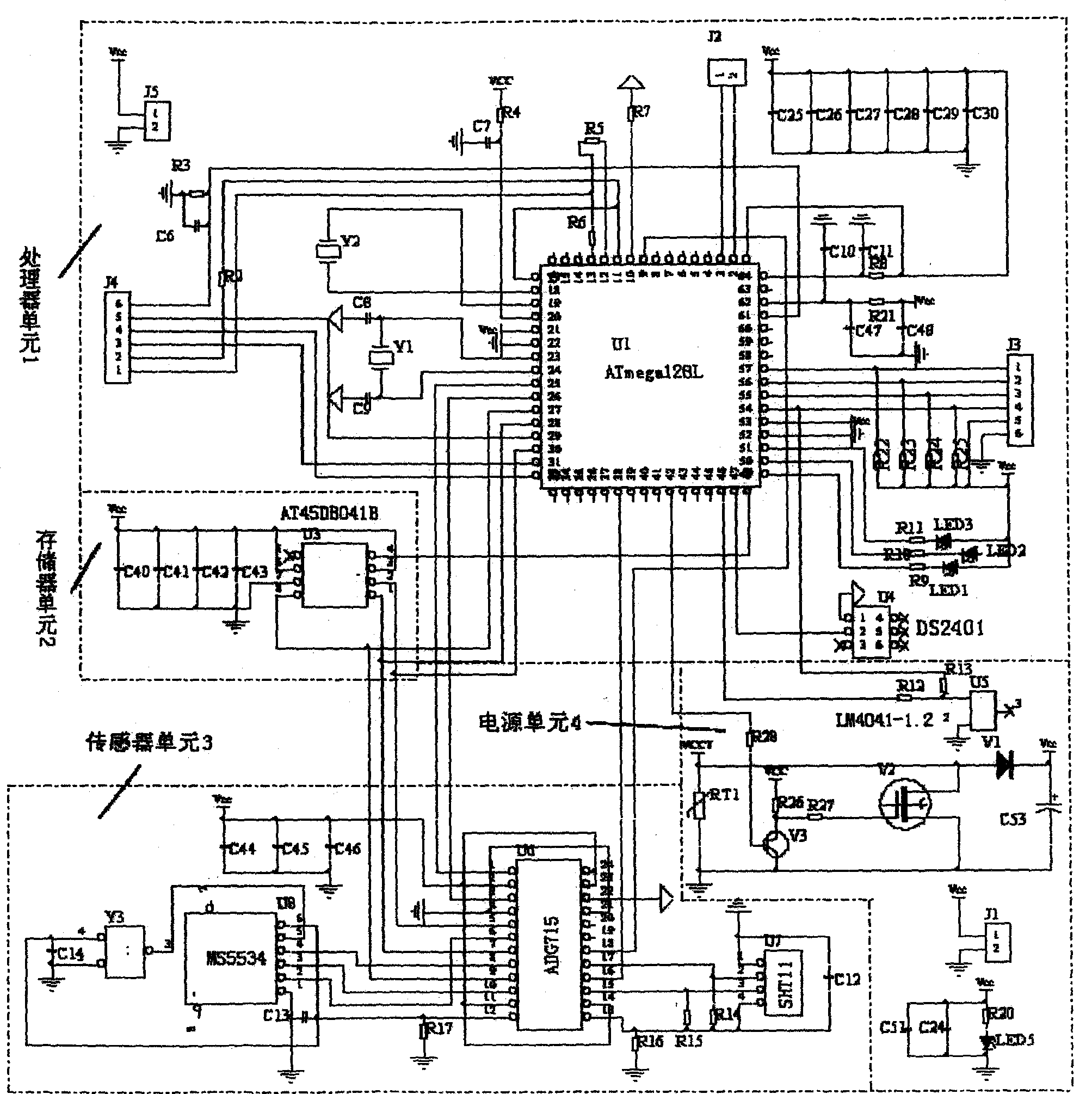

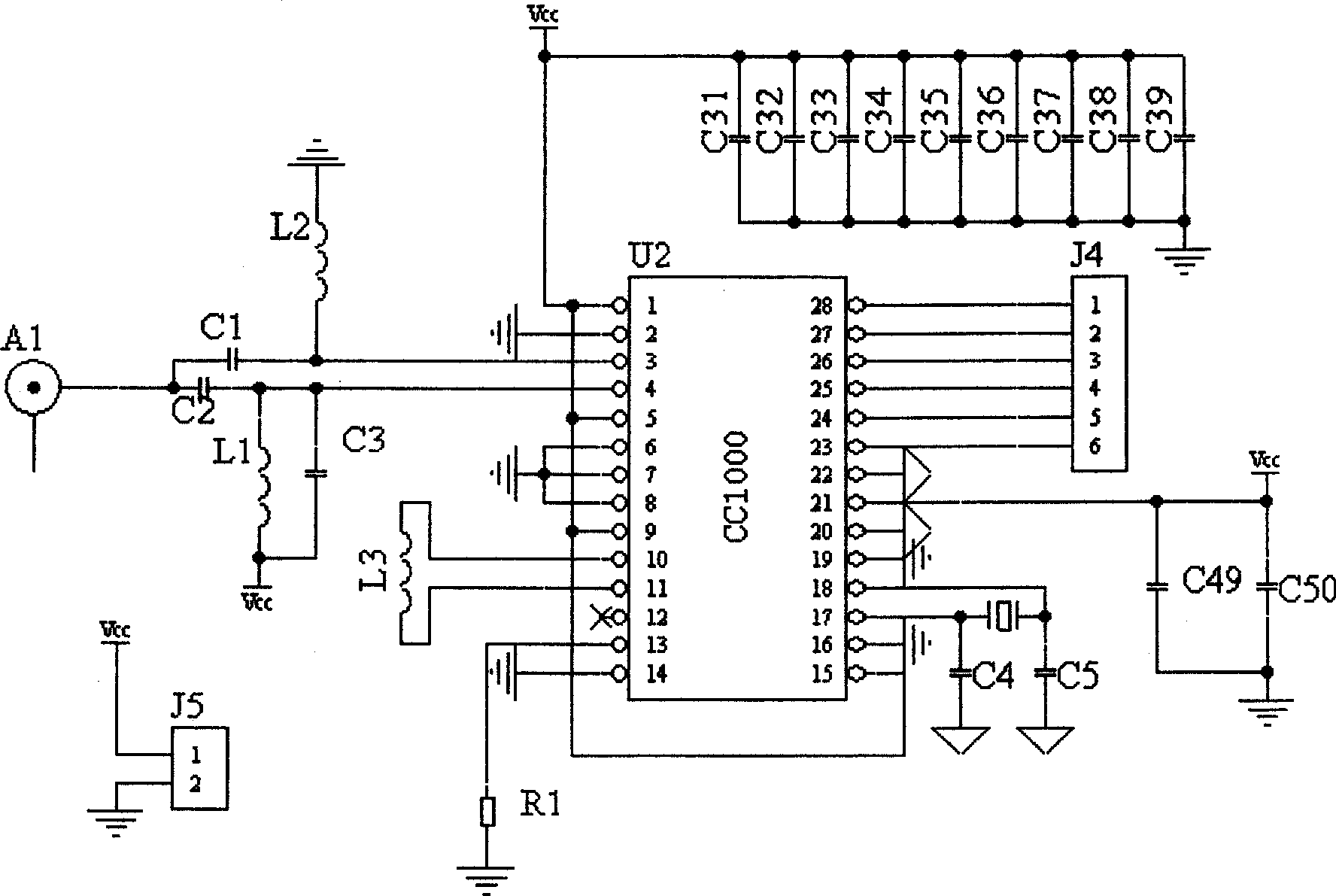

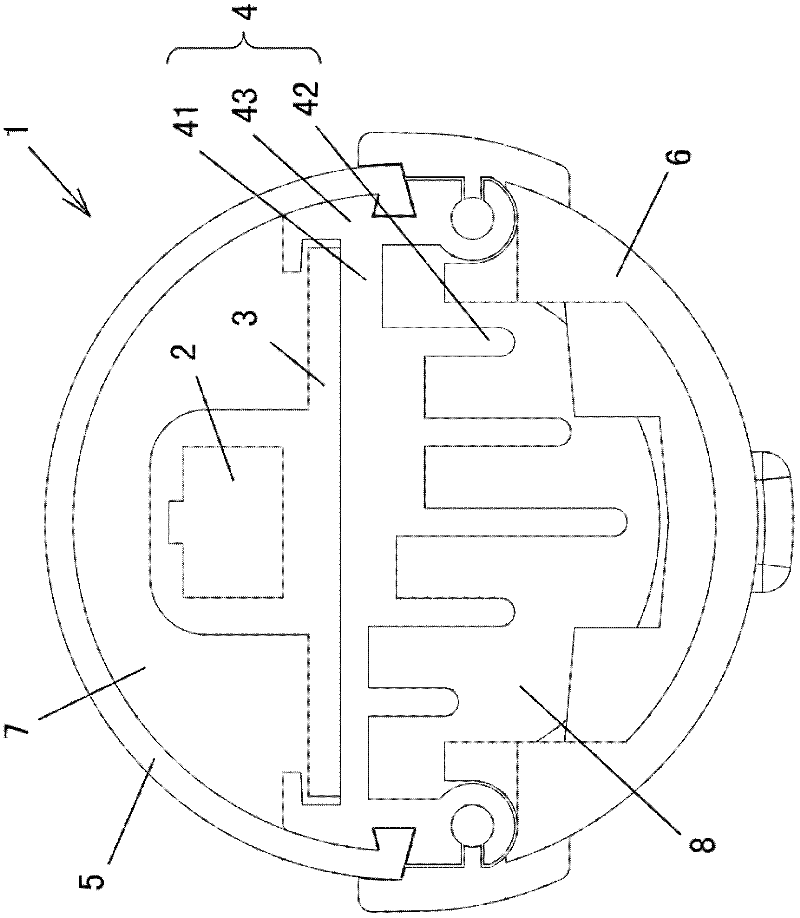

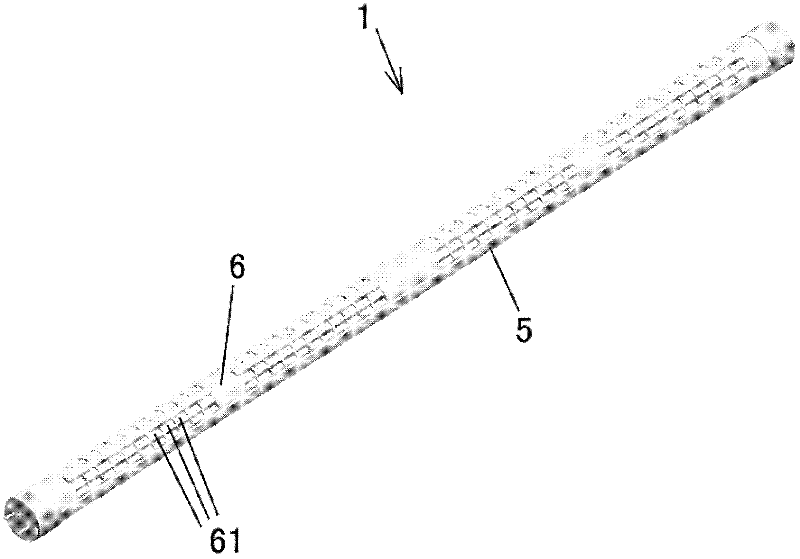

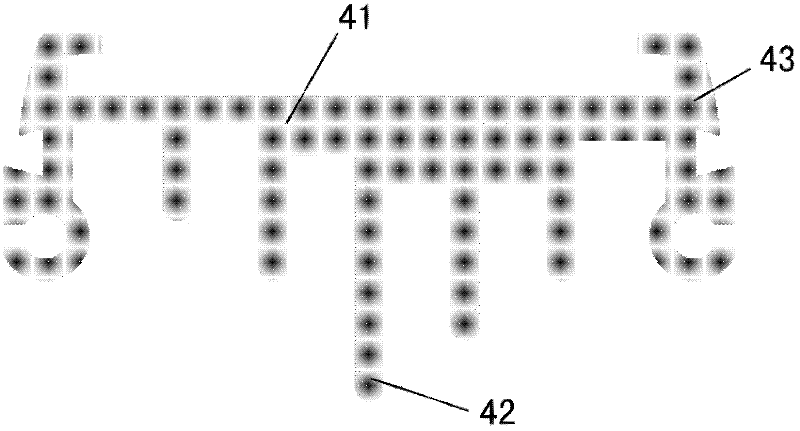

Wireless sensor network node device used for environmental monitoring

InactiveCN101042584AReasonable structureReduce power consumptionTotal factory controlProgramme total factory controlWorking environmentFunctional module

This invention relates to one wireless sensor network point device for animal and plant grow and cultivation indoor chamber, nuclear pollution area, atmosphere and industry spot environment monitor for environment temperature and humidity and atmosphere monitor; in the network, the point work environment is of complex one and independent unit with proper structure and special energy consumption, reliability and life cycle.

Owner:SOUTHEAST UNIV

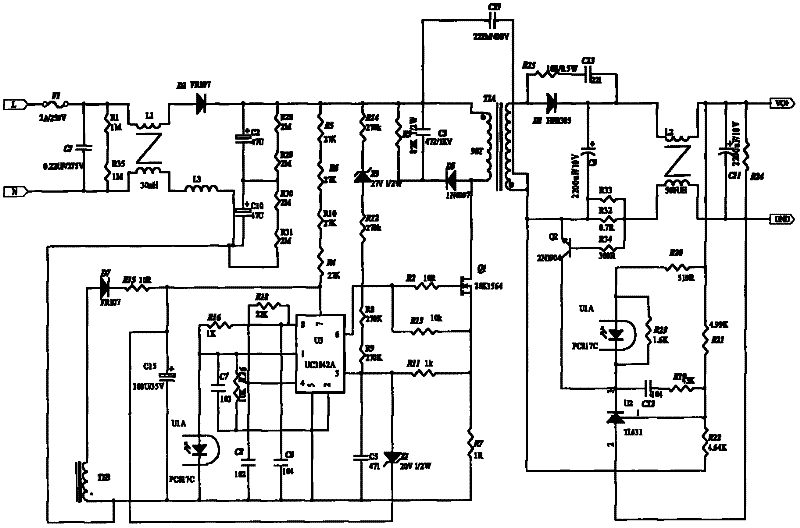

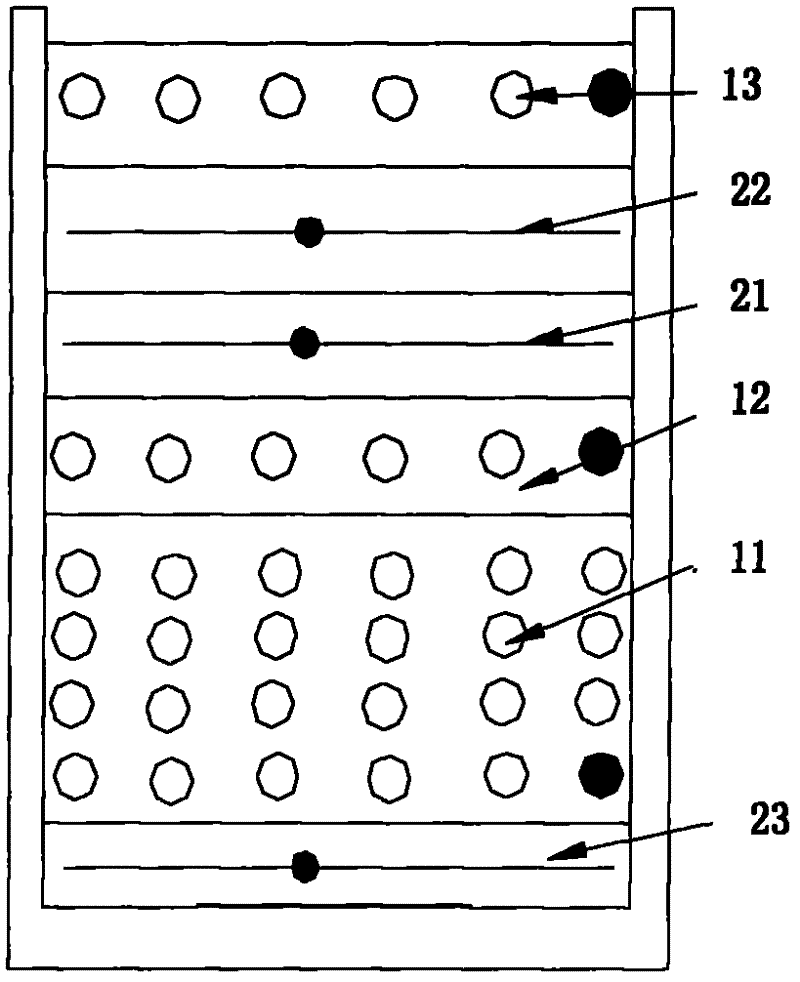

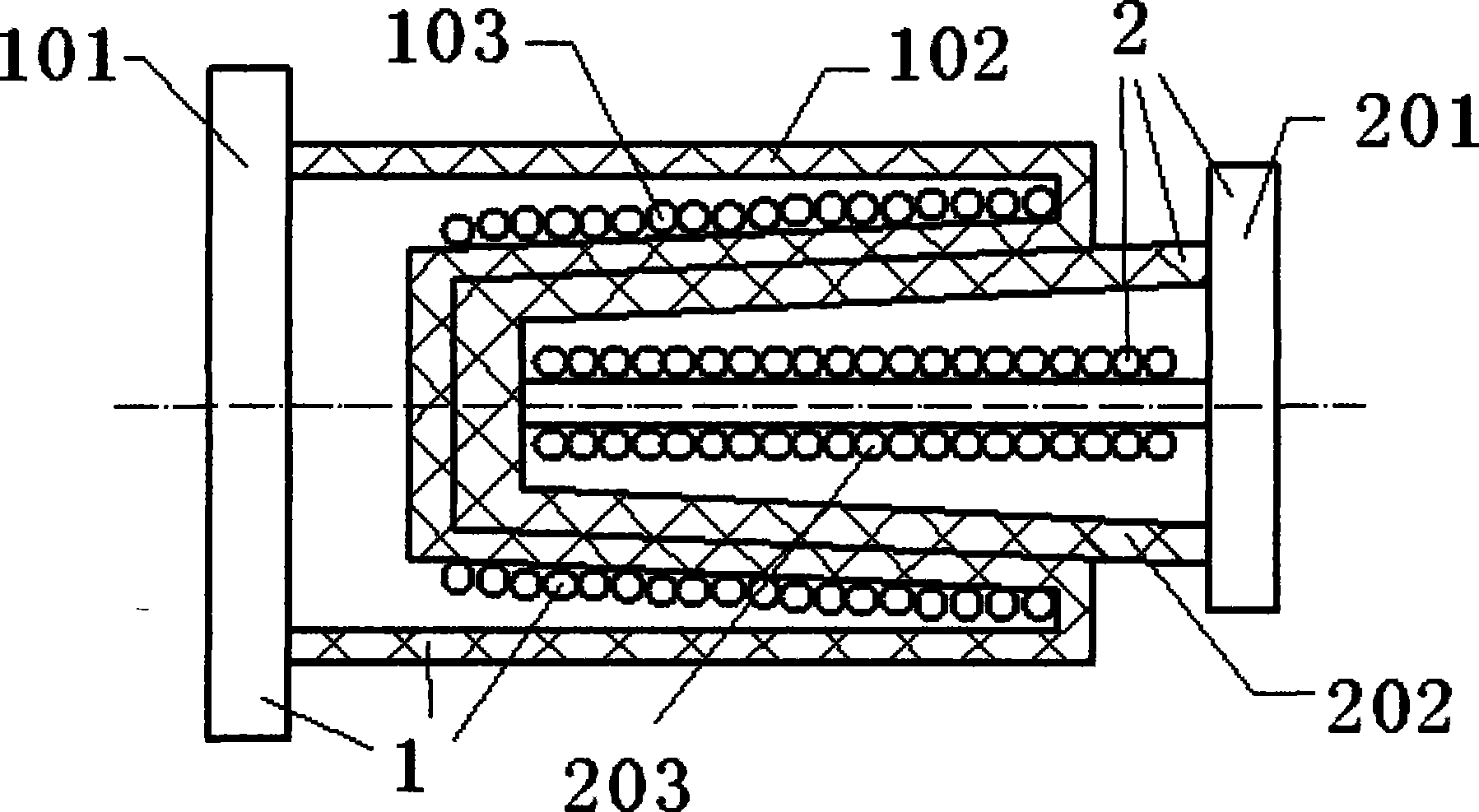

Transformer without Y capacitor and preparation method thereof

InactiveCN102163492AReduce interference currentLow effective capacitanceTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureCapacitanceTransformer

The invention discloses a transformer without Y capacitor, comprising a magnetic core, a primary main winding, a secondary winding and an auxiliary winding, wherein the primary main winding, the secondary winding and the auxiliary winding are successively winded on the magnetic core. The transformer further comprises a primary shielded winding connected with the primary main winding and a secondary shielded winding connected with the secondary winding, wherein the primary shielded winding and the secondary shielded winding have the same number of loops and the same phase. The invention solvestwo main problems of electromagnetic radiation and electric leakage in a switch power supply at the same time, realizes that the switch power supply can pass an electromagnetic radiation test withoutY capacitor, so the transformer is suitable for products fairly sensitive to leakage current, such as mobile phone chargers.

