Gorgon euryale seed husking machine and husking method

A Gorgon fruit peeling machine, shelling machine technology, applied in the direction of shelling, pod removal, food science, etc., can solve the problems of missing peeling, high peeling damage rate, high manufacturing cost, etc., to achieve stable and reliable manufacturing cost, nut kernel The effect of low damage rate and high peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

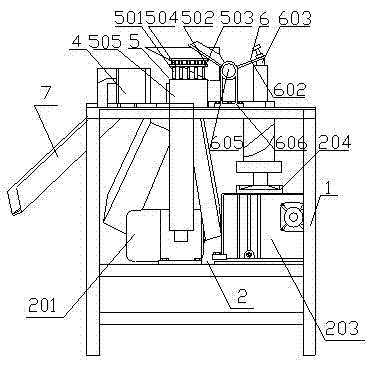

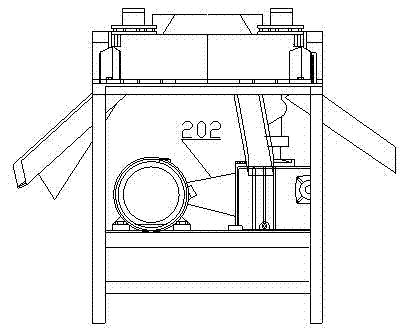

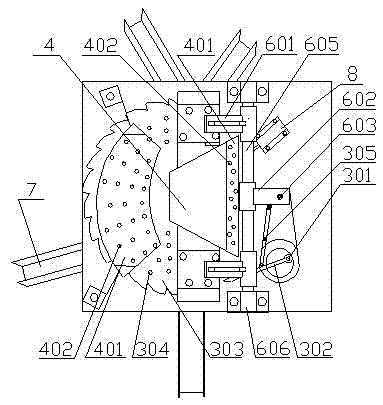

[0018] Embodiment 1: with reference to attached Figure 1-5 . A Gorgon shelling machine, comprising a frame 1, the output shaft of the power drive mechanism 2 located under the table of the frame 1 is connected to a convex fan-shaped wheel 204, and the convex fan-shaped wheel 204 is structurally designed with a raised middle and low sides Mountain-shaped structure; the lower end of the ratchet drive power input shaft 301 in the ratchet drive mechanism 3 is eccentrically fixed on the disc for fixing the convex sector wheel 204, and the front end of the ratchet drive rod 302 in the ratchet drive mechanism 3 is driven by the ratchet teeth in the ratchet wheel 303. Matching and used to drive the ratchet 303 to rotate, the edge of the ratchet 303 is provided with a stop device 8, the stop device 8 is actually a stop plate to prevent the ratchet 303 from retreating; the ratchet 303 is set on the central axis of the upper end surface of the frame 1 (The central axis is a fixed centr...

Embodiment 2

[0026] Embodiment 2: On the basis of Embodiment 1, a method for peeling the Gorgon fruit sheller, the Gorgon fruit nuts are poured into the mold hopper 4, because the ratchet wheel 303 on the central axis of the frame 1 table has multiple openings. A gorgon nut shell-breaking hole 304 corresponding to the template hole 402 at the bottom of the mold hopper 4, so the gorgon nuts in the mold hopper 4 naturally fall into the gorgon nut shell on the ratchet 303 surface through the template hole 402 in the mold hopper 4 In the hole 304, start the motor 201 at this time, and the motor 201 inputs power to the power input shaft of the reducer 203 through the transmission belt 202, and the output shaft of the reducer 203 drives the convex sector wheel 204 to rotate in a plane. The ratchet drive power input shaft 301 on the wheel 204 rotates eccentrically. At the same time, the ratchet drive power input shaft 301 pushes the ratchet 303 to rotate through the ratchet drive rod 302 and exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com