Roll belt type thin-strip casting-rolling integrated machine and using method thereof

A thin-strip casting-rolling and integrated machine technology, applied in the field of iron and steel casting, can solve the problems that the production line occupies a large area and thin strips are prone to loose shrinkage, etc., and achieve the effects of short production process, compact layout, and reduced occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

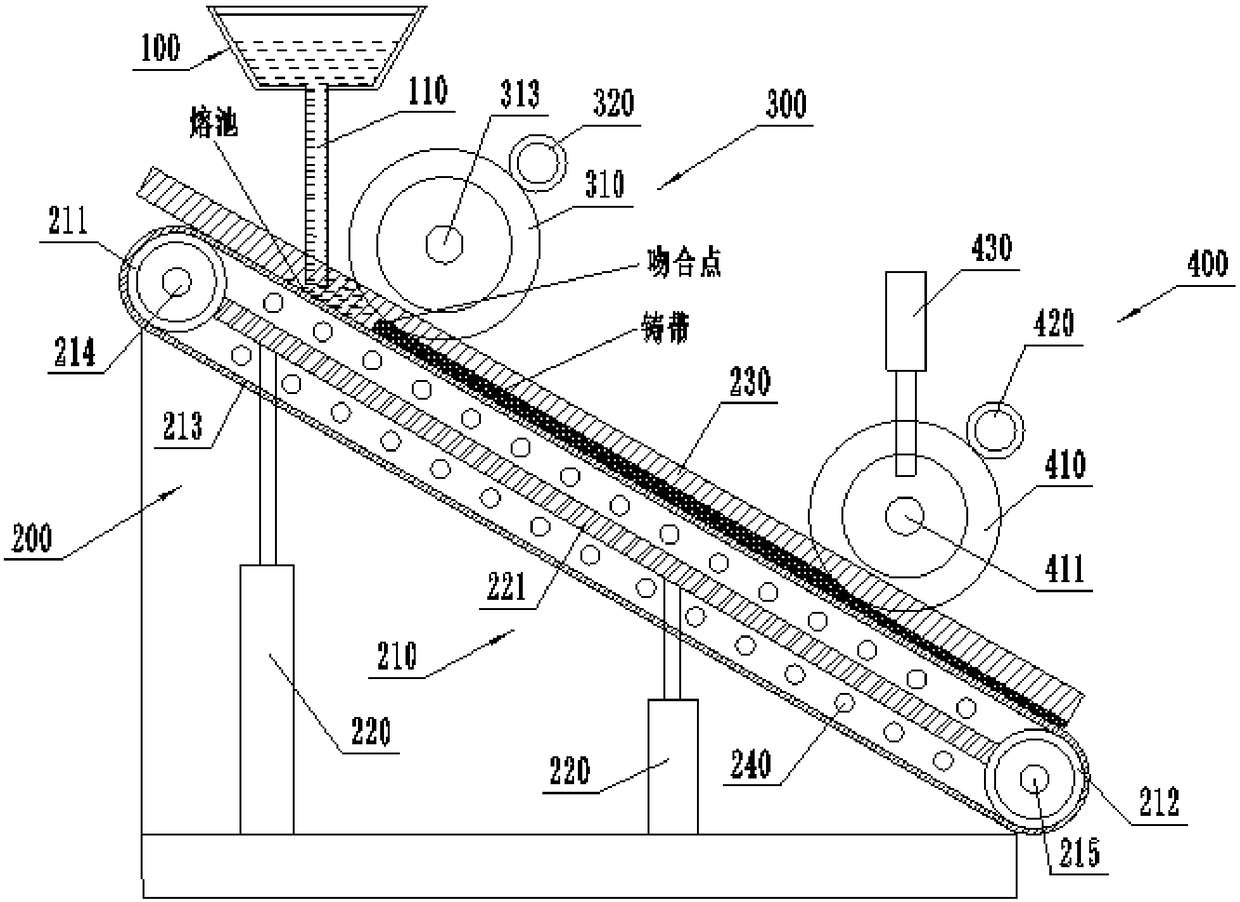

[0037] Such as image 3 , Figure 4 As shown, a roll-type thin strip casting-rolling integrated machine in this embodiment mainly includes a tundish 100, a belt conveying device 200, a continuous casting mechanism 300 and a continuous rolling mechanism 400, and the continuous casting is realized through the organic combination of four parts. and rolling operations. The structure of each part will be described in more detail below.

[0038] The belt conveying device 200 includes a conveying mechanism 210 and a side sealing plate 230 . Wherein, conveying mechanism 210 comprises driving roller 212, driven roller 211 and conveying steel belt 213, and conveying steel belt 213 is arranged obliquely, and in the viewing angle shown in the accompanying drawing, its left side is higher than right side bottom, has certain angle relative to horizontal plane; The two ends of the steel belt 213 are sleeved on the driving roller 212 and the driven roller 211 respectively, and the driving ...

Embodiment 2

[0049] A roll-type thin strip casting-rolling integrated machine of this embodiment is further improved on the basis of the structure of Embodiment 1, an angle adjustment device 220 is added to the belt conveyor 200, and rolls are added to the continuous rolling mechanism 400 Lifting assembly 430 .

[0050] Specifically, the angle adjusting device 220 is used to adjust the inclination angle of the conveying steel belt 213, and it includes a base, a supporting beam 221 and two driving cylinders. Wherein, the two ends of the supporting beam 221 are respectively connected to the driving roller 212 and the driven roller 211, the upper ends of the two driving cylinders are respectively connected to the two ends close to the supporting beam 221, and the lower ends of the two driving cylinders are connected to the base. The driving cylinder can be a hydraulic cylinder, and the distance between the steel strip 213 surface and the water-cooled crystallization roller 310 at the matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com