Owner:湖南崧顺科技有限公司

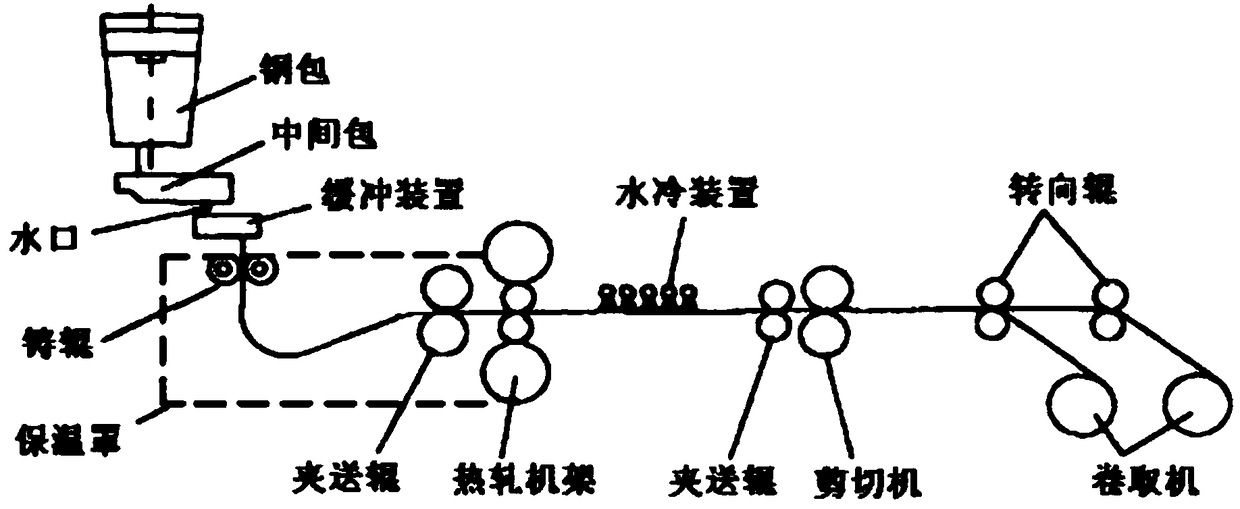

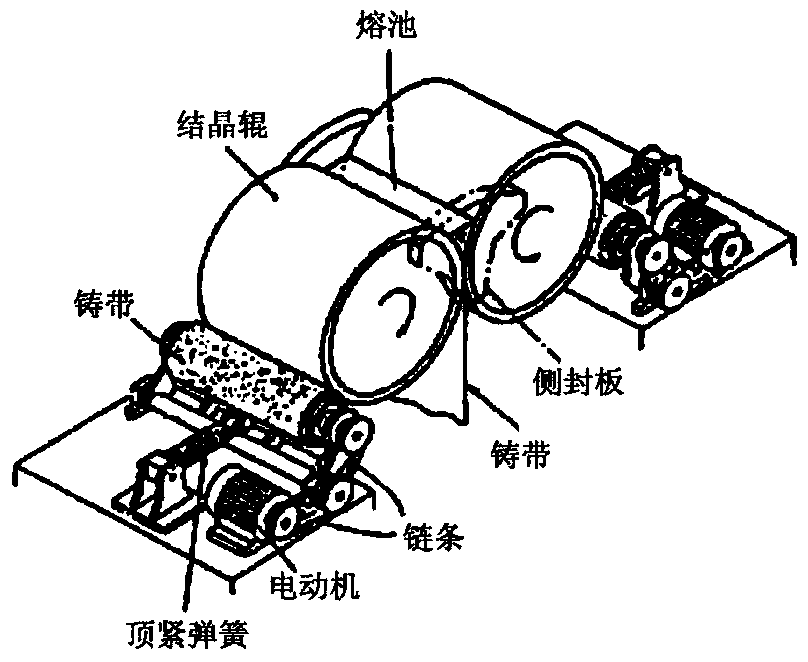

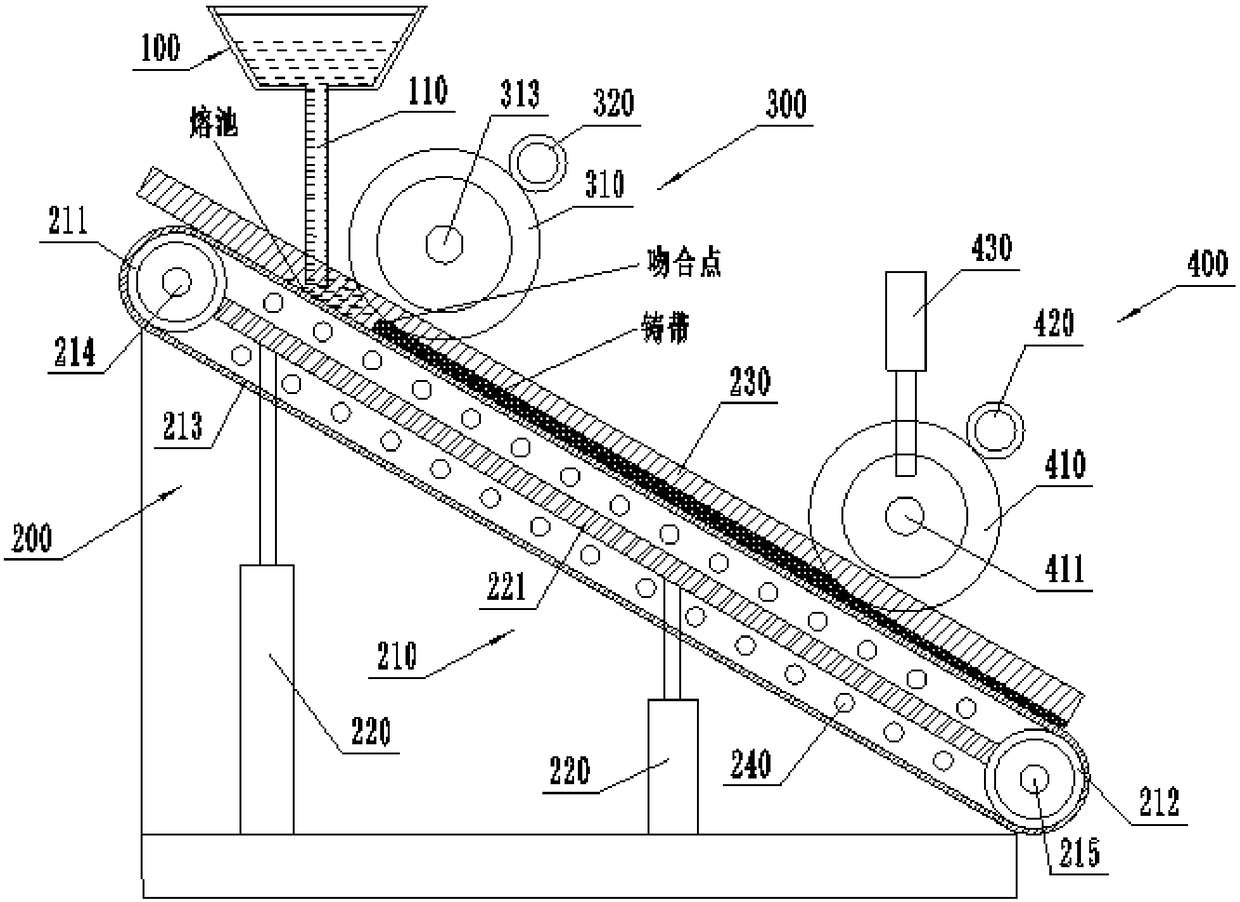

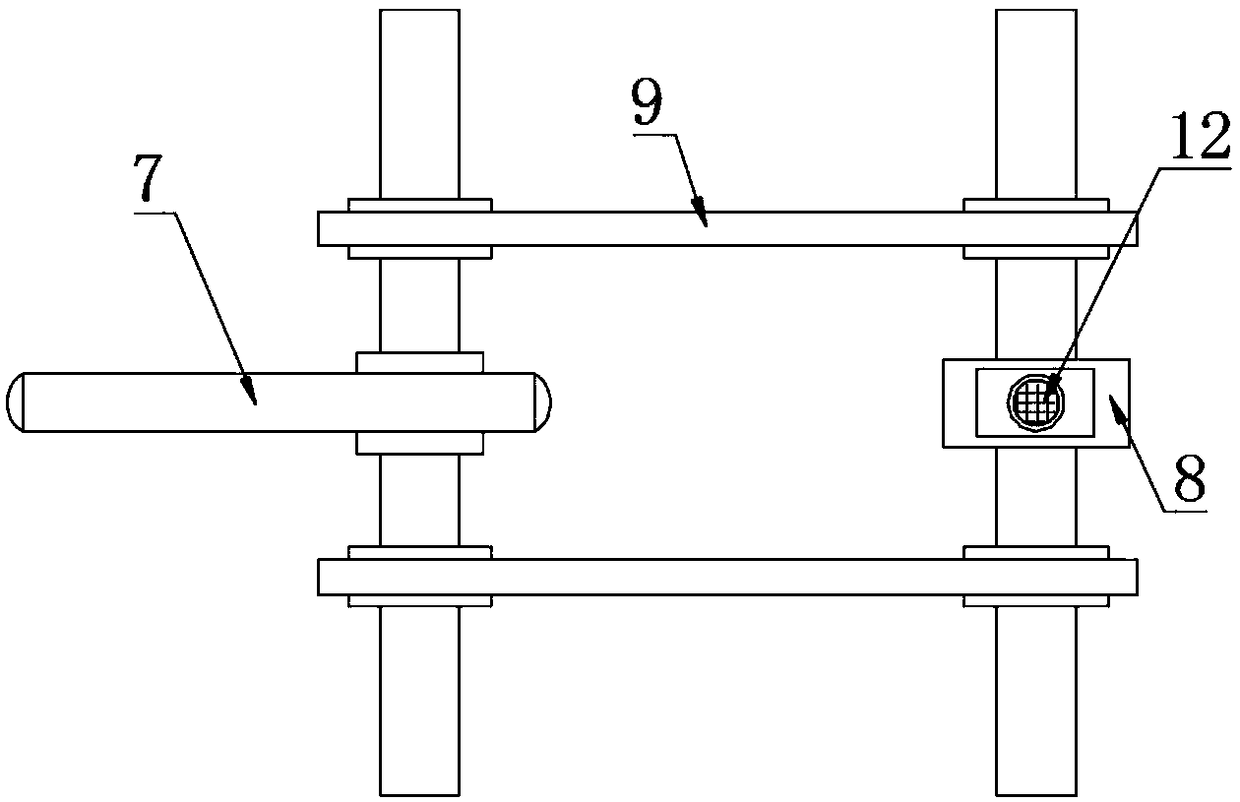

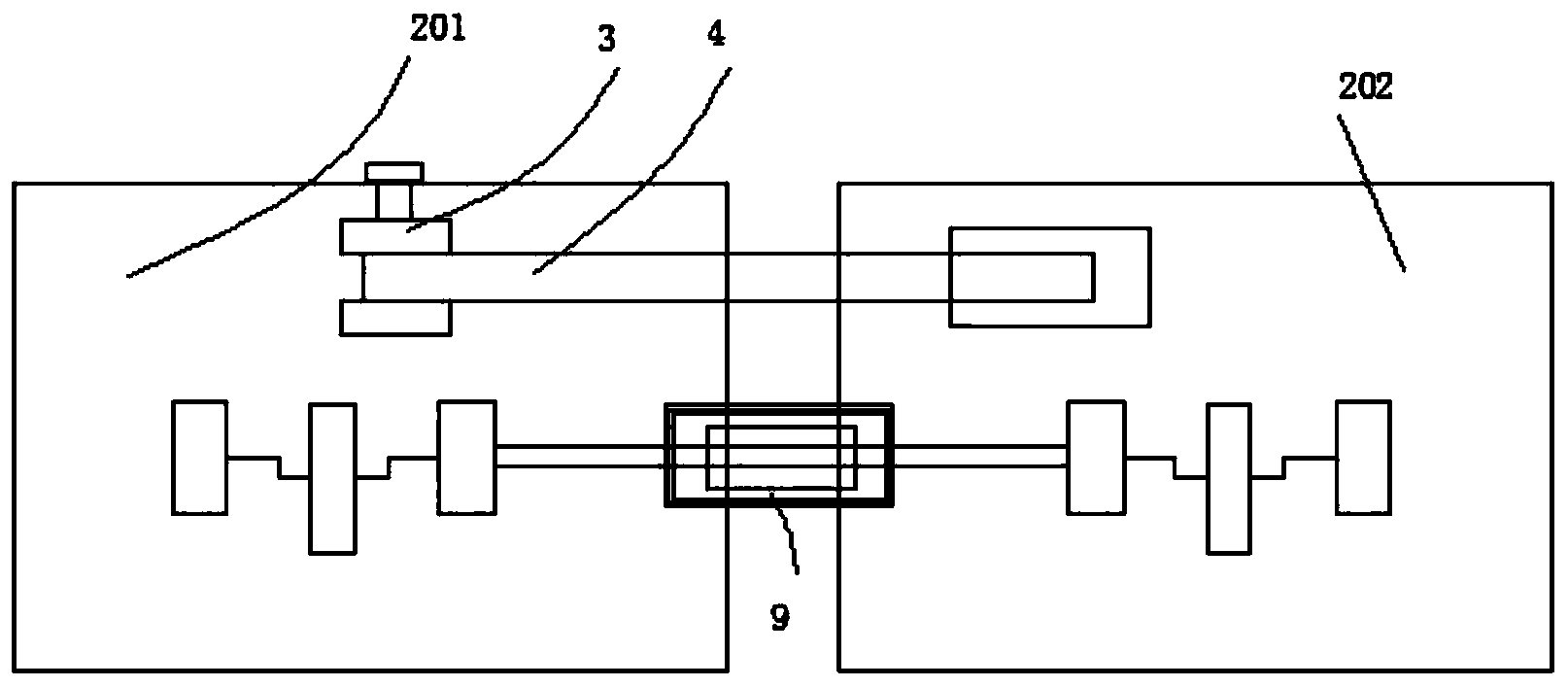

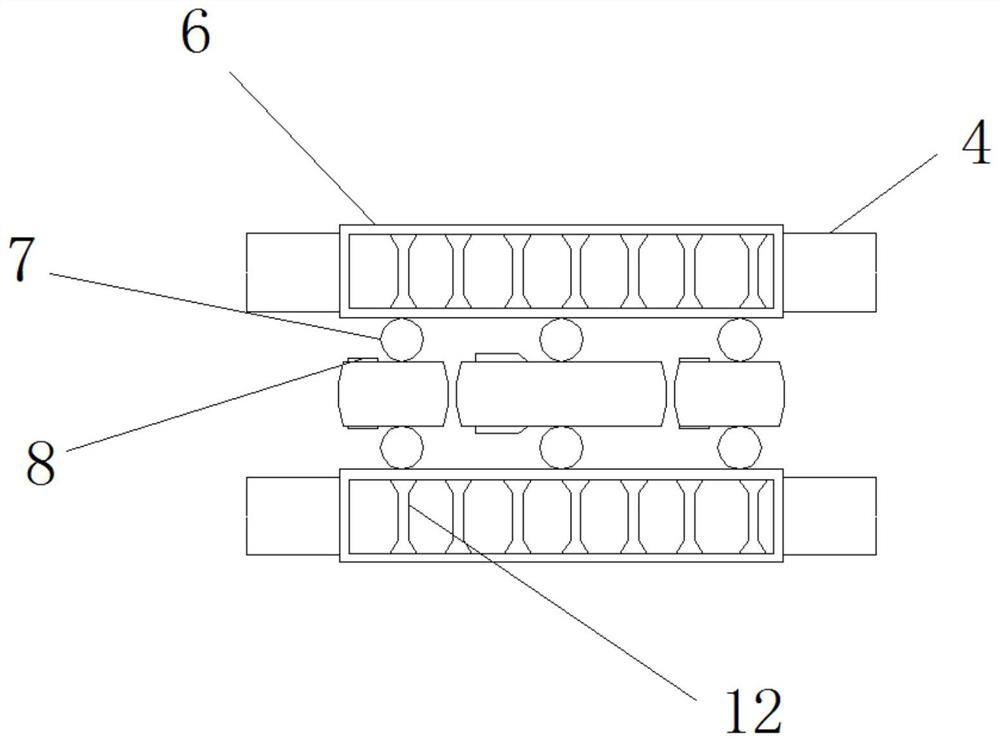

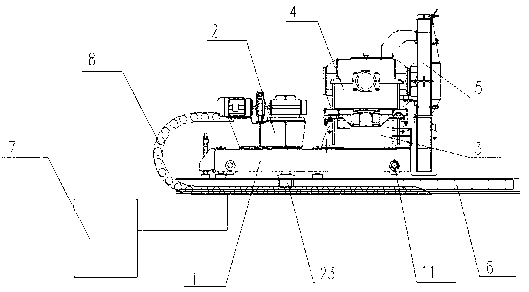

Roll belt type thin-strip casting-rolling integrated machine and using method thereof

ActiveCN108705057ASmall footprintShort production processWork cooling devicesMetal rolling arrangementsProduction lineProcess optimization

The invention discloses a roll belt type thin-strip casting-rolling integrated machine and a using method thereof, and belongs to the field of steel casting. The roll belt type thin-strip cast-rollingintegrated machine comprises a tundish, a belt type conveying device, a continuous casting mechanism and a continuous rolling mechanism. The belt type conveying device comprises a conveying steel belt which is obliquely arranged. The tundish, the continuous casting mechanism and the continuous rolling mechanism are all arranged above the conveying steel belt and sequentially arranged from high tolow in the conveying direction of the conveying steel belt. The continuous casting mechanism comprises a water-cooled crystallization roller, and an anastomosis point is formed between the water-cooled crystallization roller and the surface of the conveying steel belt. The continuous rolling mechanism comprises a hot roll, and a rolling gap is formed between the hot roll and the surface of the conveying steel belt. According to the roll belt type thin-strip casting-rolling integrated machine and the using method thereof, casting and rolling are closely combined through process optimization and improvement, the arrangement is more compact, the space occupied by the production line is reduced, the thickness of the thin strip during casting and rolling can be controlled, the occurrence of aloose shrinkage cavity in the thin strip is reduced, and the production efficiency is improved.

Owner:SHANGHAI UNIV

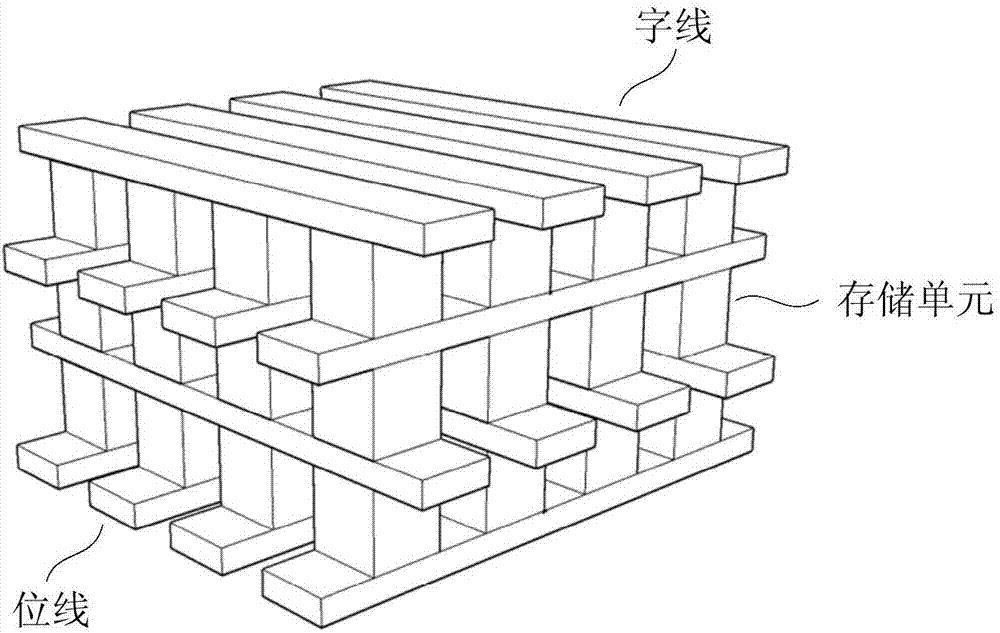

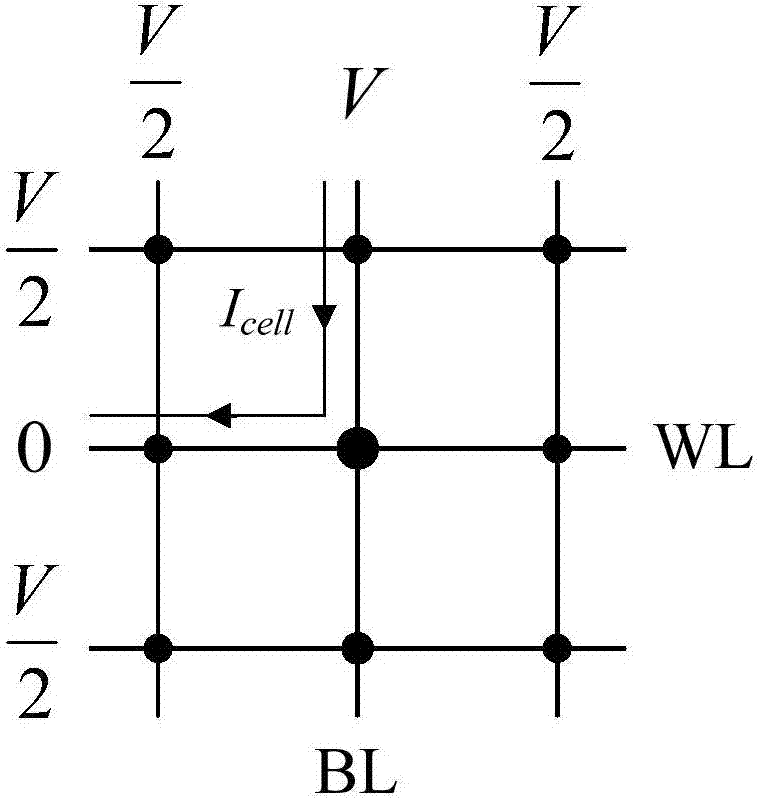

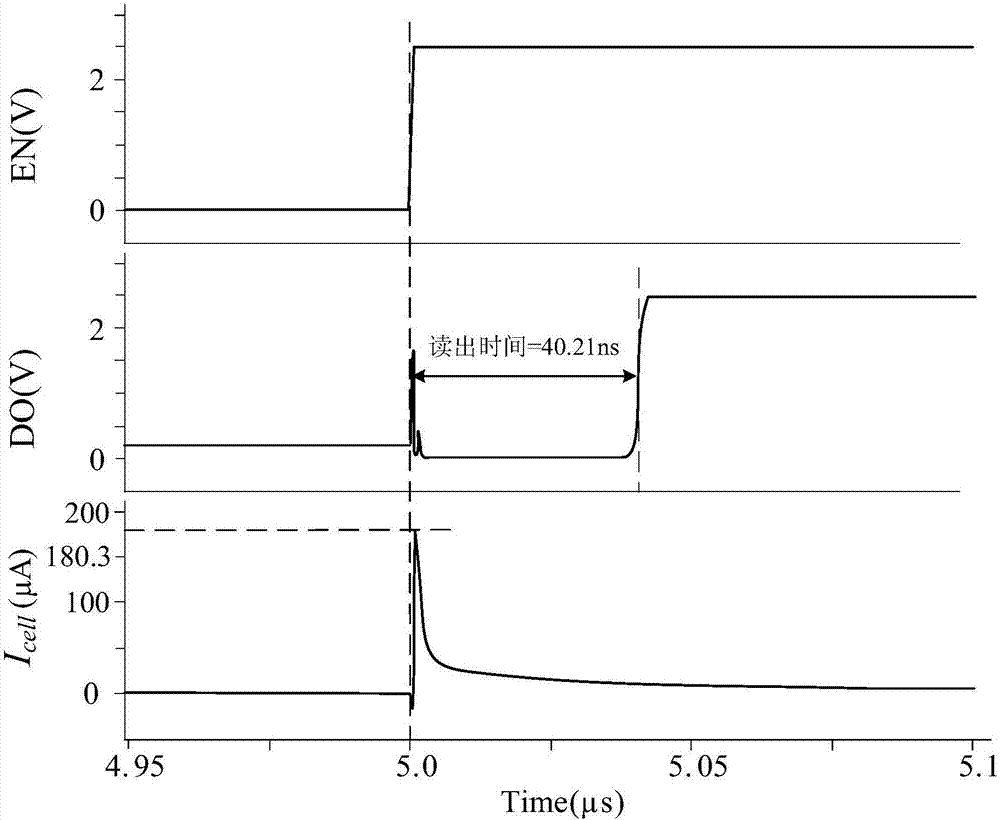

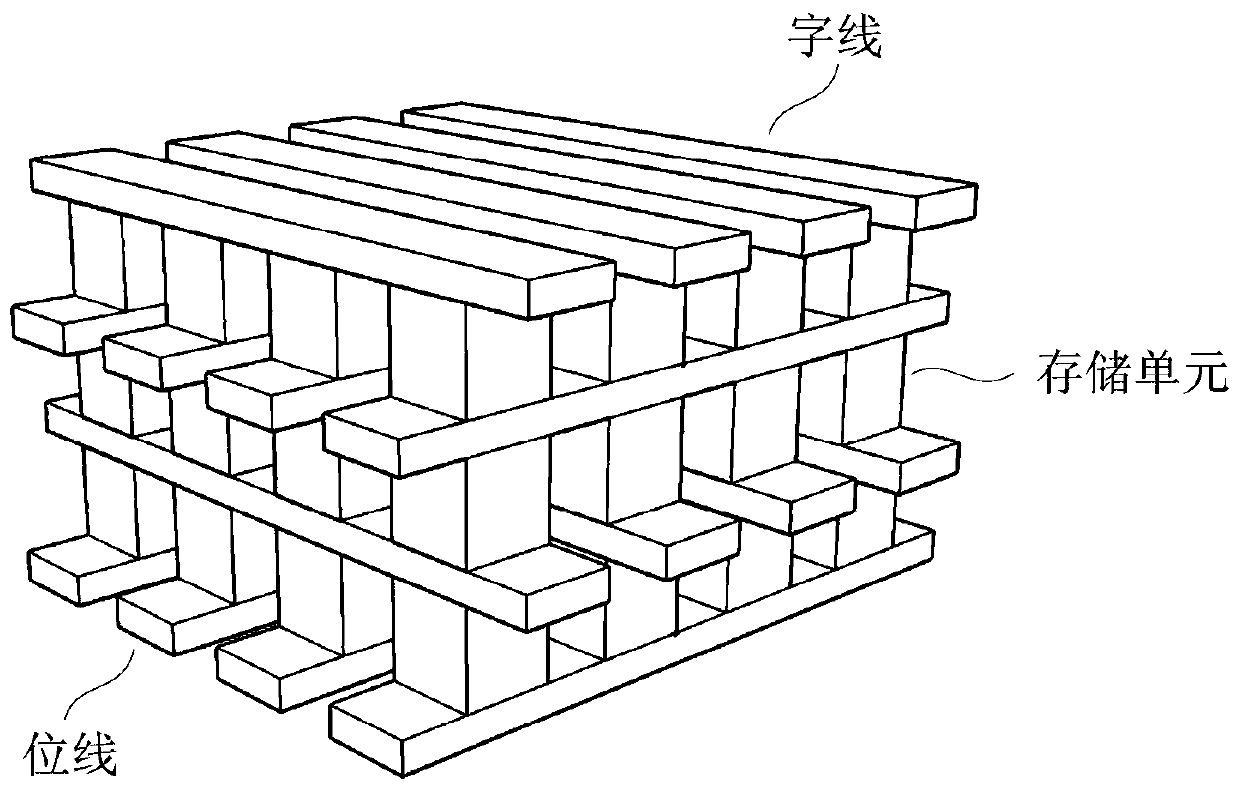

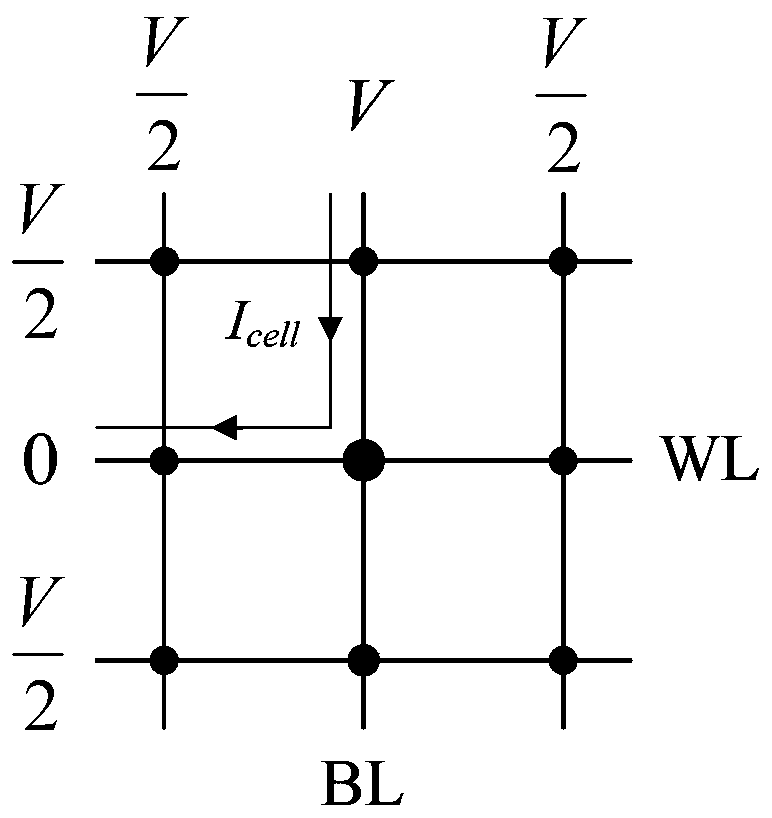

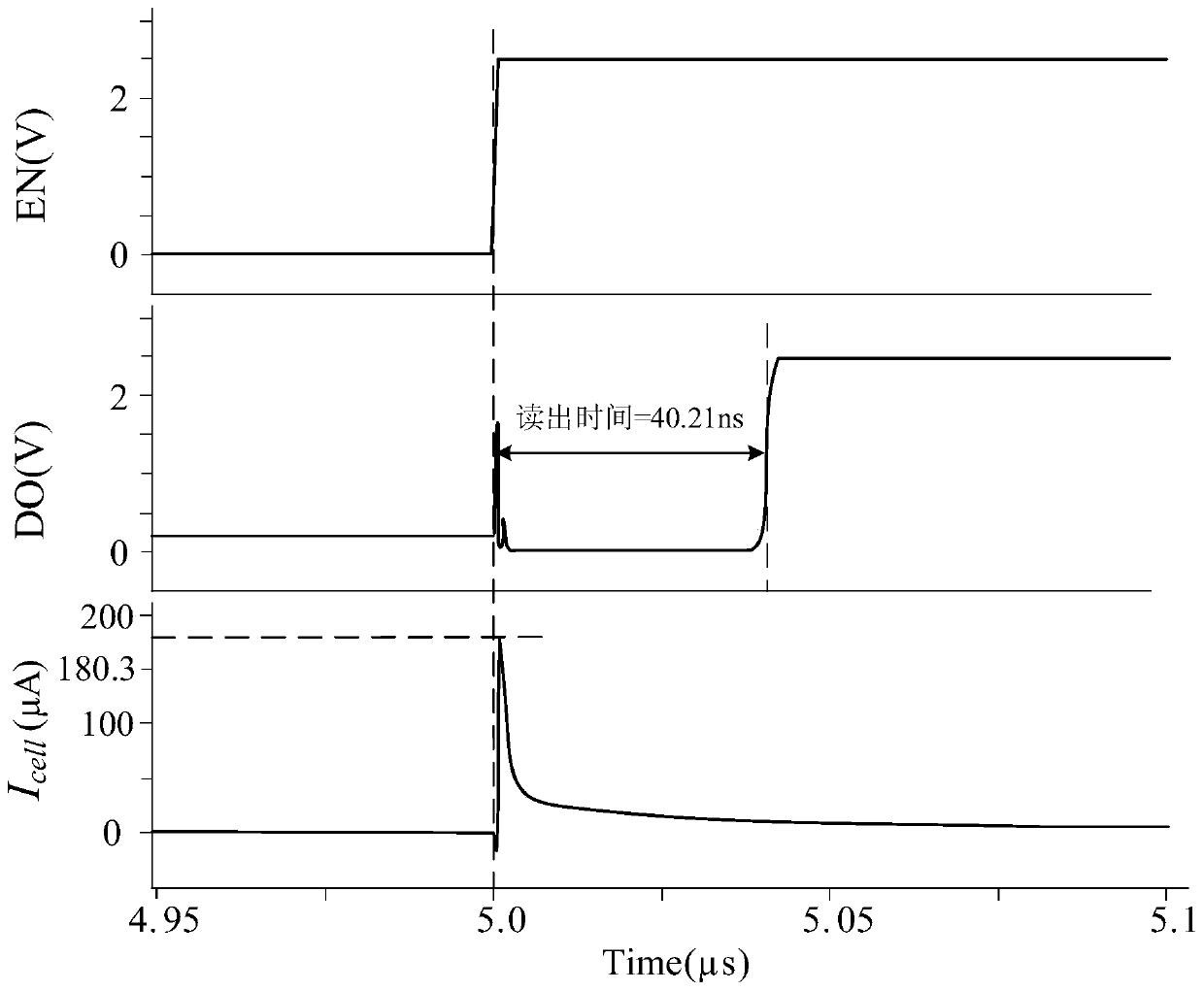

Three-dimensional memory reading circuit and word line and bit line voltage configuration method

The invention provides a three-dimensional memory reading circuit and a word line and bit line voltage configuration method. The method comprises the following steps that: when a three-dimensional memory cell array is subjected to a reading operation, setting all bit lines in the three-dimensional memory cell array as reading unselect bit line voltage through a configuration module, setting all word lines in the three-dimensional memory cell array as reading unselect word line voltage; and after a pulse signal arrives, setting the bit line where a memory cell to be read is positioned as reading voltage Vread, and setting the word line where the memory cell to be read is positioned as 0V, wherein the reading unselect bit line voltage is between Vread / 2 and Vread, and the reading unselect word line voltage is between Vread / 2 and Vread. By use of the method, the voltage of two ends of a semi-gating unit on the bit line can be lowered, the chip of the three-dimensional memory has the advantages of lower power consumption, higher speed and no full-array electricity leakage during a reading operation, and the memory unit which is not selected on the selected word line still keeps semi-gating.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

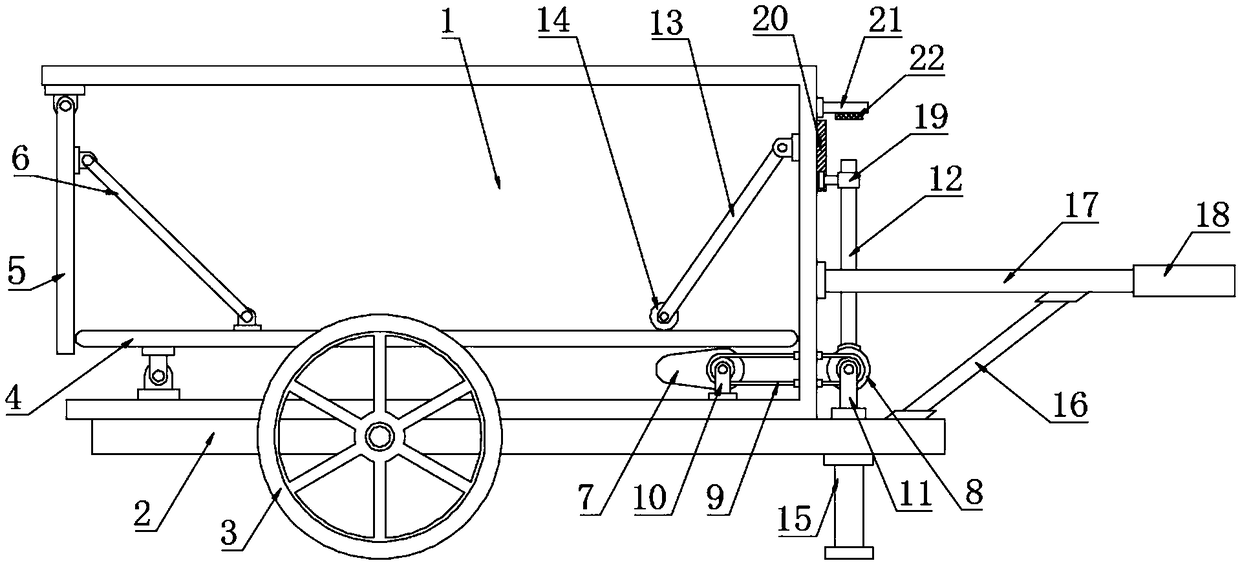

Gorgon euryale seed husking machine and husking method

InactiveCN102860571AReduce breakage rateImprove peeling efficiencyHuskingHullingEngineeringWheel drive

The invention relates to a gorgon euryale seed husking machine and a husking method. An output shaft of a power driving mechanism is connected with a convex sector-shaped wheel, the lower end of a ratchet wheel driving power input shaft in a ratchet wheel driving mechanism is fixed on the convex sector-shaped wheel, the front end of a ratchet wheel driving rod is in driving fit with ratchets in a ratchet wheel, the ratchet wheel is sleeved on a central shaft of the upper end face of a machine frame, a ratchet wheel surface is provided with a plurality of gorgon euryale seed nut cracking holes corresponding to bottom template holes in a die hopper, a multi-head elastic cracking rod assembly is located above the ratchet wheel, a plurality of ejection rods in the multi-head elastic cracking rod assembly are matched with the template holes at the bottom of a template in a die hopper assembly and the gorgon euryale seed nut cracking holes located on the ratchet wheel surface and corresponding to the template holes, ejection rod fixing plates in the multi-head elastic cracking rod assembly are driven to be in pressing elastic reset fit with a pressing sleeve plate in a pressing plate mechanism, a pressing plate in a power driving sleeve plate in the pressing plate mechanism is connected with the upper end of a rolling ejection rod, rollers are installed at the lower end of the rolling ejection rod, the rolling ejection rod is in rolling fit with the convex sector-shaped wheel, and a blanking guide groove is arranged below a table board of the machine frame.

Owner:HANGZHOU JINGHAIYUAN ECOLOGICAL AGRI DEV

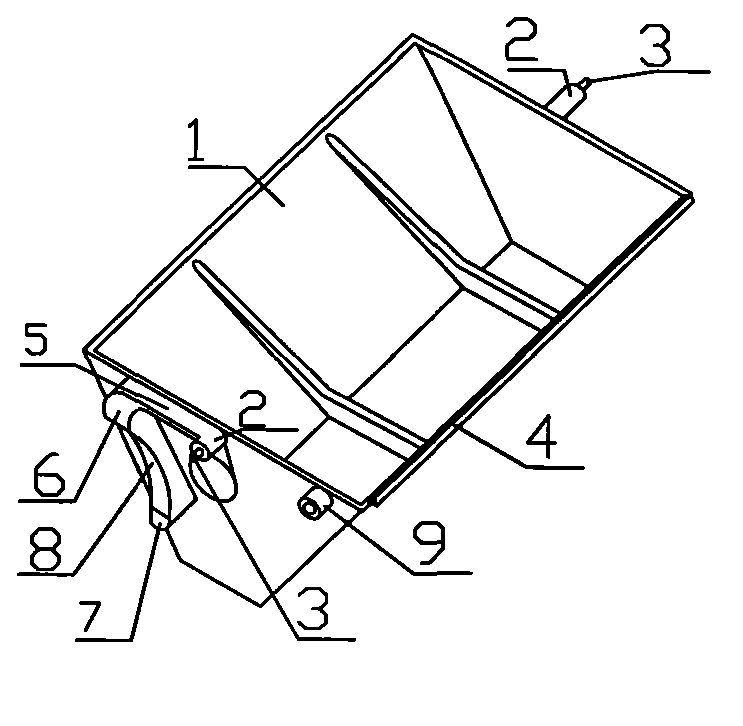

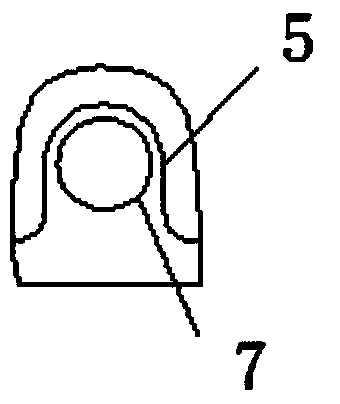

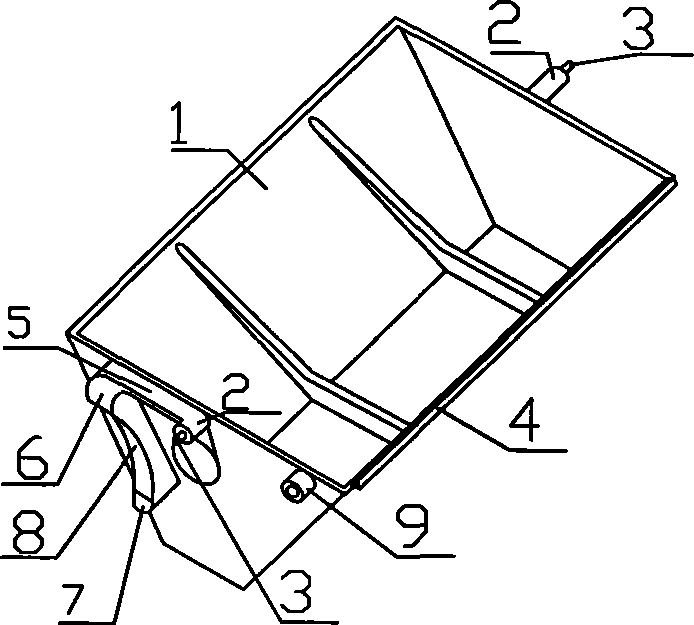

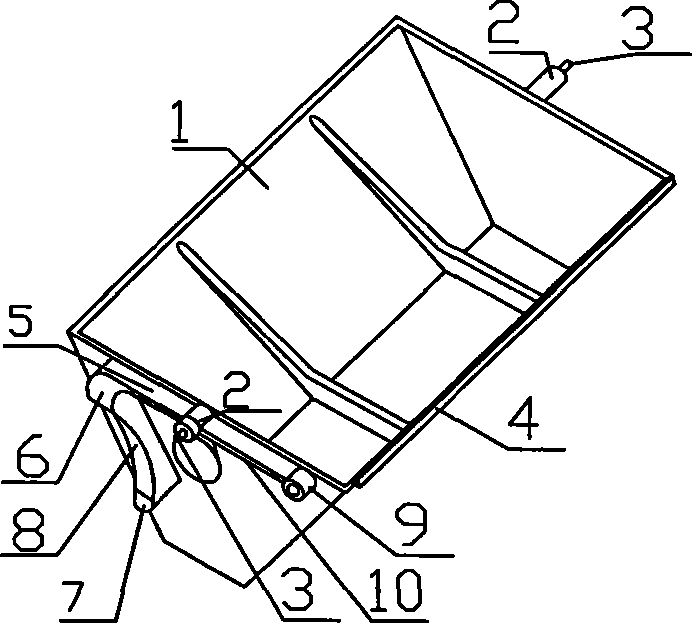

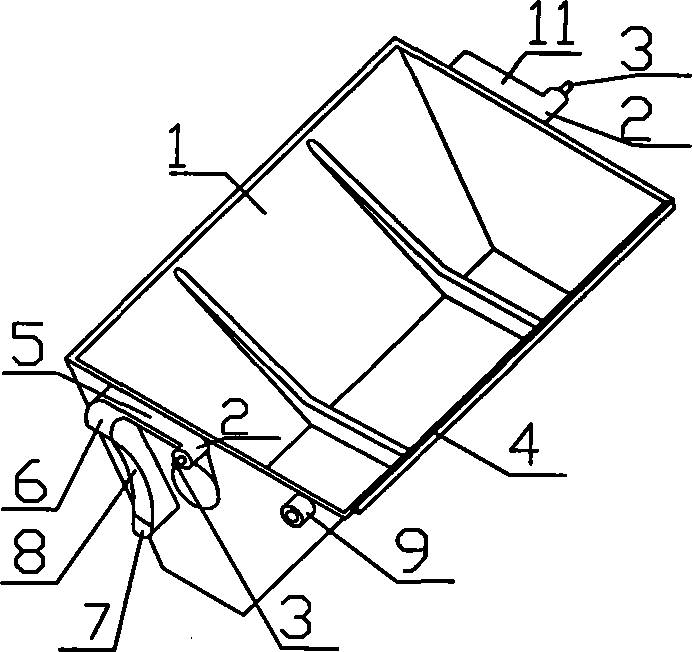

No-crushing elevator hopper

The invention discloses a no-crushing elevator hopper. The no-crushing elevator hopper comprises a ladder-shaped hopper body, wherein suspension pin bosses are arranged on two end side walls of the ladder-shaped hopper body. Suspension pins are respectively embedded in the suspension pin bosses. A clamp platform is arranged at the front end of the ladder-shaped hopper body. A strengthening flat A is arranged on a side wall of the ladder-shaped hopper body. A circular arc turning boss is arranged at one end of the strengthening flat A. A circular arc discharging boss A is arranged on a side wall, below the strengthening flat A, of the ladder-shaped hopper body. A stiffening beam is arranged between the circular arc turning boss and the circular arc discharging boss A. A guide limiting column is arranged on a side wall, on the same side with the strengthening flat A, of the ladder-shaped hopper body. The no-crushing elevator hopper has the advantages that two adjacent hoppers are in seamless connection, the triangular-prism-shaped clamp platform divides dropped materials into two adjacent hoppers, so that leakage of a gap between two adjacent hoppers is avoided, and the material is prevented from being grinded and broken. The no-crushing elevator hopper is simple in structure, convenient to maintain, low in manufacture cost and long in service life.

Owner:五原县金麦提升科技有限公司

Wireless sensor network node device used for environmental monitoring

InactiveCN100464268CReduce node sizeReasonable structureTotal factory controlProgramme total factory controlEngineeringPointing device

Owner:SOUTHEAST UNIV

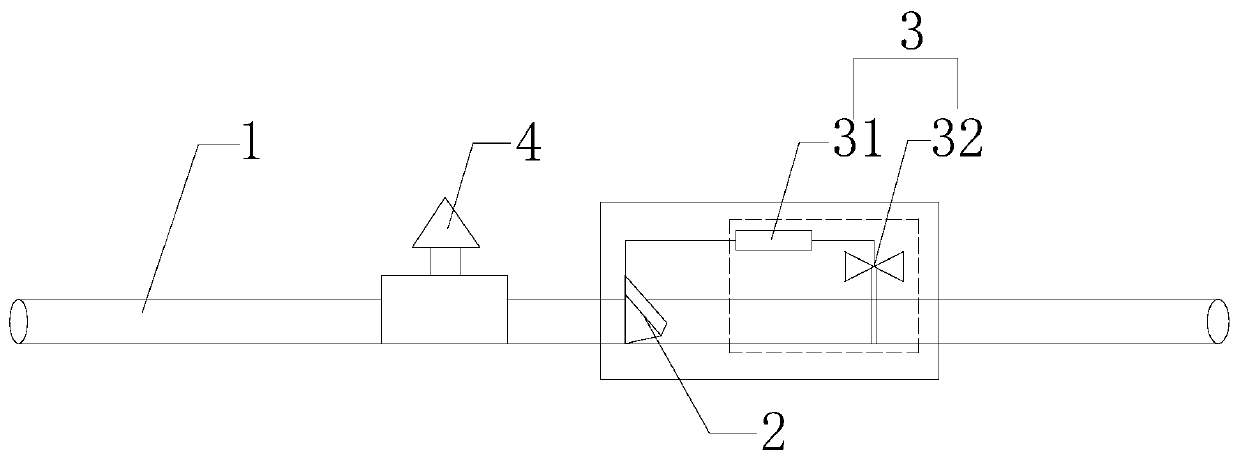

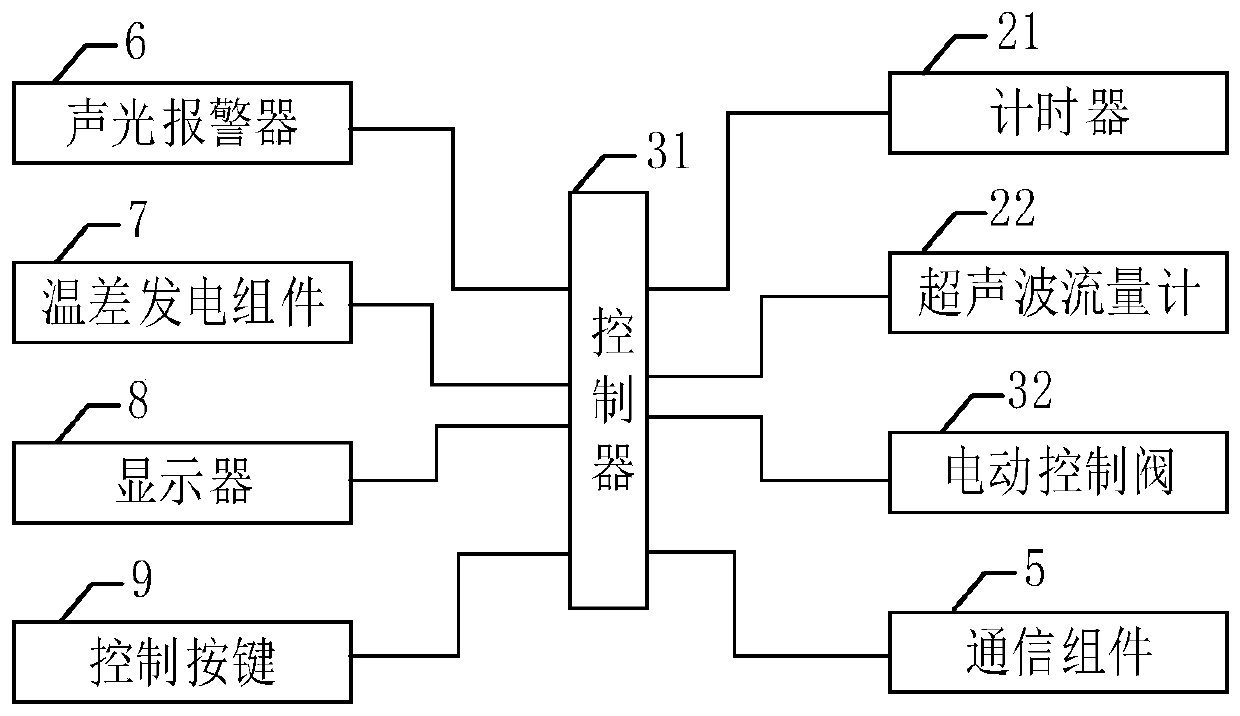

Water leakage prevention control device

PendingCN111503526AComplete the cutting process in timeGuaranteed accuracyPipeline systemsWater leakageWater discharge

The invention relates to a water leakage prevention control device. The water leakage prevention control device comprises a serial connection pipe, a detection component and a control component, wherein the serial connection pipeline is serially connected between a water charging pipeline and a water discharging pipeline; the detection component is used for detecting the water flowing time and thewater flow amount inside the serial connection pipeline; the control component is connected with the detection component; the control component is used for receiving the water flowing time and the water flow amount and stopping the water inside the water charging pipeline from flowing into the water discharging pipeline when the water flowing time reaches a preset time threshold value or when thewater flow amount reaches a preset flow amount threshold value, thereby effectively improving the accuracy of water leakage detection, also controlling and stopping continuous flowing of water in time, and ensuring that no serious water leakage problem occurs.

Owner:BEIJING JOYO SMART WATER METER

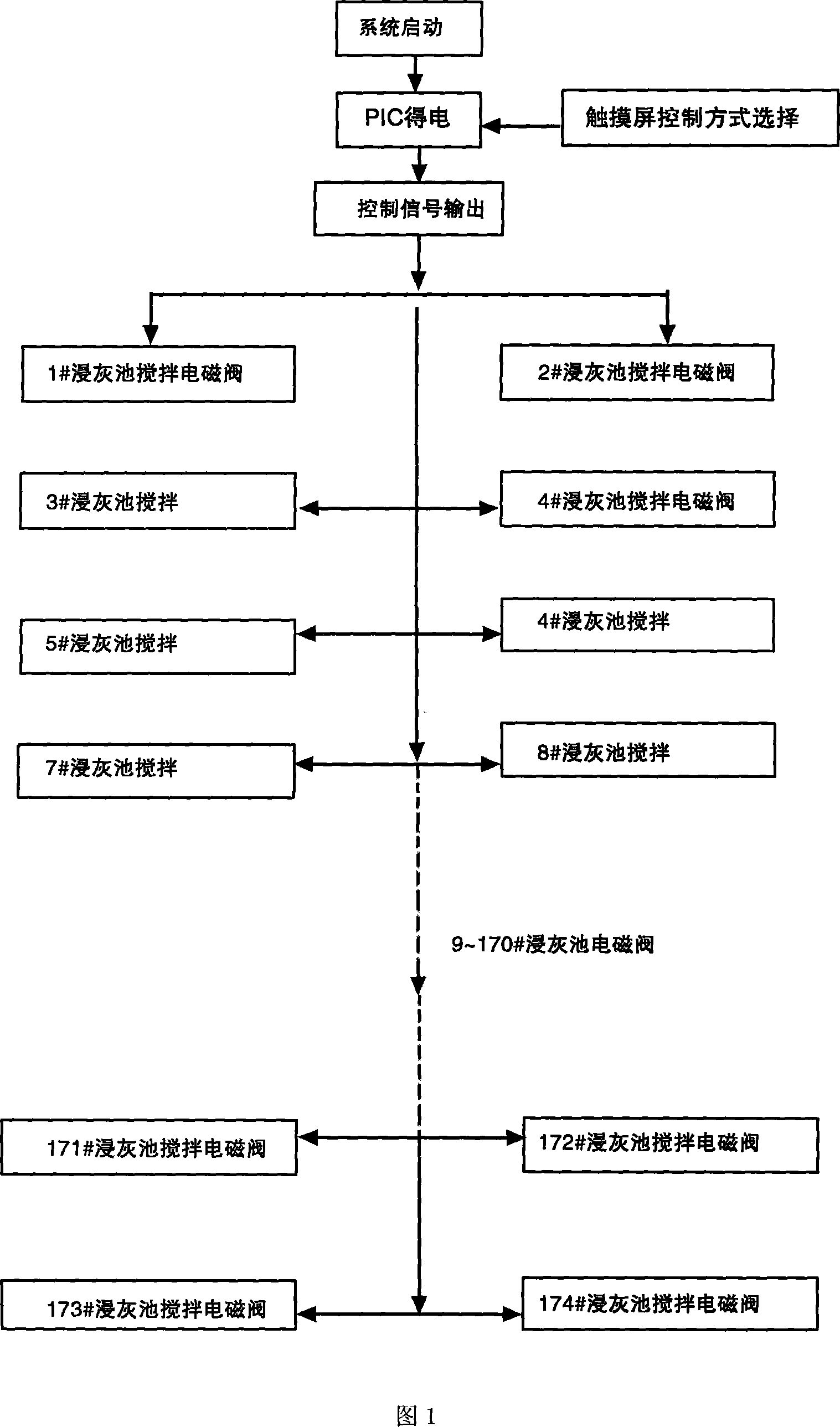

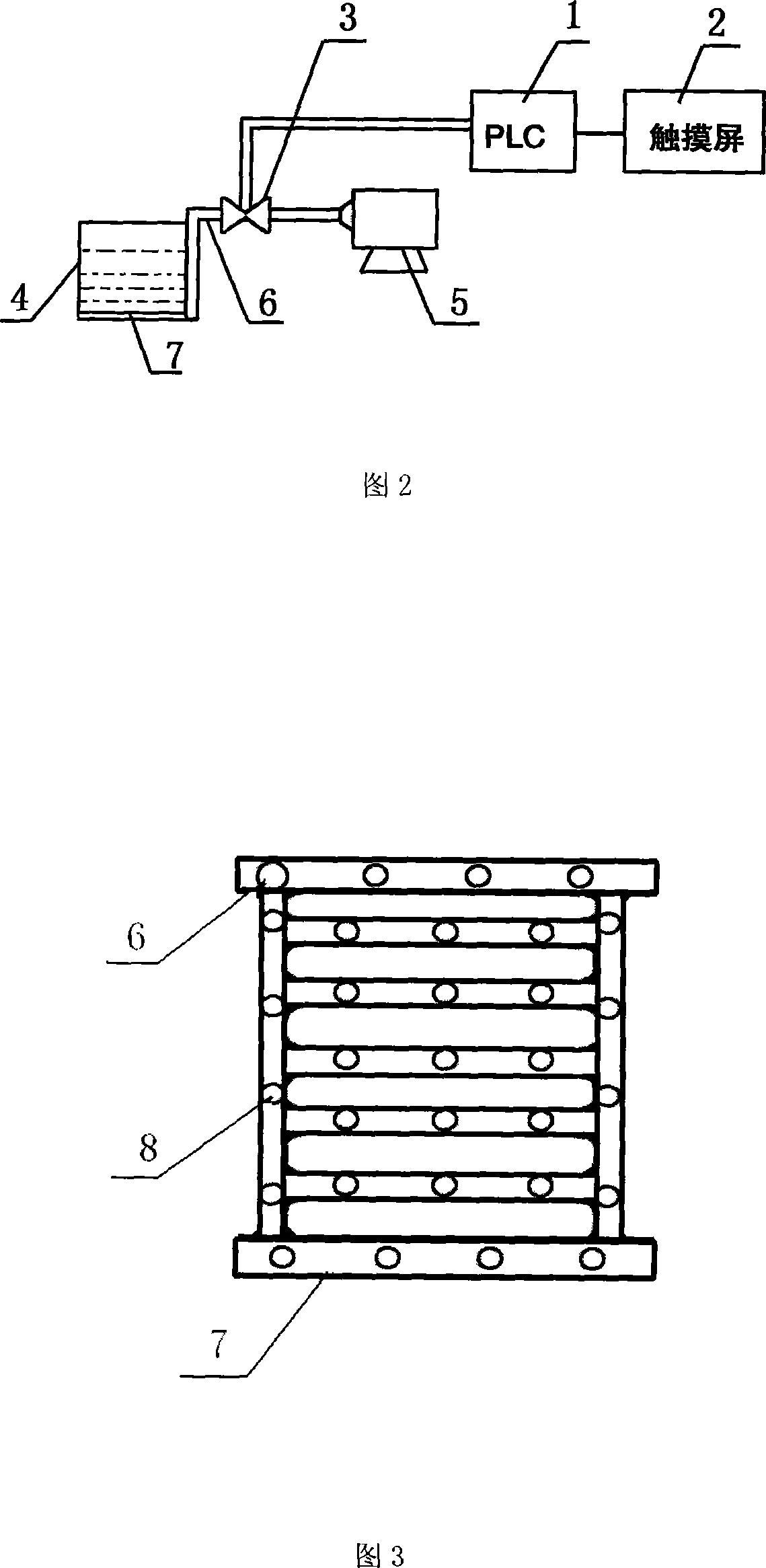

Liming stirring technique automatic control method

InactiveCN101186785AReduce labor intensityStir wellMixer accessoriesGlue/gelatin preparationAutomatic controlControl manner

The invention relates to a processing technique of gelatine glue, in particular relating to an automatic control method of liming and agitating technique in the process of the liming of skeletal grain which is the main raw material of the gelatine glue. The automatic control method of liming and agitating technique comprises (1) initiation step, (2) control mode selection step, (3A) step of choosing the control mode of regular agitation, and (3B) step of choosing an agitation control mode of arbitrarily appointing a lime. The invention has the advantages that the automatic control method of liming and agitating technique of the invention employs PLC control softwares to automatically control regular agitation of 174 limes or respectively and arbitrarily appoints a certain lime to be agitated and the function is realized by the controlling of PLC. The liming technique of the invention is realized by automatic control, which is simple in operation, absolutely replaces the manual agitation, is uniform in agitation and can not result in leaking. The invention is high in automatic level and uniform in agitation of liquid, and can be applied to the agitation procedures in the process of producing the gelatine glue and chemical production.

Owner:SHUNLIBAN INFORMATION SERVICE CO LTD

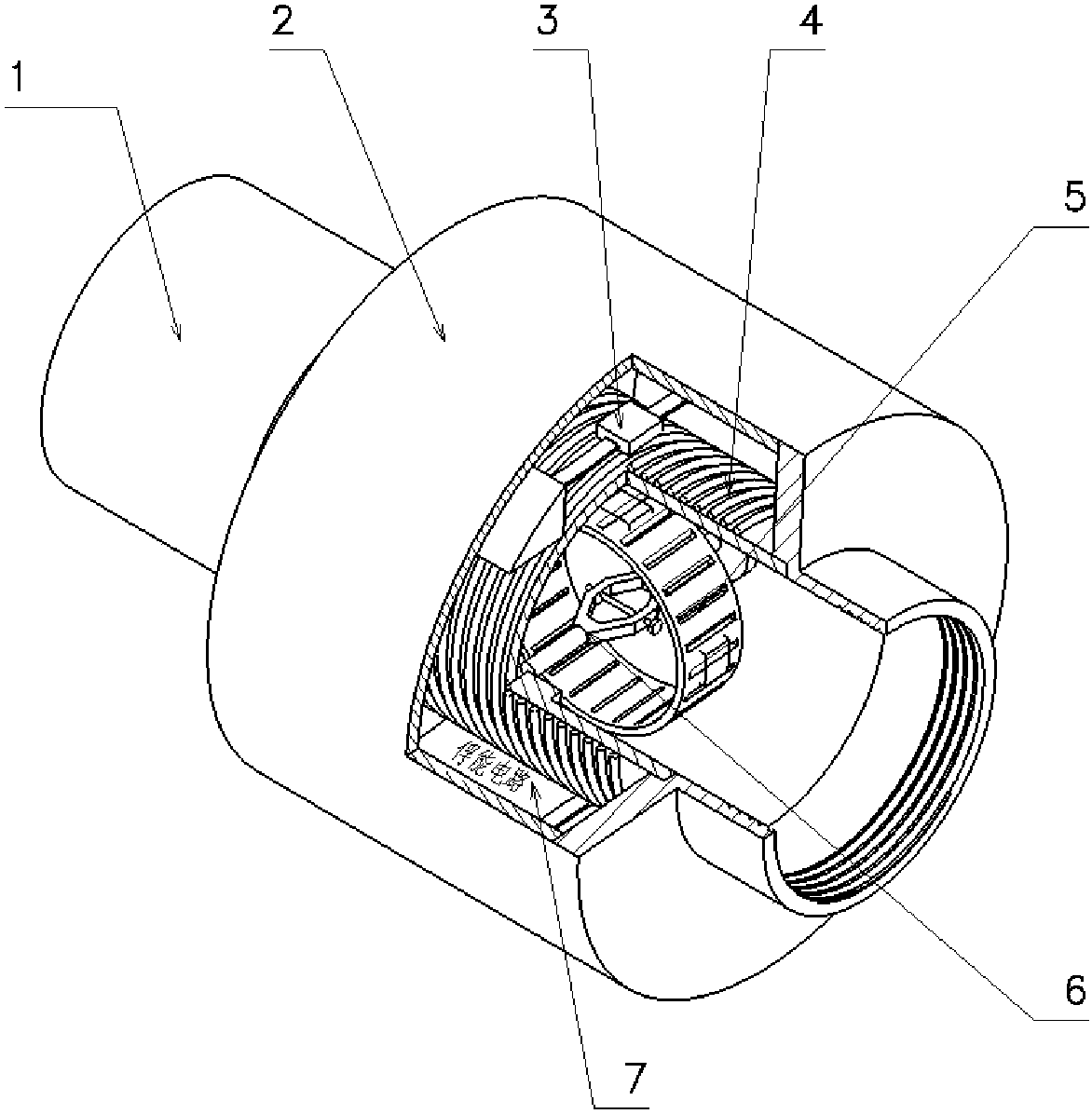

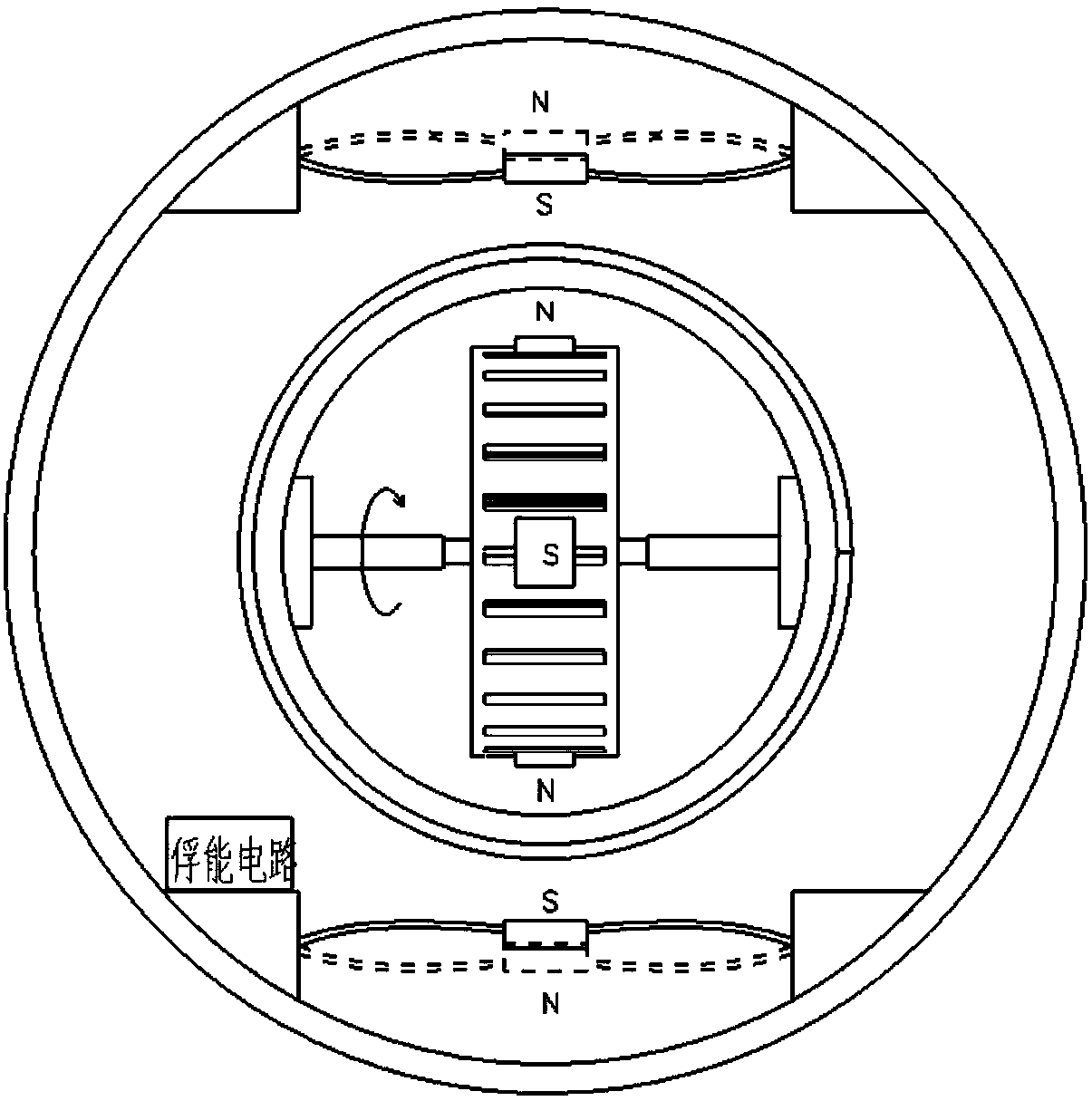

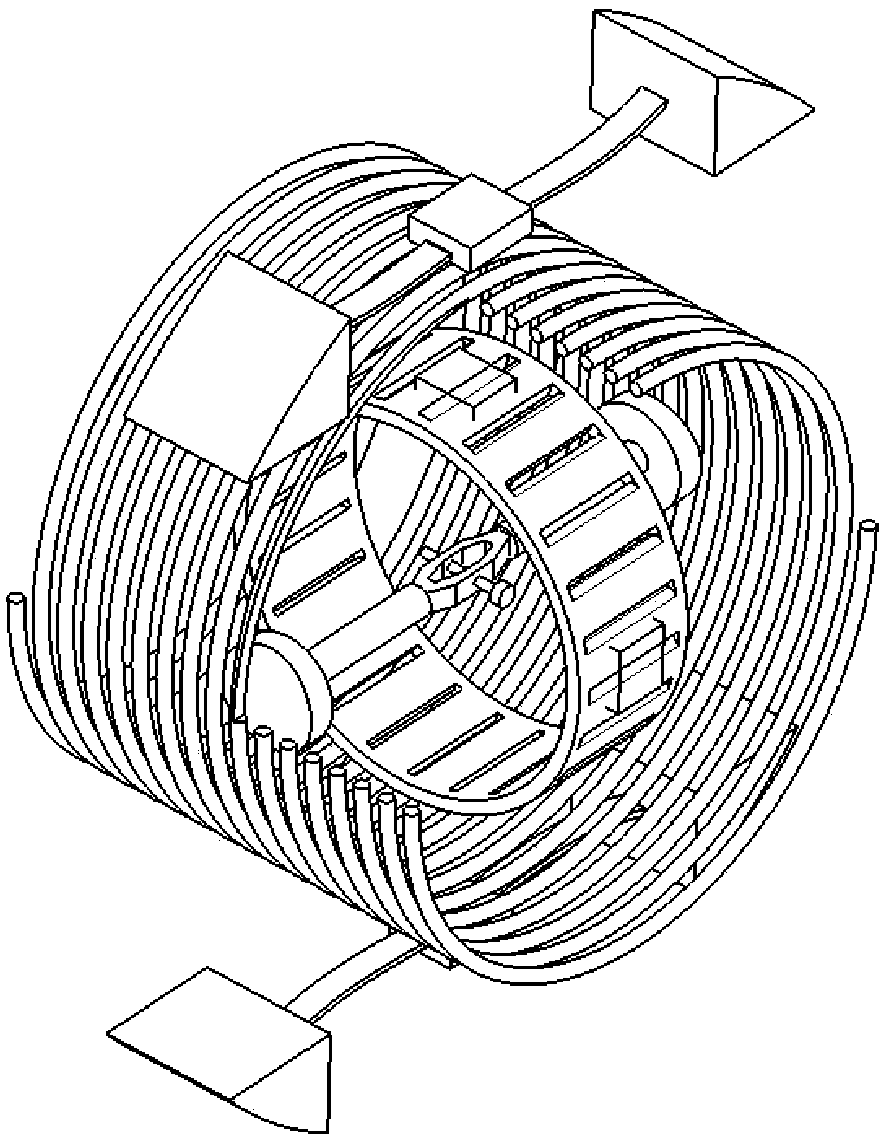

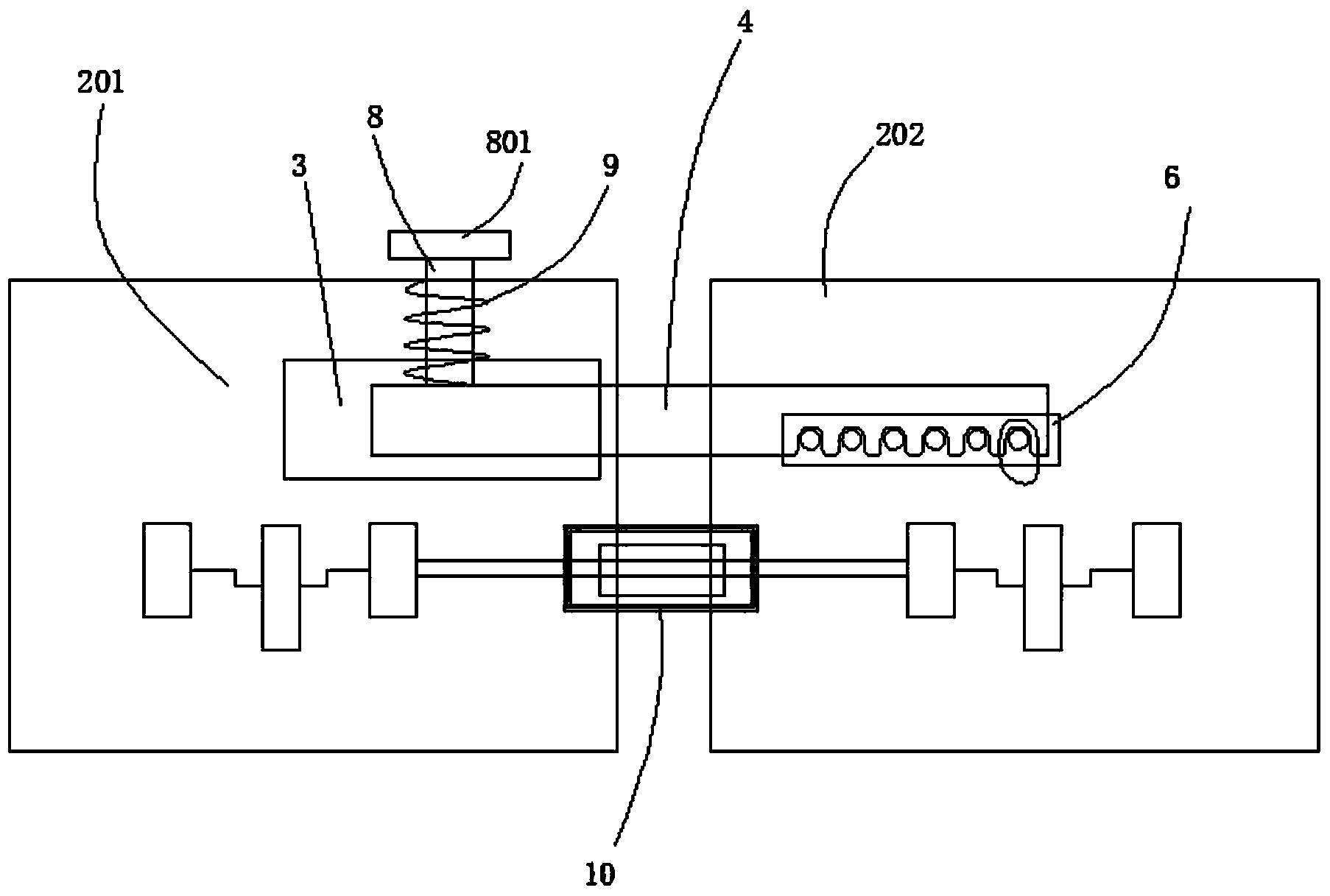

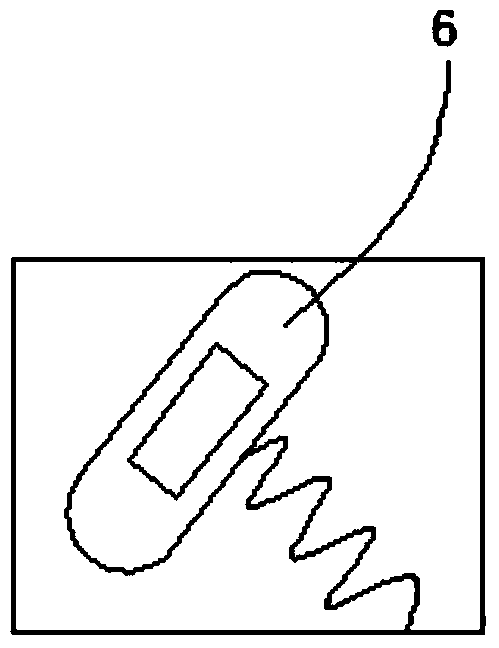

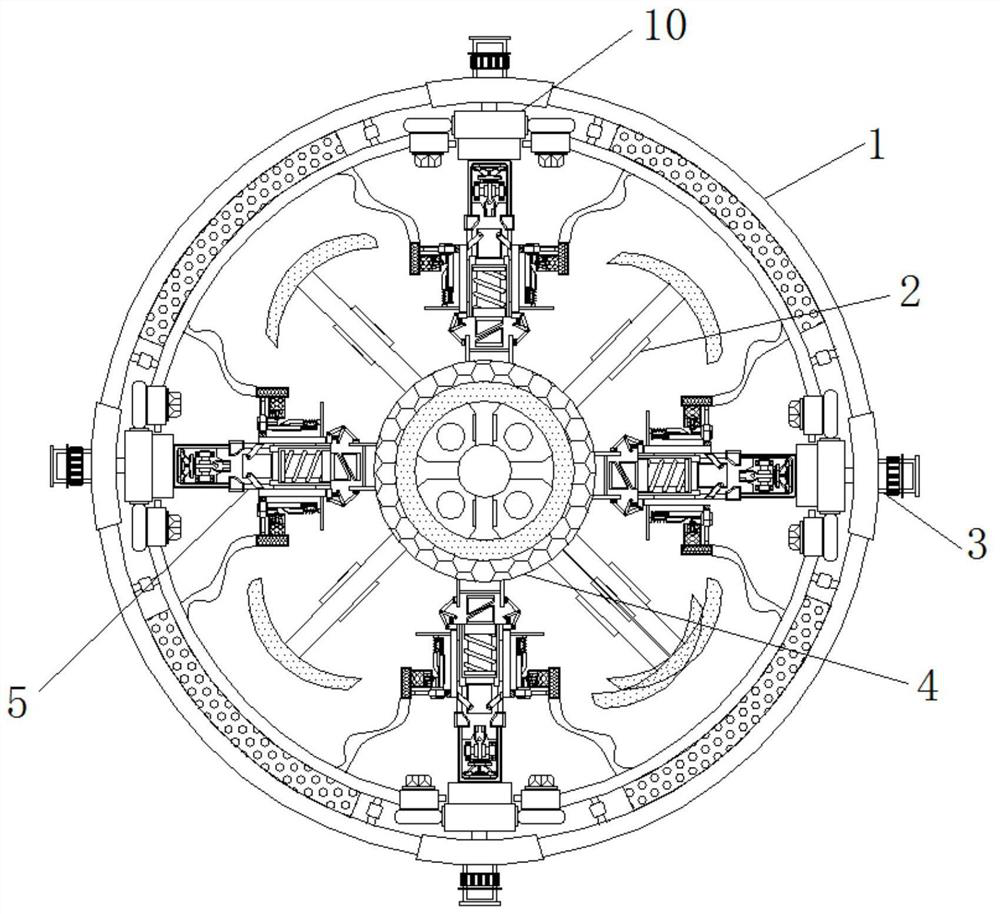

Bi-stable piezoelectric-electromagnetic power generation device making use of kinetic energy of fluid in pipeline

PendingCN108258934ANo leakageLeakage will not occurPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesImpellerElectricity

The invention discloses a bi-stable piezoelectric-electromagnetic power generation device making use of kinetic energy of fluid in a pipeline. The device structurally mainly comprises the fluid pipeline, an outer shell, two bi-stable piezoelectric components, a coil, an impeller component, a fixing shaft and an energy capture circuit. An impeller is arranged in the middle of the fluid pipeline andfixed to the inner wall of the fluid pipeline through a fixing rod, four magnets are arranged on the impeller, the outer surface of the fluid pipeline is provided with the multi-turn metal coil, andtwo sides of the coil are connected with the energy capture circuit. The outer shell is fixedly connected with the fluid pipeline, the two bi-stable piezoelectric components in vertical arrangement are arranged between the fluid pipeline and the outer shell, a flexible piezoelectric element is an MFC, two poles of the MFC are connected with the energy capture circuit, and the piezoelectric components are fixedly mounted on a boss of the shell. By the piezoelectric element and an electromagnetic element, kinetic energy of the fluid in the pipeline is converted into electric energy, the pipelineis free of holes, and a power generation component is isolated from fluid, so that risks of liquid leakage and electricity leakage are avoided; by piezoelectric-electromagnetic power generation, structural simplicity and great power generation effects are achieved.

Owner:JILIN UNIV

Extensible socket bar

The invention discloses an extensible socket bar. The extensible socket bar comprises an electric wire, socket bars, a slider, an expansion plate, clamping grooves, a clamping plate, clamping columns, a connecting rod, a return spring and a spring tube, wherein the socket bars include a first socket bar and a second socket bar; the slider is located at the internal bottom end of the first socket bar and connected with the same by use of an adhesive; the expansion plate is located in the center of the top of the slider and connected with the same in a sliding manner; each clamping groove is formed in the top of the expansion plate and in a plate-like circular shape, and a plurality of clamping grooves are orderly arranged from left to right; the clamping plate is located at the internal bottom end of the second socket bar and connected with the same by use of an adhesive; each clamping column is located at the top of the clamping plate and in a cylindrical shape, and a plurality of clamping columns are orderly arranged from left to right; the return spring penetrates through the connecting rod, and located between the first socket bar and the second socket bar, and the return spring, the first socket bar and the second socket bar are fastened to each other. The extensible socket bar is ingenious in structure, powerful in function, and capable of preventing interference of plugging into the socket bar when electrical appliance plugs are large and avoiding the waste of the socket bar in use.

Owner:CHIZHOU YICHUANG ELECTRONICS TECH

Mooncake wrapper, mooncake containing monncake wrapper and processing method of mooncake

InactiveCN107047698AEasy to wrapLeakage will not occurDough treatmentBakery productsPotato starchBiology

The invention discloses a mooncake wrapper. The mooncake wrapper is made from the following components in parts by weight: 400-600 parts of all-purpose flour, 60-100 parts of potato starch, 40-80 parts of perilla herb oil and 10-50 parts of tea seed oil. The mooncake wrapper disclosed by the invention has the advantages that after mooncakes processed through the mooncake wrapper are split from the middle, the thickness ratio of the wrapper to fillings is 2 to 8, and requirements of being thin in the wrapper and large in the fillings are achieved.

Owner:云南连宸食品有限公司

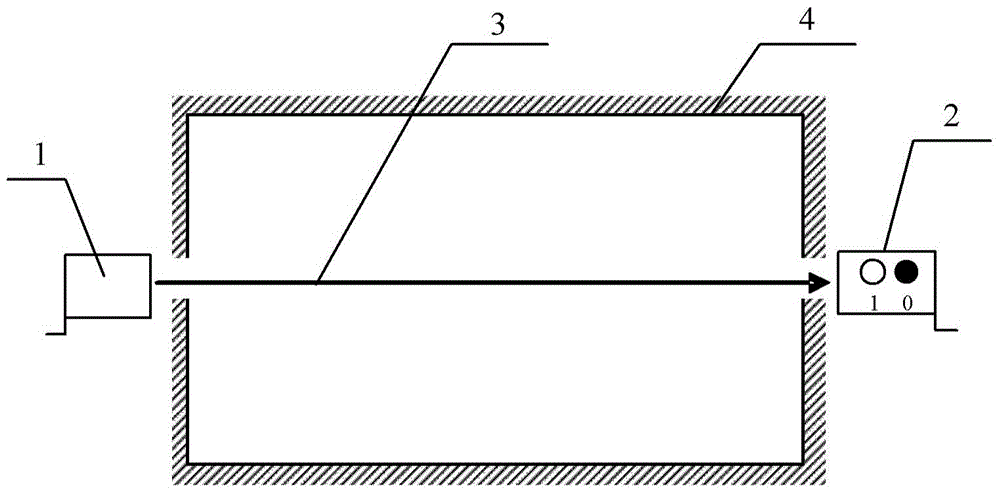

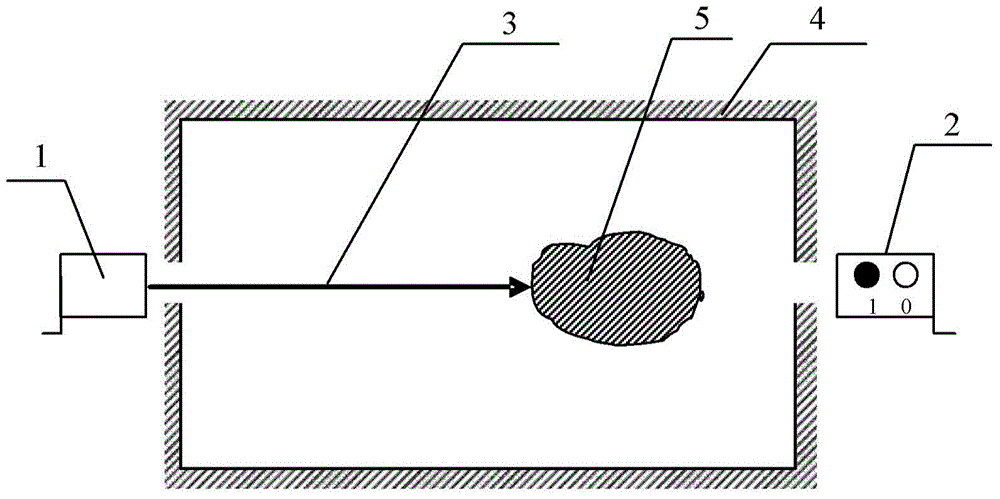

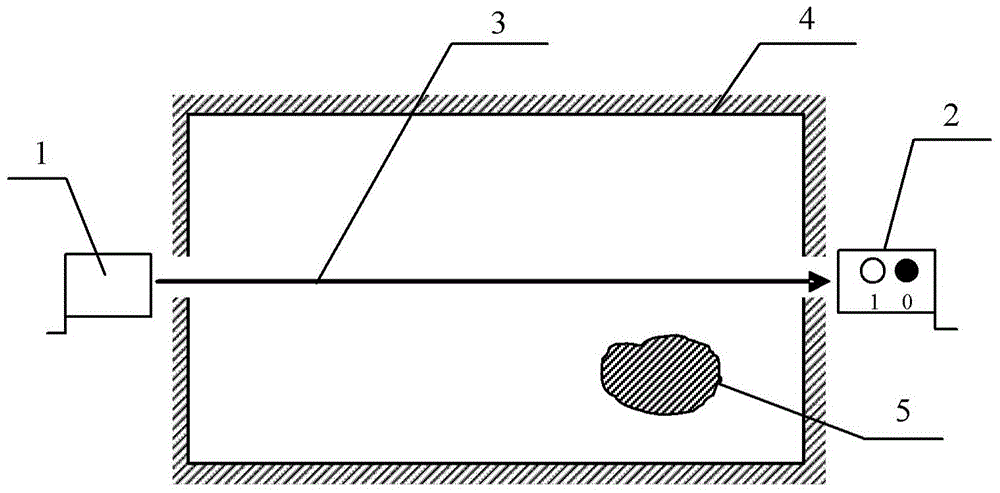

Object passing detecting system and method thereof

The invention discloses an object passing detecting system and a method thereof. The object passing detecting system comprises a photoelectric switch and reflectors which are correspondingly arranged at opposite-side frames of a detecting area. The light which is transmitted from the transmitting end of the photoelectric switch is repeatedly reflected through the reflectors that are correspondingly arranged, thereby forming W-shaped light which covers the detecting area and is received by the receiving end of the photoelectric switch. The object passing detecting system can improve accuracy in object passing detection. The object detecting system has advantages of simple structure, low cost, least number of photoelectric switches, and stable and reliable detecting signal.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

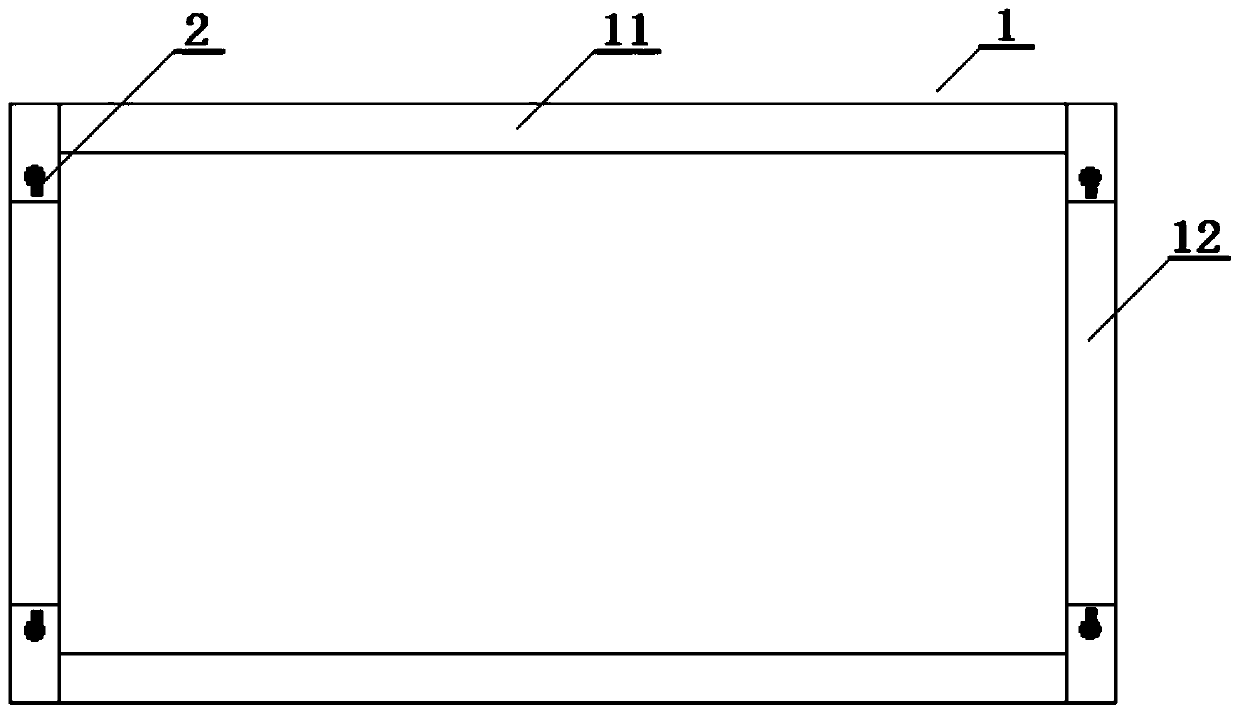

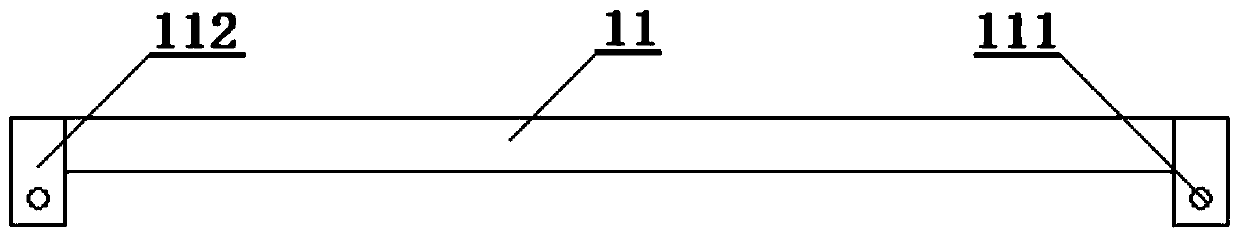

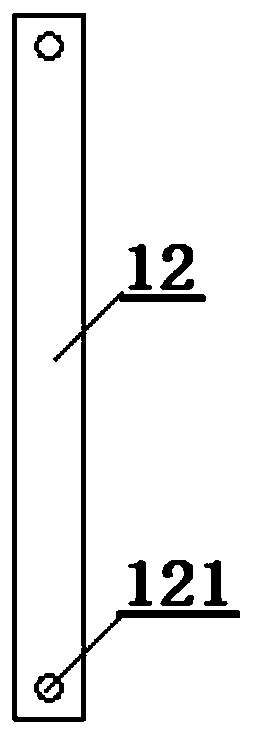

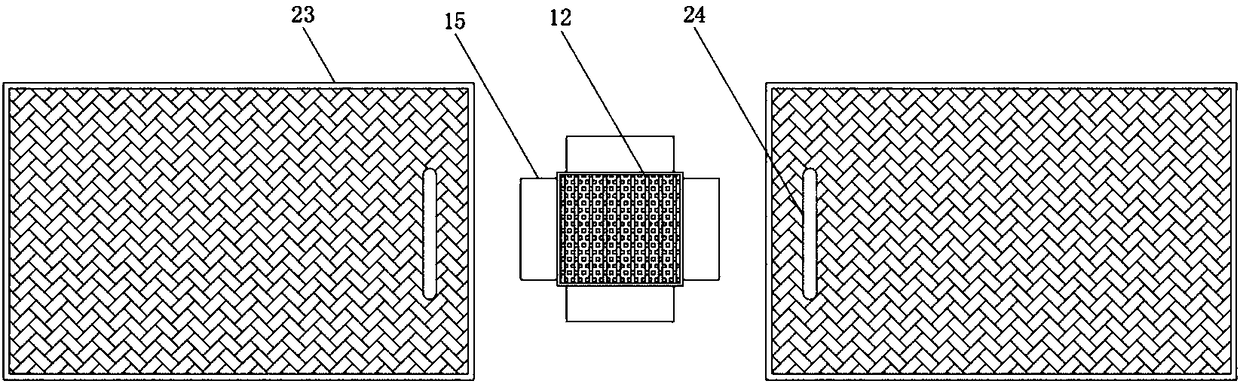

Convenient mounting and dismounting type combined prefabricated template suitable for building floor descending plate

PendingCN111535581AWon't breakImprove stabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringSteel frame

The invention relates to a convenient mounting and dismounting type combined prefabricated template suitable for a building floor descending plate. A main body comprises a template frame formed by mutually connecting the end parts of a combined transverse steel frame plate and a vertical steel frame plate which are prefabricated by square steel plates, and limiting plug pins, a twisted steel bar serves as the limiting plug pins, interconnecting plates with limiting plug pin holes A are fixedly arranged at the two ends of the transverse steel frame plate, limiting plug pin holes B are formed inthe plate faces of the two near ends of the vertical steel frame plate, the limiting plug pins are correspondingly inserted into the limiting plug pin holes A and the limiting plug pin holes B to form a stable steel template, deformation is avoided, limiting is reliable, grout leakage can be avoided, after curing and forming, bonding and interconnection are avoided, corners of concrete are not damaged during template dismounting, the forming precision can be ensured, repairing and chiseling work in the later template dismounting period is avoided, the dismounted template can be recycled, andthe defects that in the prior art, a template is poor in stability and forming effect, the quality is difficult to guarantee, the size deviation is large, the construction cost is high and the like are overcome, and high practicability is achieved.

Owner:CHINA RAILWAY CONSTR ENG GROUP

Active curing glue

InactiveCN103087657AHigh viscosityLow requirements for applicable spaceLatex adhesivesUnsaturated alcohol polymer adhesivesSodium stearateEmulsion

The invention discloses active curing glue which comprises water, polyvinyl alcohol, white emulsion, sodium stearate, and talcum powder, and is characterized in that the curing glue also comprises an active curing agent. The active curing glue of the invention has good viscosity, can be applied in various different ways such as pouring, smearing, and the like, has low requirements for application space, can be used at narrow places or gaps, can maintain stability when not used, and has no leakage or spilling phenomena.

Owner:于兰荣

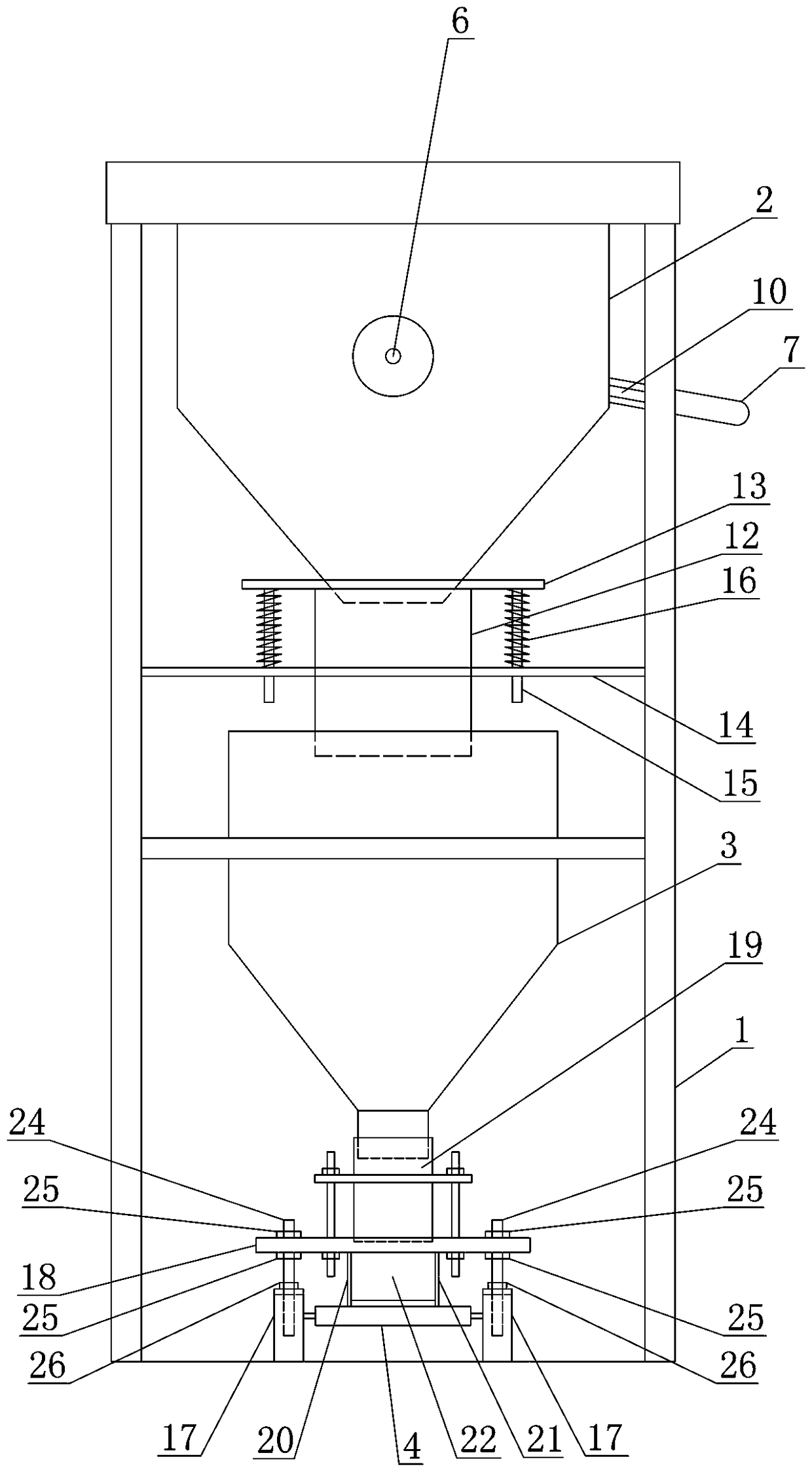

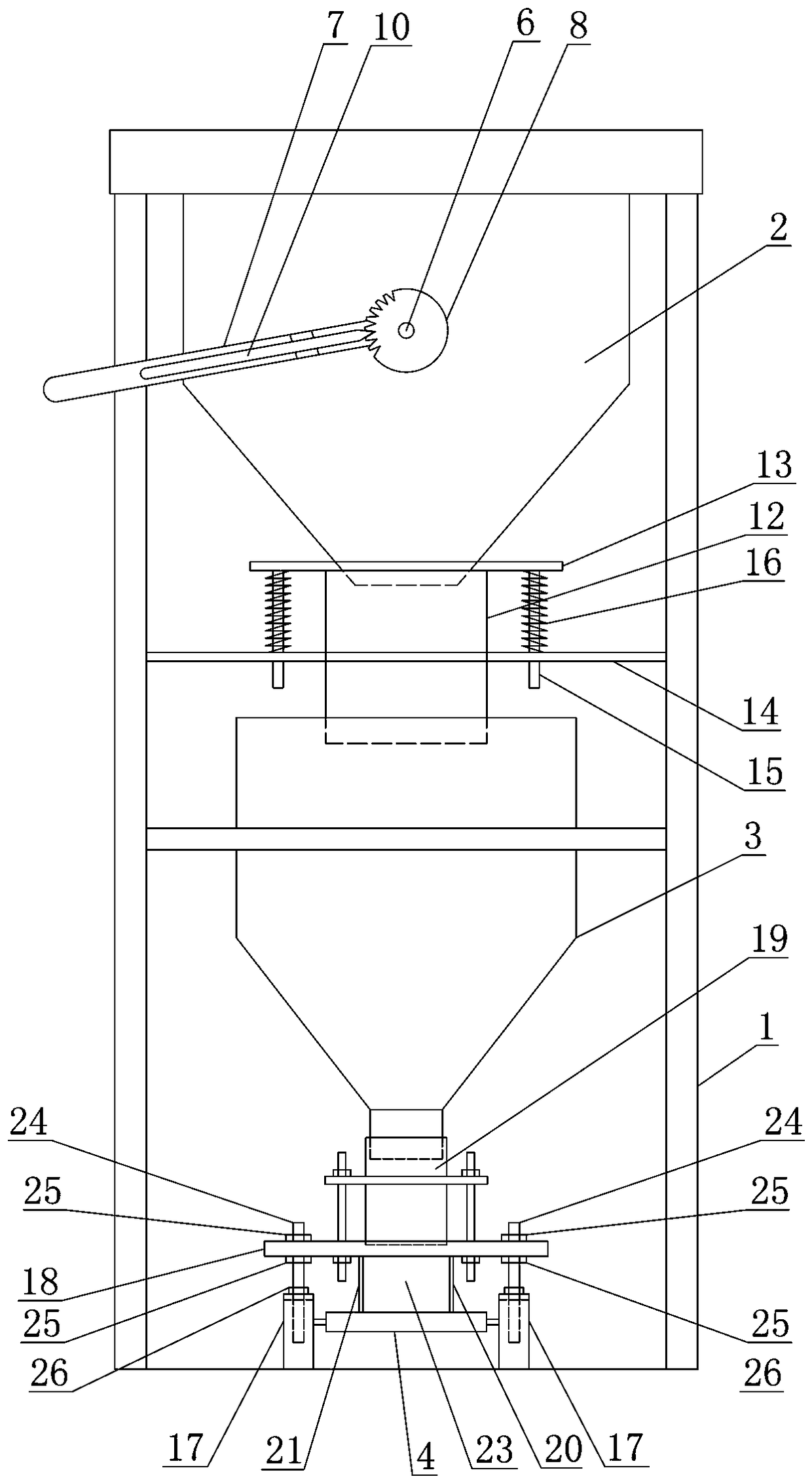

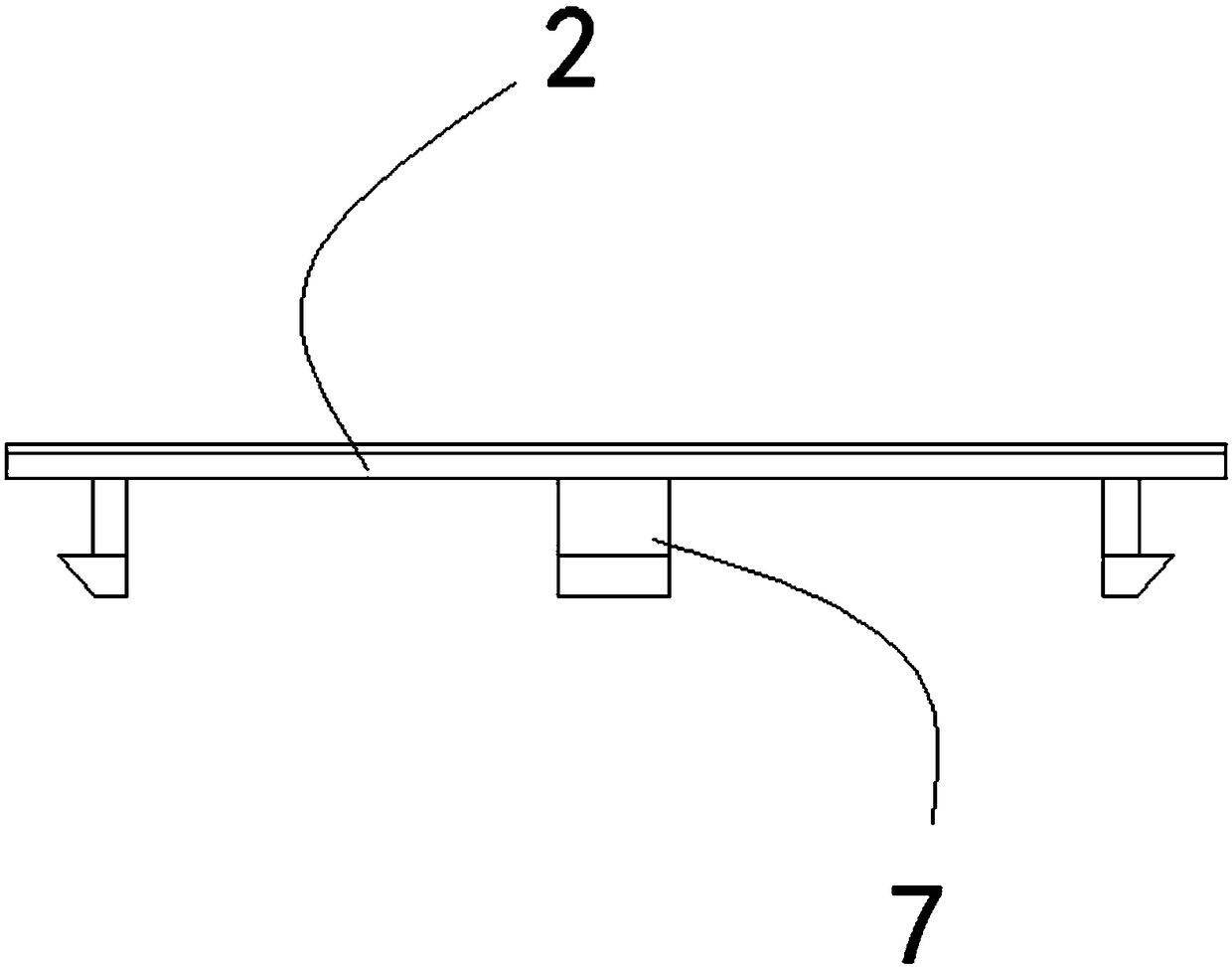

Feeding device in wire welding machine

PendingCN108584364AEffectively control the amount of feedingControl the feeding amountConveyor partsEngineeringWelding

The invention discloses a feeding device in a wire welding machine. The feeding device comprises a rack; the rack is internally provided with an upper hopper; a discharging adjusting valve for controlling the opening degree of a discharging outlet of the upper hopper is arranged in the upper hopper; a lower hopper is arranged at the position, below the upper hopper, of the rack; the discharging outlet of the upper hopper is connected with a feeding inlet of the lower hopper through a telescopic connection casing pipe assembly; a conveying belt is arranged at the position, below a discharging outlet of the lower hopper, of the rack, and is used for bearing powder conveyed out by the lower hopper and conveying the borne powder to a channel steel belt pulled by a forming unit of the wire welding machine and rolled to be provided with a U-type section; and a guide assembly for smoothly guiding the powder output by the lower hopper to the conveying belt is arranged at the position, betweenthe lower hopper and the conveying belt, of the rack. The feeding device in the wire welding machine has the advantages that (1) the discharging amount of the powder can be effectively controlled, andcontrol and adjustment are convenient; and (2) the powder can be smoothly guided to the conveying belt and does not leak when discharged to the conveying belt, powder waste is reduced, and the production cost of enterprises is effectively reduced.

Owner:JIANGSU XINZHOU WEAR-RESISTANT TECH CO LTD

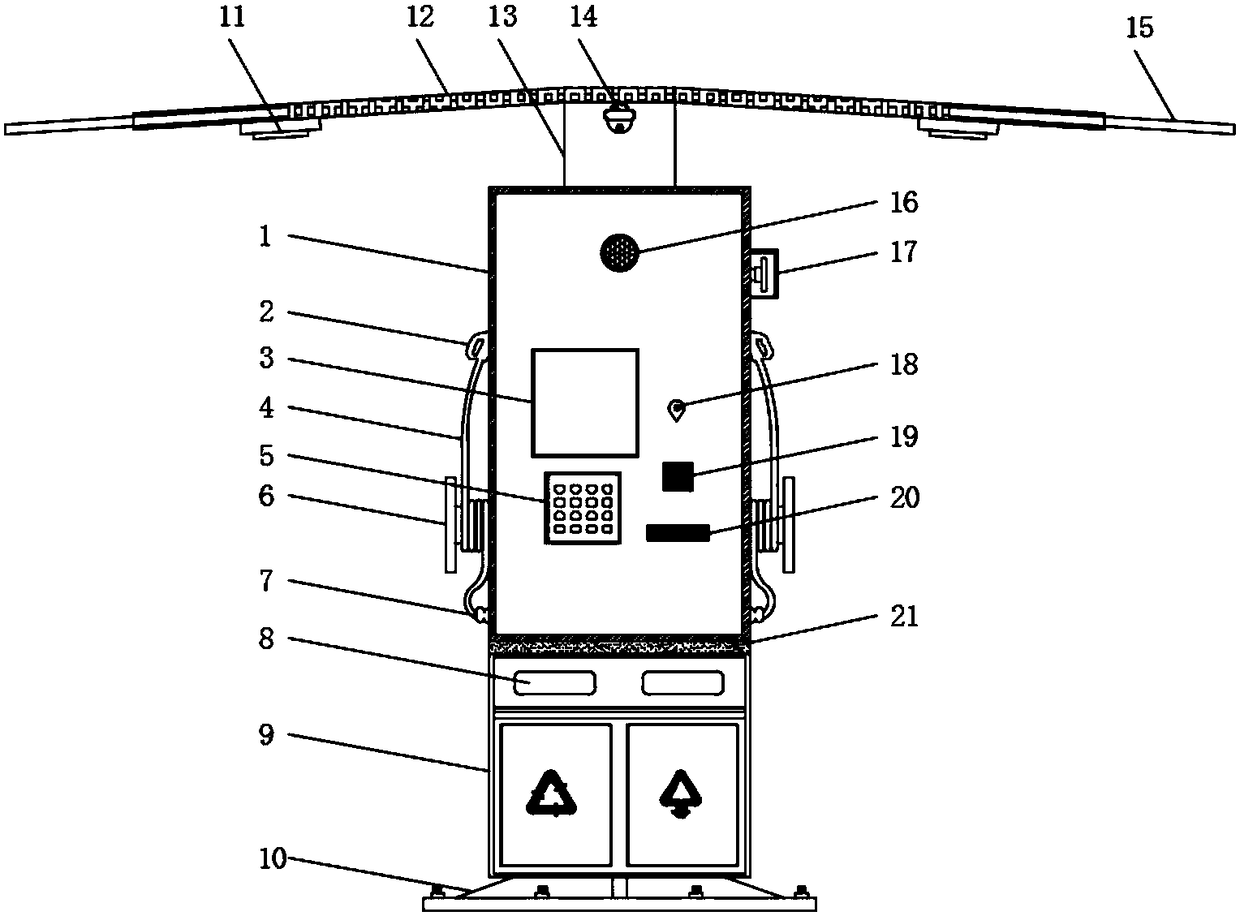

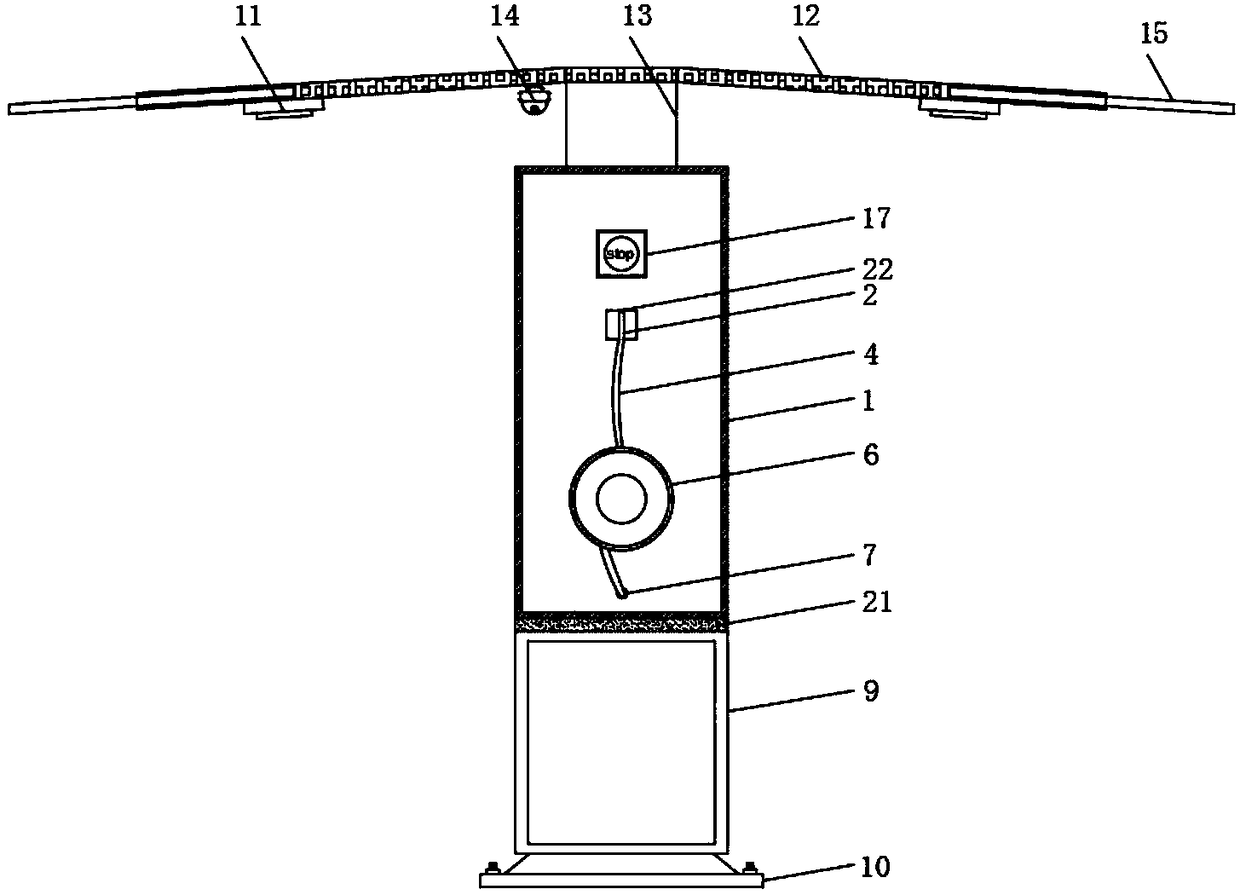

Sharing charging device provided with waterproof function and used for new energy automobile

InactiveCN108583351AProtect charging safetyGuaranteed aestheticsPhotovoltaic supportsCharging stationsInsulation layerNew energy

The invention discloses a sharing charging device provided with a waterproof function and used for a new energy automobile. The sharing charging device comprises a charging device body and a dustbin.The bottom of the dustbin is connected with a fixed base. An insulation layer is arranged at the top of the dustbin. A charging device body is installed at the top of the insulation layer. Wire outgoing ports are formed in the bottom of the surface of the side edges of the charging device body and connected with charging guns through charging wires. A voice broadcasting device is installed on theupper portion of the surface, perpendicular to the sides of the wire outgoing ports, on the other side of the charging device body. The sharing charging device is provided with the dustbin and the insulation layer, garbage generated in the charging rest process can be classified and collected, the environment is protected, urban environment beauty is guaranteed as well, the charging device body islocated at the top of the dustbin, rainwater invasion can be effectively insulated, a short circuit phenomenon happening to the device is avoided, and meanwhile, an electric leakage phenomenon is avoided.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

Garbage truck for municipal environmental sanitation cleaning

The invention discloses a garbage truck for municipal environmental sanitation cleaning. The garbage truck is characterized in that the upper part of a garbage can is opened, the bottom of the garbagecan is fixedly connected to a truck frame, the front part of the two sides of the truck frame are rotationally connected to side wheels in a bearing mode respectively, a driving wheel is arranged above the rear part of the truck frame, and the driving wheel is fixedly connected to the middle of the driving shaft; the upper part of the driving wheel is fixedly connected to a control rod, a cam isarranged behind the bottom of the garbage can, the cam is fixed to the center of a cam shaft, the two sides of the cam are provided with chain wheels respectively, and the chain wheels are fixedly connected to the cam shaft; the two sides of the driving wheel are also provided with chain wheels, and the chain wheels on the driving shaft and the two chain wheels on the cam shaft are correspondinglyconnected to each other through chains; a bottom plate is arranged below the garbage can, the lower surface of the front part of the bottom plate is hinged to the bottom of the garbage can, the lowersurface of the rear part of the bottom plate abuts against the cam, and a tail cover is arranged at the front part of the garbage can; and the upper end of the tail cover is rotationally connected tothe upper part of the front part of the garbage can, the two sides of the upper part of the tail cover are rotationally connected to the upper ends of connecting rods respectively, and the lower endsof the connecting rods are connected to the two sides of the bottom plate in a rotating mode.

Owner:HENAN YIXIANG SPECIAL VEHICLE

Drawable socket

InactiveCN104332754AFree to adjust the lengthIngenious structureCouplings bases/casesEngineeringPositioning system

The invention discloses a drawable socket, which includes an electric wire, and is characterized by including a socket body, a pulling plate seat, a pulling plate, first positioning teeth, a rotary knob, positioning plates, second positioning teeth and a spring tube, wherein the socket body includes a first socket body and a second socket body, the pulling plate seat is positioned at the bottom end in the first socket body and are connected with the same by gluing, the first positioning teeth are successively arranged from left to right, the rotary knob is positioned on the side wall of the outer side of the first socket body and connected to the pulling plate by gluing, the positioning plates are positioned on two sides of the bottom end in the second socket body, the second positioning teeth are positioned at the tops of the positioning plates and successively arranged from left to right, the spring tube is positioned between the first and second socket bodies, and the spring tube, the first socket body and the second socket body are connected by a snap joint. The socket is ingenious in structure and strong in function, and can avoid consumption in usage of the socket due to the fact that the sockets interfere with one another when an electric appliance socket outlet is oversized.

Owner:CHIZHOU YICHUANG ELECTRONICS TECH

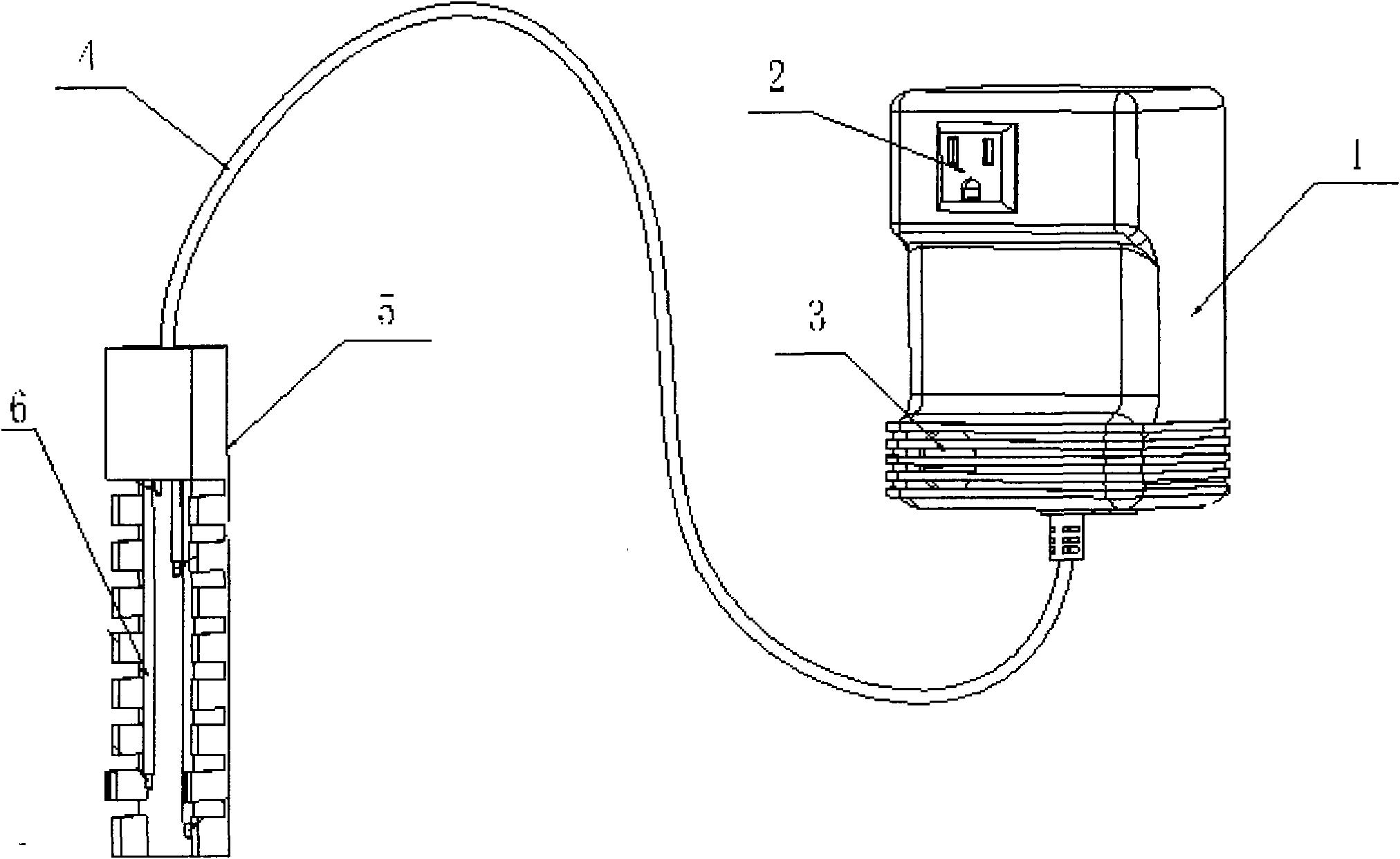

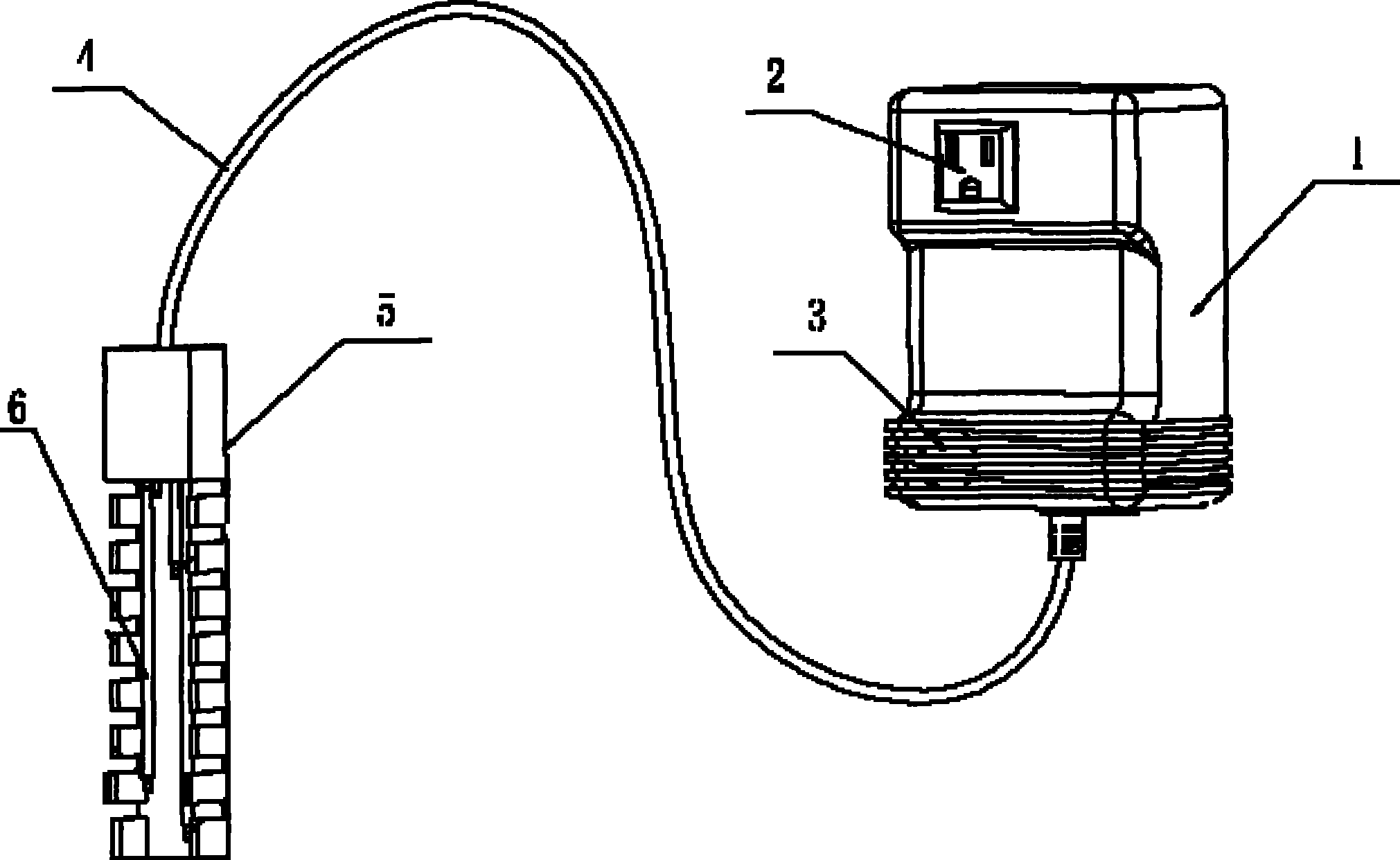

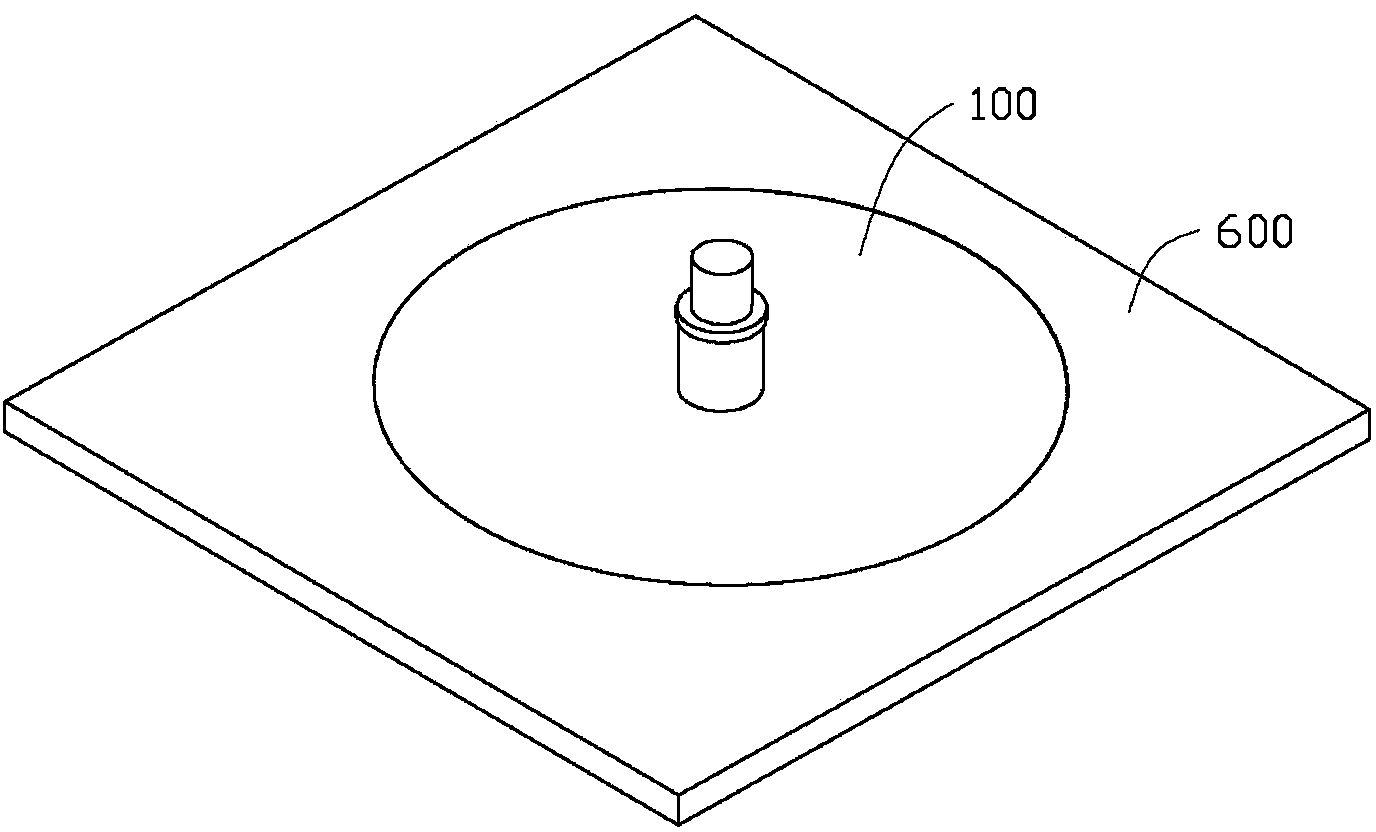

Coil induction type contact member

InactiveCN101458988AConvenience guaranteedLeakage will not occurTransformers/inductances coils/windings/connectionsFixed transformersElectrical resistance and conductanceSocial benefits

A coil induction type contactor comprises a hole contactor (1) and a pin contactor (2), which is characterized in that the hole contactor (1) and the pin contactor (2) of the coil induction type contactor adopt physical insulation, and transmit energy via electromagnetic induction. The coil induction type contactor can be applied in the field that general electric connector can not confirm required insulation resistance under moist environment, and the electrified separation of the hole contactor (1) and the pin contactor (2) in water will not lead electric leakage, thereby confirming people safety and convenient application. The coil induction type contactor has wide application range, significant economic and social benefits.

Owner:沈阳兴华航空电器有限责任公司

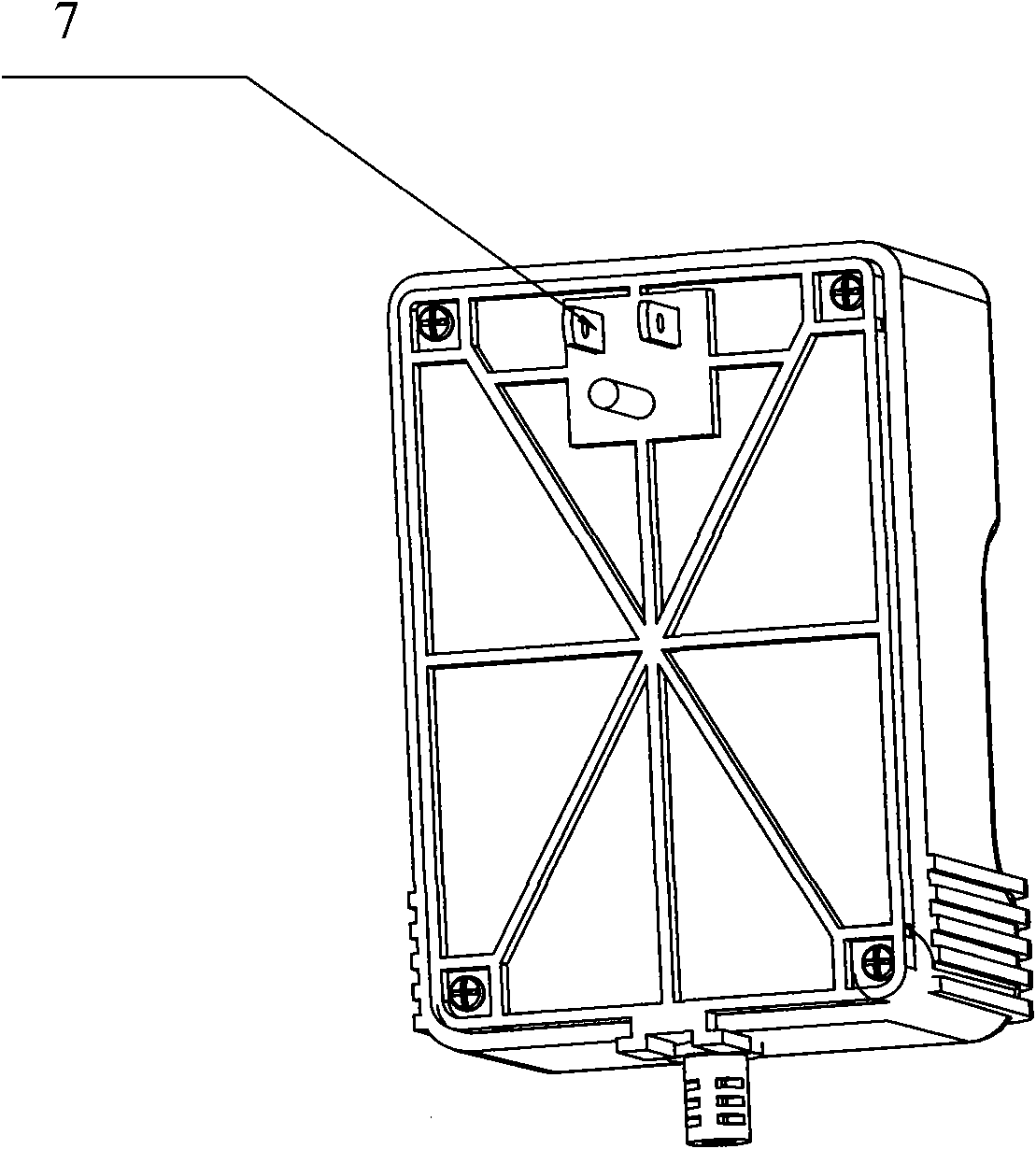

Split structure of probe and switch box

The invention discloses a split structure of a probe and a switch box. The split structure comprises the probe and the switch box which are connected with each other by an electric wire; the front surface of the switch box is provided with a three-hole plug; the back surface is provided with a three-core plug; a buzzer is arranged on the switch box; and the probe is arranged in the probe box. Due to the adoption of the split structure of the probe and the switch box, the switch box is far away from a water resource, a creepage phenomenon is avoided, a seal structure does not need to be adopted, resources are saved, manufacturing cost is reduced and benefits are increased.

Owner:GP ENTERPRISES CO LTD

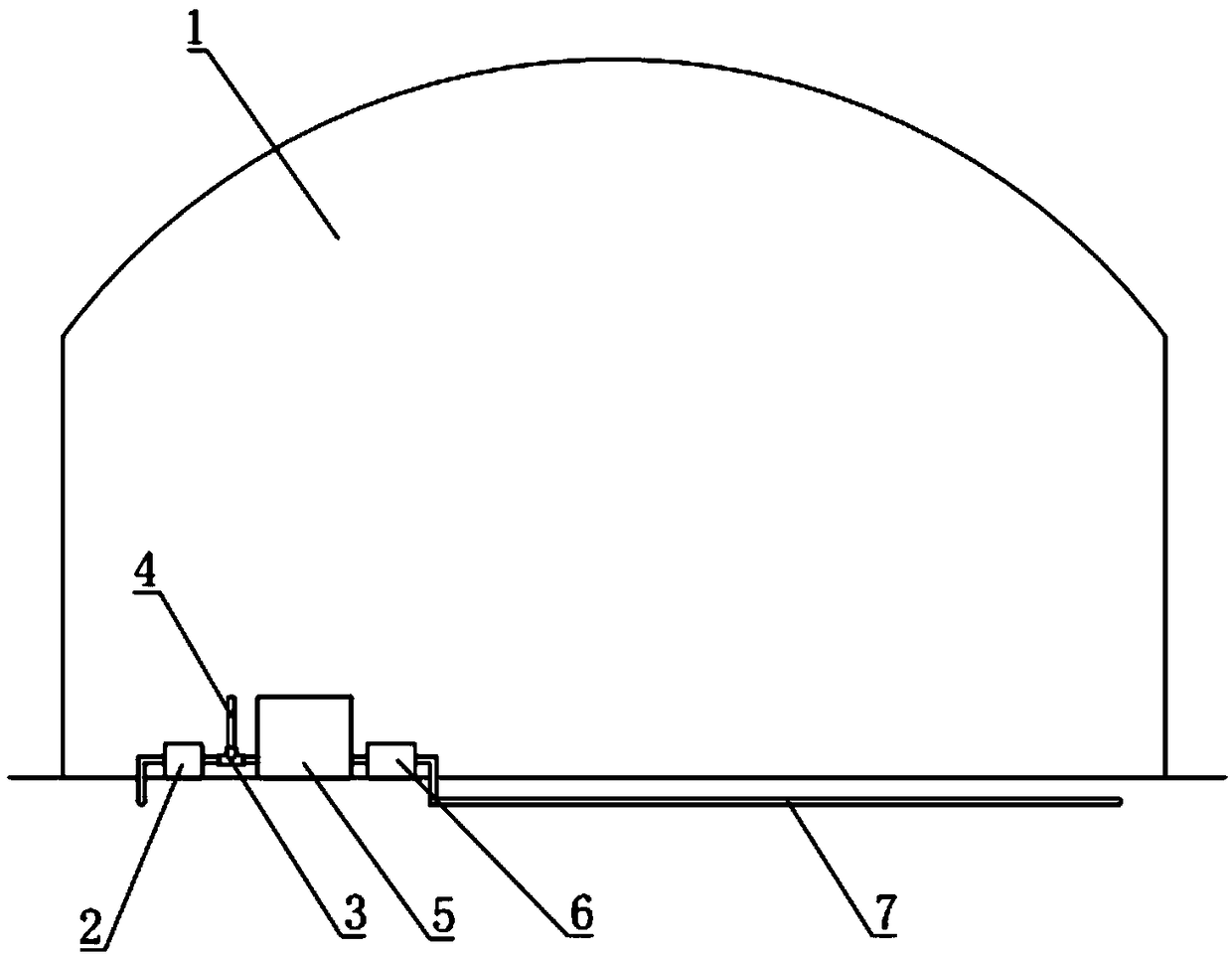

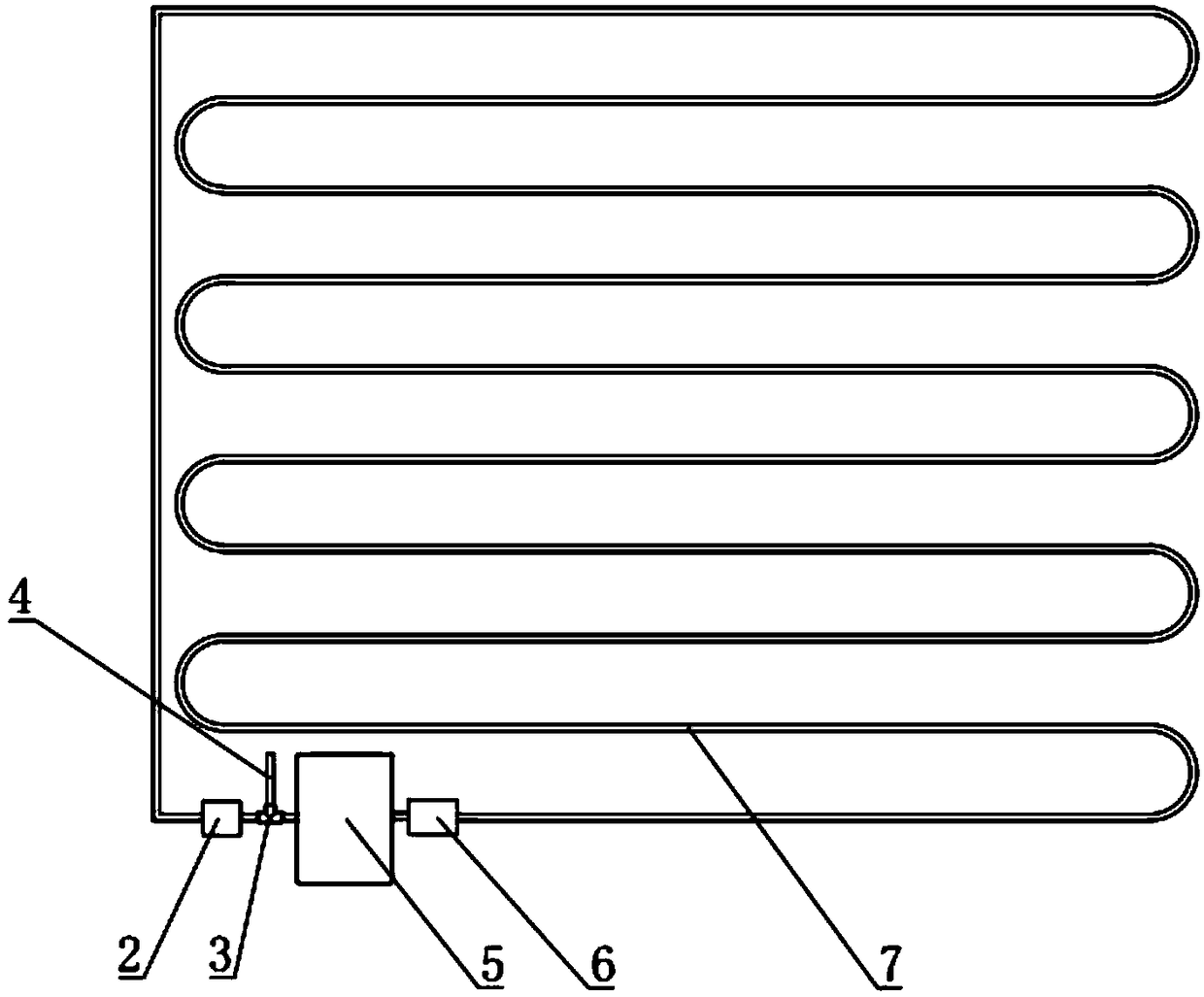

Greenhouse heating device

InactiveCN109220409AIncrease temperatureImprove germination rateClimate change adaptationGreenhouse cultivationGreenhouseCooling coil

The invention discloses a greenhouse heating device. The device comprises a greenhouse and a heating system, a temperature sensor is arranged in the greenhouse, and the heating system comprises a heater, a water tank, a water pump and a cooling coil, wherein a temperature sensor is arranged at an inlet of the heater, an inlet of the water tank is connected with an outlet of the heater, a temperature sensor is arranged at an outlet of the water tank, a water level sensor is arranged in the water tank, an inlet of the water pump is connected with an outlet of the water tank, the cooling coil isinstalled under the ground of the greenhouse, an inlet of the cooling coil is connected with an outlet of the water pump, and an outlet of the cooling coil is connected with the inlet of the heater. According to the greenhouse heating device, the cooling coil is installed under the ground in the greenhouse, an existing terrestrial heat line can be replaced, planting soil in the greenhouse is heated, the temperature of the soil is raised, and growth of crops is promoted. The heating system is simple in structure, in the cooling coil, water serves as a heat-carrying medium, leakage cannot occur,safety and reliability are achieved, environmental friendliness is achieved, and pollution does not exit.

Owner:TIANE HONGCHANG AGRI MACHINERY SPECIALIZED COOP

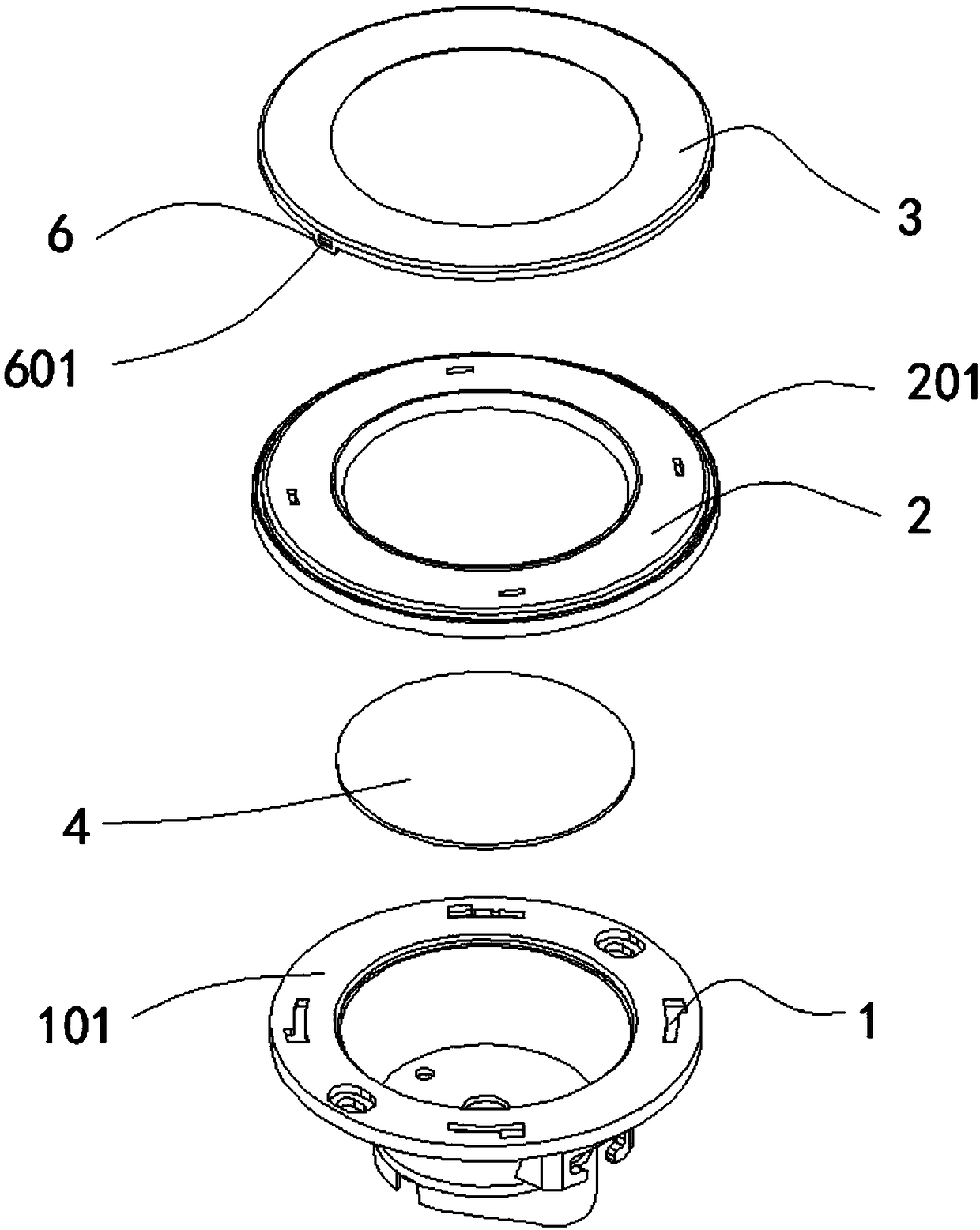

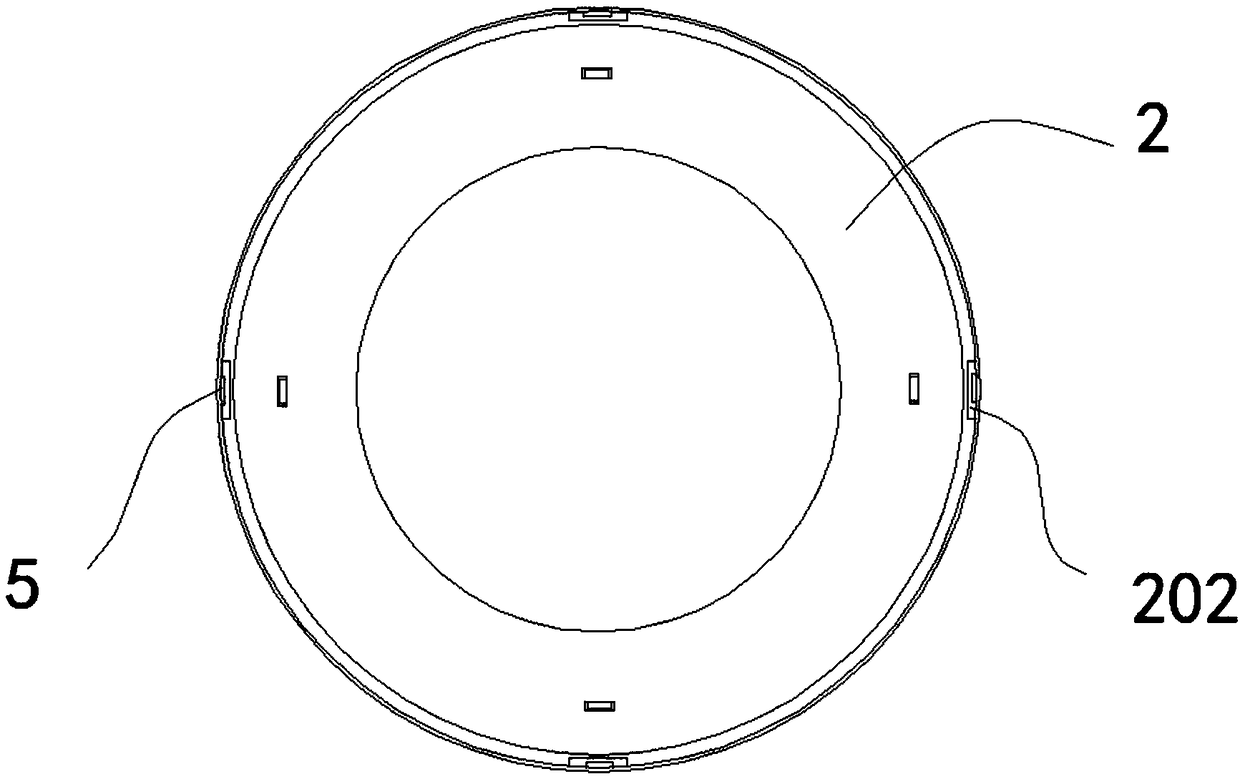

LED downlight with good insulation

PendingCN108087798AGood insulationImprove securityLight fasteningsSemiconductor devices for light sourcesEngineeringSlide plate

The invention relates to the technical field of downlights and provides an LED downlight with good insulation. The LED downlight with good insulation comprises a light holder made of a mirror face aluminum sheet. The top of the light holder is provided with an insulation plate in a coordinating manner. The top of the insulation plate is fixedly connected with a metal frame in a clamped manner. Theexterior of the light holder is connected with a shell in a coordinating and clamping manner. The shell is fixedly provided with a rapid mounting and dismounting structure. The rapid mounting and dismounting structure comprises an arc-shaped plate, arc-shaped shells and a sliding plate. The arc-shaped shells are symmetrically fixed to the shell, the arc-shaped plate is clamped into the arc-shapedshells in a sliding manner, the inner wall of the top of the arc-shaped plate is connected with the inner wall of the top of the arc-shaped shells through a spring, and the bottom of the arc-shaped plate is provided with a sliding groove. The high-safety LED downlight with the metal frame is provided, and the problem that a downlight in the prior art is not convenient to mount or demount on a suspended ceiling is solved.

Owner:中山市五安光电科技有限公司

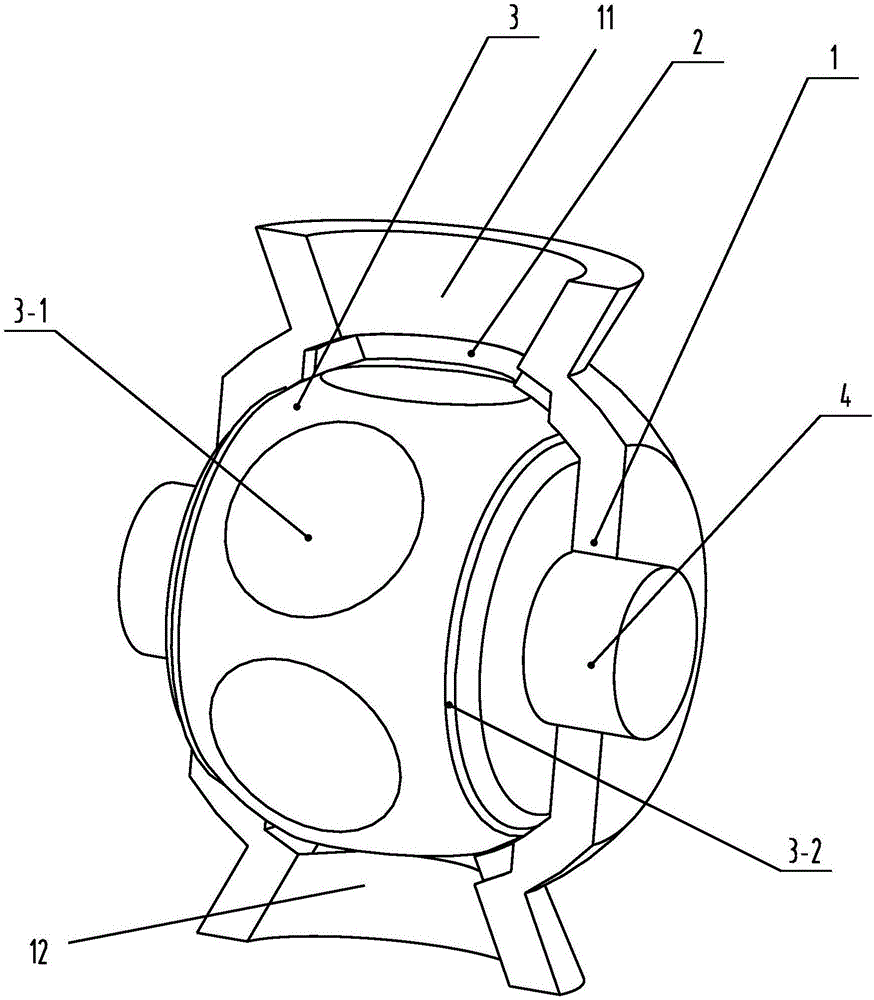

Full-sealed discharge valve

PendingCN106697811AEasy feedingLeakage will not occurPlug valvesRotary conveyorsDrive shaftEngineering

The invention discloses a full-sealed discharge valve, comprising a shell provided with a feed port and a discharge port; a valve body rotatably arranged in the shell and provided with storage devices; a drive shaft on which the valve body is installed and which is supported on the shell rotatably, when the shell is driven by the drive shaft to rotate in the shell till a certain storage device is corresponding to the feed port, materials fed from the feed port are received by the storage device; when the shell is driven by the drive shaft to rotate in the shell till the storage device is corresponding to the discharge port, the materials received by the storage device are fed into the discharge port; a bushing arranged between the valve body and the shell, a feed corresponding hole communicated with the feed port and a discharge corresponding hole communicated with the discharge port are arranged on the bushing, and the storage device is fully covered by the bushing except for the feed corresponding hole and the discharge corresponding hole in the rotating process of the shell. The full-sealed discharge valve disclosed by the invention has good sealing performance, so that the materials are uneasy to leak.

Owner:弗格森输送机械(常州)有限公司

No-crushing elevator hopper

The invention discloses a no-crushing elevator hopper. The no-crushing elevator hopper comprises a ladder-shaped hopper body, wherein suspension pin bosses are arranged on two end side walls of the ladder-shaped hopper body. Suspension pins are respectively embedded in the suspension pin bosses. A clamp platform is arranged at the front end of the ladder-shaped hopper body. A strengthening flat A is arranged on a side wall of the ladder-shaped hopper body. A circular arc turning boss is arranged at one end of the strengthening flat A. A circular arc discharging boss A is arranged on a side wall, below the strengthening flat A, of the ladder-shaped hopper body. A stiffening beam is arranged between the circular arc turning boss and the circular arc discharging boss A. A guide limiting column is arranged on a side wall, on the same side with the strengthening flat A, of the ladder-shaped hopper body. The no-crushing elevator hopper has the advantages that two adjacent hoppers are in seamless connection, the triangular-prism-shaped clamp platform divides dropped materials into two adjacent hoppers, so that leakage of a gap between two adjacent hoppers is avoided, and the material is prevented from being grinded and broken. The no-crushing elevator hopper is simple in structure, convenient to maintain, low in manufacture cost and long in service life.

Owner:五原县金麦提升科技有限公司

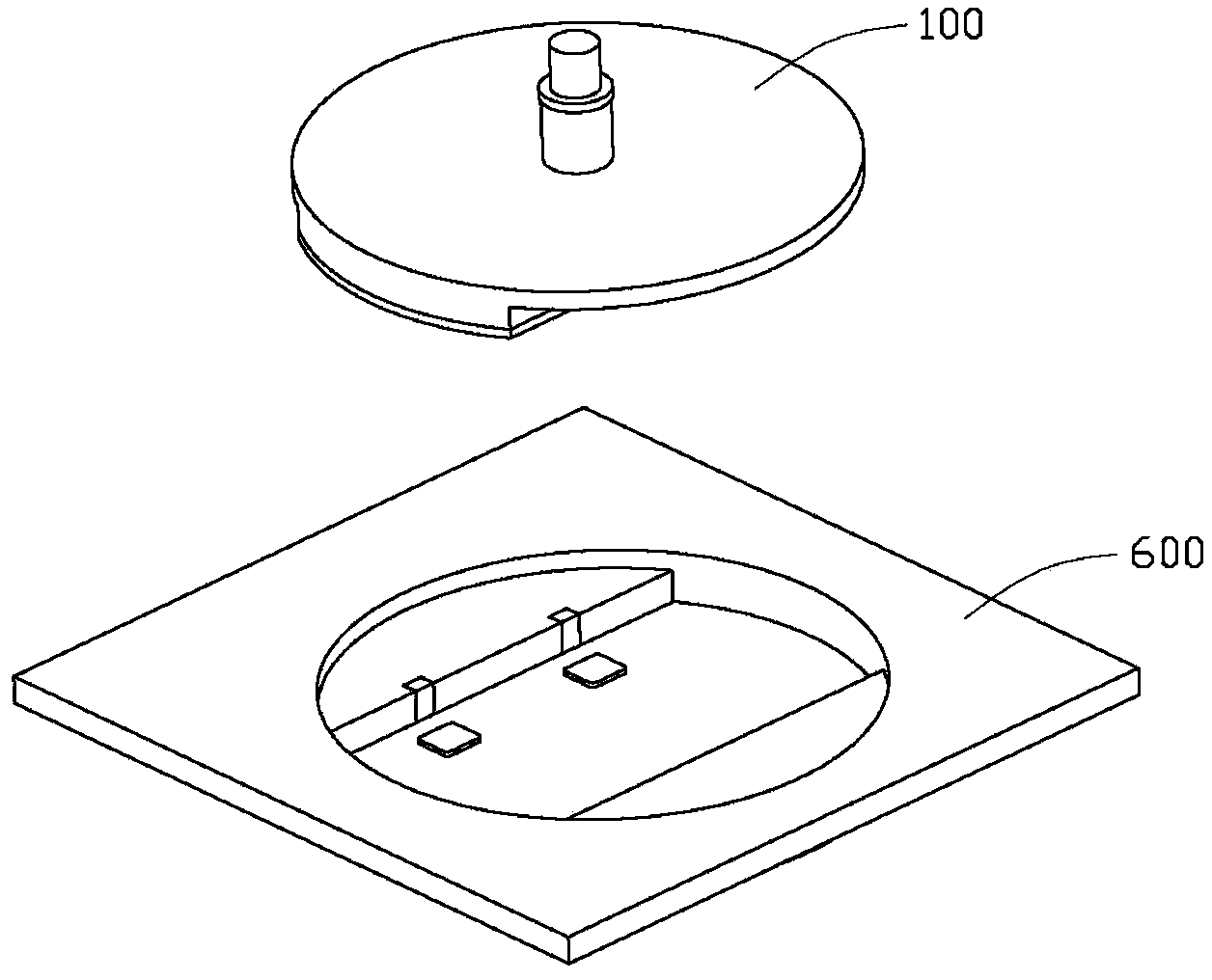

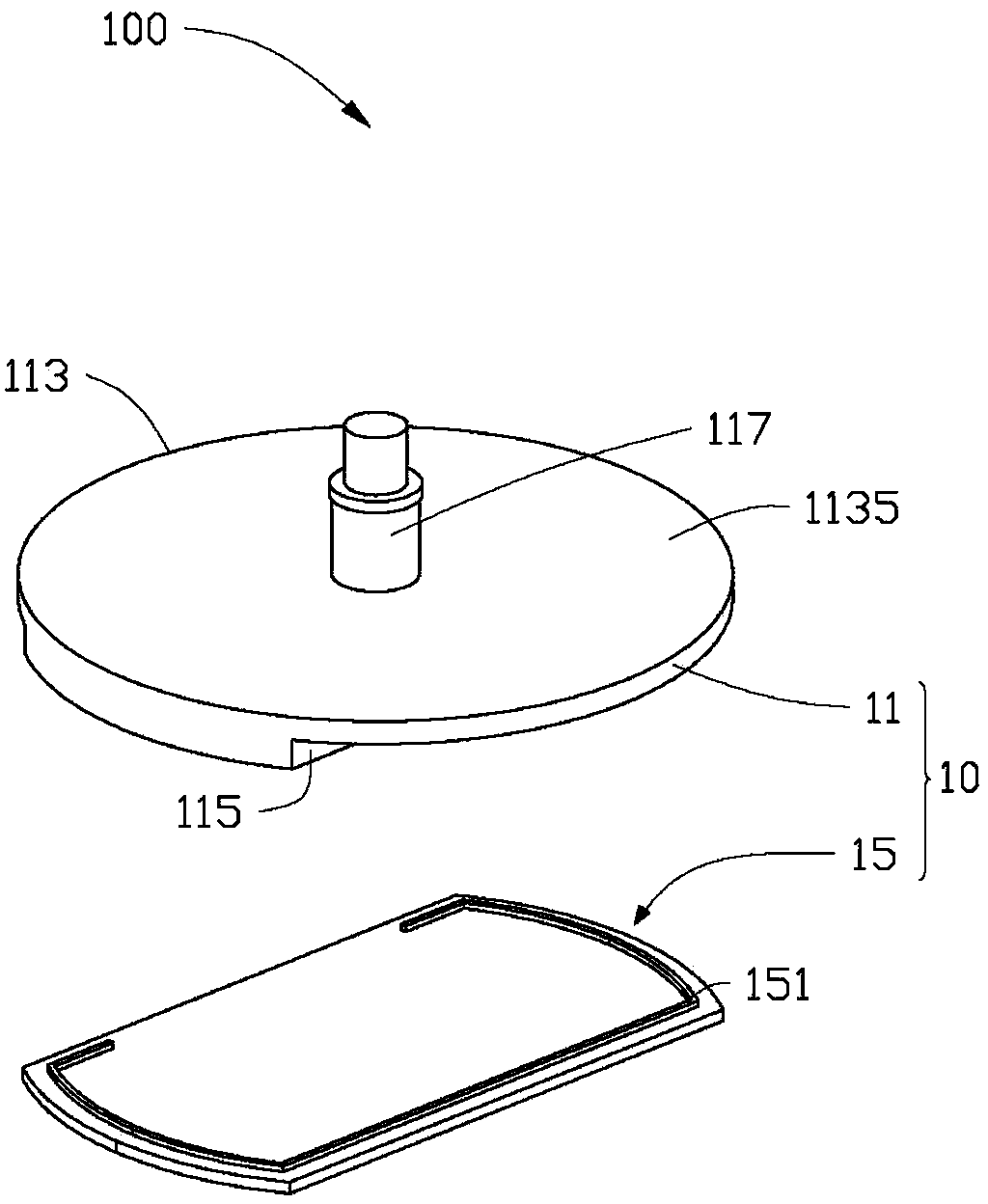

Power supply plug and power supply socket matched with power supply plug

InactiveCN102810777BAchieve electrical connectionLeakage will not occurCoupling contact membersTwo-part coupling devicesEngineeringMechanical engineering

An electronic device includes a power plug and a power socket coupled to the power plug. The power plug includes a housing, two plug contacts, one conductive member, two conductive resilient pieces, and two magnetic members. The conductive resilient pieces are positioned in the housing, and are electrically connected to the conductive member. The magnetic members are positioned in the housing, and opposite to the at least two conductive resilient pieces. The power socket includes an inner housing, two socket contacts, and two metal pieces. The inner housing defines an assembly groove to receive the power plug. The metal pieces are positioned in the assembly groove of the inner housing, and are opposite to the magnetic members, such that a magnetic attraction force exerted between the metal pieces and the magnetic member actuates the power plug.

Owner:FU TAI HUA IND SHENZHEN +1

led lights

InactiveCN102261596ADetachable connectionImprove securityPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

The invention relates to an LED lamp, which has a lampshade and a casing, the lampshade and the casing are connected to each other to define a cavity, and the cooling fins are connected to the inner side of the lampshade or the casing, so that the cooling fins divide the cavity into a cooling cavity and a housing. A light-emitting chamber of a PCB board installed with LED lamp beads, wherein the PCB board is connected to the base plate of the heat sink, and the base plate is configured to have different heat dissipation at different parts of the base plate. The invention also relates to a heat sink and a modular housing for the LED lamp.

Owner:霸士电器(上海)有限公司

Box-type substation capable of eliminating hoisting shaking

InactiveCN112332263AEliminate lifting shakeAvoid bufferingAnti-seismic devicesWheel drivePower substation

The invention relates to the technical field of box-type substations, and provides a box-type substation capable of eliminating hoisting shaking, which comprises a box-type substation; a central fixedwheel is fixedly connected to the center of the box-type substation, and regulation and control frameworks are movably connected to the upper side and the lower side of the box-type substation through the central fixed wheel. The upper side and the lower side of the box-type substation are movably connected with extrusion frameworks through regulation and control frameworks, and the outer side ofthe box-type substation is movably connected with a hoisting rod through an extrusion framework. The box-type substation capable of eliminating hoisting shaking is limited through a hoisting ring buckle of a hoisting machine, the outer side of the hoisting rod and a limiting plate. When the hoisting device shakes in the air, the rotating wheel is driven to rotate through friction force, the rotating wheel drives the extrusion framework to move inwards to be matched, the rotating wheel rotates to push the movable rod to be connected with the clamping seat through the inserting plate, the clamping seat drives the pressing rod to move downwards to the two sides, and the clamping seat pushes the electrifying guide rod to be connected with a circuit below, so that the circuit is in a closed state.

Owner:朱帅

Three-dimensional memory readout circuit and its word line and bit line voltage configuration method

The invention provides a three-dimensional memory reading circuit and a word line and bit line voltage configuration method. The method comprises the following steps that: when a three-dimensional memory cell array is subjected to a reading operation, setting all bit lines in the three-dimensional memory cell array as reading unselect bit line voltage through a configuration module, setting all word lines in the three-dimensional memory cell array as reading unselect word line voltage; and after a pulse signal arrives, setting the bit line where a memory cell to be read is positioned as reading voltage Vread, and setting the word line where the memory cell to be read is positioned as 0V, wherein the reading unselect bit line voltage is between Vread / 2 and Vread, and the reading unselect word line voltage is between Vread / 2 and Vread. By use of the method, the voltage of two ends of a semi-gating unit on the bit line can be lowered, the chip of the three-dimensional memory has the advantages of lower power consumption, higher speed and no full-array electricity leakage during a reading operation, and the memory unit which is not selected on the selected word line still keeps semi-gating.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

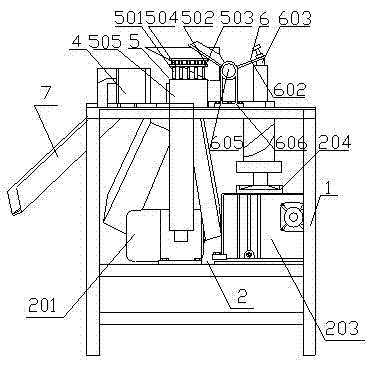

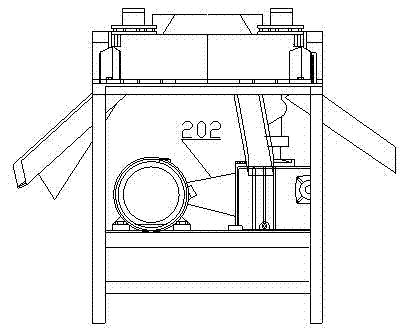

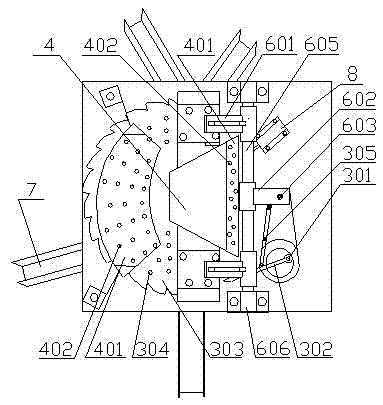

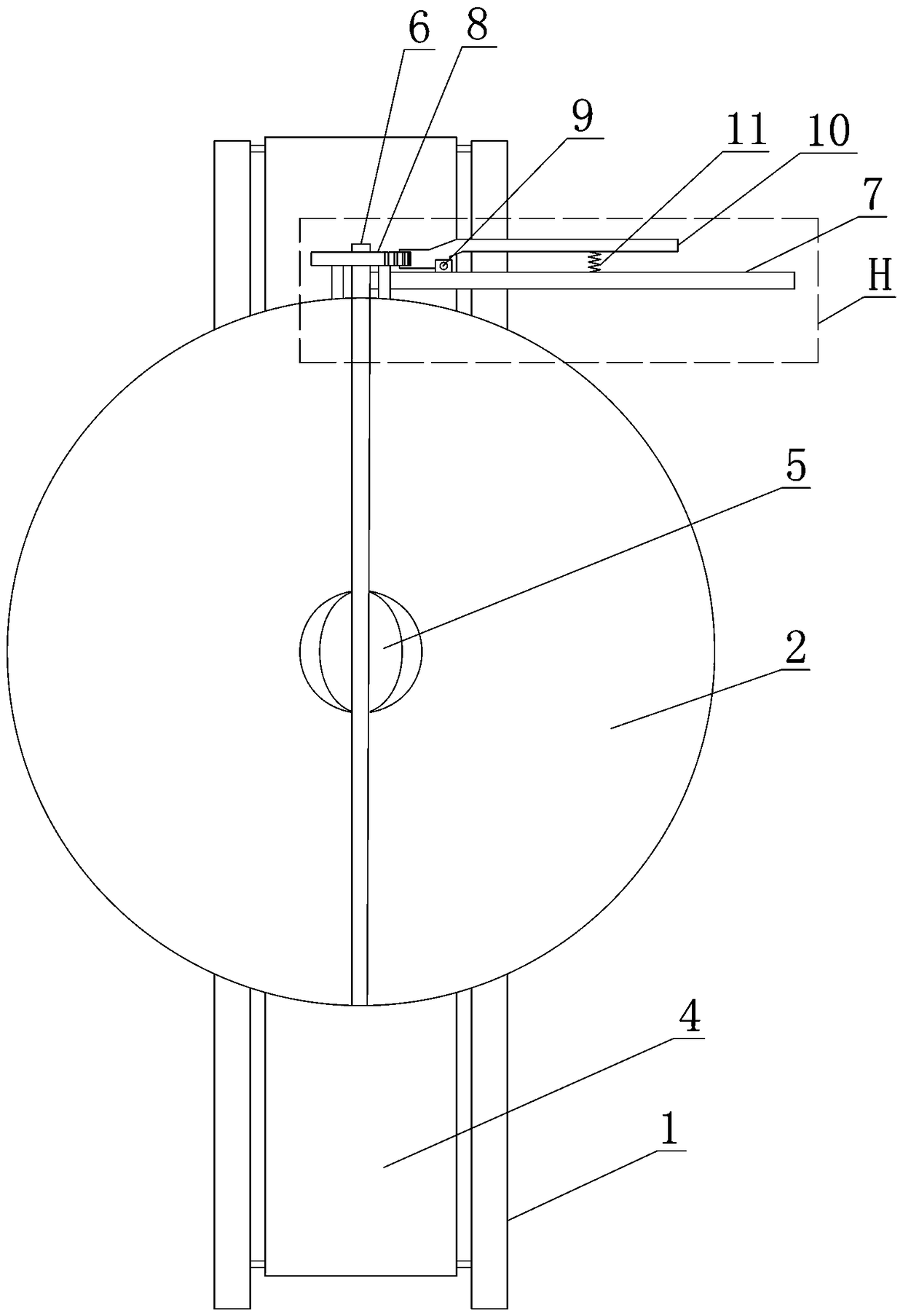

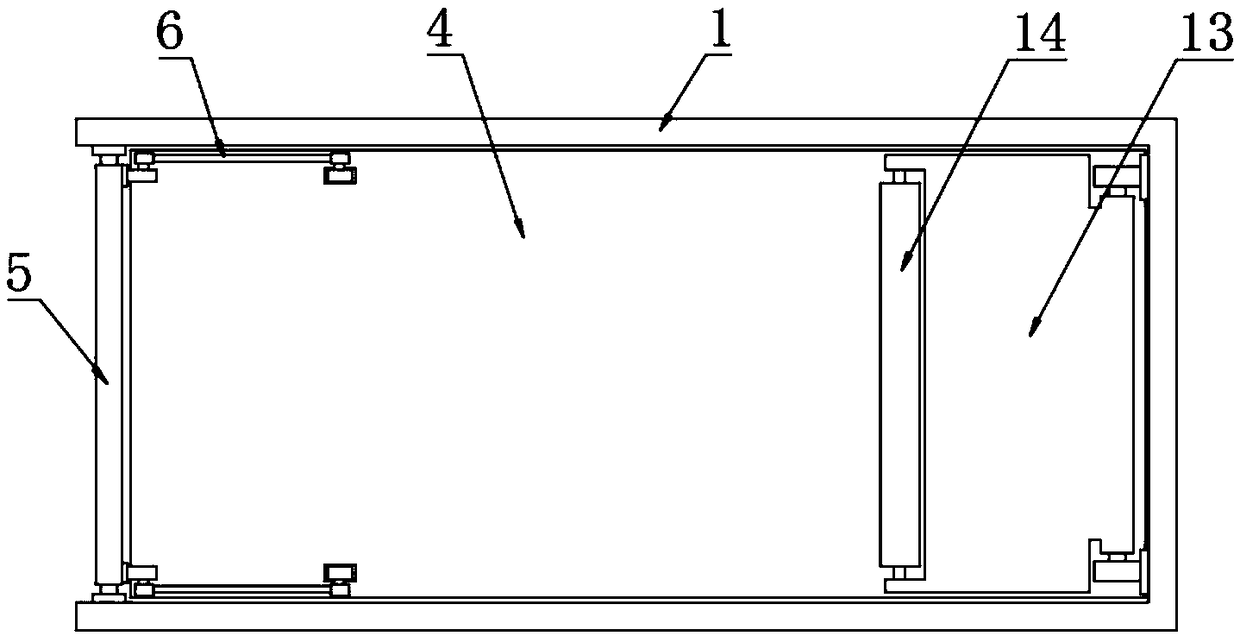

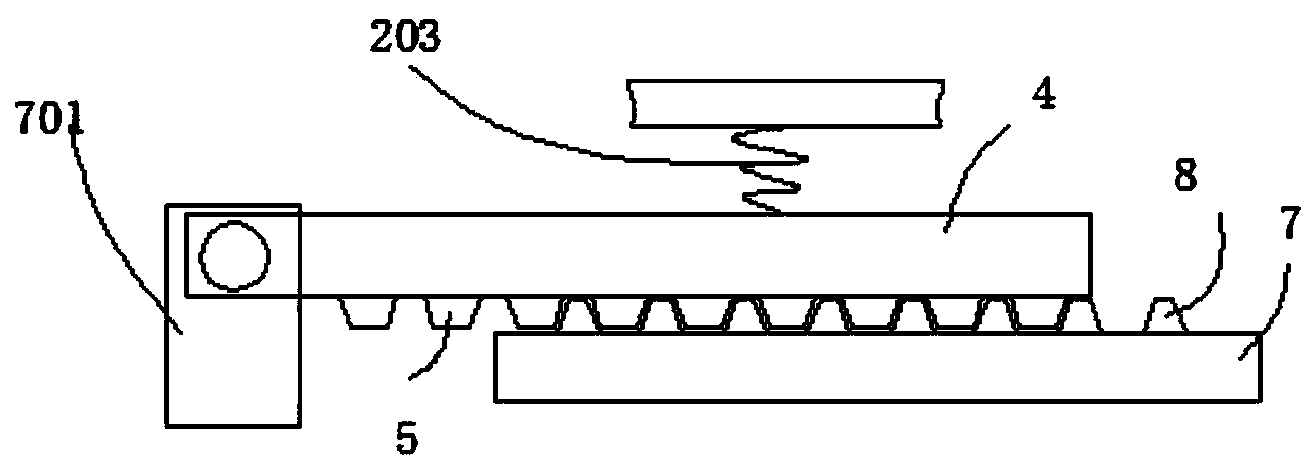

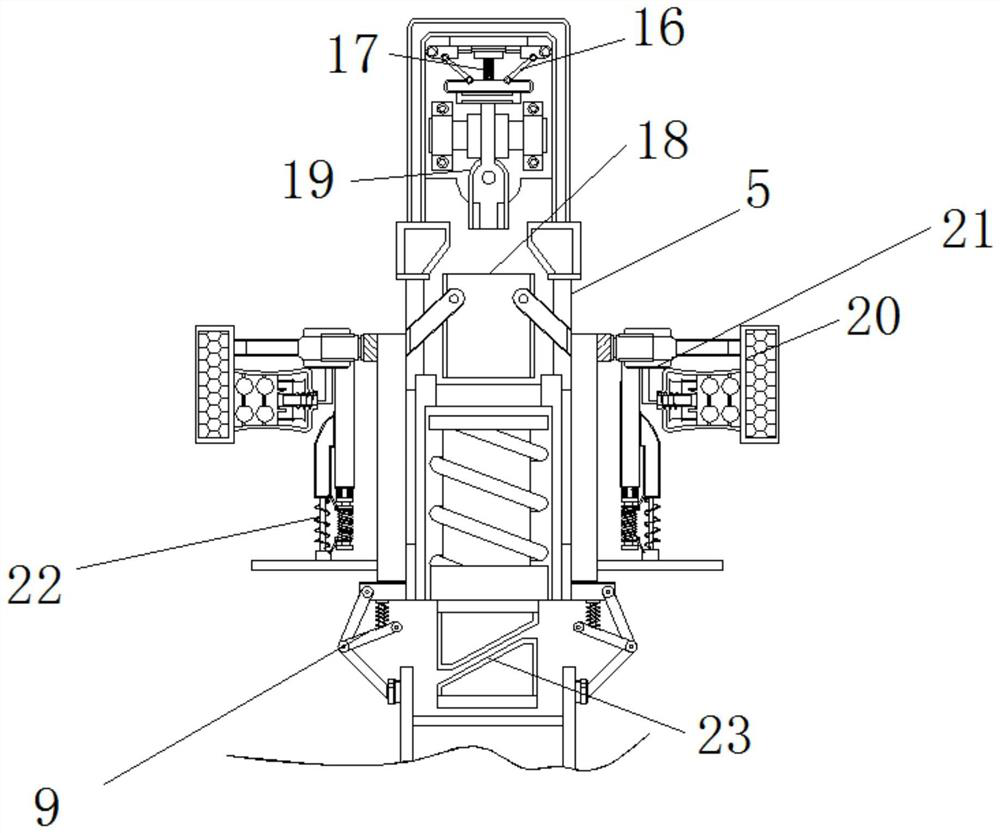

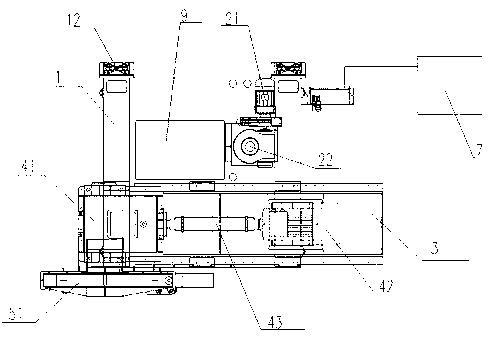

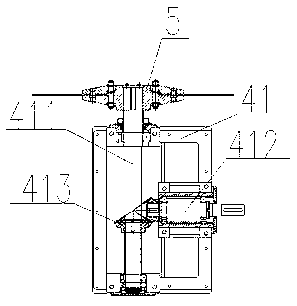

Cold sawing machine

ActiveCN102699425AGuarantee personal safetyLow costMetal sawing devicesMaintainance and safety accessoriesAgricultural engineeringLubrication

The invention discloses a cold sawing machine, which comprises a frame (1), wherein a transmission device (2) and a hydraulic station (9) are arranged on one side of the frame (1); a base (3) is arranged on the other side of the frame (1); a saw blade transmission device (4) is arranged on the base (3); a saw blade device (5) is connected to the saw blade transmission device (4); a lubrication oil station (7) is arranged outside the frame (1); and the lubrication oil station (7) is connected with the frame (1) through a drag chain (8). The cold sawing machine is small in size, the transmission design is compact, bidirectional movable cutting can be realized, the cost is low, and damage to the personal safety of operator workers can be avoided.

Owner:JIANGYIN DADI EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com